Preparation method of aluminum alloy

A technology of aluminum alloy and aluminum alloy melt, which is applied in the field of aluminum alloy manufacturing, can solve the problems of low mechanical properties and achieve the effect of improving mechanical properties and high impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

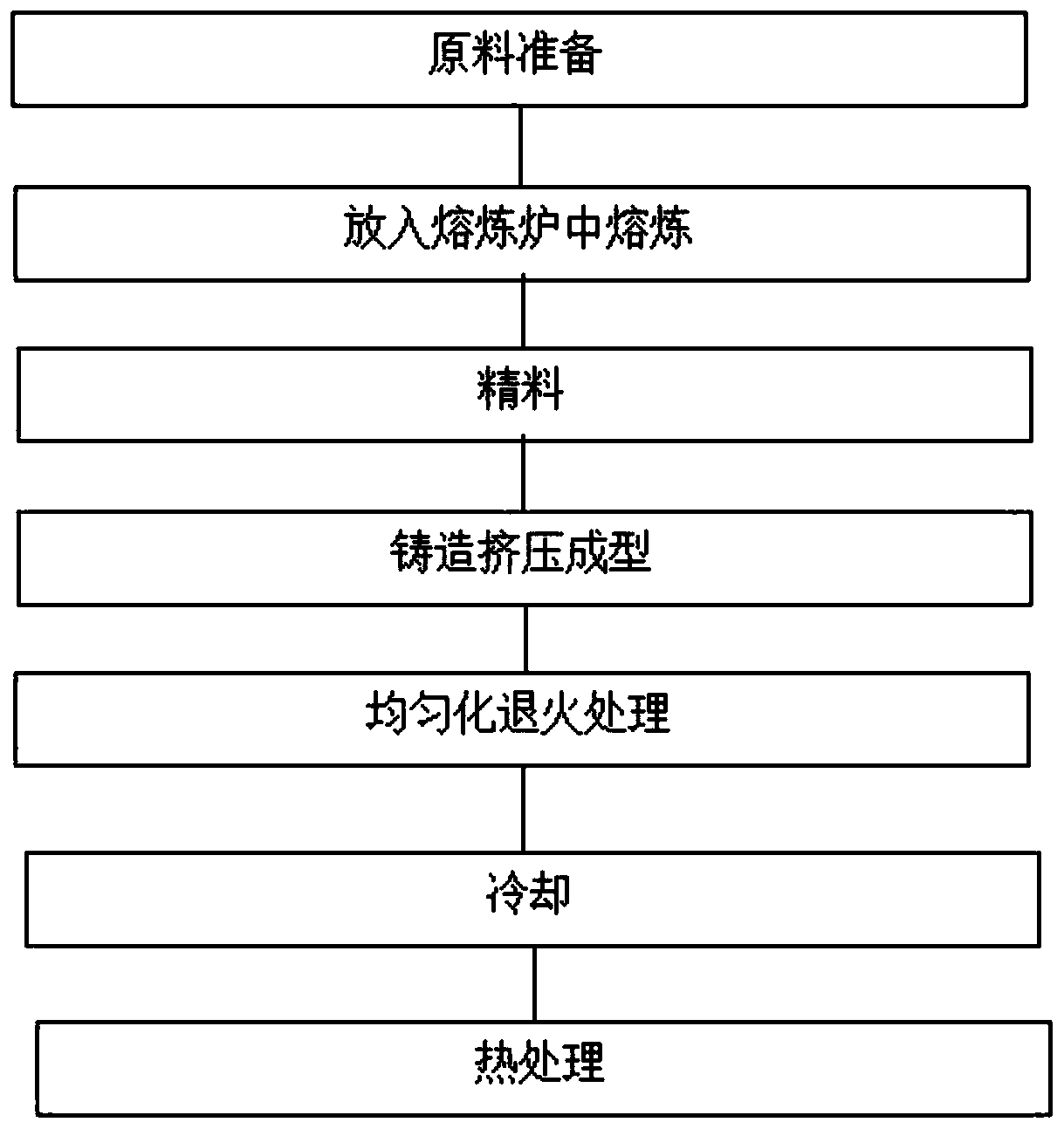

[0025] Such as figure 1 As shown, a method for preparing an aluminum alloy is characterized in that: comprising the following manufacturing steps:

[0026] Step 1: raw material preparation, prepare raw materials of aluminum, silicon, magnesium, copper, yttrium, silicon, chromium, cadmium, ytterbium, samarium, terbium; raw material preparation, prepare aluminum, silicon, magnesium, copper, yttrium, silicon, chromium, cadmium The raw materials of ytterbium, samarium and terbium include the following components by mass fraction: silicon 1.5%, magnesium 1.2%, copper 1.2%, yttrium 0.8%, chromium 0.5%, cadmium 0.3%, ytterbium 0.1%, samarium 0.05%, terbium 0.22 %, the rest is Al.

[0027] Step 2: Melting in a smelting furnace. When putting in the raw materials, put the aluminum on the bottom layer. After the raw materials of aluminum, silicon, copper, yttrium, silicon, and chromium are melted, measure the temperature of the mixture. When the temperature reaches 825 ℃, use a slag re...

Embodiment 2

[0034] A method for preparing an aluminum alloy, characterized in that: comprising the following manufacturing steps:

[0035]Step 1: raw material preparation, prepare raw materials of aluminum, silicon, magnesium, copper, yttrium, silicon, chromium, cadmium, ytterbium, samarium, terbium; raw material preparation, prepare aluminum, silicon, magnesium, copper, yttrium, silicon, chromium, cadmium The raw materials of ytterbium, samarium and terbium include the following components by mass fraction: 2% silicon, 1.4% magnesium, 1.3% copper, 0.9% yttrium, 0.7% chromium, 0.4% cadmium, 0.2% ytterbium, 0.05% samarium, and 0.22% terbium %, the rest is Al.

[0036] Step 2: Melting in a smelting furnace. When putting in the raw materials, put the aluminum on the bottom layer. After the raw materials of aluminum, silicon, copper, yttrium, silicon, and chromium are melted, measure the temperature of the mixture. When the temperature reaches 840 ℃, use the slag removal device to remove the...

Embodiment 3

[0043] A method for preparing an aluminum alloy, characterized in that: comprising the following manufacturing steps:

[0044] Step 1: raw material preparation, prepare raw materials of aluminum, silicon, magnesium, copper, yttrium, silicon, chromium, cadmium, ytterbium, samarium, terbium; raw material preparation, prepare aluminum, silicon, magnesium, copper, yttrium, silicon, chromium, cadmium The raw materials of ytterbium, samarium and terbium include the following components by mass fraction: 2.5% silicon, 1.6% magnesium, 1.4% copper, 1% yttrium, 0.8% chromium, 0.4% cadmium, 0.2% ytterbium, 0.1% samarium, and 0.3% terbium %, the rest is Al.

[0045] Step 2: Melting in a smelting furnace. When putting in the raw materials, put the aluminum on the bottom layer. After the raw materials of aluminum, silicon, copper, yttrium, silicon, and chromium are melted, measure the temperature of the mixture. When the temperature reaches 855 ℃, use the slag removal device to remove the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com