Patents

Literature

75results about How to "High elongation after break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

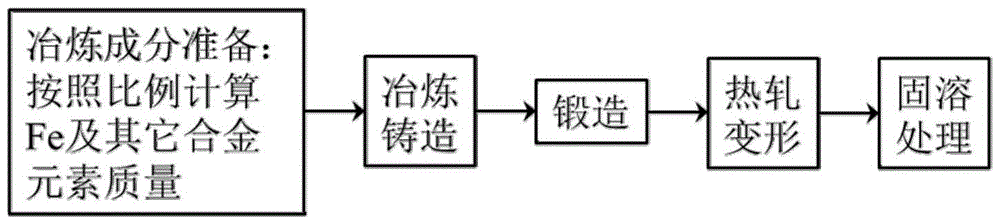

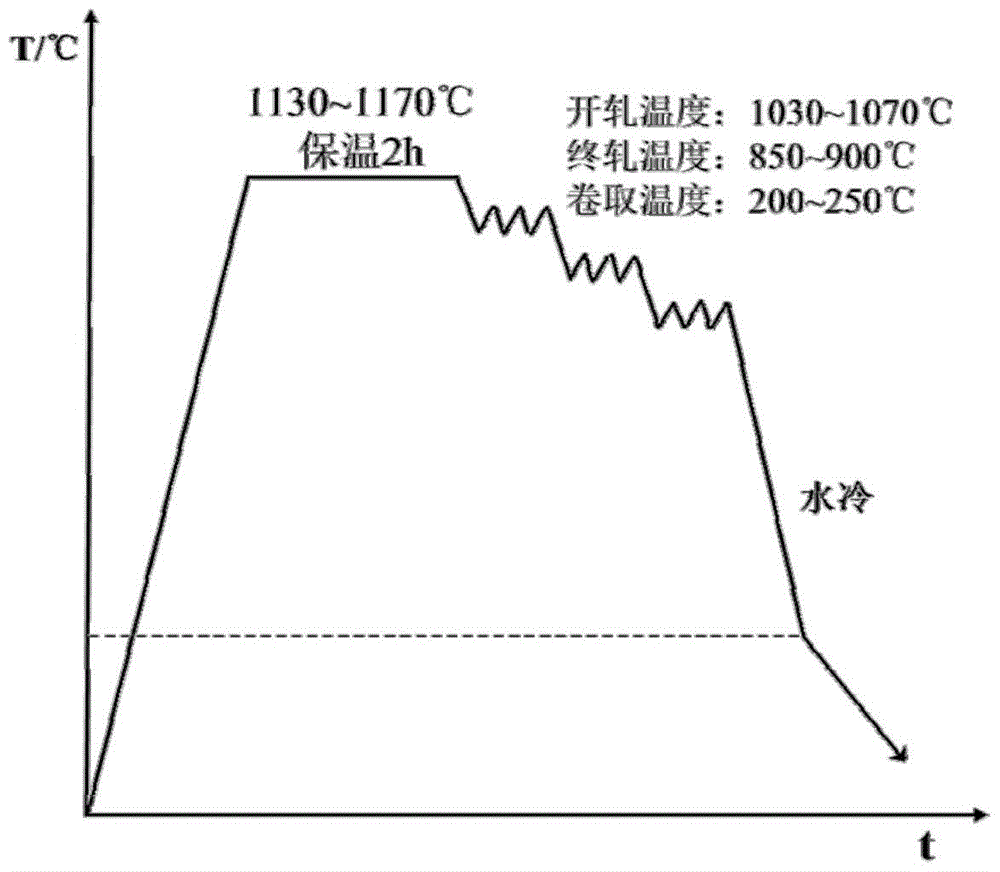

Low-density and high-toughness automobile-used steel board and preparation process

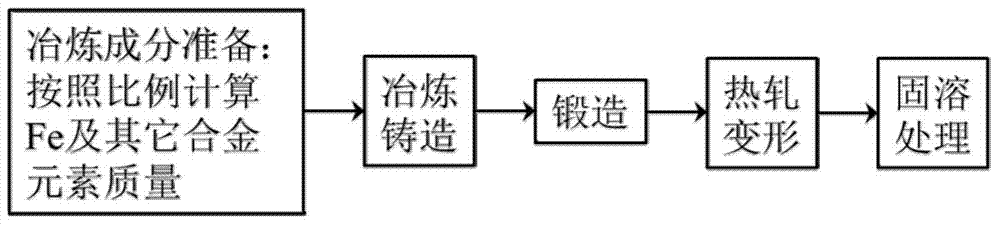

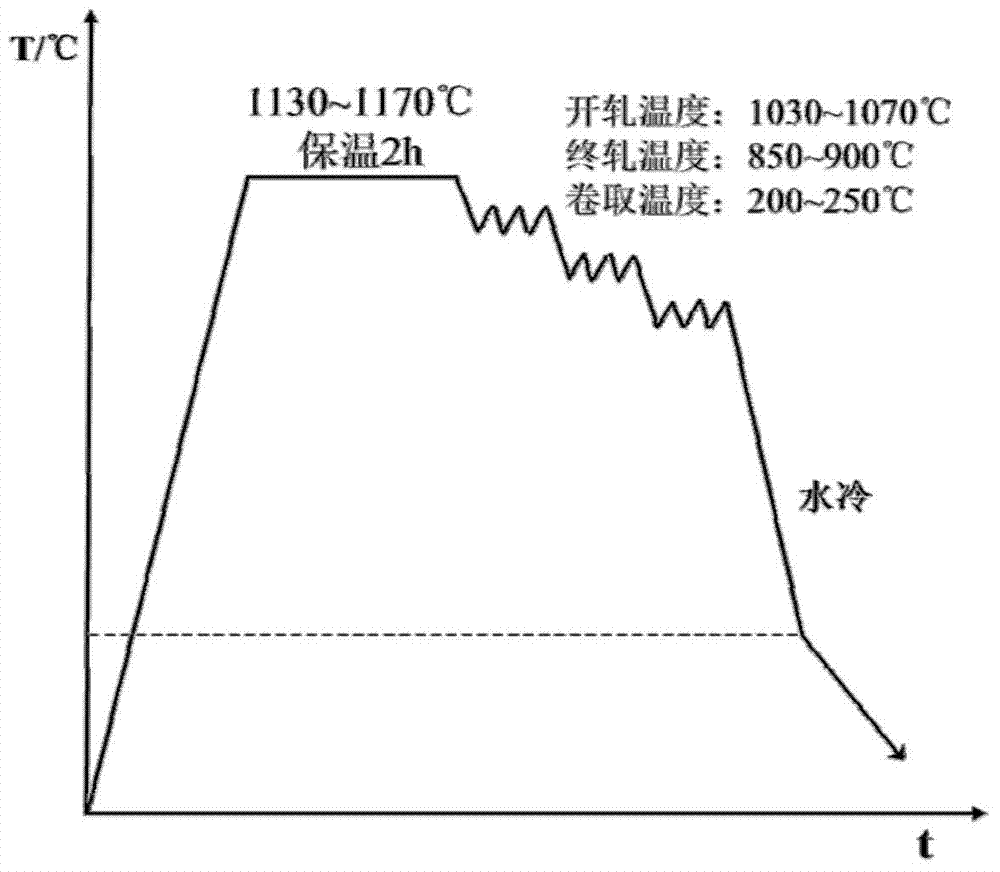

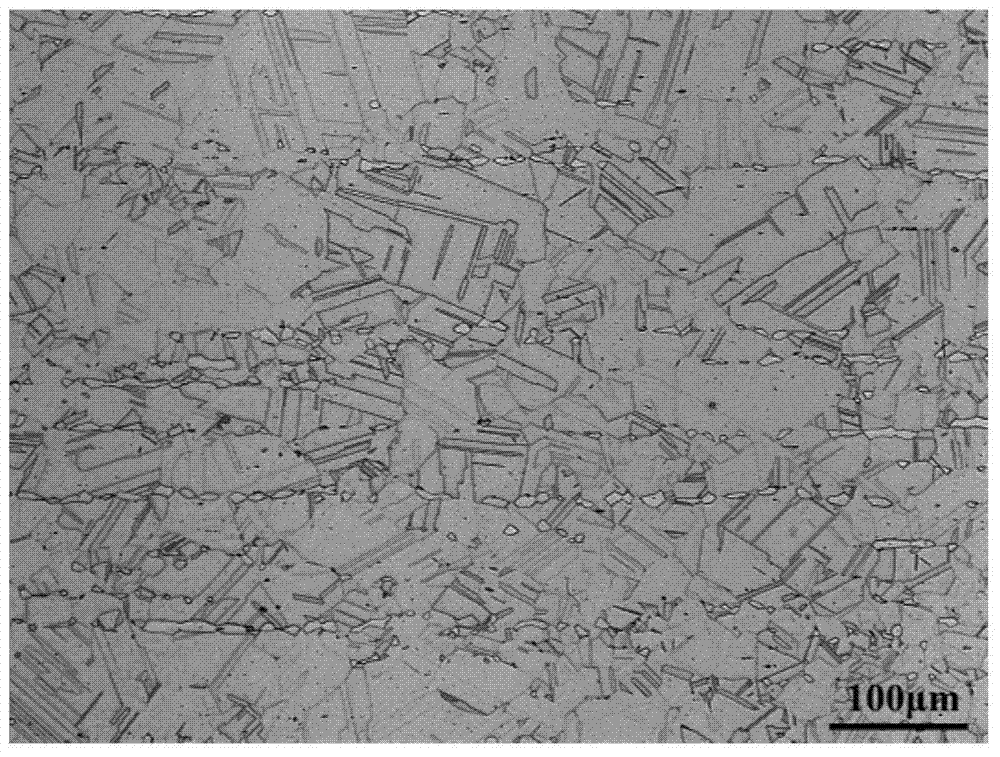

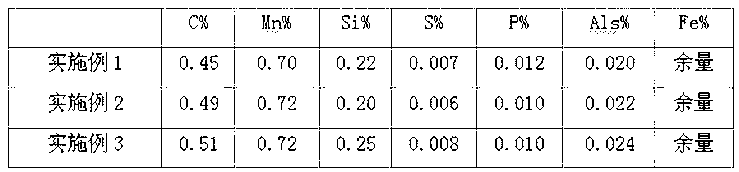

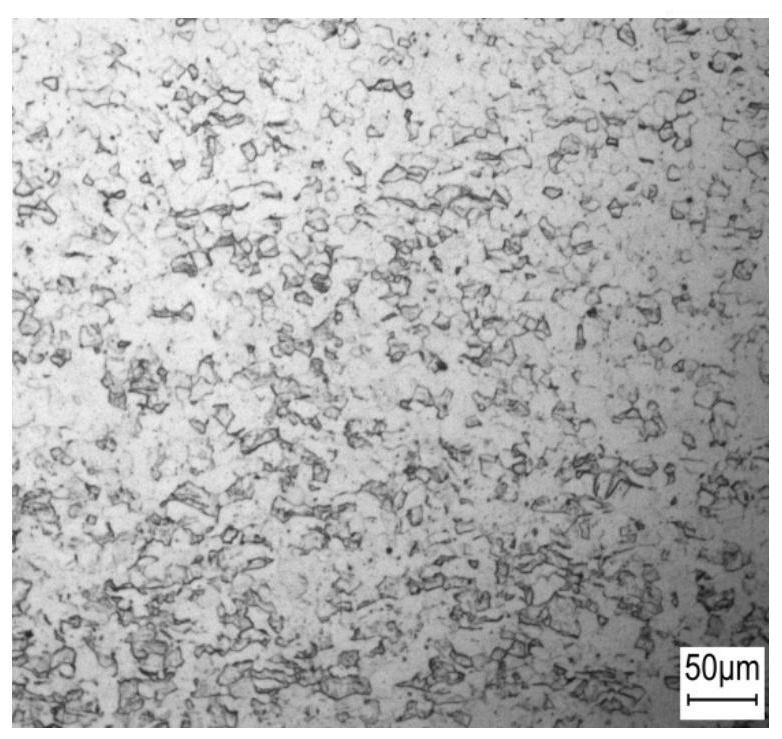

The invention belongs to the field of metal materials, and relates to a novel high strength steel board low in density, high in strength and good in anti-corrosion performance, in particular to component design and a preparation method of the novel automobile-used steel. The automobile-used steel board is characterized by comprising the following specific chemical compositions by mass percentage: 0.60-0.70 percent of C, 0.30-0.40 percent of Si, 10.0-15.0 percent of Mn, 5.0-10.0 percent of Al, less than 0.005 percent of P, less than 0.003 percent of S and Fe and unavoidable impurities in balancing amount. The preparation process comprises the following steps: performing smelting according to the chemical compositions, and forging casting blank material into a steel blank; heating the steel blank to 1,130-1,170 DEG C, keeping the temperature for 2 hours, and performing multi-pass hot-rolling deformation, wherein the rolling starting temperature ranges from 1,030-1,070 DEG C, the rolling stopping temperature ranges from 850-900 DEG C, the accumulated deformation amount ranges from 80 percent to 85 percent, and the rolling temperature is from 200 DEG C to 250 DEG C; after hot rolling, further performing solution treatment of the steel board, keeping the temperature at 1,000-1,050 DEG C for 0.5-1 hour, and performing water quenching treatment; taking a dual-phase organization combining austenite and ferrite, and obtaining the lower density and high toughness automobile-used steel board.

Owner:UNIV OF SCI & TECH BEIJING

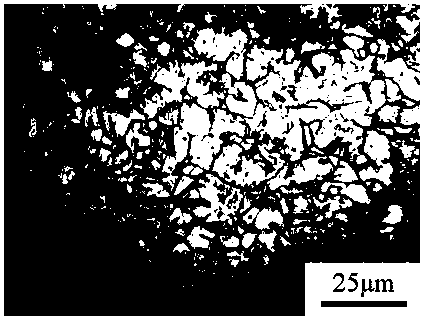

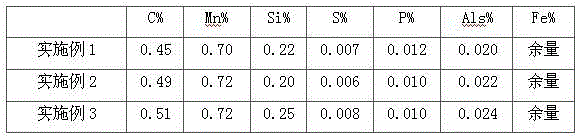

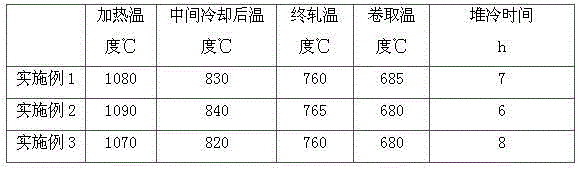

Annealing-free medium-high carbon steel plate making technology

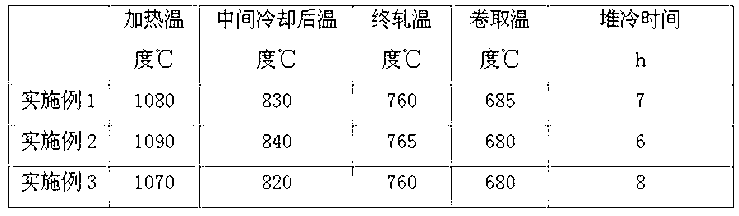

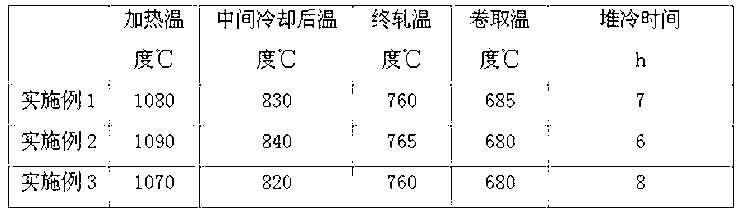

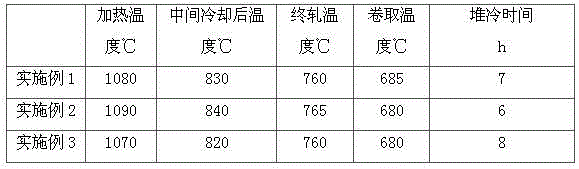

The invention relates to an annealing-free medium-high carbon steel plate making technology, and belongs to the technical field of steel rolling technologies. A technical scheme adopted in the invention is characterized in that the technology comprises the operations of heating furnace heating, vertical roll rolling, roughing scale removal, roughing rolling, intermediate cooling, precision rolling scale removal, precision rolling, laminar cooling, reeler reeling and concentrated pile cooling, the intermediate cooling operation is carried out after the roughing rolling operation and before the precision rolling scale removal operation and is realized through cooling plate blanks by a cooling device, and the cooling capability of the cooling device makes the temperature of the plate blanks decrease to below 840DEG C. The technology has the following beneficial effects: the elongation rate after fracture of produced products obviously rises, the hardness of the products decreases by 7.2-21%, the proportion of ferrite in the structure of the products is above 60%, ferrite crystal grains are appropriately coarsened, the pearlite colony is small and dispersed, and the cementite sheet in pearlite is attenuated, fragmented and partially granulated. An annealing operation after rolling can be avoided because of the low hardness and high plasticity in order to reach an online softening purpose.

Owner:HEBEI IRON AND STEEL

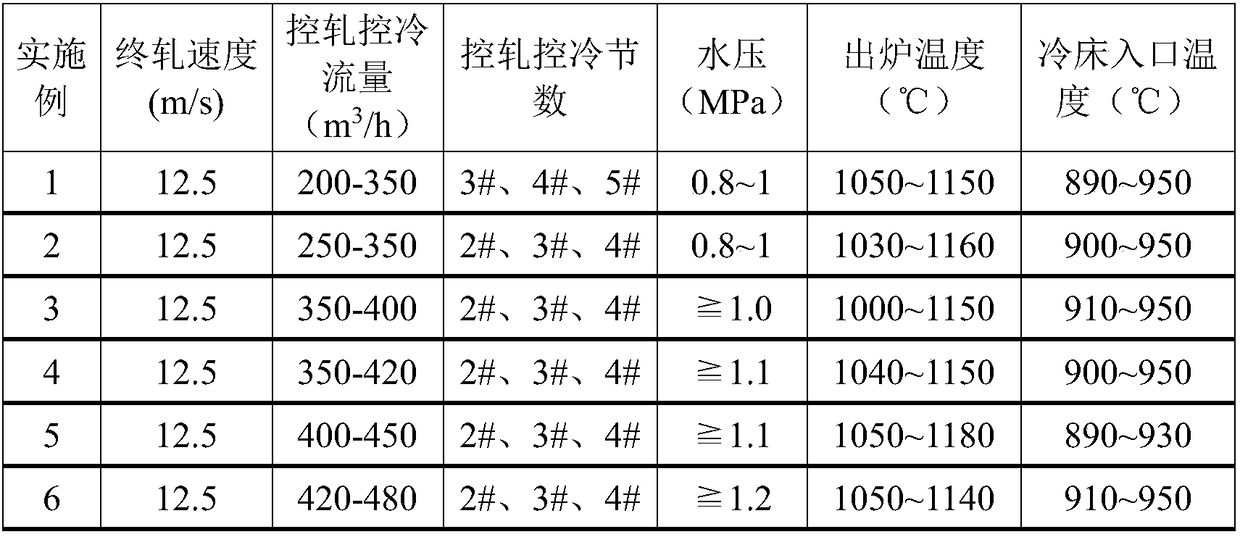

Steel bar with high weather resistance, low cost and seawater corrosion resistance and production process

ActiveCN108251746AGood weather resistanceLow costProcess efficiency improvementWeather resistanceRebar

The invention provides a steel bar with high weather resistance, low cost and seawater corrosion resistance and a production process. The steel bar comprises the following elementary compositions of,by weight, 0.04%-0.10% of C, 0.10%-0.50% of Si, 0.5%-1.6% of Mn, 0.03% or less of P, 0.02% or less of S, 2%-4% of Cr, 0.3%-0.5% of Cu, 0.2%-0.6% of Ni, and the balance Fe and inevitable impurities. According to the steel bar, the mechanical property meets the requirement of the steel bar for corrosion resistance, the aging strain is low, and the corrosion rate is lower than 70% that of common steel bars. The technical path of the process comprises a 70-ton ultrahigh-power electric furnace, LF ladle refining, deoxidation and alloying after steel discharging, argon blowing, continuous casting of165 square billets at four streams by four machines, a heat accumulating type stepping heating furnace, 18 non-twist tandem mills, controlled-rolling and controlled-cold cooling, finishing, packagingand storage.

Owner:福建三宝钢铁有限公司

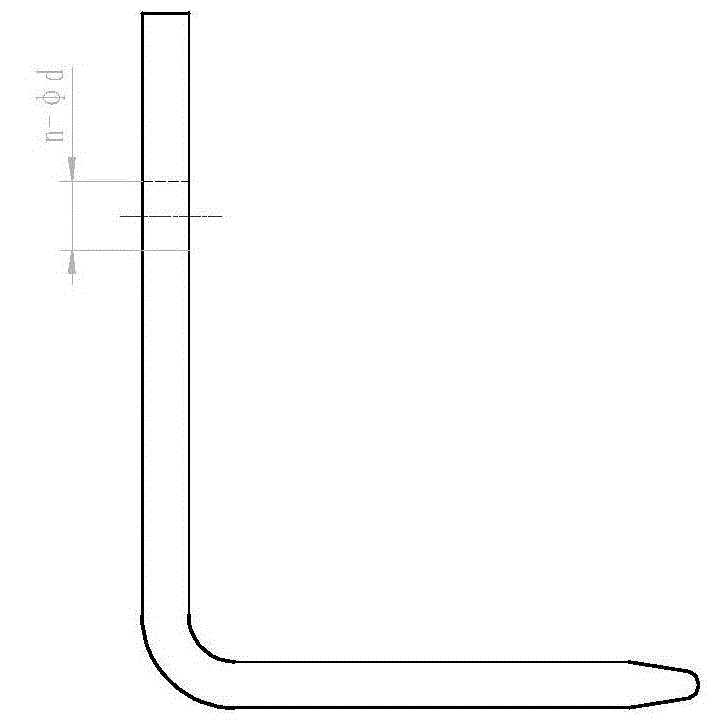

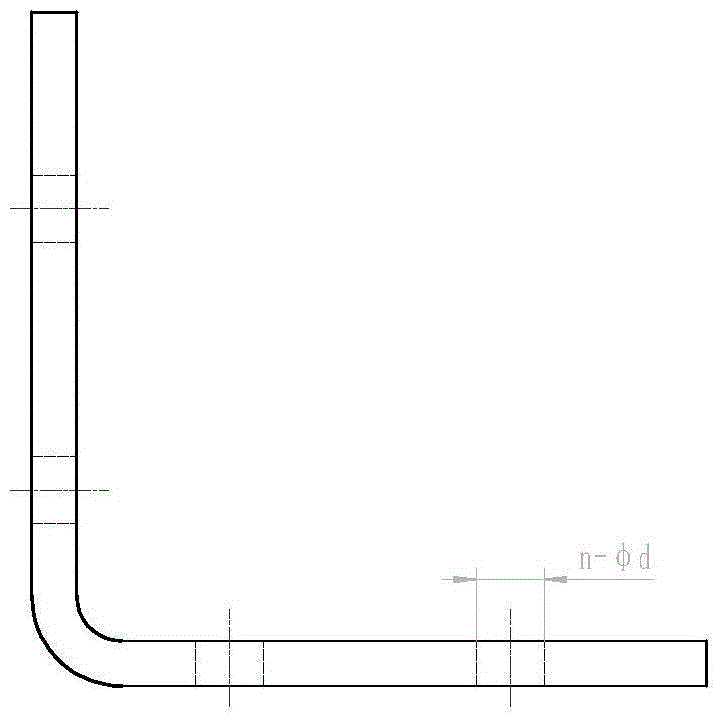

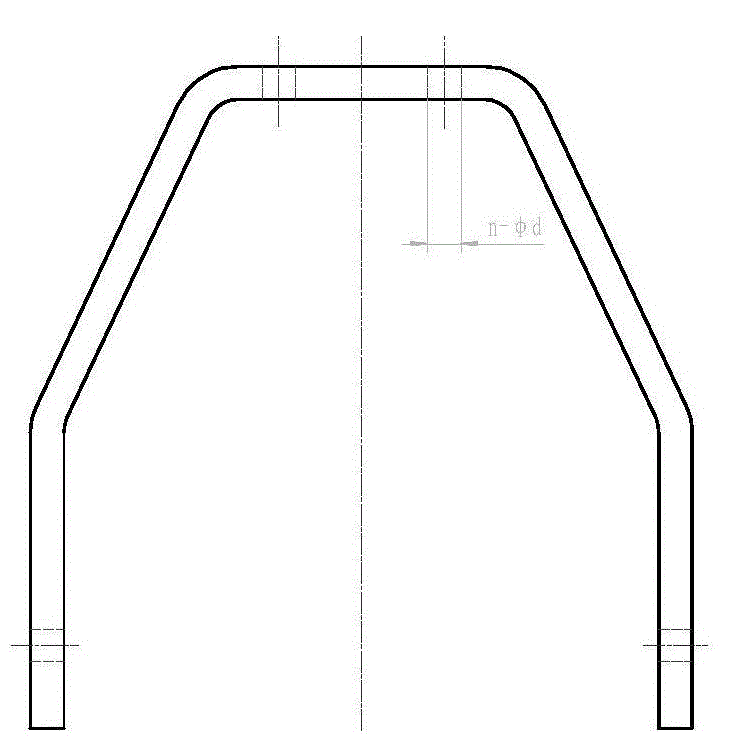

Cylinder barrel of oil cylinder of crane and processing process thereof

ActiveCN102517491AReduce welding defectsImprove safety and reliabilityArc welding apparatusCylindersHydraulic cylinderWelding defect

The invention discloses a cylinder barrel of an oil cylinder of a crane and a processing process thereof. The invention belongs to the field of hydraulic cylinders. The material of a cylinder barrel body is Q345B. The material contains alloy elements, such as Cr, Nb, Ni, V and the like, and the mechanical property and the welding property are both better than those of 45# steel. The processing process comprises the following steps: (1) using a hot rolling steel pipe: selecting on a pipe blank, blanking, aligning, rough turning on an outer circle, welding on a flange, scraping on an inner hole, rough turning and finish turning; and (2) using a high-accuracy cold drawing steel pipe: cold drawing, aligning, blanking, welding on a flange, scraping on an inner hole, rough turning and finish turning; and the cylinder barrel of the oil cylinder of the crane and the processing process thereof are characterized by the technological parameter of welding, the technological parameter of cold-drawing processing and the technological parameter of scraping processing. The cylinder barrel of the oil cylinder of the crane and the processing process thereof have the beneficial effects that the welding defect of the oil cylinder is lowered by more than 50 percent; and moreover, the after-fracture elongation rate of the material of the cylinder barrel is enhanced, the toughness of the cylinder barrel is ensured, and the danger of the occurrence of brittle fracture of the cylinder barrel is decreased, so that the safety reliability of the oil cylinder is greatly enhanced.

Owner:XCMG HYDRAULICS CO LTD

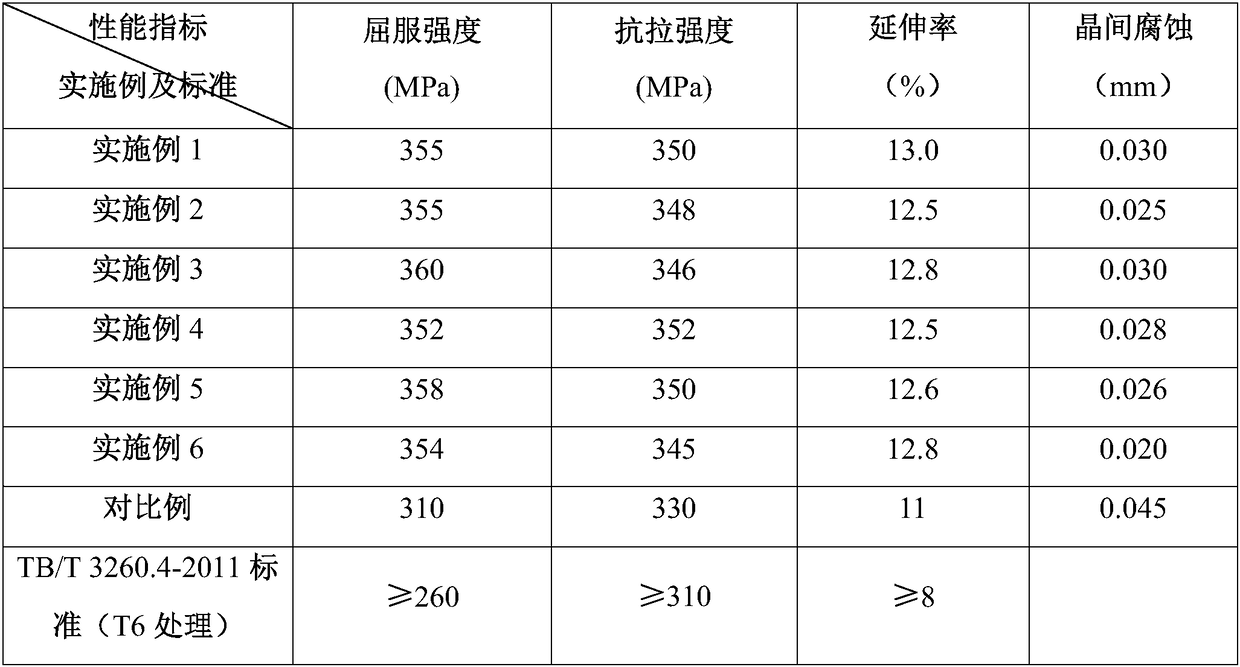

6082 aluminium alloy thick-wall pipe production technology

The invention belongs to the field of aluminium alloy profile production, and relates to a 6082 aluminium alloy thick-wall pipe production technology. Aluminium alloy comprises the elements in percentage by weight: 1.19-1.24% of Si, 0.94-0.99% of Mg, 0.2-0.4% of Cu, 0.84-0.89% of Mn, 0.13-0.18% of Cr, 0.11-0.18% of Ti, 0.19-0.24% of Fe, less than or equal to 0.05% of Zn, less than or equal to 0.03% of other single impurities, less than or equal to 0.10% of total impurities and the balance of Al, wherein in an aluminium alloy thick-wall pipe water cooling process, liquid nitrogen is sprayed onto the portion, from an extruder outlet to a water cooling sink inlet, on the periphery of an aluminium alloy thick-wall pipe, artificial aging of the aluminium alloy thick-wall pipe subjected to tension leveling at 150+ / -5 DEG C is 10 h, artificial aging at 200+ / -5 DEG C is 2 h, by reasonably choosing extrusion technology parameters and heat processing technology parameters, not only is the surface quality of the 6082 alloy profile improved, but also the percentage elongation (higher than 10%) after fracture and the corrosion resistance performance of the 6082 alloy are improved, so that a product meets the requirements.

Owner:CHINA ZHONGWANG

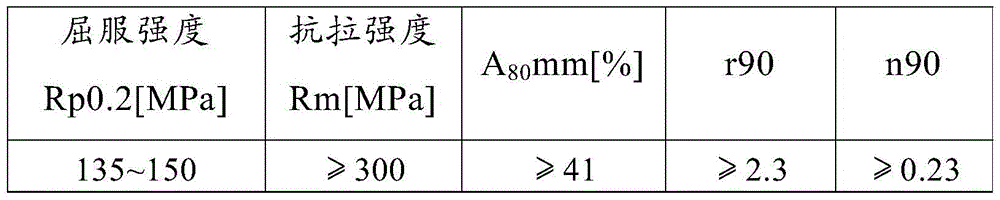

Extra-deep drawing interstitial free steel and production method thereof

InactiveCN105603299AGood resistance to secondary processing brittlenessLower yield strengthLower yieldChemical composition

The invention discloses extra-deep drawing interstitial free steel. The extra-deep drawing interstitial free steel comprises the following chemical components in percentage by weight: 0.0010%-0.0030% of C, less than or equal to 0.04% of Si, 0.10%-0.20% of Mn, 0.01%-0.03% of P, less than or equal to 0.02% of S, 0.04%-0.06% of Ti, 0.0002%-0.0008% of B, less than or equal to 0.006% of N and the balance of iron and unavoidable impurities. The invention further discloses a production method of the extra-deep drawing interstitial free steel. According to the extra-deep drawing interstitial free steel and the production method, a finished product has relatively high tensile strength but still preserves relatively low yield strength, so that the extra-deep drawing IF steel with low yield ratio and high percentage elongation and r value can meet requirements of complex deformation and rigidity of a vehicle body.

Owner:SHOUGANG CORPORATION

Automotive cold-rolled high-strength steel and production method thereof

The invention discloses automotive cold-rolled high-strength steel and a production method thereof. The high-strength steel comprises the following chemical components in percentages by mass: less than or equal to 0.006 of C, 0.10-0.20 of Si, 0.50-0.80 of Mn, 0.06-0.10 of P, less than or equal to 0.005 of S, less than or equal to 0.040 of Al, 0.040-0.060 of Ti, less than or equal to 50 ppm of N and the balance of Fe and inevitable impurities. The production method successively comprises the following steps: preparation of molten iron through a blast furnace, converter smelting, RH refining, slab continuous casting, hot rolling and cold rolling. By P, Si and Mn solution strengthening and Ti, C and N precipitation strength, the strength is improved, the tensile strength is improved while high fracture elongation is ensured, and meanwhile, high fracture elongation and good stamping property are ensured.

Owner:BAOTOU IRON & STEEL GRP

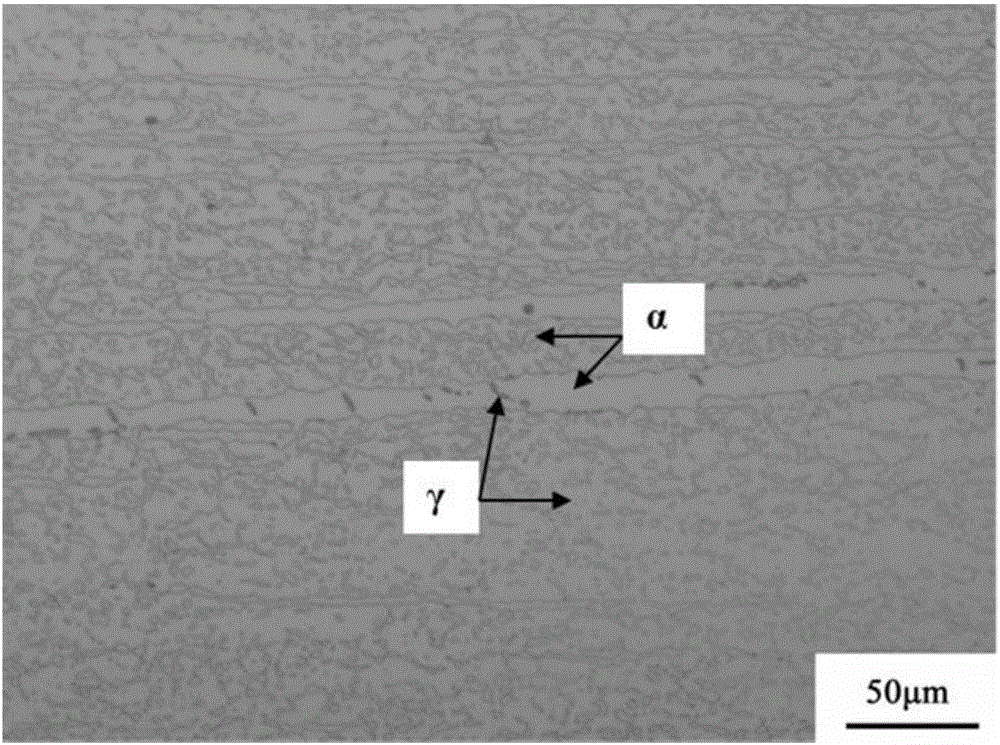

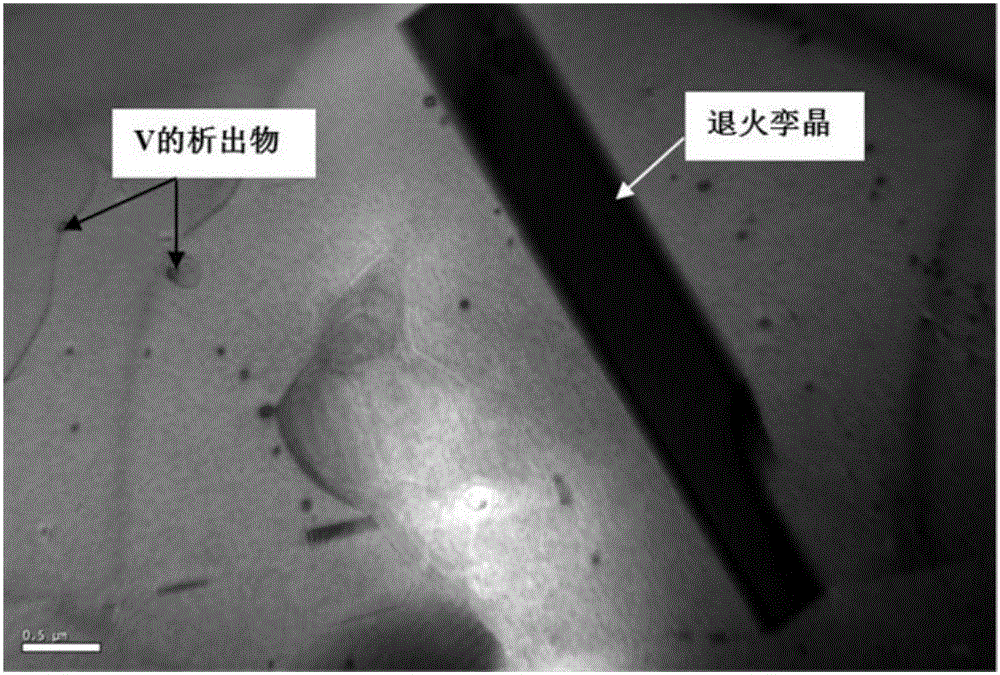

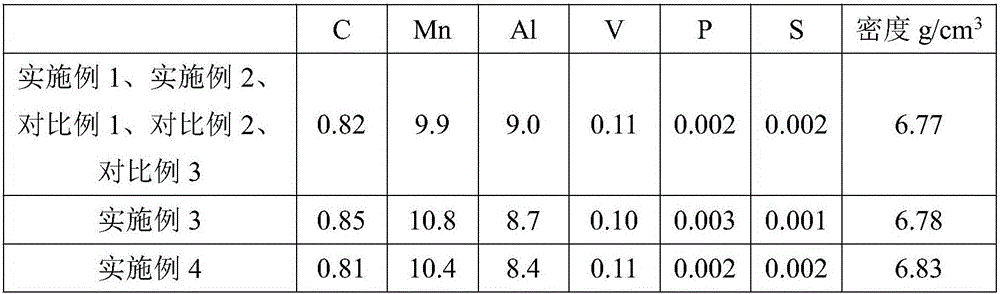

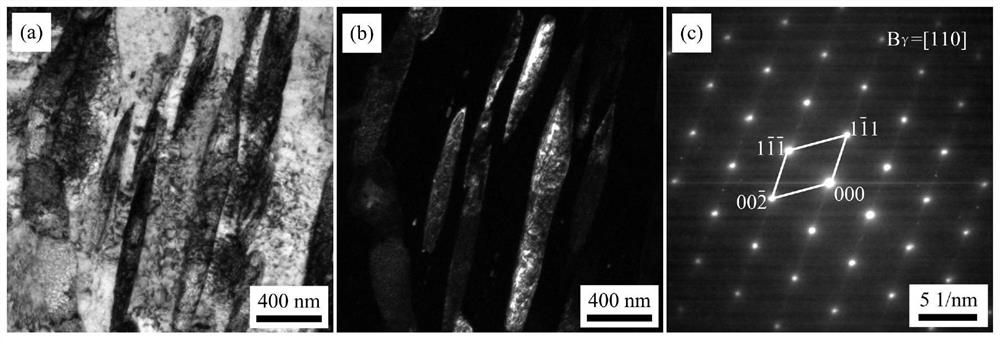

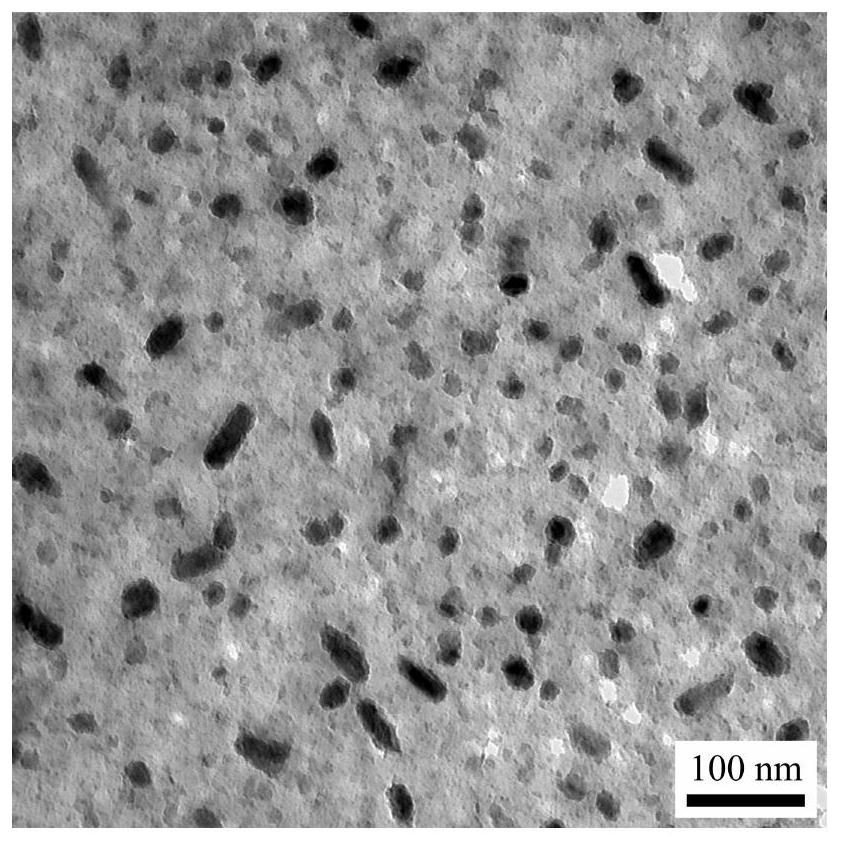

Preparation method for hot-rolled low-density steel with strength and ductility product being greater than or equal to 40 GPa.%

The invention discloses a p reparation method for hot-rolled low-density steel with the strength and ductility product being greater than or equal to 40 GPa.% and belongs to the field of metal materials. Chemical components of the hot-rolled low-density steel with the strength and ductility product being greater than or equal to 40 GPa.% comprise, by mass, 0.6-1.0% of C, 8-12% of Mn, 7-11% of Al, 0.01-0.2% of V, less than or equal to 0.003% of P, less than or equal to 0.002% of S and the balance Fe and inevitable impurities. The preparation process comprises the steps of smelting, forging, hot rolling and solid solution hardening treatment, the structure of the obtained low-density steel comprises annealing twins, precipitates of nanoscale vanadium exist in the twins, and the strengthening effect is obvious. The steel has the characteristics of low density and high strength and ductility, and the strength and ductility product is greater than or equal to 40 GPa.%.

Owner:UNIV OF SCI & TECH BEIJING

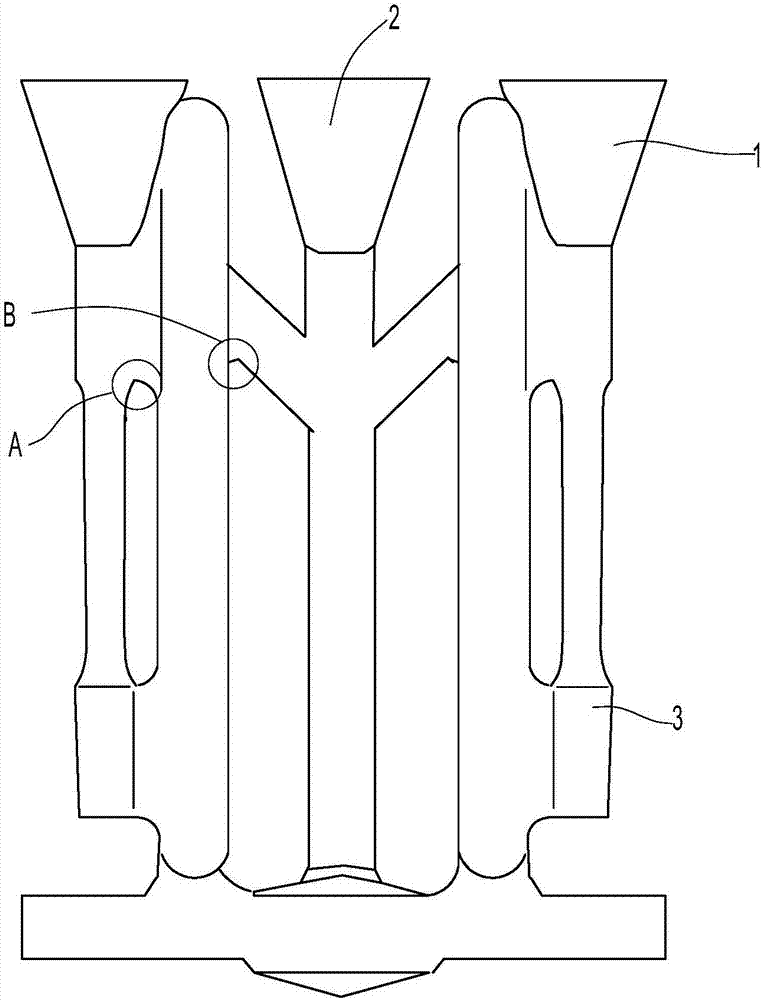

High-wear-resistance long-life ductile iron and method of producing lower cylinder with ductile iron

ActiveCN106834901AImprove wear resistanceExtended service lifeFoundry mouldsFurnace typesHigh wear resistanceDuctile iron

The invention discloses high-wear-resistance long-life ductile iron, comprising, by weight, 3.80-3.88% of C, 2.20-2.30% of Si, 0.55-0.65% of Mn, < / =0.020% of P, < / =0.010% of S, 0.45-0.55% of Cu, 0.30-0.40% of Mo, 0.0040-0.0060% of La, 0.035-0.045% of Mg, and the balance of iron and unavoidable impurity. The invention is intended to provide the high-wear-resistance long-life ductile iron that has high rigidity and fatigue strength and has improved tensile strength and plasticity, and a method of producing a lower cylinder with the ductile iron.

Owner:GUANGDONG ZHONGTIAN CHUANGZHAN DUCTILE IRON CO LTD

Method for machining cylinder tube of oil cylinder

InactiveCN103801907AReduce welding defectsImprove safety and reliabilityArc welding apparatusWelding/cutting media/materialsHydraulic cylinderBrittle fracture

The invention discloses a method for machining a cylinder tube of an oil cylinder and belongs to the field of hydraulic cylinders. The body of the cylinder tube is made of Q345B, and the Q345B contains Cr, Nb, Ti, Ni, V and other alloying elements and is superior to 45# steel in mechanical property and welding property. A cold-drawn steel pipe is adopted in the method; the method includes the steps of cold drawing, natural aging, straightening, blanking, flange welding, inner hole skiving, rough turning and finish turning, and is characterized by welding technological parameters, cold-drawing technological parameters and skiving technological parameters. The method has the advantages that welding defects of the oil cylinder are reduced by more than 55%, the percentage elongation after fracture of the cylinder tube is improved, the tenacity of the cylinder tube is guaranteed, the risks of brittle fracture of the cylinder tube are reduced, and therefore the safety and reliability of the air cylinder are improved.

Owner:QINGDAO XINGCHEN MACHINE TOOL

Cu-Ni-Co-Fe-Si-Zr-Zn copper alloy material and preparation method thereof

ActiveCN110951990AEasy to spreadPromote precipitationMetal rolling arrangementsSolution treatmentUltimate tensile strength

The invention discloses a Cu-Ni-Co-Fe-Si-Zr-Zn copper alloy material and a preparation method thereof. The copper alloy material is prepared from, by weight, 2.0%-3.0% of Ni, 0.3%-0.8% of Co, 0.3%-0.8% of Fe, 0.5%-1.1% of Si, 0.1%-0.2% of Zr, 0.1% 0.3% of Zn and the balance Cu. The preparation method of the copper alloy material comprises the following steps of alloy casting, homogenization treatment, hot rolling, solid solution treatment, deep cold rolling and pulse magnetic field aging treatment. The copper alloy material has the advantages of high yield strength, high tensile strength and conductivity, high elongation at break, and good comprehensive mechanical property and conductive performance. In addition, no toxic element is contained in the composition of the copper alloy material, the sources of raw materials are rich, the preparation process does not generate toxic compounds, and the harm to human bodies and the environment is small.

Owner:FUZHOU UNIV +2

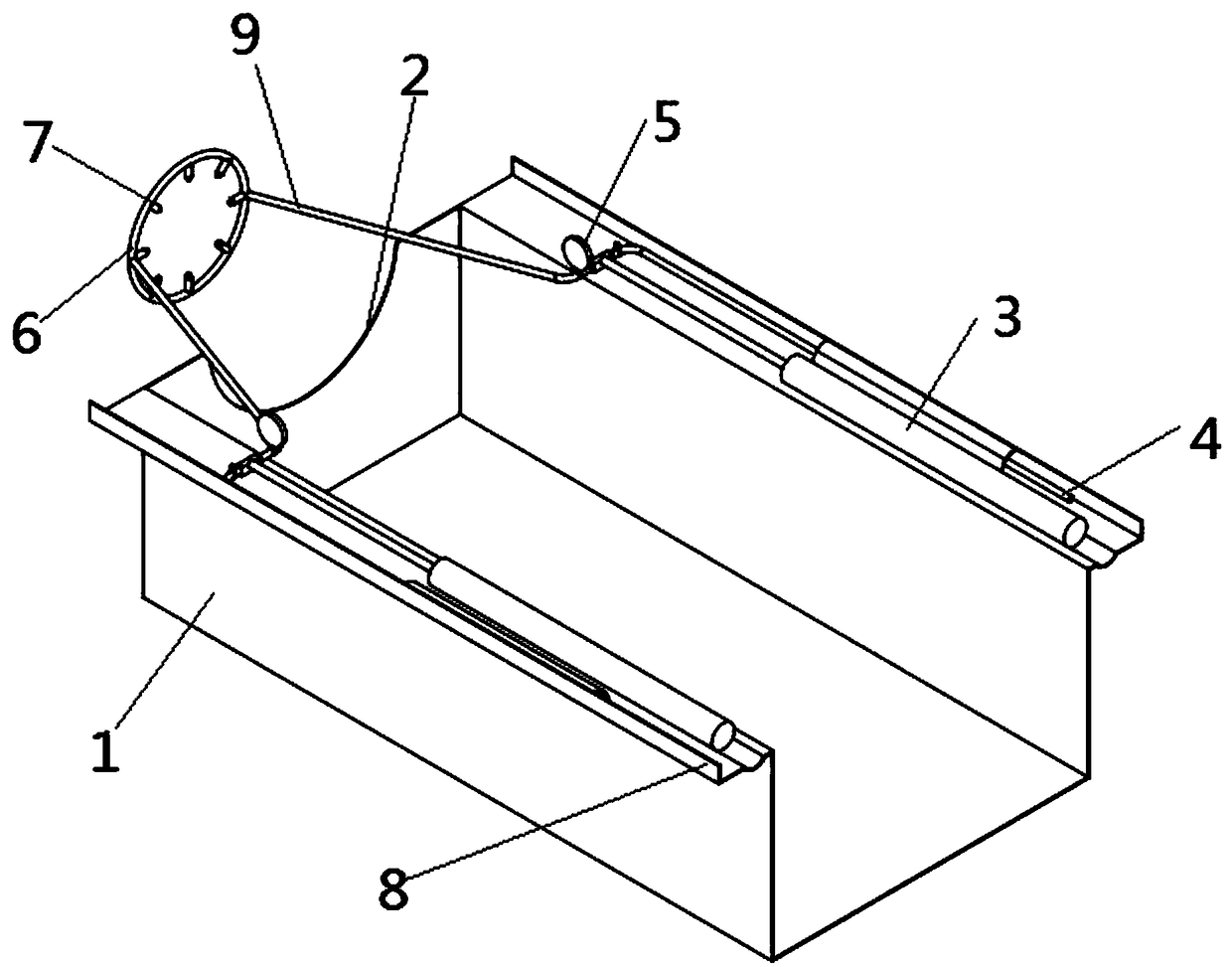

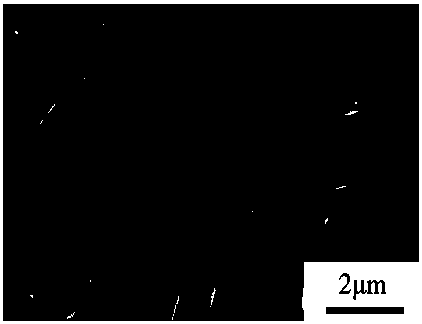

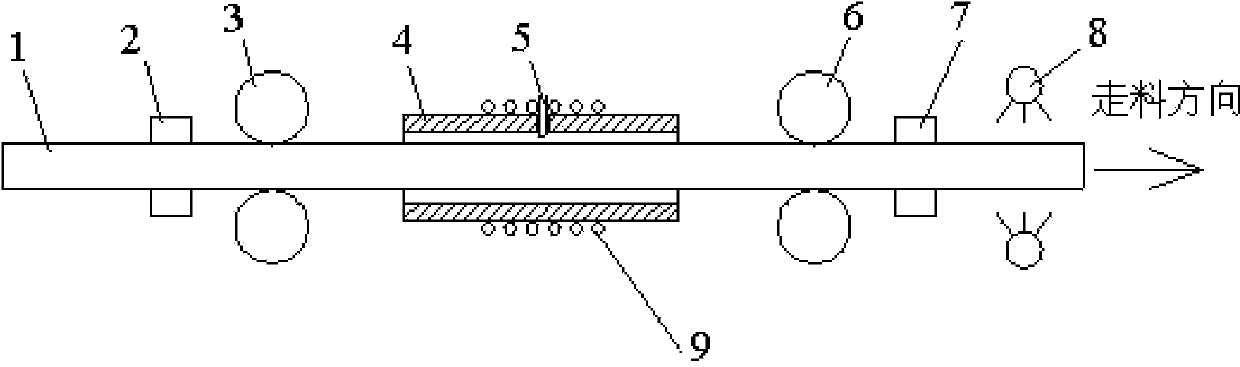

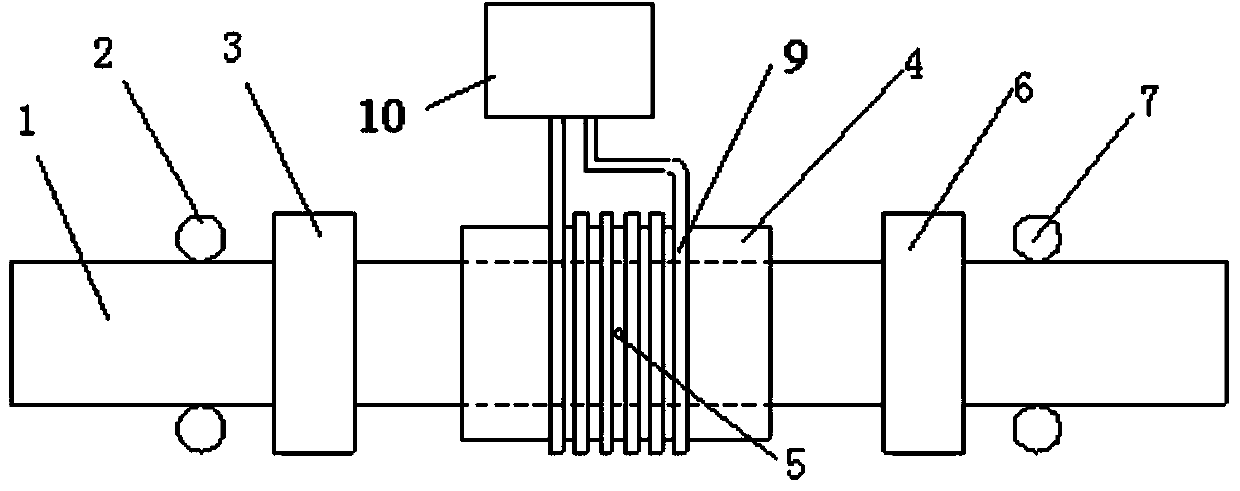

High-frequency induction annealing device and technology for regulation and control of copper-clad aluminum composite flat bus

ActiveCN103695609AControl thicknessImprove performanceIncreasing energy efficiencyFurnace typesHeating timeAluminum composites

The invention discloses a high-frequency induction annealing device and technology for regulation and control of a copper-clad aluminum composite flat bus. The high-frequency induction annealing device mainly comprises a guide roller, a driving device, a ceramic tube, temperature measuring device, an induction heating device, and an air blast cooling device. The high-frequency induction annealing device is characterized in that an induction heating power supply adopts high-frequency induction heating to improve the heating rate, shorten the heating time and control the interface layer thickness; an induction heating coil is designed to be flat similar to the cross-sectional shape of the copper-clad aluminum flat bus, so that in induction heating, the temperature distribution at different parts of the copper-clad aluminum flat bus is uniform, the heating time can be shortened, and the interface layer thickness is controlled; as the ceramic tube with a certain length is arranged, the temperature is uniform in heating, and the copper cladding layer and the aluminum core can be recrystallized synchronously; the annealed flat bus temperature can be quickly reduced to below 150 DEG C through a forced air cooling section, so that the thickness-increasing of the aluminum-copper interface is avoided; the aluminum-copper interface layer thickness is controlled within 2-3 microns.

Owner:UNIV OF SCI & TECH BEIJING

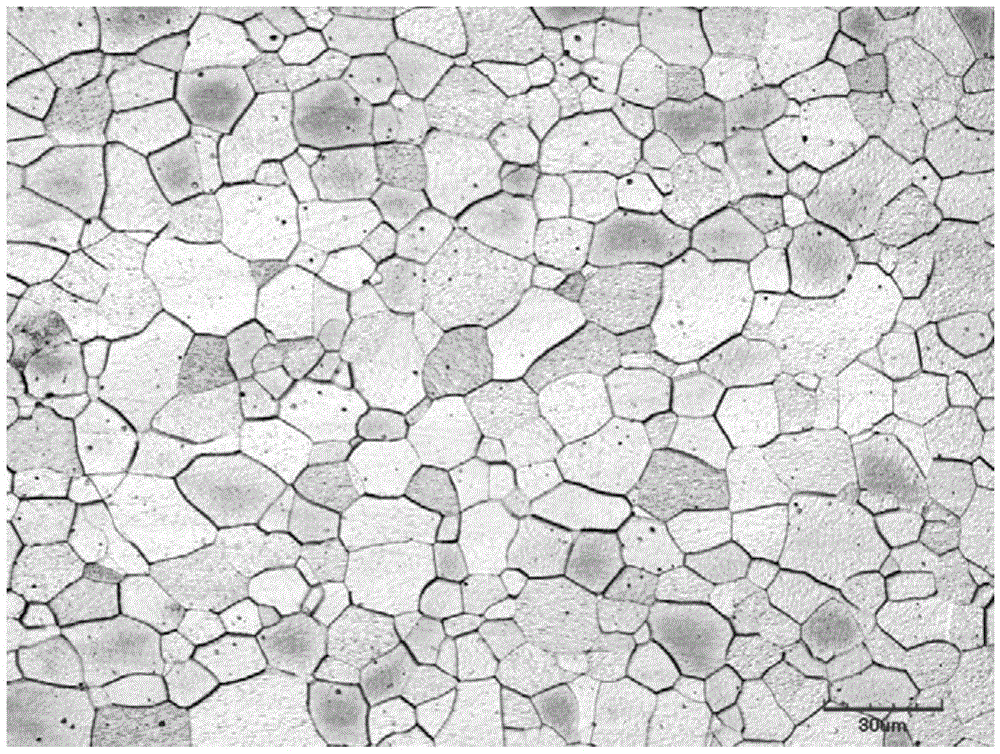

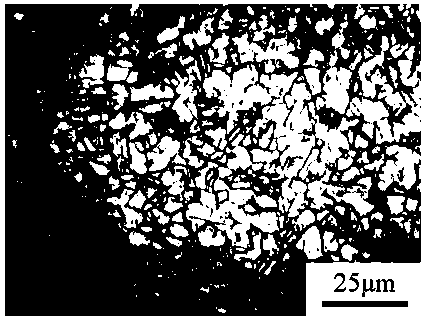

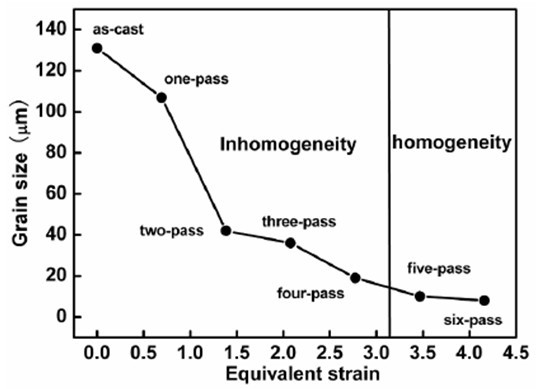

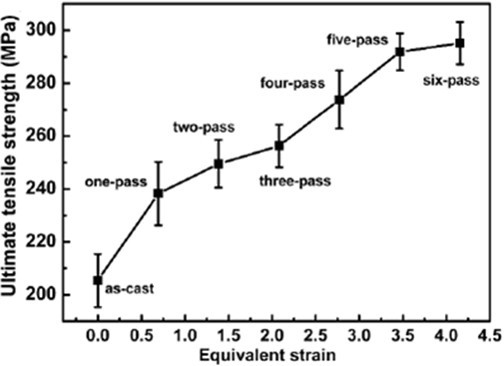

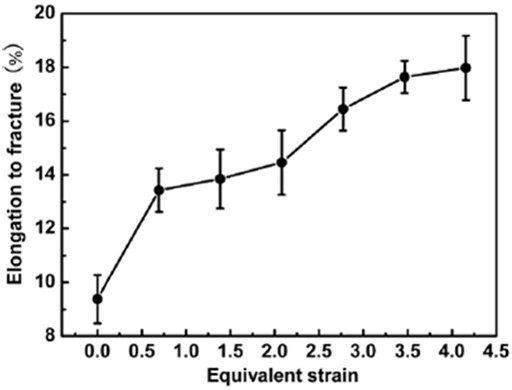

Preparation method of fine grain magnesium alloy

The invention relates to a preparation method of a fine grain magnesium alloy. In the method, the preheating temperature of a mould is 350+ / -5 DEG C; a magnesium alloy blank is subjected to at least five passes of extrusion and deformation; the preheating temperature of the magnesium alloy blank is 250+ / -5 DEG C-380+ / -5 DEG C; the extrusion rate is 2mm / s-15mm / s, and the extrusion direction each time is different; and the preheating temperature of the magnesium alloy blank changes from high to low, and the extrusion rate is varied from large to small. According to the preparation method provided by the invention, a multi-pass multi-direction temperature-variable extrusion technology is adopted, i.e., the temperature and extrusion rate of the magnesium alloy blank are gradually reduced along with the increase of extrusion pass, and forces are applied in the different directions of magnesium alloy so as to carry out extrusion and deformation, thereby improving the deformation nonuniformity of a magnesium alloy structure in the conventional isothermal extrusion deformation and preventing full growth and grain mixing of dynamically recrystallized grains due to high temperature in the extrusion process. Thus, the grains of the magnesium alloy obtained by using the multi-pass multi-direction temperature-variable extrusion deformation are obviously fined, and the size of the grain is uniform.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

A manufacturing process of annealing-free medium and high carbon steel plate

The invention relates to an annealing-free medium-high carbon steel plate making technology, and belongs to the technical field of steel rolling technologies. A technical scheme adopted in the invention is characterized in that the technology comprises the operations of heating furnace heating, vertical roll rolling, roughing scale removal, roughing rolling, intermediate cooling, precision rolling scale removal, precision rolling, laminar cooling, reeler reeling and concentrated pile cooling, the intermediate cooling operation is carried out after the roughing rolling operation and before the precision rolling scale removal operation and is realized through cooling plate blanks by a cooling device, and the cooling capability of the cooling device makes the temperature of the plate blanks decrease to below 840DEG C. The technology has the following beneficial effects: the elongation rate after fracture of produced products obviously rises, the hardness of the products decreases by 7.2-21%, the proportion of ferrite in the structure of the products is above 60%, ferrite crystal grains are appropriately coarsened, the pearlite colony is small and dispersed, and the cementite sheet in pearlite is attenuated, fragmented and partially granulated. An annealing operation after rolling can be avoided because of the low hardness and high plasticity in order to reach an online softening purpose.

Owner:HEBEI IRON AND STEEL

Hard copper busbar annealing method, processed hard copper busbar product and conductive part

InactiveCN105112829AHigh elongation after breakImproving cold work forming process performanceBusbarCopper

The invention discloses a hard copper busbar annealing method, a processed hard copper busbar product and a conductive part. The hard copper busbar annealing method comprises the following steps: performing heat preservation of a hard copper busbar for 120-240 min at the annealing temperature of 340-360 DEG C for annealing treatment, and then cooling the hard copper busbar to room temperature. Compared with the hard copper busbar which is subjected to annealing treatment, the processed hard copper busbar product prepared according to the hard copper busbar annealing method is improved in mechanical property, which embodies in that on the premise that the tensile strength and the hardness are guaranteed to meet the standard requirements (the tensile strength is higher than or equal to 206 MPa, and the hardness is higher than or equal to 65 HB), the percentage elongation after fracture of the hard copper busbar is increased remarkably, the cold-forming processing property of the hard copper busbar is improved obviously, the rejection rate caused by fracture when the hard copper busbar is directly cold-formed is greatly reduced, the production efficiency is improved, the waste of resources is avoided, and the processing cost is lowered.

Owner:PINGGAO GRP +1

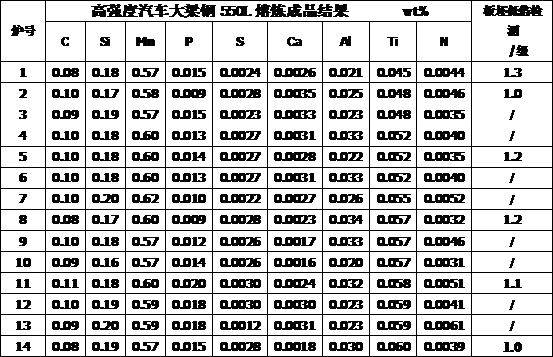

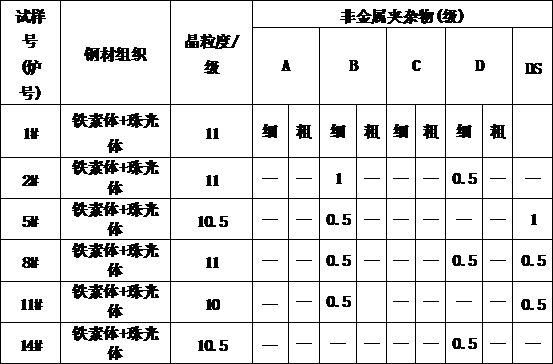

Preparation method of high-strength 550L automobile beam steel

ActiveCN113265502AImprove performance and stabilityReduce manganese contentManufacturing convertersMolten steelContinuous rolling

The invention discloses a preparation method of high-strength 550L automobile beam steel, which comprises the steps of enabling beam steel to comprise the following components: 0.080-0.11 wt% of C, less than or equal to 0.20 wt% of Si, 0.55-0.65 wt% of Mn, less than or equal to 0.018 wt% of P, less than or equal to 0.004 wt% of S, 0.045-0.060 wt% of Ti, 0.020-0.035 wt% of Al, 0.0030-0.0045 wt% of N and less than or equal to 0.0020 wt% of steel TO; performing converter smelting tapping control, wherein [C] is 0.06-0.08%, [P] is less than or equal to 0.015%, [S] is less than or equal to 0.008% and [O] is less than or equal to 400PPm, during converter tapping, fluorite, calcium carbide and active lime are mixed according to a mass ratio of 1:1:3, and are added in three times according to the interval of 1 minute, 2 minutes and 3 minutes in the converter tapping process, and the adding target value is 600 kg per converter; performing oxygen determination before LF refining treatment; and performing continuous casting, wherein continuous casting molten steel is cast under the protection of argon, the heating temperature of a plate blank is 1210-1230 DEG C, a hot-rolled coil with the thickness of 3.0-10 mm is obtained by adopting a hot continuous rolling mill through rolling, and the finish rolling temperature is 854-858 DEG C.

Owner:XINJIANG BAYI IRON & STEEL

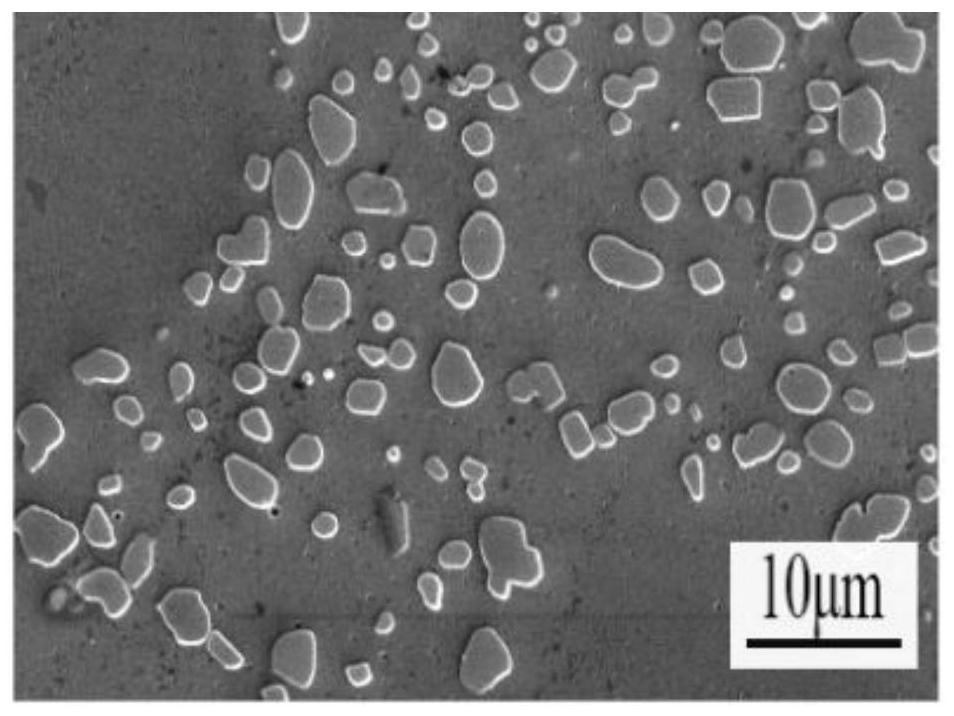

Cast aluminum-copper alloy material and preparation method and application thereof

ActiveCN107267825ASolve available puzzlesHigh elongation after breakDuctile ironUltimate tensile strength

The invention provides a cast aluminum-copper alloy material. The cast aluminum-copper alloy material is characterized by being prepared from, by weight, 4.70%-5.80% of Cu, 0.50%-0.70% of Mn, 0.20%-0.40% of Mg, 0.15%-0.35% of Ti, 0.30%-0.60% of Zr, 0.15%-0.30% of Sc, smaller than or equal to 0.30% of Fe and Si, smaller than or equal to 0.02% of Na and K and the balance Al and inescapable impurities. The invention further discloses a preparation method and application of the alloy material. Compared with the prior art, the cast aluminum-copper alloy material has the advantages that the aluminum alloy material can be used for replacing a QT450-10 ductile iron material for making pump shells, the lightweight, casting molding and bearing strength requirements are met, and the problem that no high-strength cast aluminum material can be used is solved.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH +1

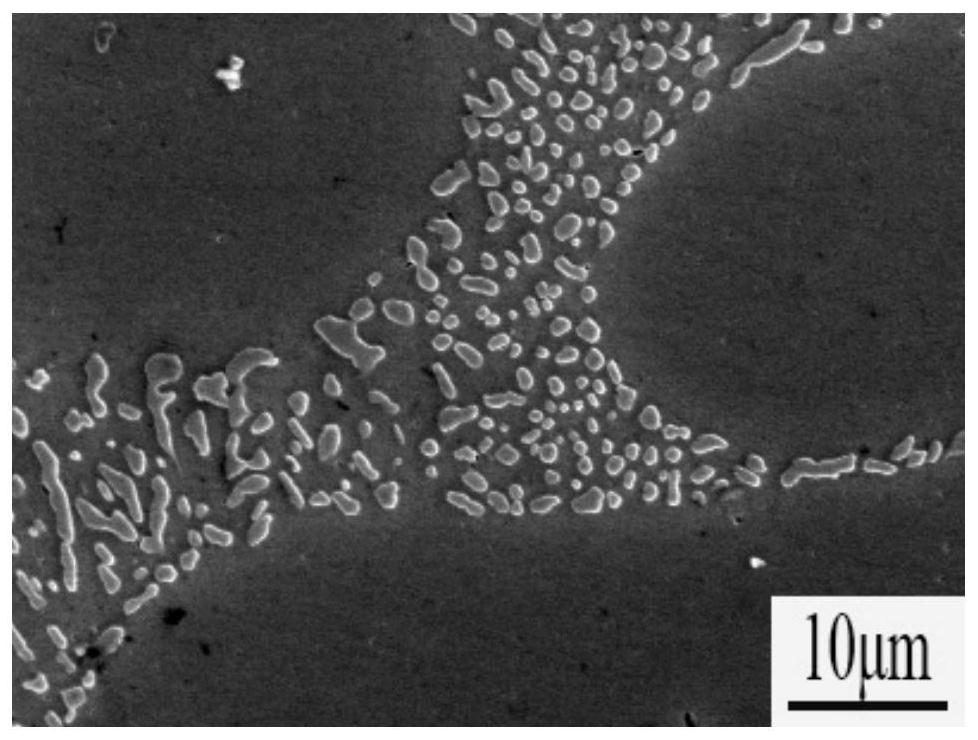

Composite rare earth RE cast aluminum alloy material and preparation method thereof

The invention provides a composite rare earth RE cast aluminum alloy material and a preparation method thereof. The alloy is mainly prepared from the following components in percentage by mass: 0.12%-0.85% of Er, 0.18%-0.68% of Sc, 5.8%-7.5% of Si, 0.15%-0.48% of Mg, 0.08%-0.20% of Ti, less than 0.25% of Fe, less than 0.10% of Cu, less than 0.05% of Mn, less than 0.08% of Zn and the balance of Al.Eutectic silicon is refined into 1[mu]m granules, and the structure of the cast aluminum alloy is improved, a Al3.21Si0.47 phase, a Al3Sc phase, a Sc Phase, a ScSi2 phase, an ErSi2 phase and other hard phases are formed, the performance is greatly improved, especially the erbium and scandium elements are dispersed and distributed in the aluminum alloy, so that the aluminum alloy has higher strength, plastic deformation, elastic modulus and wider melting temperature range and has stronger practicability.

Owner:KUNMING METALLURGY INST

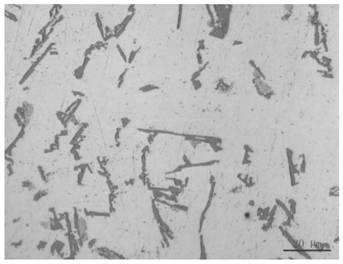

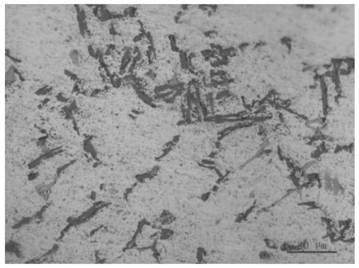

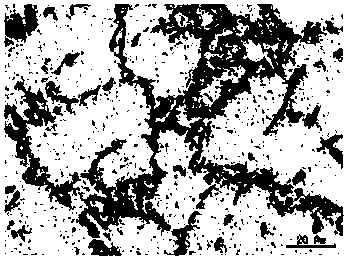

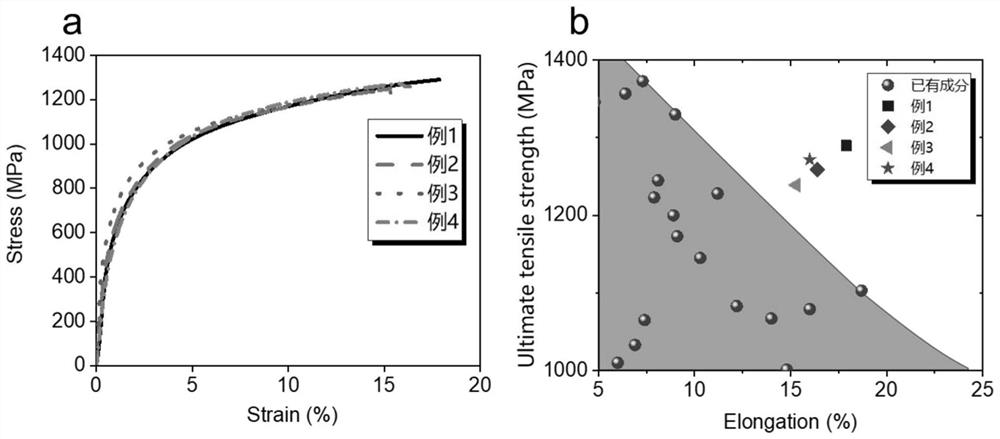

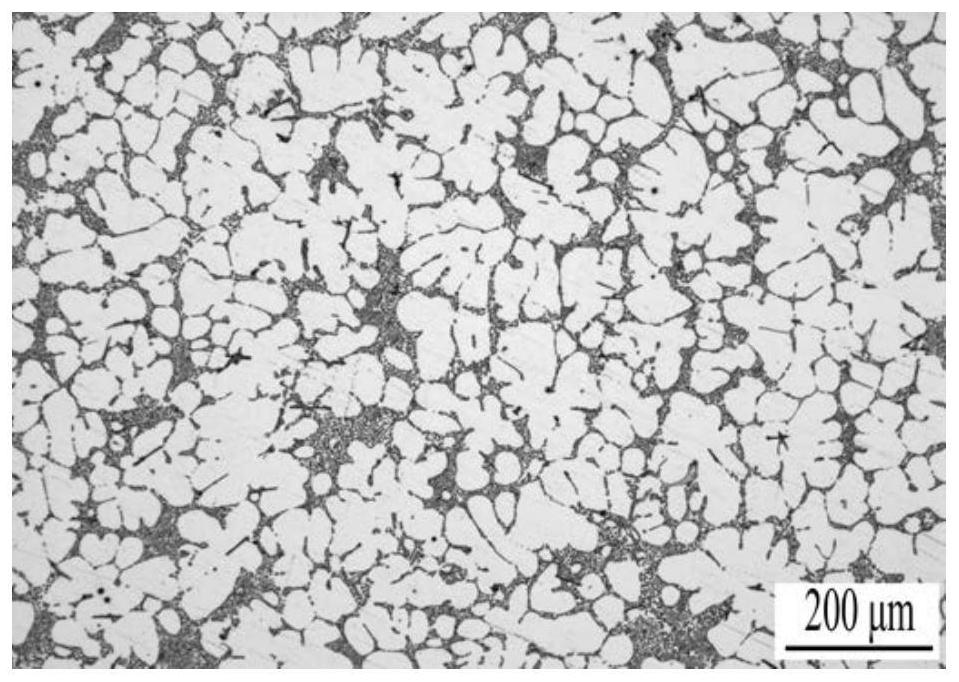

High-entropy alloy with excellent strength and plasticity and preparation method thereof

The invention discloses a high-entropy alloy with excellent strength and plasticity and a preparation method thereof, and the high-entropy alloy comprises the following components in percentage by atom: 18 to 21% of Al, 1 to 10% of Co, 15 to 19% of Cr, 20 to 24% of Fe and 33 to 41% of Ni. The preparation of the high-entropy alloy is completed by adopting an electric arc melting method. In the alloy provided by the invention, a primary BCC phase dendritic crystal and an intergranular eutectic structure are generated. The BCC phase is high in strength but low in plasticity, the intercrystalline eutectic structure has high strength and plasticity, due to the eutectic structure, the primary BCC phase can be cooperatively deformed through back stress strengthening, the strength is remarkably improved, and good plasticity is guaranteed. The high-entropy alloy with excellent strength and plasticity provided by the invention has excellent breaking strength and good percentage elongation after fracture. For the optimal component proportion, the tensile strength can reach 1290 MPa, the percentage elongation after fracture is 17.6%, and compared with an existing AlCoCrFeNi series high-entropy alloy, the strength and plasticity are remarkably improved under the same electric arc melting process condition.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

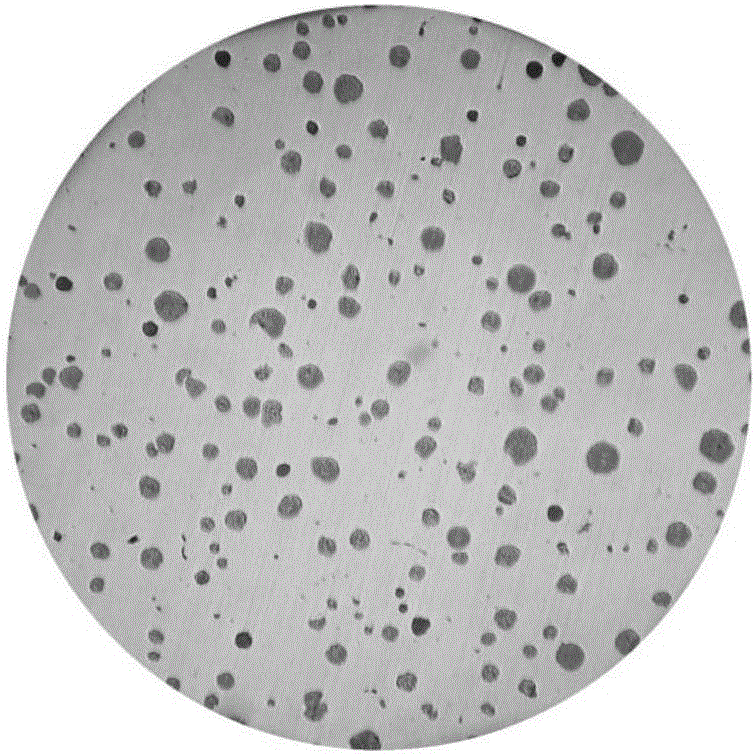

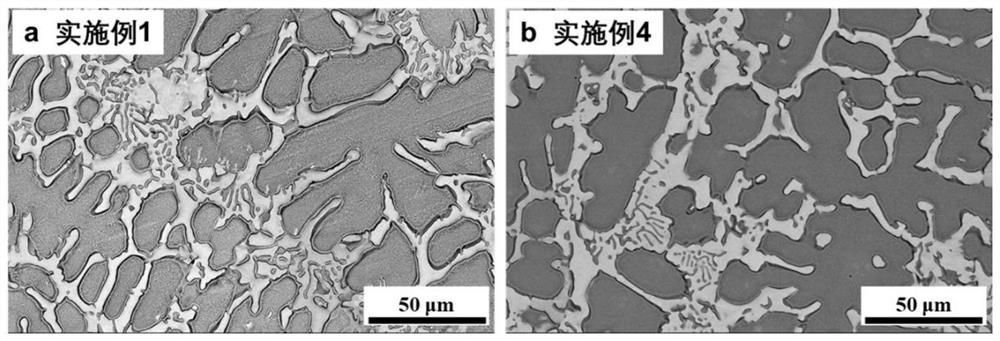

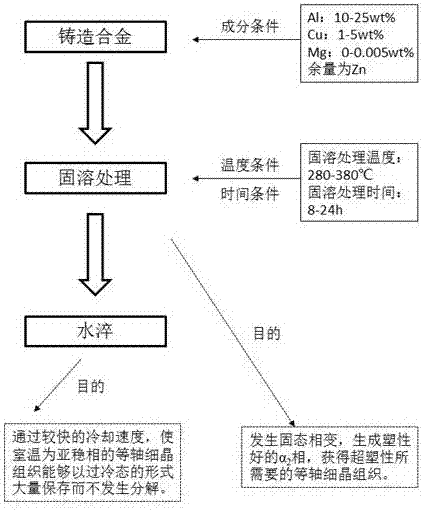

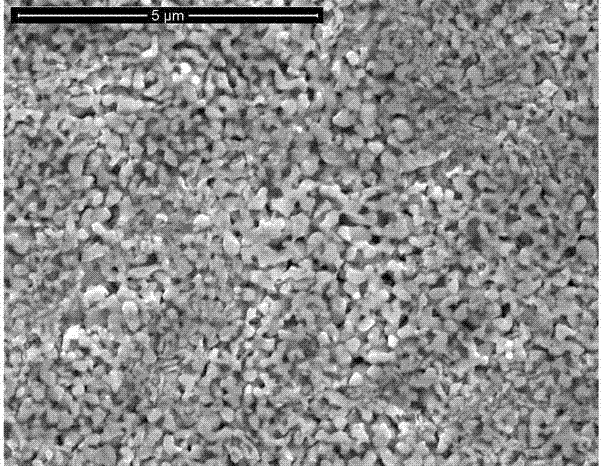

Method for improving superplasticity of zinc-aluminum alloy through heat treatment

InactiveCN107058925AIncreased superplasticityHigh elongation after breakSolution treatmentTime range

The invention discloses a method for improving superplasticity of a zinc-aluminum alloy through heat treatment. The provided method comprises the following steps that the zinc-aluminum alloy is subjected to solution treatment at the temperature ranging from 280 DEG C to 380 DEG C; the solution treatment time ranges from 8 h to 24 h; and water quenching is conducted after solution treatment is finished. By means of the above manner, the zinc-aluminum alloy can obtain an equiaxial fine grain structure composed of a large number of metastable alpha 2 phase grains with good plasticity, and accordingly the superplasticity of the alloy is greatly improved. The post-fracture elongation percentage of the zinc-aluminum alloy treated through the provided method reaches 1,970%; and compared with 200% which is the post-fracture elongation percentage of the zinc-aluminum alloy not treated through the method, the post-fracture elongation percentage of the alloy is greatly improved.

Owner:ANYANG INST OF TECH

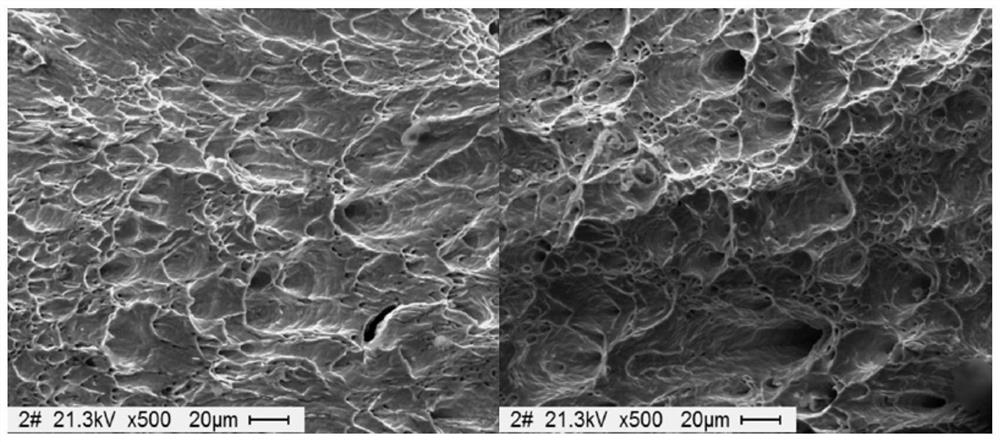

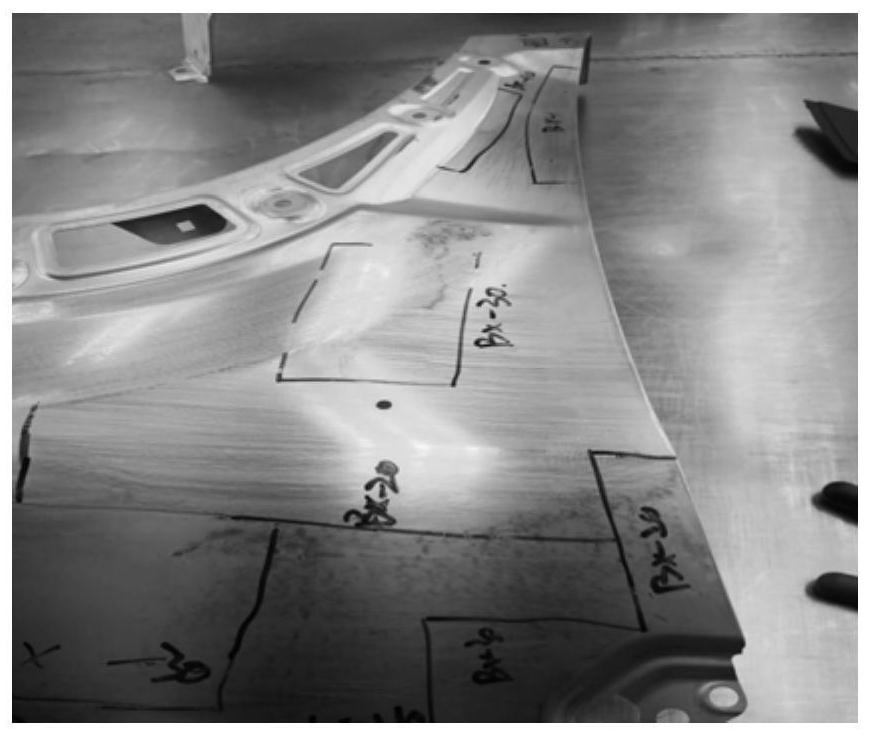

70 kg-class TMCP type high-strength steel and method for manufacturing extend rate detection samples thereof

The invention discloses a piece of 70 kg-class TMCP type high-strength steel and a method for manufacturing extend rate detection samples of the 70 kg-class TMCP type high-strength steel. The low-carbon, high-manganese and boron-charged component design is adopted, the 70 kg-class TMCP type high-strength steel is produced through the TMCP process, the finish rolling temperature ranges from 810 DEG C to 850 DEG C, the finish cooling temperature ranges from 450 DEG C to 550 DEG C, stacking slow cooling is conducted offline for at least 72 hours after cooling is further conducted through a cooling table, and then the 70 kg-class TMCP type high-strength steel is obtained. Fire cut sampling is further conducted, concentrated stacking is conducted for 24 hours, the surfaces of the samples are covered with asbestos so that heat preservation can be achieved, all the samples are machined to be round bar samples with the diameter of 10, and then the extend rate detection samples are obtained. Stacking slow cooling is conducted on steel plates, and therefore residual stress inside the steel plates is released, and the post-breakage extend rate of the steel plates is greatly increased and reaches more than 18%. By means of special sample cutting and thermal insulation treatment, the influences of fire cut on performance are greatly reduced; the samples are machined into the round bar samples, and therefore the detection percent of pass of the products is larger than 98%.

Owner:JIGANG GRP

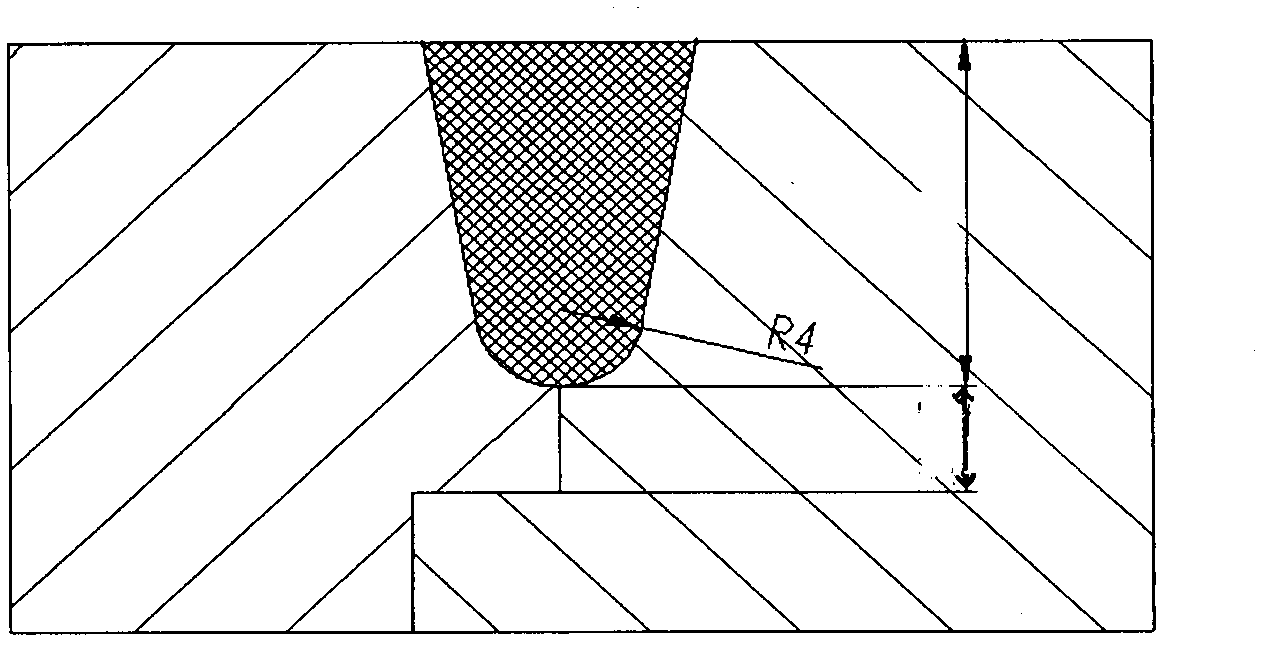

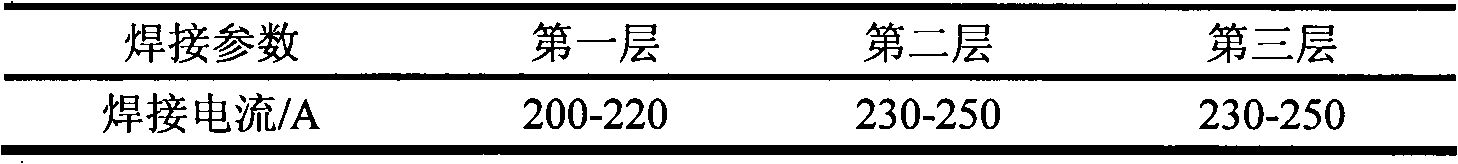

Process for machining cylinder barrel of oil cylinder

InactiveCN103801801AReduce welding defectsImprove safety and reliabilityArc welding apparatusWelding/cutting media/materialsHydraulic cylinderEngineering

The invention discloses a process for machining a cylinder barrel of an oil cylinder, and belongs to the field of hydraulic cylinders. A body of the cylinder barrel is made of Q345B which includes Cr, Nb, Ni, V and other alloy elements, and the mechanical property and the welding property of Q345B are both better than those of 45# steel. The process for machining the cylinder barrel of the oil cylinder includes the steps of selecting a tube blank of a hot rolling steel tube, conducting discharging, conducting straightening, conducting rough cylindrical turning, welding flanges, scraping inner holes, conducting rough turning and conducting finish turning. The process is characterized in that welding parameters are as follows. The process has the advantages that the welding defects of the oil cylinder are reduced by more than 50%, the percentage elongation after fracture of the materials of the cylinder barrel is increased, toughness of the cylinder barrel is guaranteed, the risk that the cylinder barrel is fractured is reduced, and safe reliability of the oil cylinder is greatly improved.

Owner:QINGDAO XINGCHEN MACHINE TOOL

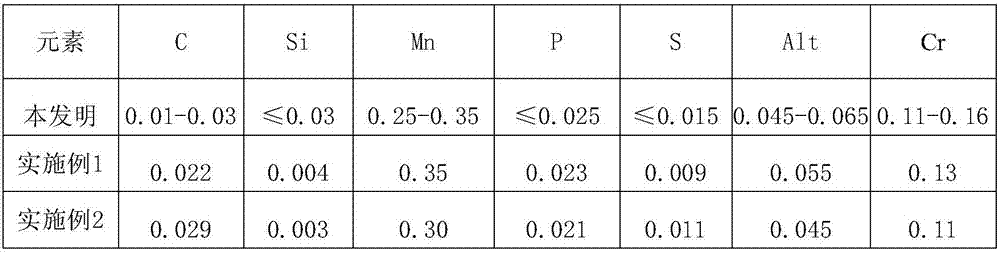

Electroplated tin steel plate for beverage can and production method of electroplated tin steel plate

ActiveCN107541663AImprove mechanical propertiesImprove product qualityChemical compositionUltimate tensile strength

The invention relates to an electroplated tinned steel plate for beverage cans and a production method thereof, which mainly solves the technical problems of high strength, poor strength stability, low elongation after breaking and easy cracking in the can making process of existing electroplated tinned steel plates used for beverage cans . An electroplated tin-plated steel plate for beverage cans provided by the present invention, the weight percentage of the chemical composition of the substrate: C: 0.01% to 0.03%, Si≤0.03%, Mn: 0.25% to 0.35%, P≤0.025%, S≤0.015 %, Alt: 0.045% to 0.065%, Cr: 0.11% to 0.16%, and the balance is Fe and unavoidable impurity elements. The yield strength of the steel plate is 300MPa-330MPa, the tensile strength is 400MPa-430MPa, the hardness value is 55‑58HR30Tm, and the elongation after fracture is A50≥28%. The invention is mainly used in the field of beverage can packaging.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

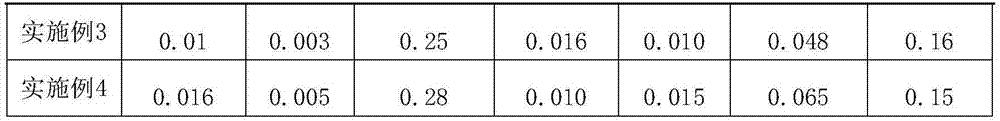

Precipitation strengthening type high-strength and high-toughness medium-manganese steel plate and preparation method thereof

The invention discloses a precipitation strengthening type high-strength and high-toughness medium-manganese steel plate. The precipitation strengthening type high-strength and high-toughness medium-manganese steel plate is prepared from the following chemical components in percentage by mass: 0.04%-0.10% of C, 0.2%-0.6% of Si, 4.0%-6.0% of Mn, 0.4%-1.0% of Al, 0.02%-0.08% of Nb, 1.0%-2.5% of Cu,1.5%-2.5% of Ni, 0.001%-0.004% of B, less than or equal to 0.005% of P, less than or equal to 0.003% of S and the balance of Fe and inevitable impurities. The invention further discloses a preparationmethod. The preparation method comprises the following steps that smelting and forging are carried out on the chemical components to obtain a steel billet; the steel billet is rolled to obtain a hotrolled plate; and the hot rolled plate is sequentially subjected to annealing and tempering to prepare the high-strength and high-toughness medium-manganese steel plate, wherein the annealing temperature is 610 DEG C-650 DEG C for 1h-2h, and tempering is carried out at the temperature of 450 DEG C-550 DEG C for 1.5h-2.5h. The high-strength and high-toughness medium-manganese steel plate is high instrength and impact toughness.

Owner:SHOUGANG CORPORATION

A kind of low-density, high-strength and toughness automobile steel plate and its preparation process

The invention belongs to the field of metal materials, and relates to a novel high strength steel board low in density, high in strength and good in anti-corrosion performance, in particular to component design and a preparation method of the novel automobile-used steel. The automobile-used steel board is characterized by comprising the following specific chemical compositions by mass percentage: 0.60-0.70 percent of C, 0.30-0.40 percent of Si, 10.0-15.0 percent of Mn, 5.0-10.0 percent of Al, less than 0.005 percent of P, less than 0.003 percent of S and Fe and unavoidable impurities in balancing amount. The preparation process comprises the following steps: performing smelting according to the chemical compositions, and forging casting blank material into a steel blank; heating the steel blank to 1,130-1,170 DEG C, keeping the temperature for 2 hours, and performing multi-pass hot-rolling deformation, wherein the rolling starting temperature ranges from 1,030-1,070 DEG C, the rolling stopping temperature ranges from 850-900 DEG C, the accumulated deformation amount ranges from 80 percent to 85 percent, and the rolling temperature is from 200 DEG C to 250 DEG C; after hot rolling, further performing solution treatment of the steel board, keeping the temperature at 1,000-1,050 DEG C for 0.5-1 hour, and performing water quenching treatment; taking a dual-phase organization combining austenite and ferrite, and obtaining the lower density and high toughness automobile-used steel board.

Owner:UNIV OF SCI & TECH BEIJING

High-strength Al-Mg-Zr welding wire for ships and preparation method of high-strength Al-Mg-Zr alloy welding wire

InactiveCN111334693AImprove mechanical propertiesHigh tensile strengthWelding/cutting media/materialsSoldering mediaMechanical propertyZr alloy

The invention discloses a high-strength Al-Mg-Zr welding wire for ships. Alloy plate material of the alloy welding wire comprises, by weight: 5.5-6.5% of Mg, 0.7-1.1% of Mn, 0.02-0.15% of Zr, 0-0.3% of Er, 0-0.4% of Si, 0-0.4% of Fe, less than or equal to 0.1% of other single impurity element, and the balance Al. The invention also discloses a preparation method of the alloy welding wire. According to the high-strength Al-Mg-Zr alloy welding wire for the ships and the preparation method of the alloy welding wire, the micro Er element is selected as an effective component of the alloy, so thatthe mechanical property of the whole aluminum alloy welding wire is effectively improved, meanwhile, the deformation energy storage of the surface layer of the aluminum alloy is higher, and thus the tensile strength of a welding wire joint, the bending degree of the welding joint and the elongation rate after the joint is broken are effectively improved; and in addition, the process is simple andeasy to operate, and through adopting the method, the homogenization annealing treatment is thorough in the process of manufacturing the welding wire, so that the mechanical property and corrosion resistance of the manufactured product are effectively improved.

Owner:BEIJING ALUMIP DEVING +2

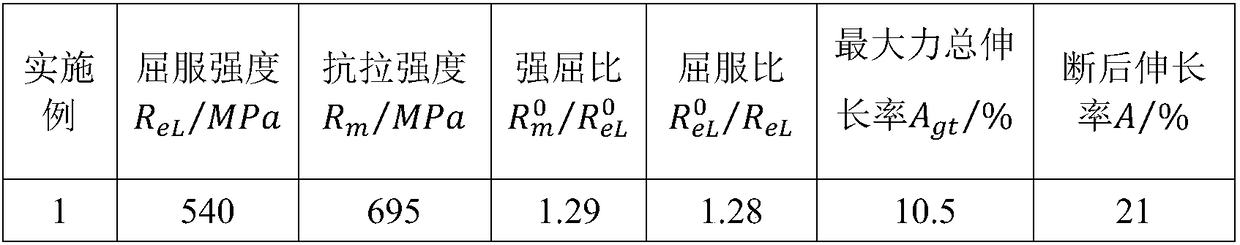

Method for enhancing strength and toughness of medium-carbon V steel

The invention discloses a method for enhancing strength and toughness of medium-carbon V steel, which comprises the following steps: 1) in the smelting process, adding N to control [C], [V] and [N] in the steel; 2) heating the smelted continuous casting billet until the crystalline VN compound is dissolved back to austenite, and rolling into round steel; 3) keeping the temperature within the maximum precipitation peak value range to precipitate abundant VN particles; and 4) controlling the subsequent cooling rate of the round steel within a certain range so that the particle size of more than 80% of VN precipitated phase in the steel is 20-100nm, thereby obtaining the medium-carbon V steel with higher strength and toughness. By using the influence of the N element on different aspects of steel performance, the minor element component system is designed without modifying the production equipment or greatly adjusting the technique; and the yield strength of the medium-carbon V steel can be enhanced by 80-170 MPa, the ductility and fracture toughness of the steel are well improved, the percentage elongation after fracture A is enhanced by 3-5%, and the ballistic work Aku2 is enhanced by 10-50J.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

400 MPa grade hot dip galvanized high-strength IF steel for car front fender and manufacturing method of high-strength IF steel

The invention discloses a 400 MPa grade hot dip galvanized high-strength IF steel for a car front fender and a manufacturing method of the high-strength IF steel. According to the method, P, Si and Mnelements are appropriately added on an IF steel base body to perform solid solution strengthening to ensure the strength, Ti alloy elements are added to eliminate interstitial atoms and achieve precipitation strengthening, an appropriate amount of B element is added to inhibit segregation of P at the grain boundary position, a high elongation after fracture and a low yield ratio are ensured, andmeanwhile, the tensile strength is improved; in combination with the capacity characteristics of production equipment, through smelting, a 2250 mm hot rolling mill, a pickling continuous rolling unitand a continuous annealing process, the finished product yield strength 180-240 MPa, the tensile strength 340-400 MPa, the elongation after fracture >= 34% (tensile test: L0=80 mm, b=20 mm), n value >= 0.18, and r value >= 1.7 are achieved, and a low yield ratio and a good punching performance are ensured.

Owner:BAOTOU IRON & STEEL GRP

Aluminum alloy material for high-performance thin-wall 3D printing sand casting and preparation method thereof

InactiveCN111926220AImprove casting fluiditySolve the problem of difficult fillingSand castingUltimate tensile strength

The invention discloses an aluminum alloy material for high-performance thin-wall 3D printing sand casting and a preparation method thereof, and relates to the technical field of aluminum alloy production. The material comprises the following components of, in percentage by mass, 6.5%-8% of Si, 0.25%-0.45% of Mg, 0.05%-0.16% of Ti, 0.01%0-0.04% of Sr, 0.1%-0.2% of Fe, 0.16%-0.6% of Zr, 0%-0.4% ofSc, less than or equal to 0.10% of other inevitable impurity elements, and the balance Al. In addition, the invention further discloses the preparation method of the high-performance aluminum alloy. According to the alloy, the contents of Si, Mg, Sr, Ti, Zr and Sc are controlled, so that the alloy has good fluidity, a cast 3D printing sand mold casting is fine and uniform in structure, the strength and toughness of the alloy are remarkably improved, and the requirement of thin-wall 3D printing sand mold casting market development can be well met.

Owner:SOUTH CHINA UNIV OF TECH

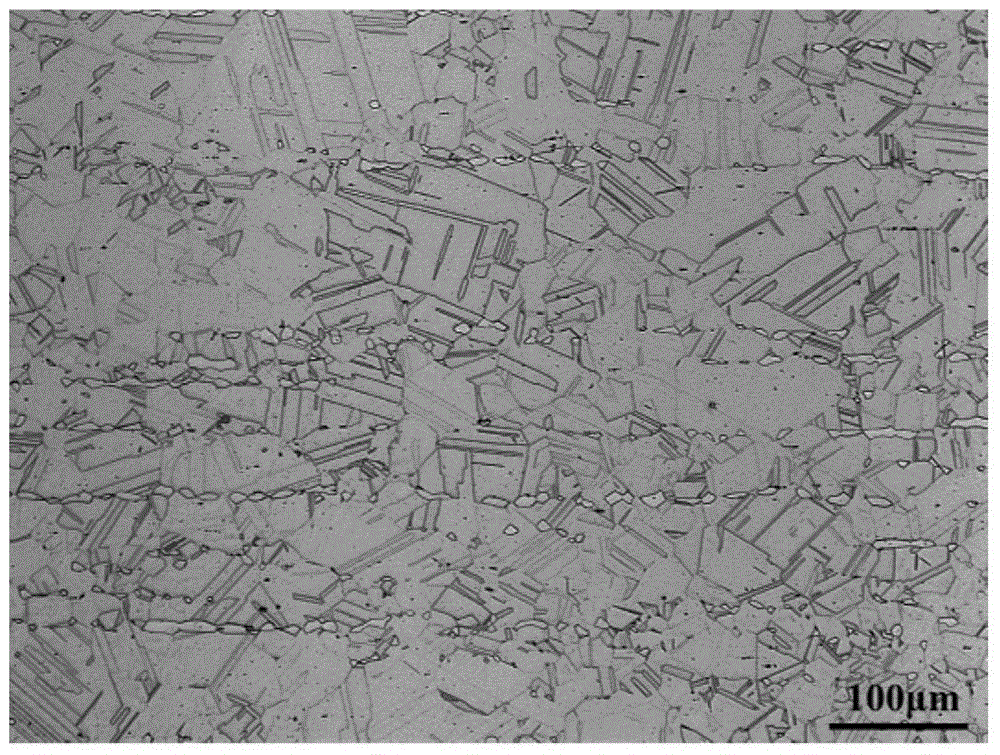

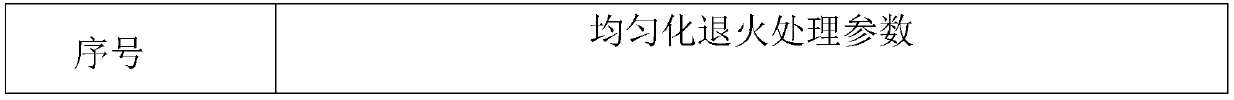

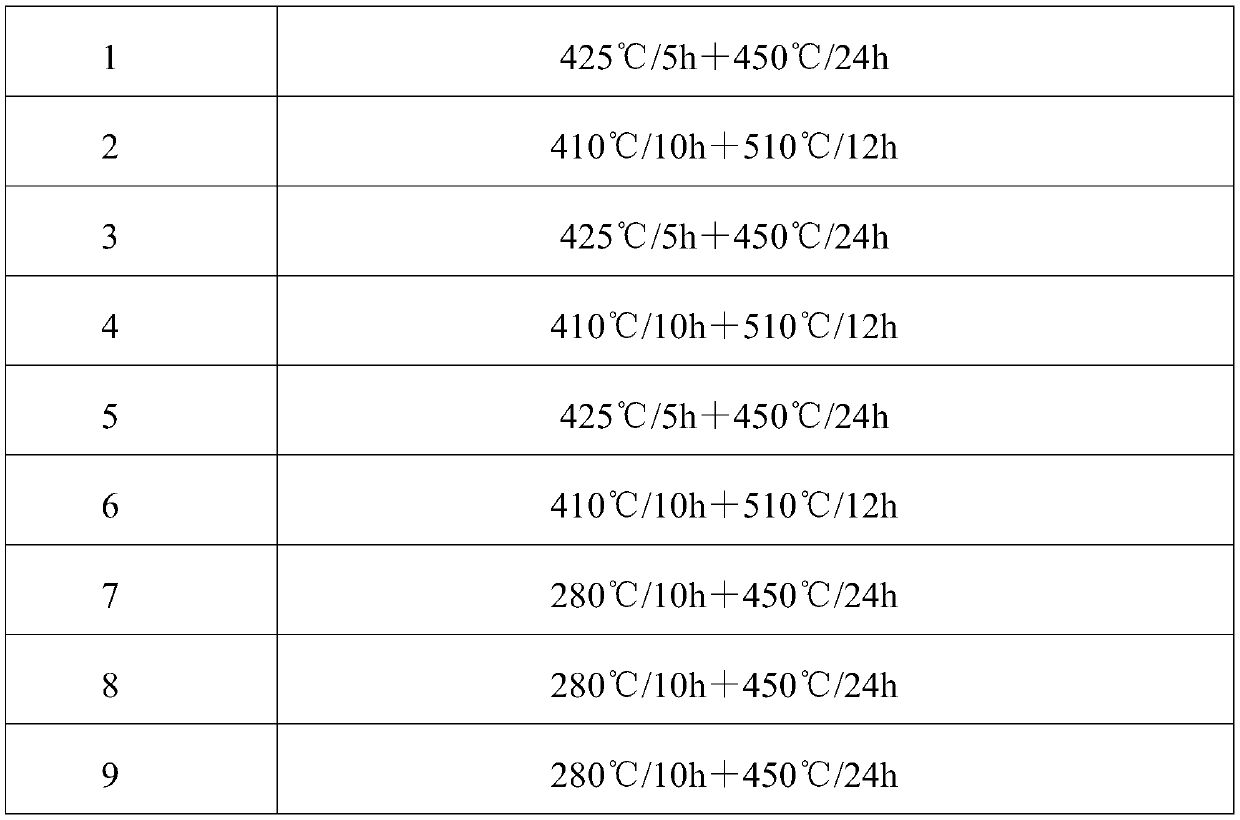

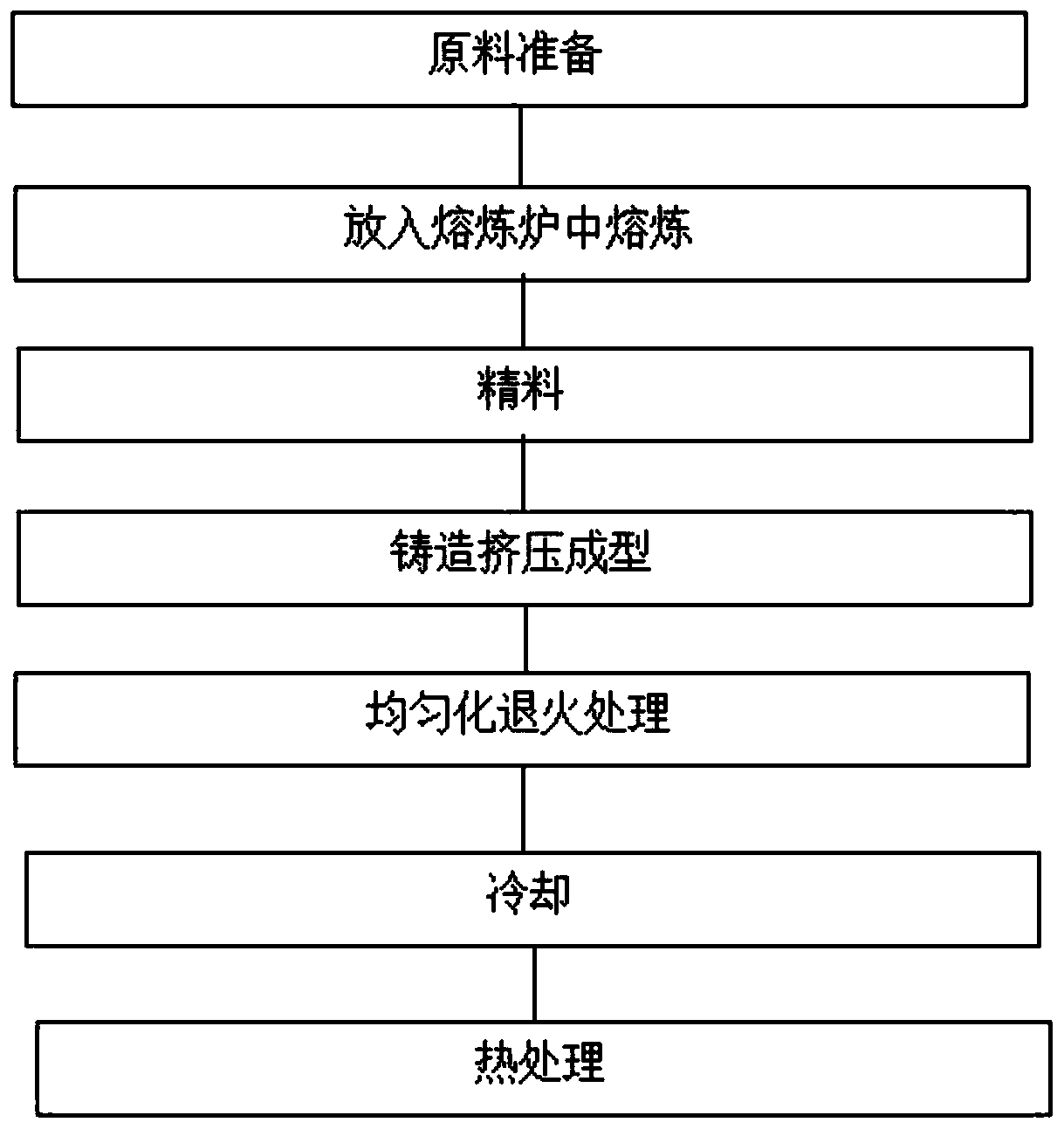

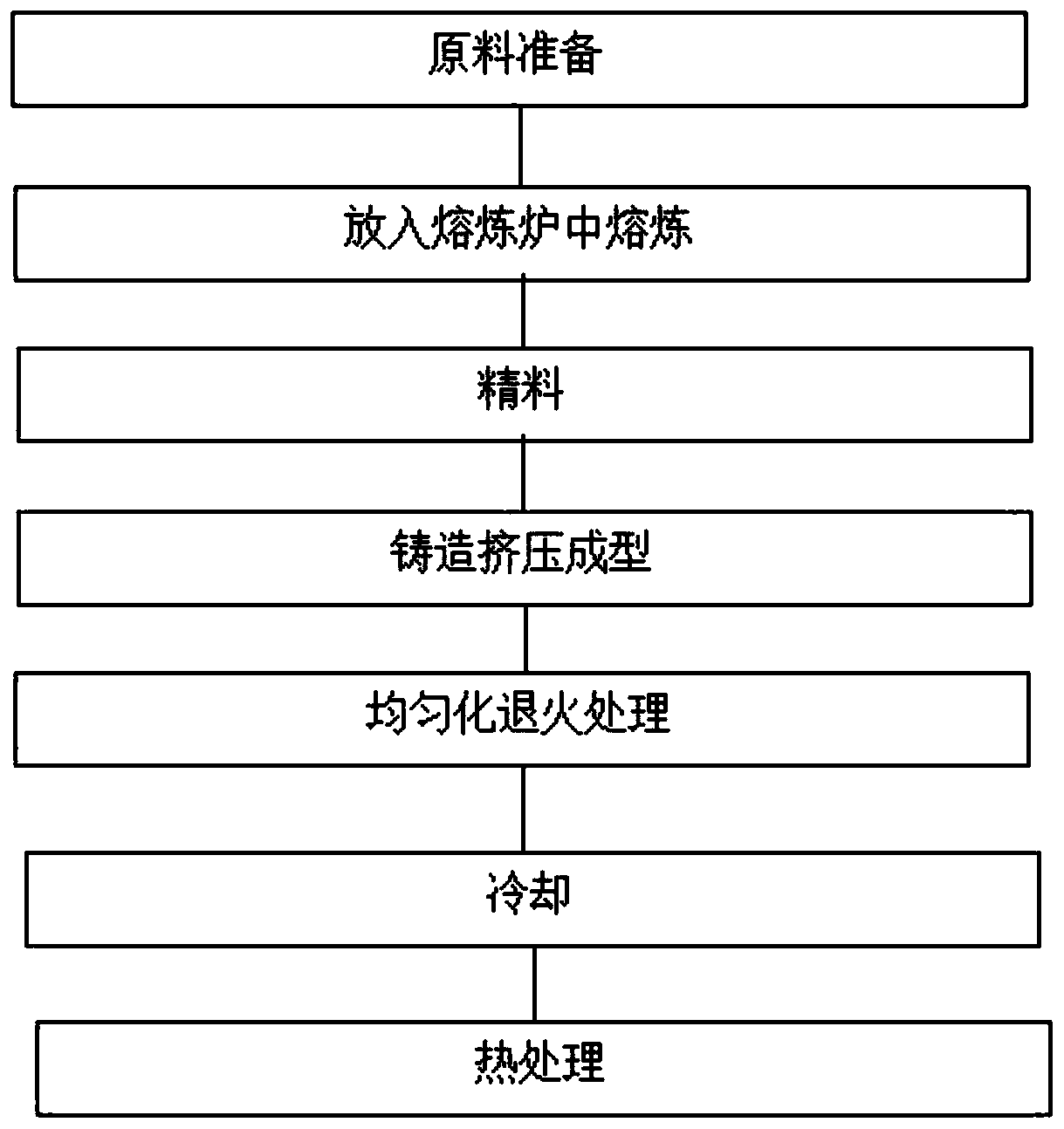

Preparation method of aluminum alloy

The invention relates to a preparation method of an aluminum alloy. The preparation method comprises the following steps of 1, preparing raw materials; 2, smelting raw materials in a smelting furnace,placing aluminum in the lowermost layer when the raw materials are put into the smelting furnace, smelting and melting the raw materials of aluminum, silicon, copper, yttrium, silicon, chromium, carrying out temperature measurement on the mixture, adopting a slag removal device to remove dross on the surface of a molten liquid when the temperature reaches 825-855 DEG C, then adding magnesium according to the weight ratio, stirring the molten liquid in the furnace for 10-15 minutes by using a stirring device, then using a metallurgical slag removal device to remove slag again, then adding theraw materials of cadmium, ytterbium, samarium and terbium, stirring for 20-30 minutes, using a bell jar to press the hexachloroethane to carry out degassing and deslagging, carrying out standing for 20-30 minutes, carrying out slag removal and filtration to obtain an aluminum alloy melt; 3, finishing; 4, casting and extruding and forming; 5, homogenizing annealing treatment; 6, cooling; and 7, carrying out heat treatment. According to the method, the mechanical property of the alloy is improved by virtue of a reasonable extrusion and heat treatment process, so that the tensile strength of thealuminum alloy reaches more than 370 MPa.

Owner:江苏礼德铝业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com