400 MPa grade hot dip galvanized high-strength IF steel for car front fender and manufacturing method of high-strength IF steel

A manufacturing method, 400mpa technology, applied in the field of high-strength automotive steel, can solve problems such as increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

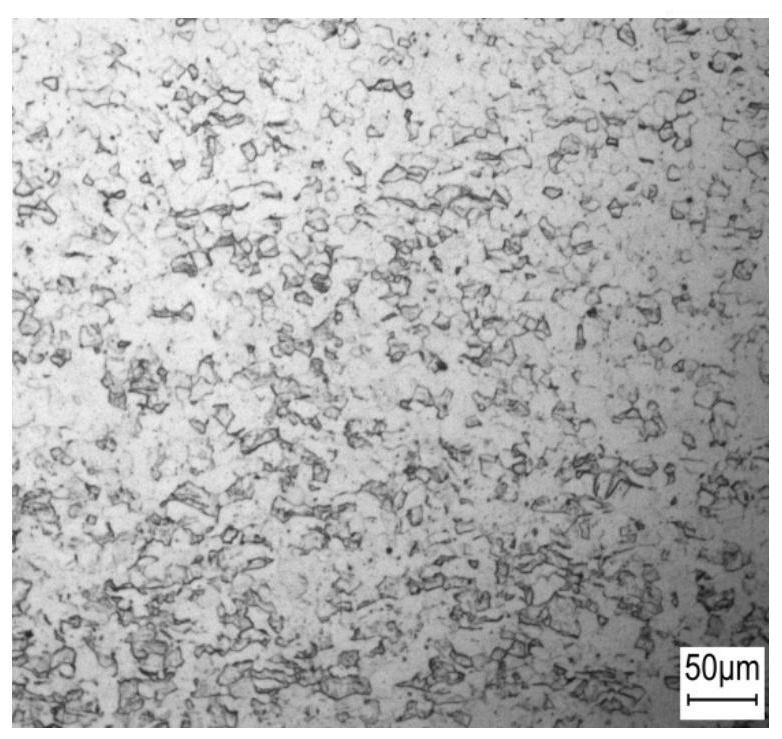

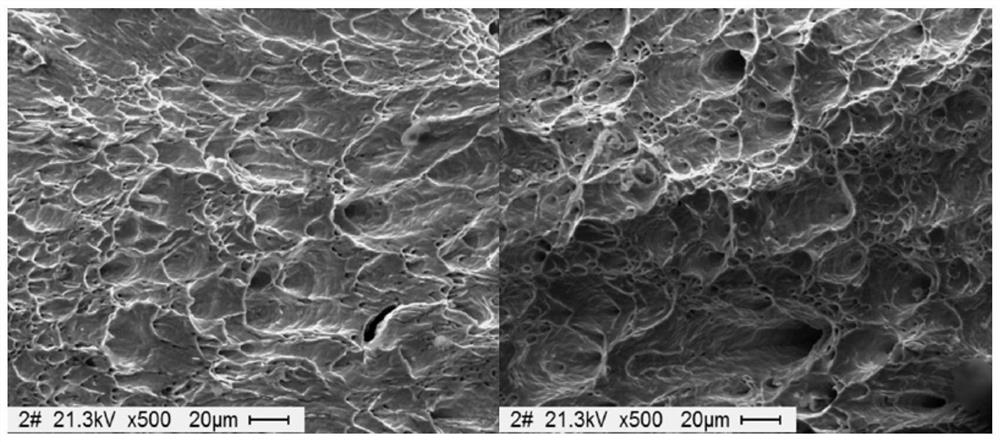

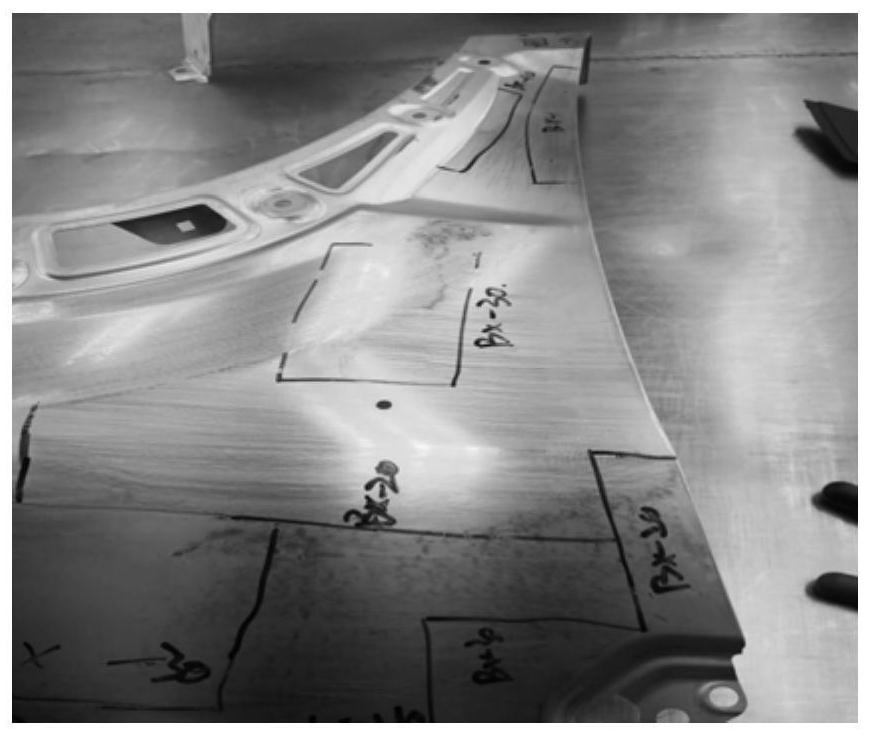

Image

Examples

Embodiment Construction

[0027] 1. Smelting process

[0028] 1.1 KR desulfurization: KR hot metal desulfurization technology is adopted, and the final sulfur content after deep desulfurization is required to be within 0.002%. KR desulfurization is desulfurized by mechanical stirring, and desulfurizing agent is added to the molten iron, so that the sulfur in the desulfurizing agent and molten iron is produced in constant stirring The desulfurization reaction removes the sulfur content in the molten iron. After the desulfurization is completed, the desulfurization slag is completely removed to prevent the high-sulfur slag from being mixed into the converter to cause sulfur return. The temperature stability control of the molten iron in the furnace ensures that the temperature of the molten iron is above 1300°C, which is conducive to stabilizing the control of the converter smelting process and improving the hit rate of the converter end point temperature.

[0029] 1.2 Converter smelting:

[0030] Scrap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com