A manufacturing process of annealing-free medium and high carbon steel plate

A manufacturing process, medium and high carbon technology, applied in the field of steel rolling process, can solve the problems of medium and high carbon steel plate hardness reduction, double production cycle, difficulty in deep processing deformation, etc., and achieve the effect of increased elongation and high plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Steel mills refine qualified molten steel and continuously cast it into a slab of 72*1500mm. The chemical composition is C: 0.48%, Si: 0.22%, Mn: 0.70%, P: 0.012%, S: 0.007%, Als: 0.020 %, the balance is Fe; the continuous casting slab is heated by a 230m tunnel-type heating furnace, and the heating temperature is 1080°C. Intermediate cooling down to 830°C, after finishing rolling and descaling, enter 5 finishing mills for rolling, the thickness of the finished product is 5.0mm, immediately enter the laminar flow cooling section after finishing rolling, cool down to 680±20°C for coiling, after coiling Heap cold. The chemical composition is listed in Table 1, the process parameters are listed in Table 2, and the mechanical properties and hardness of the finished product are shown in Table 3.

Embodiment 2

[0016] Example 2: Steel mills refine qualified molten steel and continuously cast it into a slab of 72*1250mm. The chemical composition is C: 0.49%, Si: 0.20%, Mn: 0.72%, P: 0.010%, S: 0.006%, Als: 0.022 %, the balance is Fe; the continuous casting slab is heated by a 230m tunnel-type heating furnace, and the heating temperature is 1090°C. Intermediate cooling down to 840°C, after finishing rolling and descaling, enter 5 finishing mills for rolling, the thickness of the finished product is 5.0mm, immediately enter the laminar flow cooling section after finishing rolling, cool down to 680±20°C for coiling, after coiling Heap cold. The chemical composition is listed in Table 1, the process parameters are listed in Table 2, and the mechanical properties and hardness of the finished product are shown in Table 3.

Embodiment 3

[0017] Example 3: Refining qualified molten steel in a steel factory, and continuously casting it into a slab of 72*1500mm, the chemical composition is C: 0.51%, Si: 0.25%, Mn: 0.72%, P: 0.010%, S: 0.008%, Als: 0.024 %, the balance is Fe; the continuous casting slab is heated by a 230m tunnel-type heating furnace, and the heating temperature is 1070°C. Intermediate cooling down to 810°C, after finish rolling and descaling, enter 5 finishing mills for rolling, the thickness of the finished product is 4.5mm, immediately enter the laminar flow cooling section after finishing rolling, cool down to 680±20°C for coiling, after coiling Heap cold. The chemical composition is listed in Table 1, the process parameters are listed in Table 2, and the mechanical properties and hardness of the finished product are shown in Table 3.

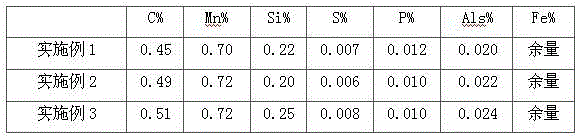

[0018] Table 1

[0019]

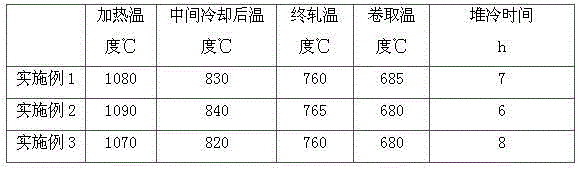

[0020] Table 2

[0021]

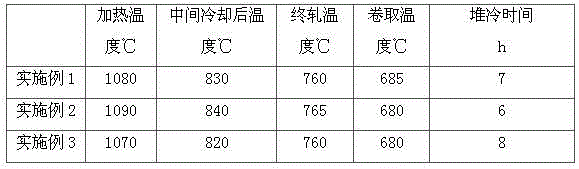

[0022] table 3

[0023]

[0024] In the medium-high carbon steel plate produced by the anneali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com