Patents

Literature

95results about How to "Increased superplasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometer zirconium oxide thermal barrier coating and preparation method thereof

ActiveCN102094164AWon't spreadHigh strengthMolten spray coatingEfficient propulsion technologiesThermal insulationThermal barrier coating

The invention relates to a nanometer zirconium oxide thermal barrier coating and a preparation method thereof. The nanometer zirconium oxide thermal barrier coating is characterized by comprising an adhesive layer and a ceramic layer, wherein NiCrAlY is prepared on the adhesive layer by adopting supersonic flame spraying and comprises the following components in percentage by weight: 20-30% of Cr, 4.0-10% of Al, 0.3-0.7% of Y, and the balance of Ni; a ZrO2 / Y2O3 layer is prepared as the ceramic layer by adopting plasma spraying, the ceramic layer is a nanometer zirconium oxide layer comprising5%-8% of partially stable yttrium oxide, and zirconium oxide powder is at a nanometer grade. The oxidation-resisting thermal barrier coating is prepared on a metal surface by combining the supersonic flame spraying with the plasma spraying, has better combining capacity with a base body and both thermal shock resistance and thermal insulation superior to those of a common ZrO2 / Y2O3 thermal barrier coating.

Owner:沈阳天贺新材料开发有限公司

Processing method of fine-grain superplastic TA15 titanium alloy medium-thickness plate

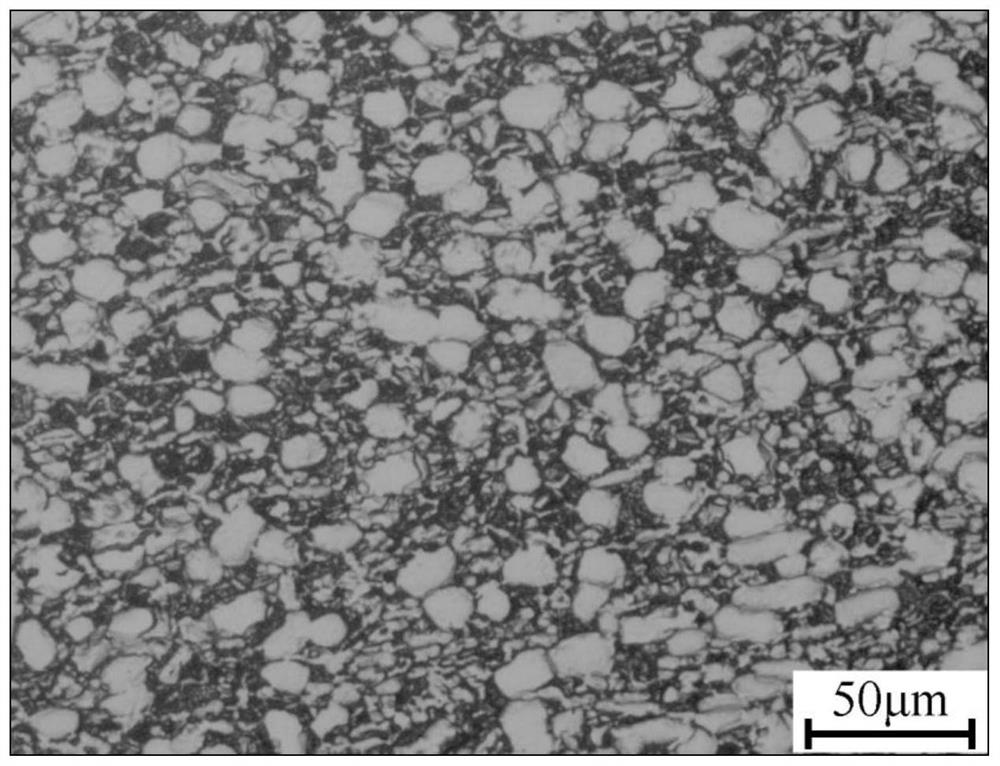

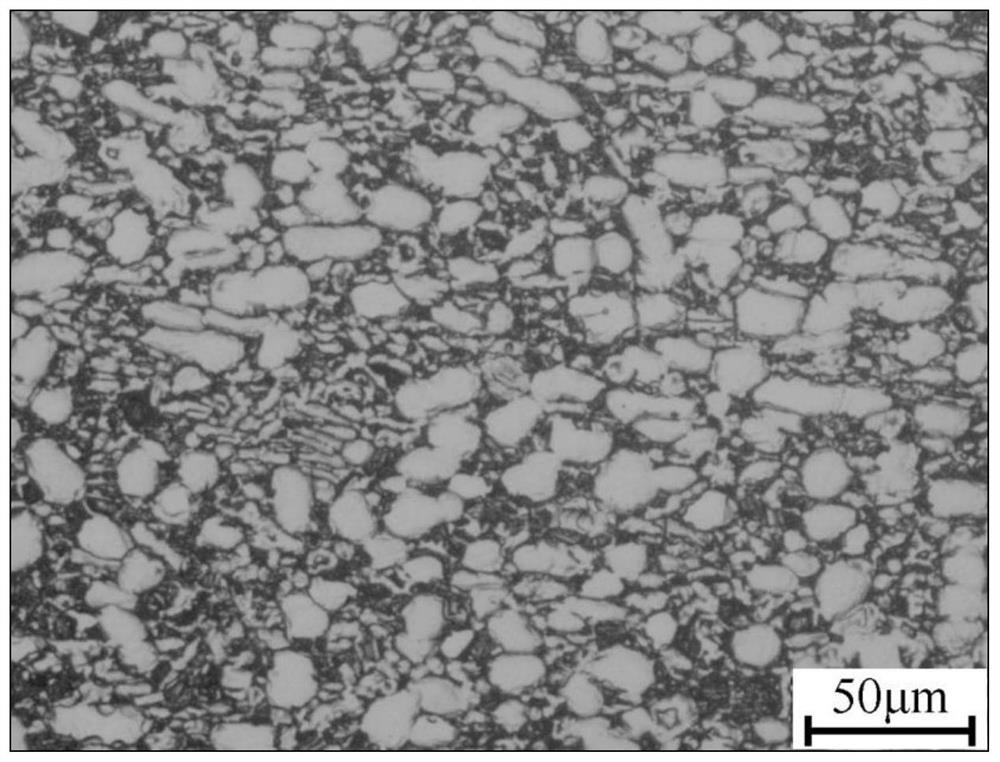

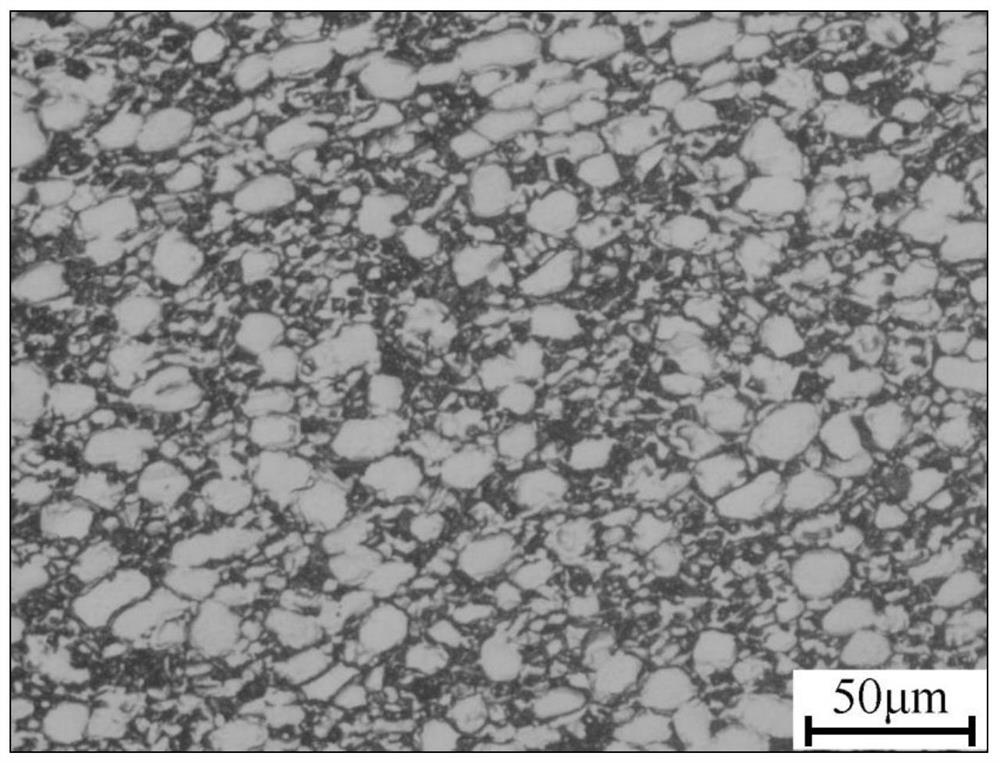

The invention discloses a processing method of a fine-grain superplastic TA15 titanium alloy medium-thickness plate. The processing method comprises the following steps that 1, vacuum consumable arc melting is carried out to obtain a TA15 titanium alloy cast ingot; 2, after heat preservation, a primary forging stock is obtained through upsetting, drawing, cogging and forging; 3, after heat preservation, a second-stage forging stock is obtained through beta-phase region upsetting and drawing forging; 4, upsetting and drawing forging in an alpha + beta two-phase region is carried out to obtain afourth-stage forging stock; 5, a forge piece is obtained through upsetting, drawing and finish forging; 6, after heat preservation, a first-fire rolled plate blank is obtained through first-fire rolling; 7, after heat preservation, a second-fire rolled plate blank is obtained through second-fire rolling; and 8, the TA15 titanium alloy medium-thickness plate is obtained through annealing treatment. According to the processing method of the fine-grain superplastic TA15 titanium alloy medium-thickness plate, the corresponding deformation temperature is selected and combined with multi-heating-number large-deformation upsetting and drawing forging, so that the TA15 titanium alloy cast ingot with a coarse structure is crushed under the large deformation, driving force is provided for recrystallization, the grain refinement and homogenization degree is improved, and the fine-grain superplasticity TA15 titanium alloy medium-thickness plate is obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Plating diamond tool with glass hard high-wearing feature and production method thereof

Disclosed is an electroplating diamond tool with high hardness and high wear resistance. The invention is formed by covering a coating of nano nickel-cobalt material on a green body of the diamond tool. The method of the tool comprises preparing electroplating liquid, preparing before electroplating of the green body of the diamond tool, and electroplating the green body of the diamond tool after the preparation. When electroplating the green body of the diamond tool after the preparation, the green body of the diamond tool is electroplated with the nano nickel-cobalt material by the utilization of the method of impulse electroplating. The electroplating liquid of the invention is formed by components of nickel sulfate, nickel chloride, cobalt sulfate, grain refiner, dodecyl sodium sulfate, boracic acid and the like. The tool has high hardness and high wear resistance, and thereby the service life is long. Further, the invention has the advantages of short manufacture period.

Owner:HENAN AGRICULTURAL UNIVERSITY

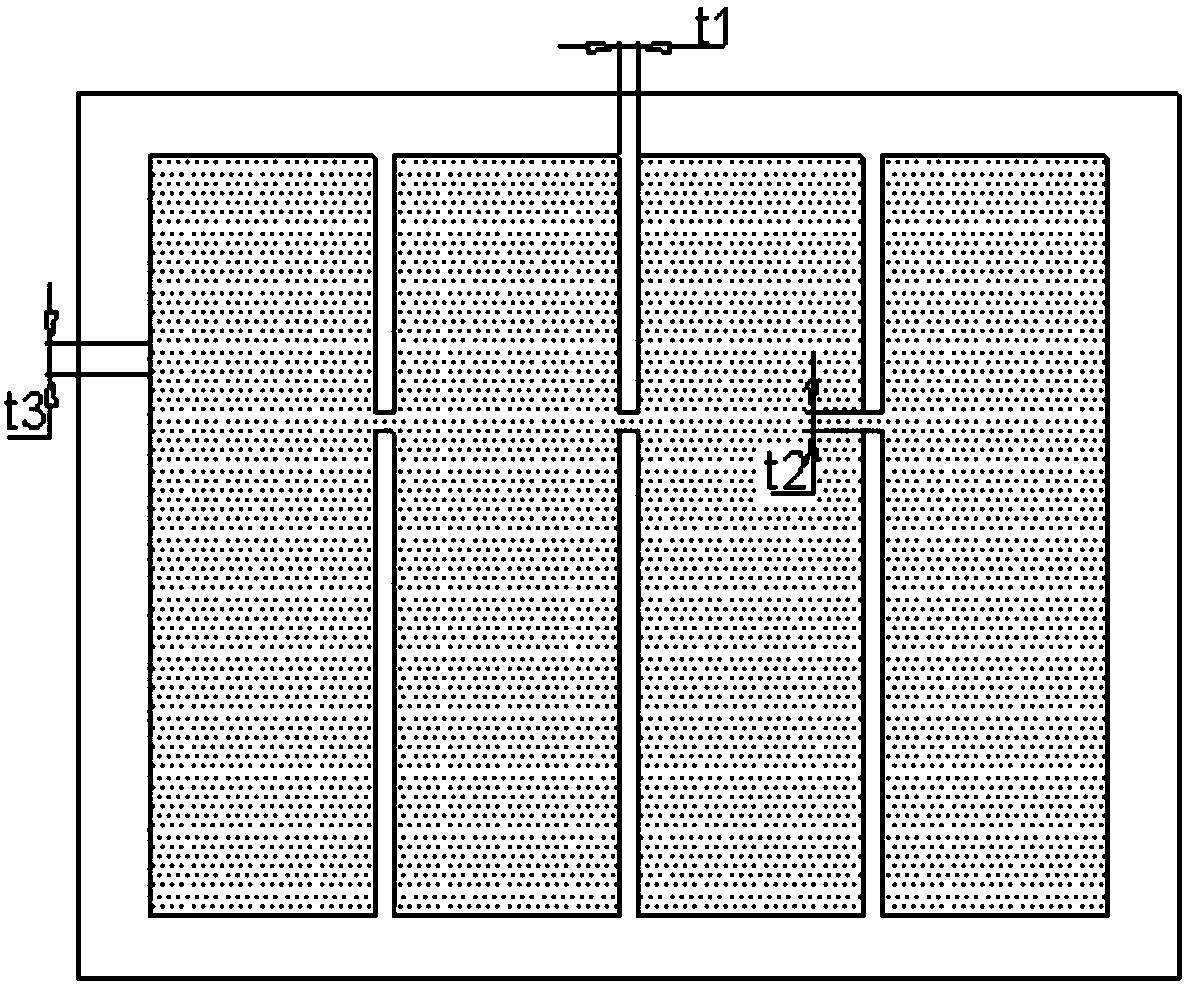

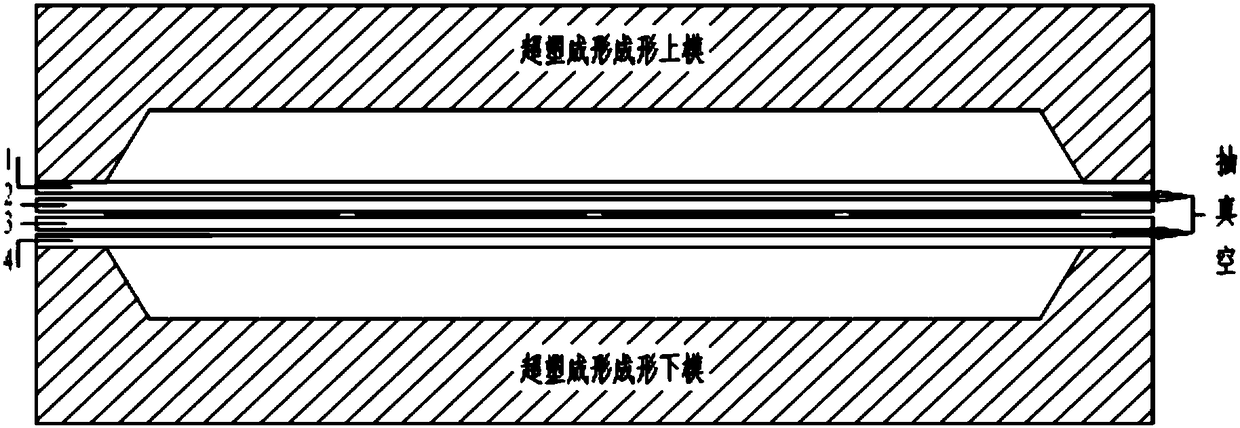

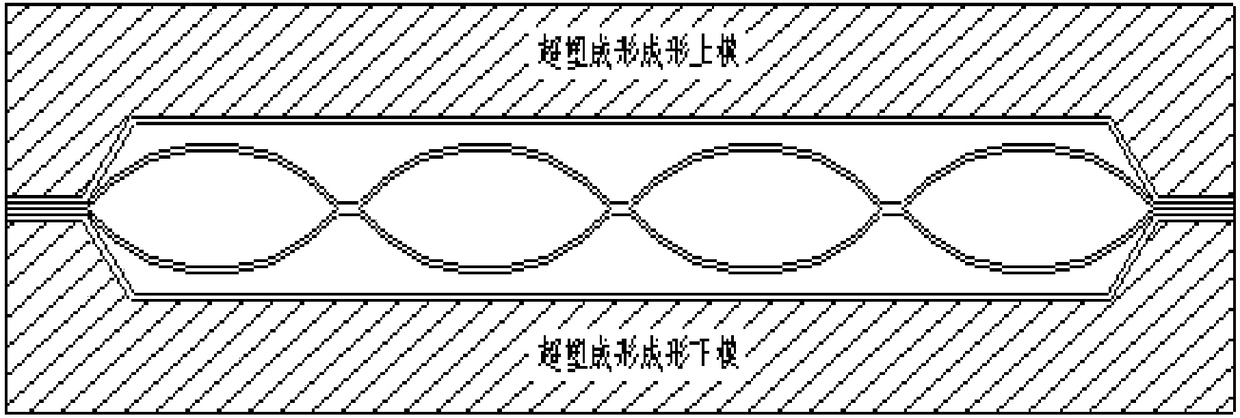

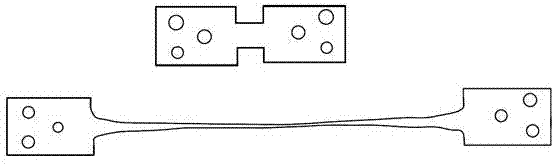

Preparation method of Ti2AlNb/TA15 bi-metal titanium alloy composite hollow structure

The invention provides a preparation process of a Ti2AlNb / TA15 bi-metal titanium alloy composite hollow structure part. The Ti2AlNb / TA15 bi-metal titanium alloy composite hollow structure wing type component is prepared through the steps of blank preparation, surface treatment, welding stop agent coating, superplastic forming / diffusion bonding, cooling, out of a furnace and the like. The superplastic forming / diffusion bonding process method of the dissimilar material hollow structure part breaks through the key technology of the multi-layer hollow structure prepared by combining a Ti2AlNb intermetallic compound and an ordinary titanium alloy, the high-temperature resisting characteristic of the Ti2AlNb intermetallic compound and the good superplasticity of the TA15 titanium alloy are givento full play, structure weight losing is achieved, the guided missile thrust-weight ratio is increased, the application of the Ti2AlNb intermetallic compound to types is promoted, the material application range is expanded, the material utilization rate is increased, and the cost is reduced.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Mo-Si-B-W multi-phase composite material and preparation method thereof

ActiveCN102424928AImprove high temperature strengthImprove reliabilityAlloyUltimate tensile strength

The invention discloses a Mo-Si-B-W multi-phase composite material, which is prepared with raw materials of the following atom percentages: 5-25 percent of silicon, 1-10 percent of tungsten, 5-30 percent of boron, and the resting being molybdenum. The mass purity of the silicon is no less than 98 percent, the mass purity of the tungsten is no less than 99 percent, the mass purity of the boron is no less than 99 percent, and the mass purity of the molybdenum is no less than 99 percent. The invention also discloses a preparation method of the Mo-Si-B-W multi-phase composite material. Mechanicalalloy and hot pressure sintering are adopted in the method to prepare the Mo-Si-B-W composite material, the method has the advantages of low energy consumption, short cycle and the like, and tungstenpowder is introduced into an Mo-Si-B composite material system so as to increase the high-temperature strength of the material and improve the reliability of the material in use. The composite material prepared in the method has a uniform and fine microstructure, the tensile strength of the composite material at 1400 DEG C is 400-460MPa, and the tensile elongation of the composite material is up to 400 percent.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Titanium alloy capable of resisting high temperature higher than 600 DEG C

The invention discloses a titanium alloy capable of resisting high temperature higher than 600 DEG C. The chemical elements of the titanium alloy are 5.5 to 7.0 percent by weight of Al, 2.5 to 4.0 percent by weight of Sn, 1.0 to 3.0 percent by weight of Zr, 1.0 to 3.0 percent by weight of Mo, 1.5 to 3.0 percent by weight of Nb, 0.10 to 0.40 percent by weight of Si, 0.05 to 1.0 percent by weight of Ce, 0.1 to 5.0 percent by weight of Ta, 0.1 to 2.0 percent by weight of C, 0.1 to 2.0 percent by weight of B and the balance of Ti and other inevitable impurities. The titanium alloy can be used under the temperature higher than 600 DEG C, and guarantees excellent mechanical properties under the high temperature at the same time.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing short-flowpath fine crystal super-plastic material

ActiveCN101333583AShort manufacturing processIncreased superplasticityPlastic materialsFriction stir processing

Disclosed is a process for preparing short process fine crystalline superplasticity materials, which is characterized in that: cast alloy is used as a starting material for carrying out the agitation and friction processing after the homogenization heat treatment, and a bulky, loose and uneven cast structure is changed into an even and compact fine crystalline superplasticity structure.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

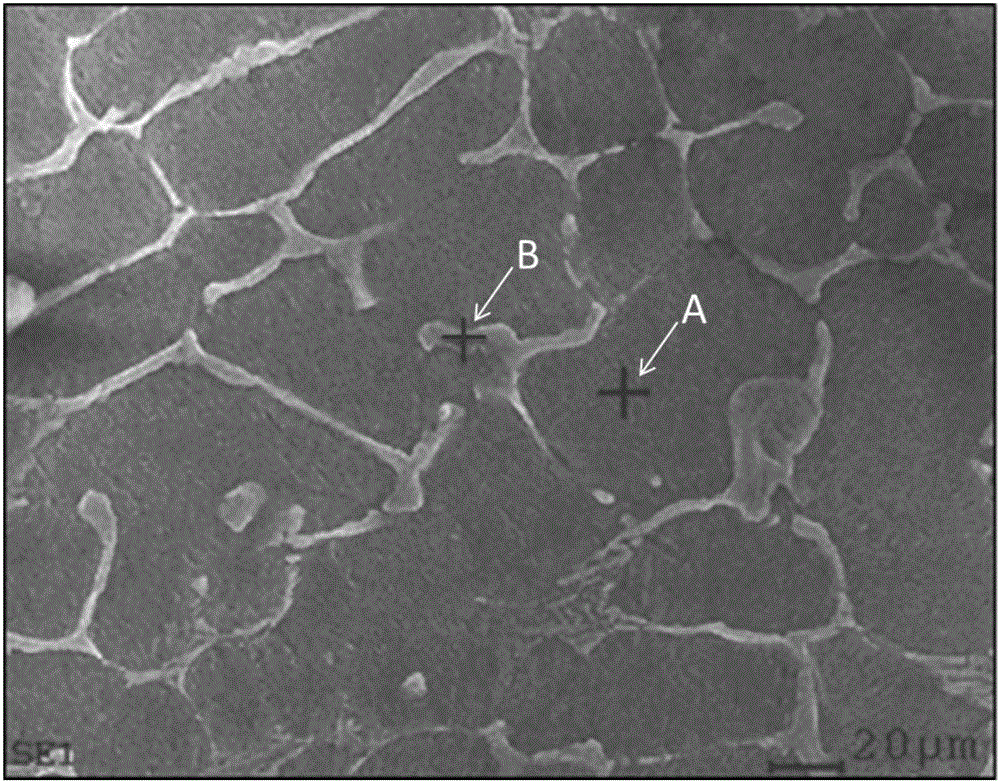

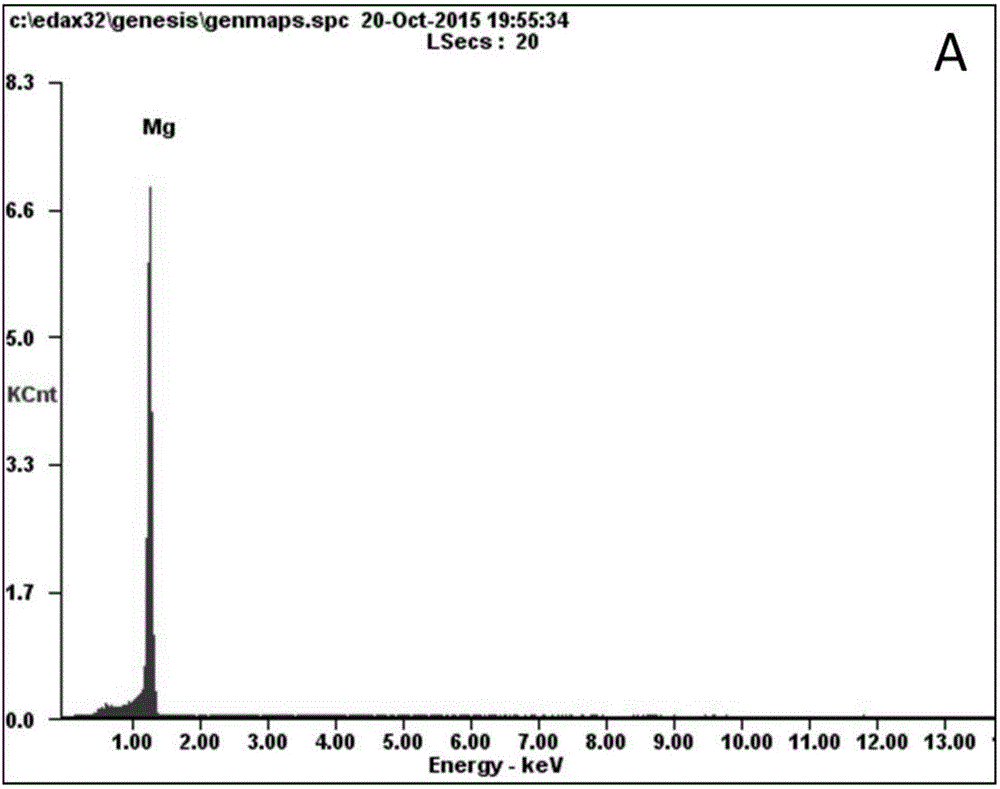

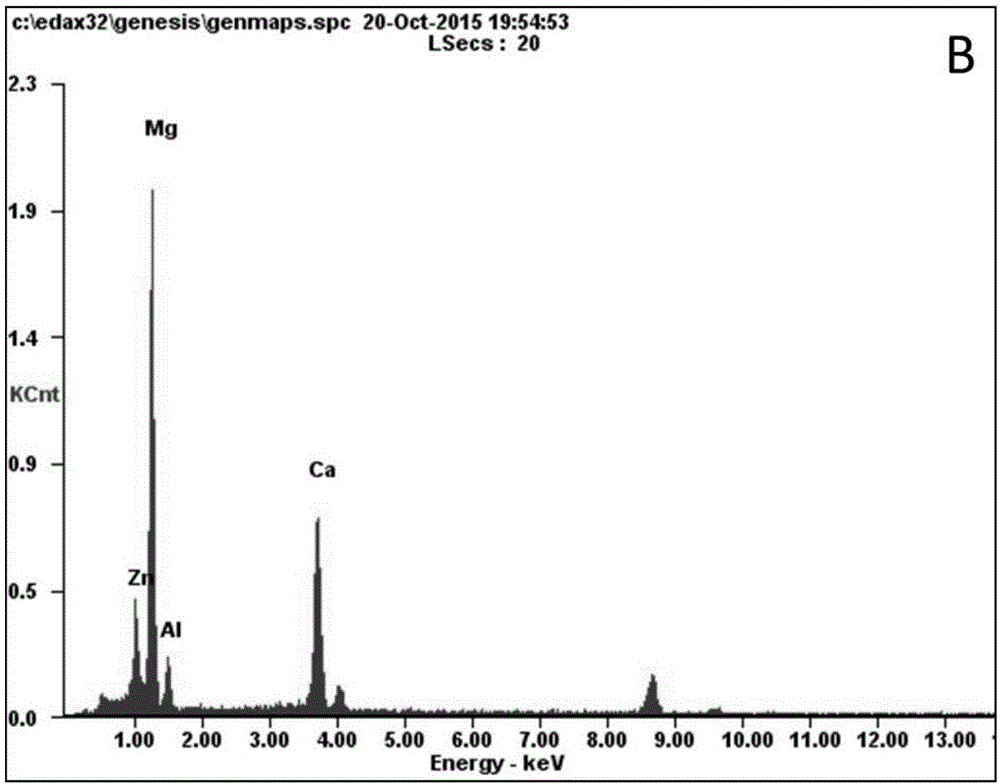

Preparation method of fine crystalline superplastic heat-resistance magnesium alloy

InactiveCN101760710AImprove thermal stabilityGrain refinementHeat resistanceFriction stir processing

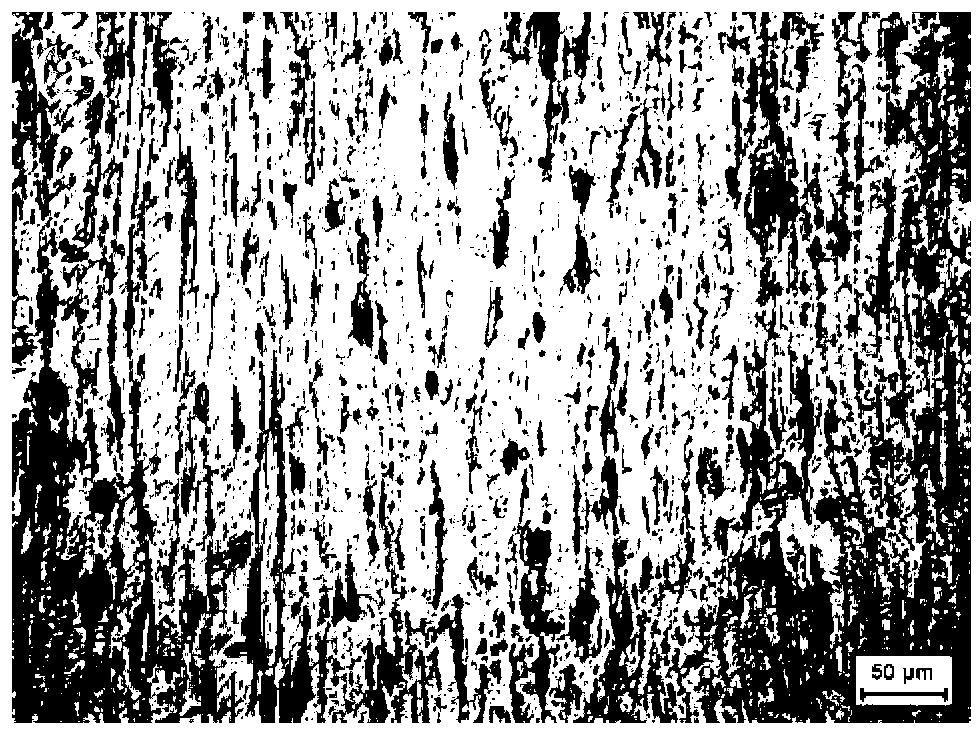

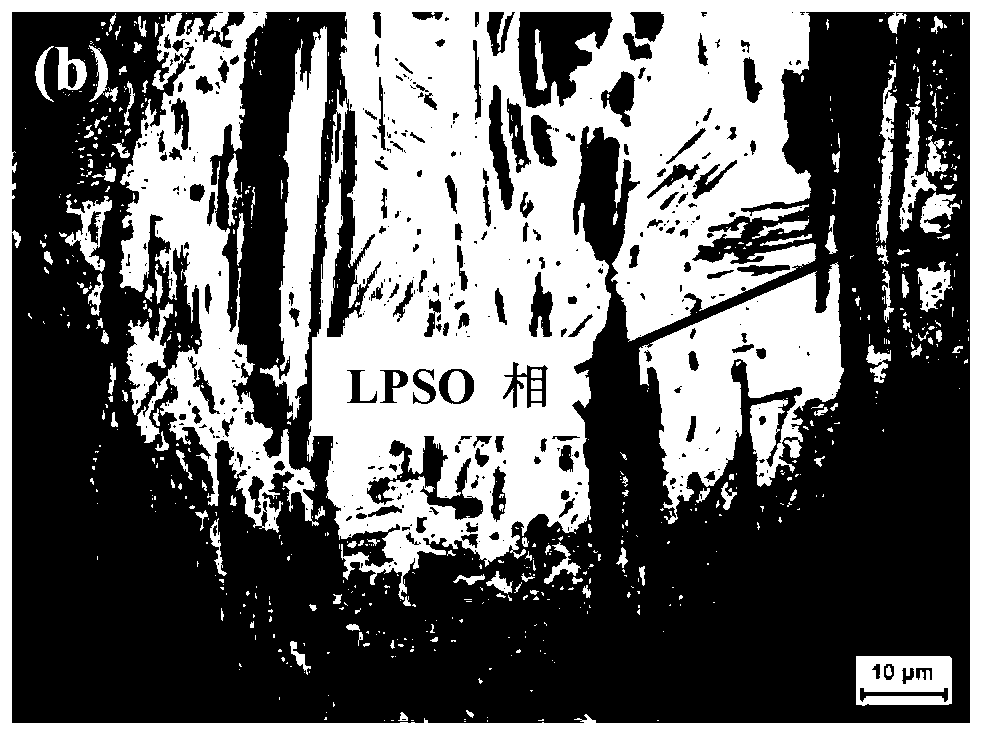

The invention relates to a preparation method of fine crystalline superplastic heat-resistance magnesium alloy, which is characterized by comprising the following steps of: processing heat-resistance magnesium alloy containing a bulky second phase with uneven distribution by adopting a stirring friction processing technique, thinning the crystal grains of a magnesium matrix, crushing a heat-resistance phase and enabling the heat-resistance phase to be evenly distributed in the matrix so as to form a fine crystalline superplastic structure.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

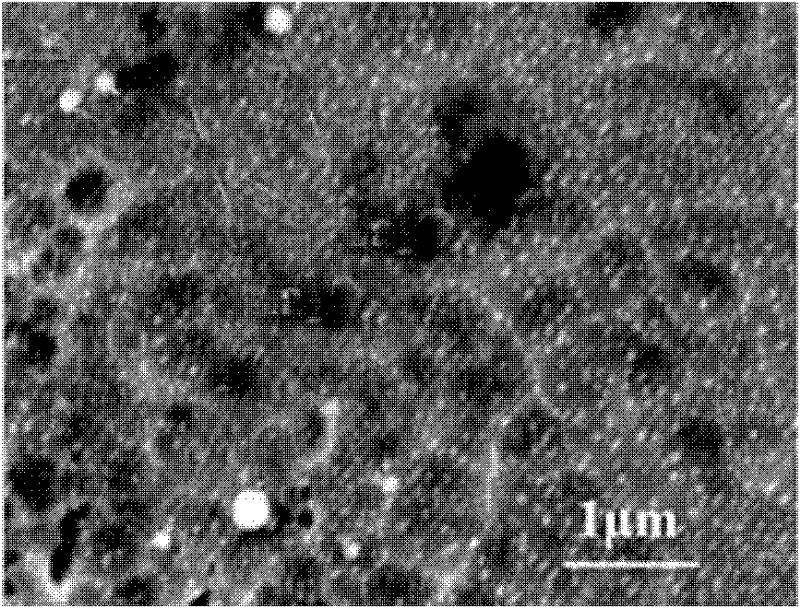

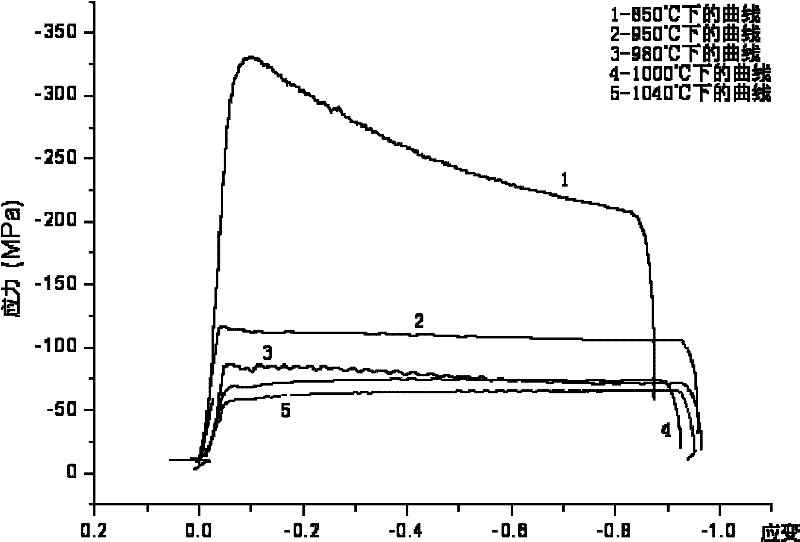

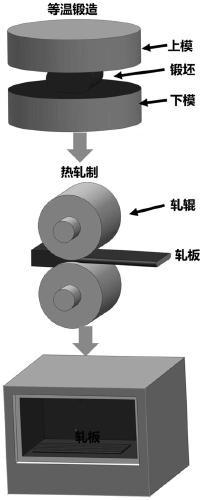

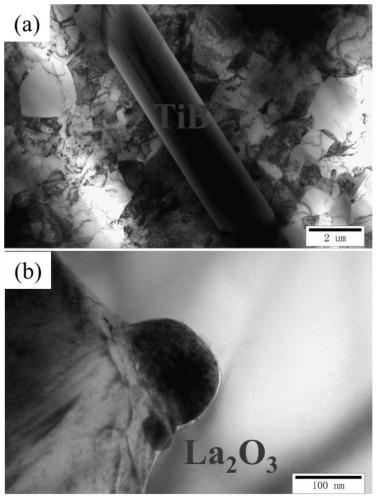

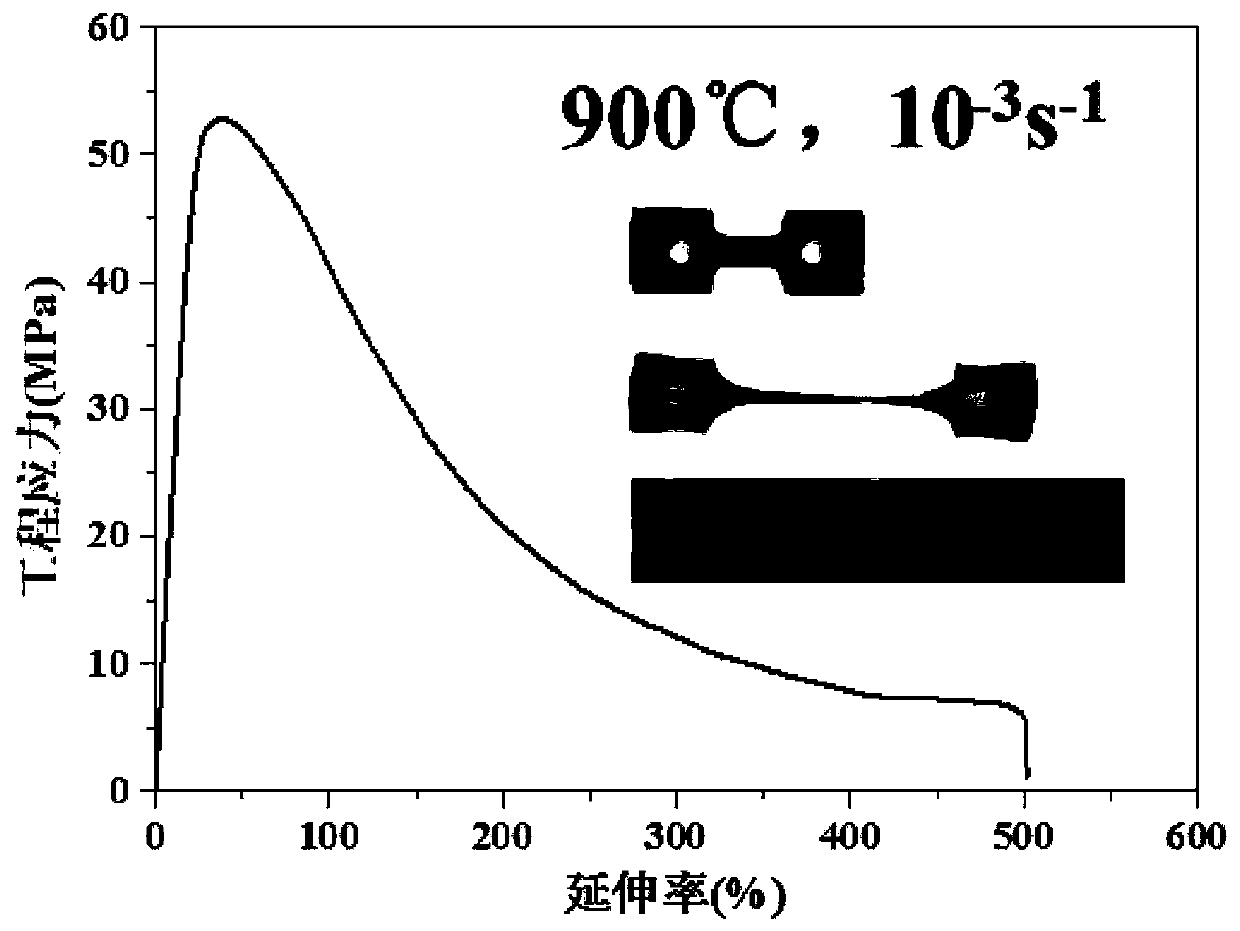

Isothermal superplastic deformation method for micro/nano particulate reinforced titanium matrix composite

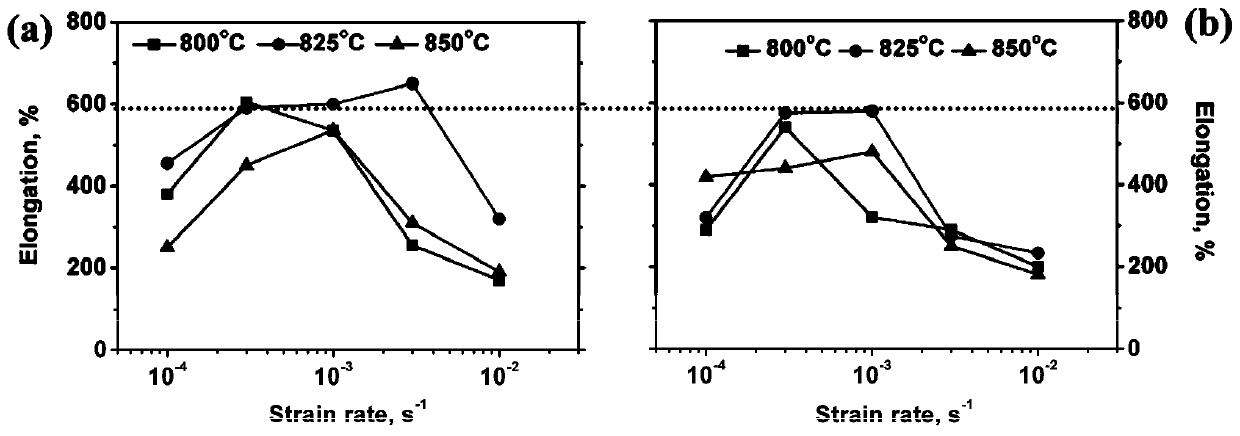

The invention discloses an isothermal superplastic deformation method for a micro / nano particulate reinforced titanium matrix composite. The method comprises the following steps of A, preparing a titanium boride and rare earth oxide micro / nano particulate hybrid reinforced titanium matrix composite by utilizing an in-situ synthesis technique, and performing vacuum consumable electrode arc melting on the composite for more than two times; B, performing cogging forging on the composite in a Beta single-phase region, wherein deformation amount is greater than or equal to 50 %; performing isothermal forging on the composite in an (Alpha + Beta) two-phase region to obtain a titanium matrix composite forging blank, wherein deformation amount is greater than or equal to 60 %; and C, performing hot rolling on the titanium matrix composite forging blank in a near Beta phase region, wherein deformation amount is greater than or equal to 80 %, and performing annealing treatment to obtain the micro / nano particulate reinforced titanium matrix composite. The micro / nano particulate reinforced titanium matrix composite is formed by the isothermal forging technology and hot rolling, and thus, the matrix structure can be effectively refined, and the material forming rate is increased; and a plate has good superplasticity within the deformation process range of 800-1000 DEG C and 5 x 10<-3>-10<-4>s<-1>.

Owner:上海交通大学包头材料研究院 +1

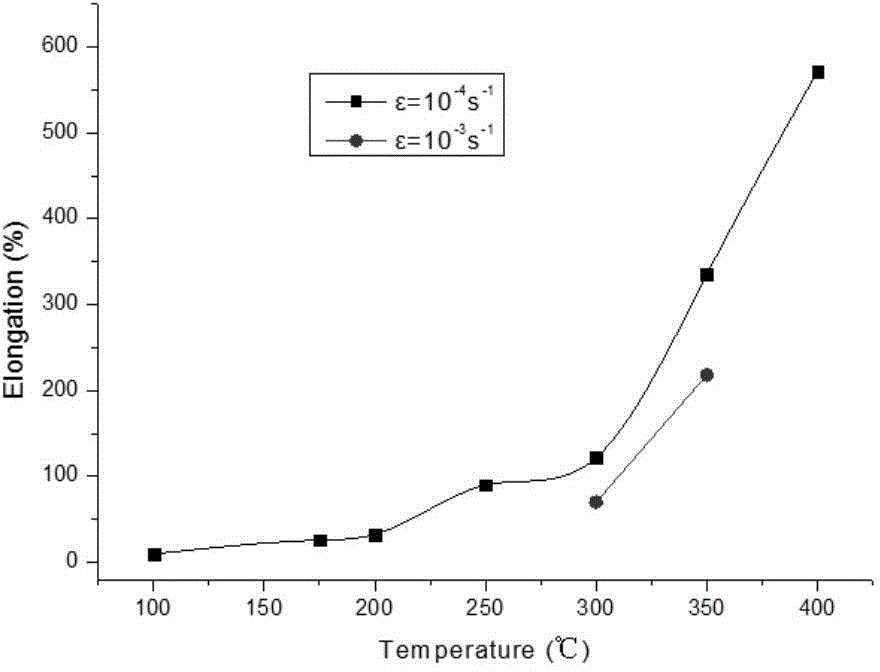

Superplastic high-strength heatproof magnesium alloy and preparation method thereof

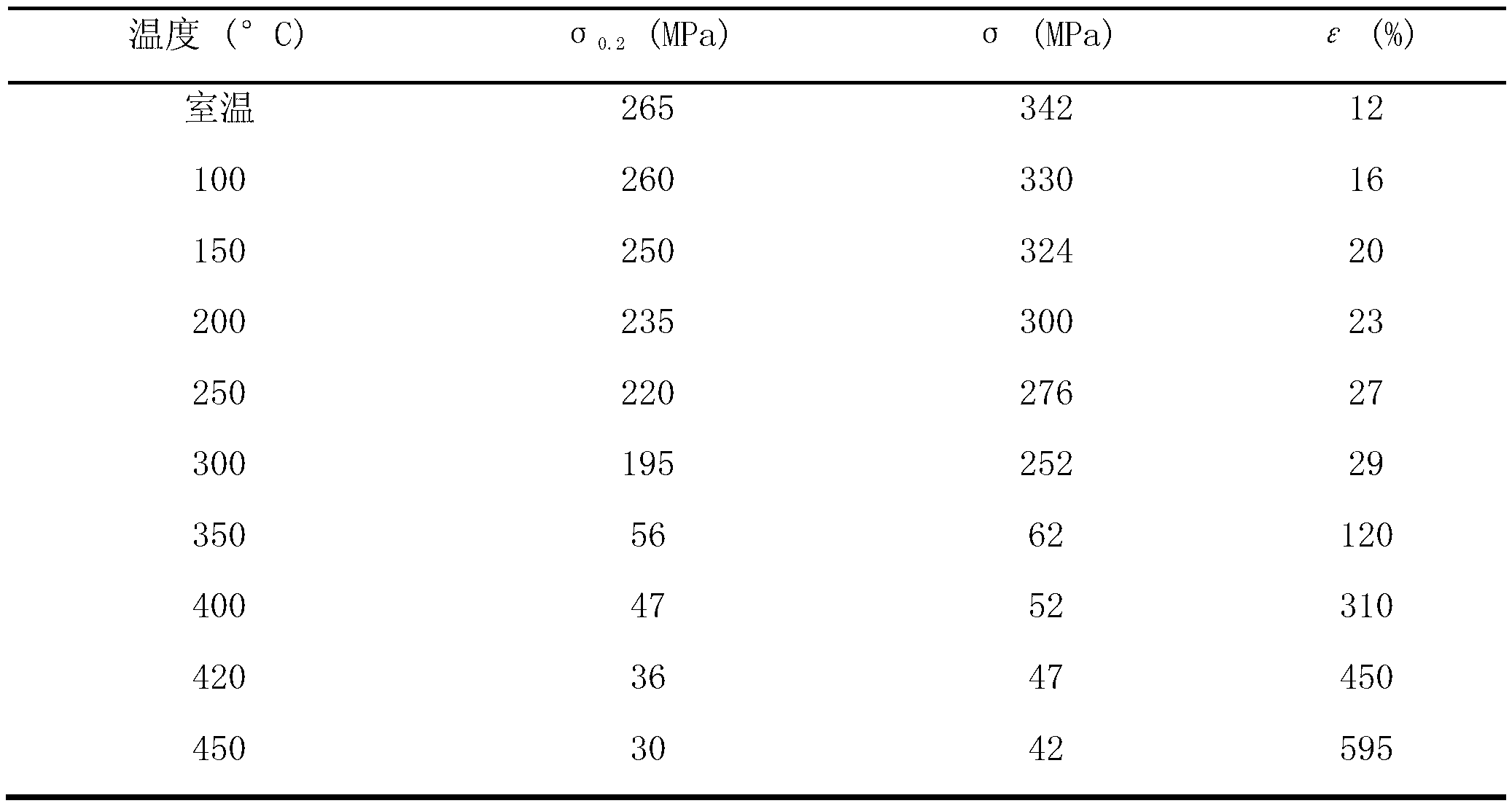

InactiveCN103266247AGuaranteed high strength and heat resistanceExcellent thermoformabilitySlagRoom temperature

The invention provides a superplastic high-strength heatproof magnesium alloy and a preparation method thereof. The method which treats pure Mg, pure Zn an Mg-Y intermediate alloy and an Mg-Nd intermediate alloy as raw materials comprises the following steps: melting alloy elements, refining, removing slag, allowing the obtained mixture to stand at a constant temperature, cooling through utilizing a water cooling die to obtain magnesium alloy cast bars, carrying out high temperature homogenization treatment, and carrying out hot extrusion molding on an extruder to obtain the superplastic high-strength heatproof magnesium alloy, wherein the superplastic high-strength heatproof magnesium alloy includes 5.0-8.0mass% of Y, 0.5-2.5mass% of Nd, 1.5-3.5mass% of Zn, below 0.03mass% of inevitable Fe, Cu, Ni and Si impurities, and the balance Mg. The superplastic high-strength heatproof magnesium alloy has a high strength of 230-350MPa and a good plasticity of 10-30% at a temperature in a range of room temperature to 300DEG C, and has a superplastic characteristic and an elongation rate after break of 270-600% at a temperature in a range of 350-450DEG C.

Owner:HARBIN ENG UNIV

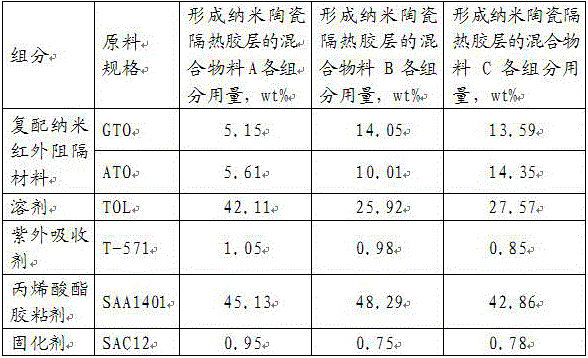

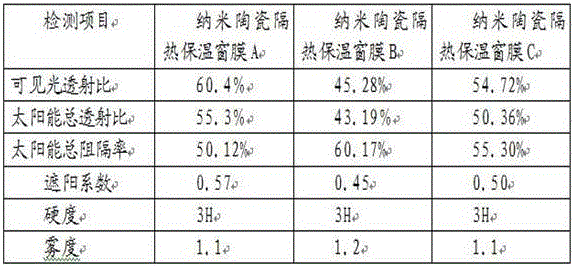

Nanophase ceramic heat-insulation window membrane

InactiveCN106183148ASelective and effective barrier effectGood heat insulationProtective equipmentSynthetic resin layered productsInfraredTectorial membrane

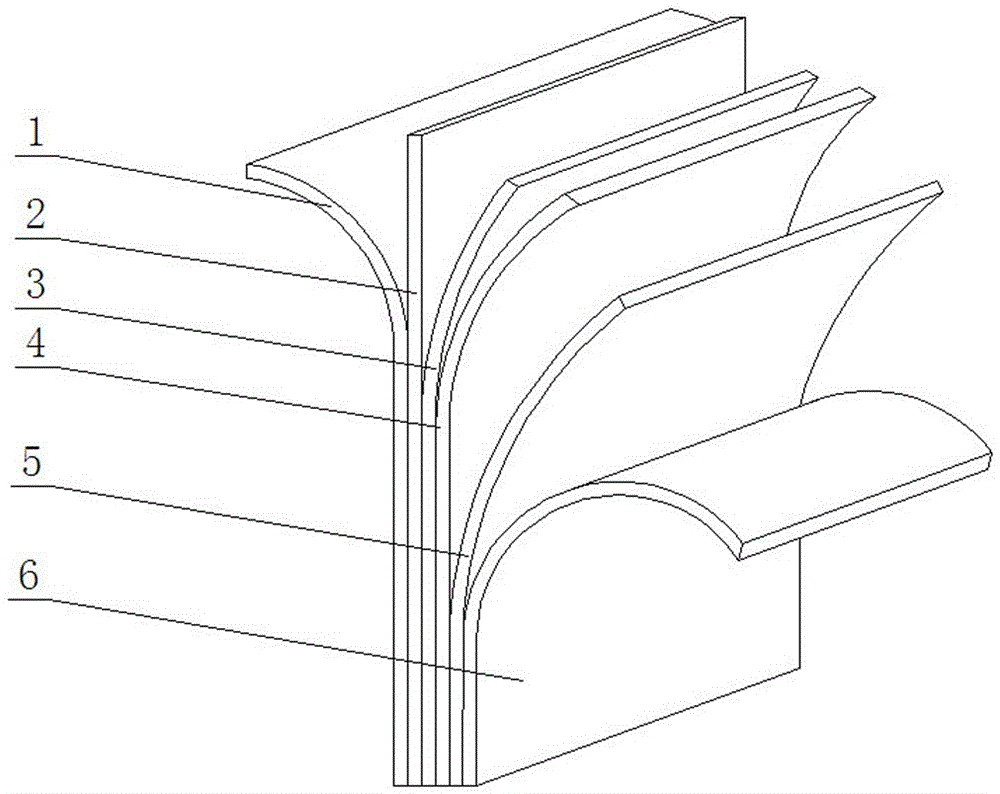

The invention discloses a nanophase ceramic heat-insulation window membrane which is of a composite structure. The nanophase ceramic heat-insulation window membrane comprises a wear-resistant layer (1), a base membrane layer (2), a nanophase ceramic heat-insulation adhesive layer (3), a function membrane layer (4), a pressure sensitive adhesive layer (5) and a protection membrane layer (6), and the layers are composited into a whole; the wear-resistant layer (1) is combined on one surface of the base membrane layer (2) through ultraviolet light polymerization; the nanophase ceramic heat-insulation adhesive layer (3) is combined on the other surface of the base membrane layer (2) through thermocuring; one surface of the function membrane layer (4) is composited on the outer surface of the nanophase ceramic heat-insulation adhesive layer (3); the pressure sensitive adhesive layer (5) is combined on the other surface of the function membrane layer (4) through thermocuring; the protection membrane layer (6) is composited on the outer surface of the function membrane layer (4). The layers produce a synergistic effect, infrared rays can be selectively blocked, the thermal radiation of sun is blocked in summer to reduce the energy consumption of refrigeration of an air conditioner, and the loss of internal heat is blocked in winter to lower the heating cost, so that the nanophase ceramic heat-insulation window membrane has a green energy-saving effect.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

Method for precipitating large area amorphous, nanocrystalline alloy layer using magnesium alloy surface glow plasma

InactiveCN101008078AImprove corrosion resistanceHigh strengthVacuum evaporation coatingSputtering coatingGlow plasmaAtmospheric pressure

The invention provides a method for settling corrosion-proof amorphous nanocrystalline alloying layer with magnesium alloy surface glow plasma, which is suited for preparing corrosion-proof modified layer for magnesium alloysurface, belonging to field of advanced light alloy surface corrosion- proof technology. It is characterized in that it takes bicathode glow sputtering device composed of target electrode and workpiece electrode and the method, and said target material comprises pure metal or its alloy material with its fusion point being 600- 1800 Deg. C, the target material voltage is 300- 650V, working voltage is 300- 450 V, the distance between target material and workpiece is 30 -40 mm, air pressure (Ar gas) is 20- 45 Pa. The deposited layer possesses outstanding corrosion resistant preformance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

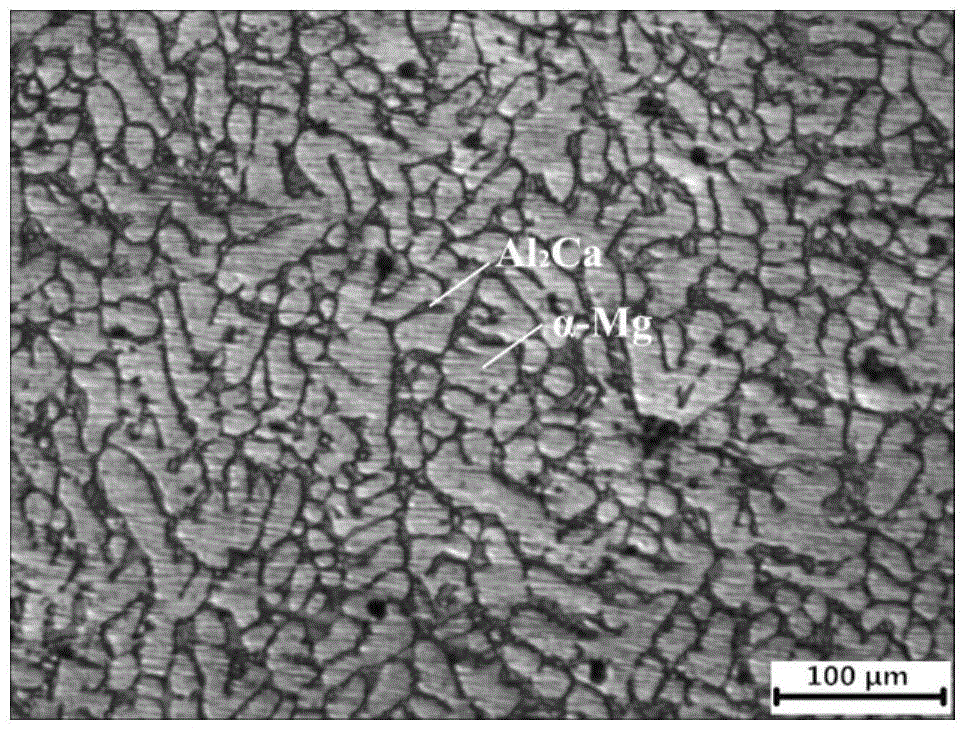

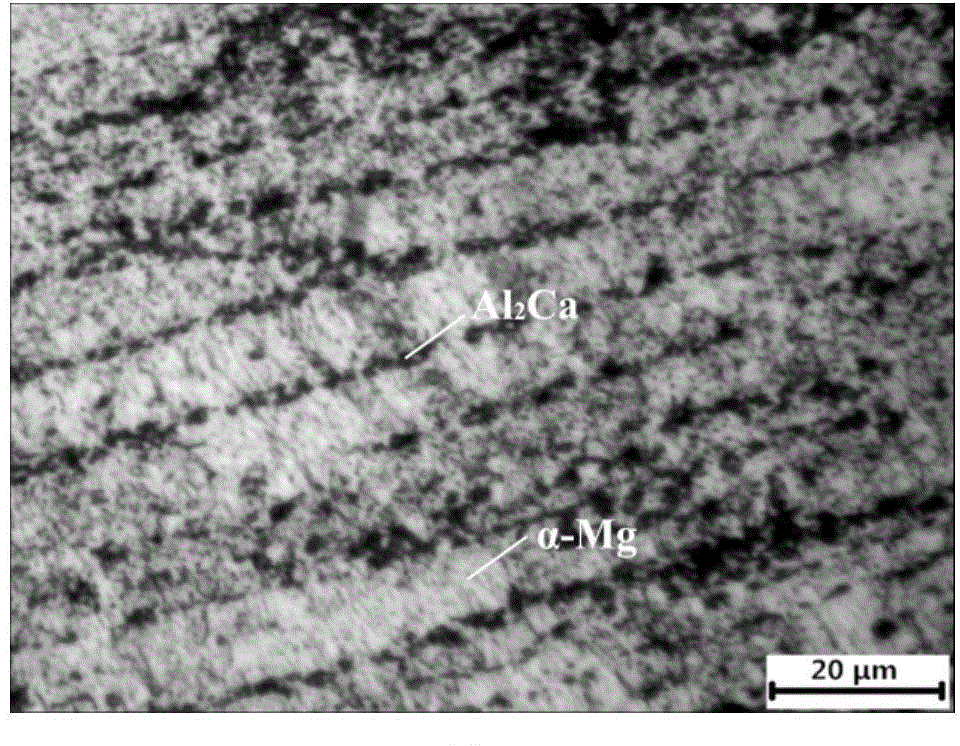

Mg-Ca-Al alloy and preparation method

The invention discloses Mg-Ca-Al alloy high in Ca / Al ratio and a preparation method. The alloy comprises, by weight, 4-12% of Ca, 5-10% of Al and the balance of Mg or a solid solution of Mg, and the mass ratio of Ca / Al is 0.8 to 1.2. The alloy is cast through a direct water cooling semicontinuous casting die or a rapid cooling casting die, microscopic structures comprising net-shaped Al2Ca structures are obtained, the net-shaped Al2Ca structures are fully smashed into micrometer or submicron particles through extrusion, and meanwhile, crystal grains are further fined so that a Mg-Al2Ca composite material can be obtained. The prepared Mg-Ca-Al alloy has good mechanical property, high burning temperature, high anti-corrosion performance and superelasticity, and the defects that existing Mg alloy is prone to corrosion and combustion and difficult to machine thermally, and application of the Mg alloy is seriously affected are overcome. The alloy solves the problems that the existing Mg alloy is prone to corrosion and combustion and difficult to machine thermally to a certain degree and can effectively expand the industrial application value of the Mg alloy.

Owner:HUNAN UNIV +1

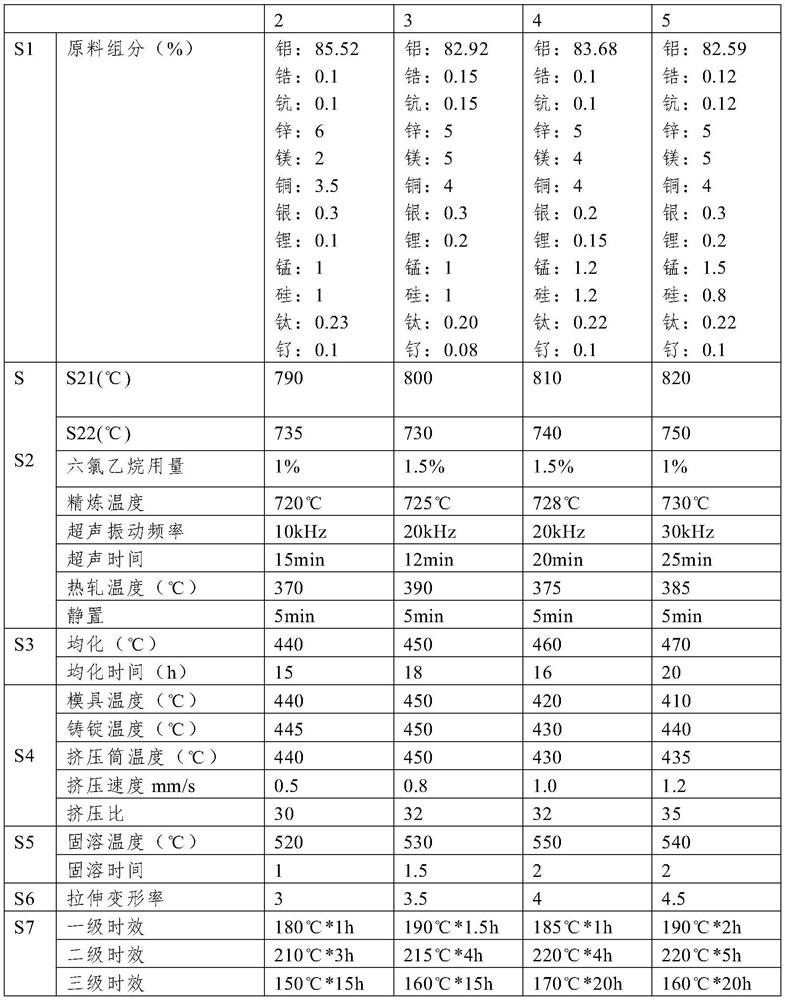

Corrosion resistance aluminum alloy plate for aviation and preparation method of corrosion resistance aluminum alloy plate

InactiveCN111926225AImproves corrosion performance and toughnessGood overall performanceCorrosionAluminium alloy

The invention relates to the technical field of aluminum alloy processing, in particular to a preparation method of an aluminum alloy plate for aviation. The aluminum alloy comprises the following chemical components of, in percentage by mass, 0.05%-0.2% of zirconium, 0.05%-0.2% of scandium, 3.0%-6.0% of zinc, 3.0%-6.0% of magnesium, 3.0%-4.0% of copper, 0.2%-0.4% of silver, 0.05%-0.2% of lithium,1.0%-1.5% of manganese, 0.8%-1.5% of silicon, 0.20%-0.40% of titanium, 0.05%-0.1% of ruthenium, and the balance aluminum and inevitable impurities, and the content of the impurities is controlled tobe 0.15% or below; and an aluminum alloy melt is prepared according to pre-prepared materials, ultrasonic vibration is adopted in a refining process to refine grains, and then the aluminum alloy platefor the aviation is obtained through pouring, homogenization, extrusion, solid solution treatment, pre-stretching and three-stage aging treatment. According to the corrosion resistance aluminum alloyplate for the aviation and the preparation method of the corrosion resistance aluminum alloy plate, the Vickers hardness of the prepared aluminum alloy plate ranges from 175 Hv to 190 Hv, the yield strength ranges from 520 MPa to 562 MPa, the tensile strength ranges from 605 MPa to 656 MPa, the elongation ranges from 9.4% to 12%, the overall performance is excellent, and the aluminum alloy plateis particularly suitable for being used in the aerospace field.

Owner:湖南恒佳新材料科技有限公司

Superplastic magnesium alloy and preparation method thereof

The invention relates to a superplastic magnesium alloy and a preparation method thereof and belongs to the technical field of magnesium alloys. The magnesium alloy comprises the following components in percentage by weight: 10-30wt.% of Zn, 10-15wt.% of Er, and the balance of Mg, wherein Zn and Er are taken as main alloying elements and the ratio of Zn / Er is 1-2. The magnesium alloy is prepared by a melting process and an extruding process. The alloy has good plasticity at an initial strain rate of 0.5-5mm / min at 100-150 DEG C and shows good superplasticity in a low temperature range from 175 to 300 DEG C. The alloy is a potential magnesium alloy material which can be applied to superplastic forming and processing.

Owner:北京二七铁丰龙科技有限公司

Superplastic magnesium lithium alloy material with high strain rate and preparation method thereof

The invention provides a superplastic magnesium lithium alloy material with high strain rate and a preparation method thereof. The method is as below: a) preparing the following raw materials for melting alloy according to the weight proportion: 6%-11% of Li, 0.1%-3% of Al and the balance of Mg and trace impurity elements; b) melting by using a vacuum electromagnetic induction furnace under the protection of argon; c) conducting uniformity annealing on the obtained ingot in a heat treatment furnace at 200 DEG C-350 DEG C for 6-24 h, and cooling to room temperature; and d) lathing a surface oxide layer on the ingot obtained in the step c), and then conducting a one-time extrusion with large extrusion ratio higher than 75% at 200-300 DEG C. The product of the invention is superplastic magnesium lithium alloy with low lithium content, proper amount of aluminum content and high strain rate, and the invention uses a relatively simple melting and deformation processing method for the preparation of the superplastic magnesium lithium alloy with high strain rate.

Owner:HARBIN ENG UNIV

Superplastic nano AlN ceramic material and preparation method thereof

The invention discloses a preparation method for superplastic AlN ceramic nano-materials, which is characterized in that: (1) preparation of molybdenum silicon powder sintering additives: mixing the molybdenum powder with an average grain diameter of 1-10 Mum with silicon powder in a certain proportion and then ball-milling the mixture in a high-energy ball mill in a mechanical alloying method; (2)mixing powders: mixing the AlN powder with a nanometer average grain diameter of 10-100 nm with the produced molybdenum silicon powder sintering additives, wherein the mass percentage of the additives is 1%-20%; (3) sintering technology: hot pressing or discharge plasma sintering, the sintering technology has the same sintering process as the common AIN sintering process, which a nitrogen protection is required by filling nitrogen after vacuum pumping. The superplastic AlN ceramic nano-material with a grain diameter between 50nm-200nm can be hot press molded or superplastic formed, thereby solving the problem that ceramic parts with complex shape are difficult to be formed.

Owner:YANSHAN UNIV

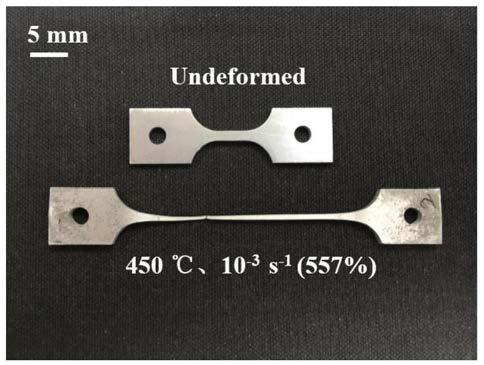

Preparation method of superplastic aluminum-based composite material plate

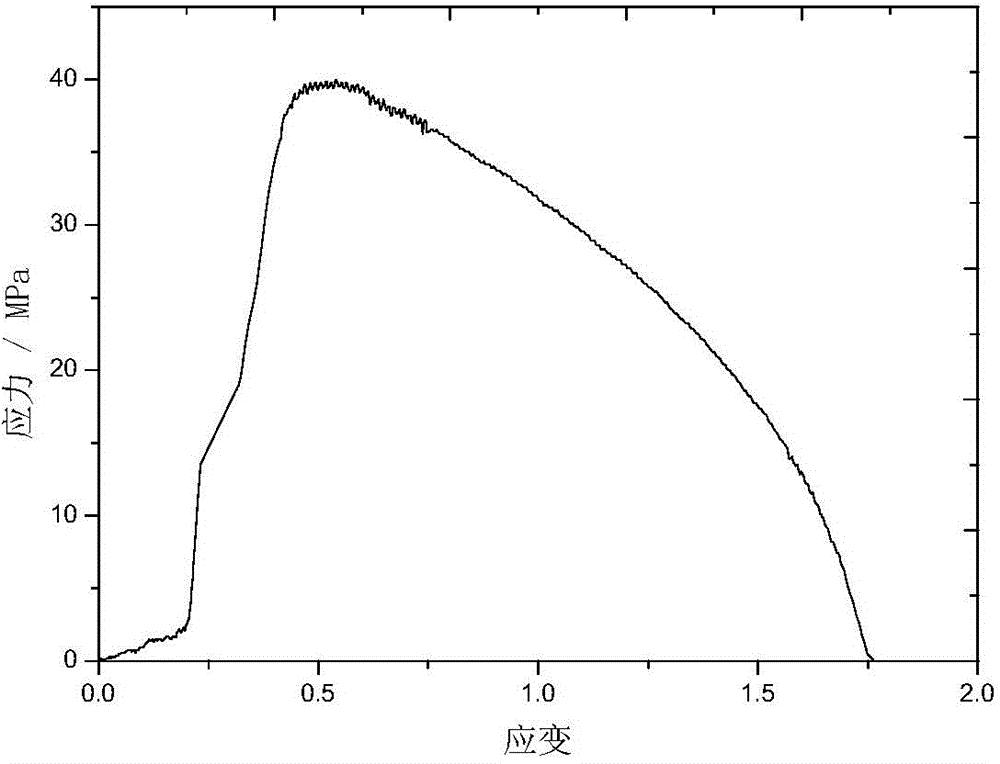

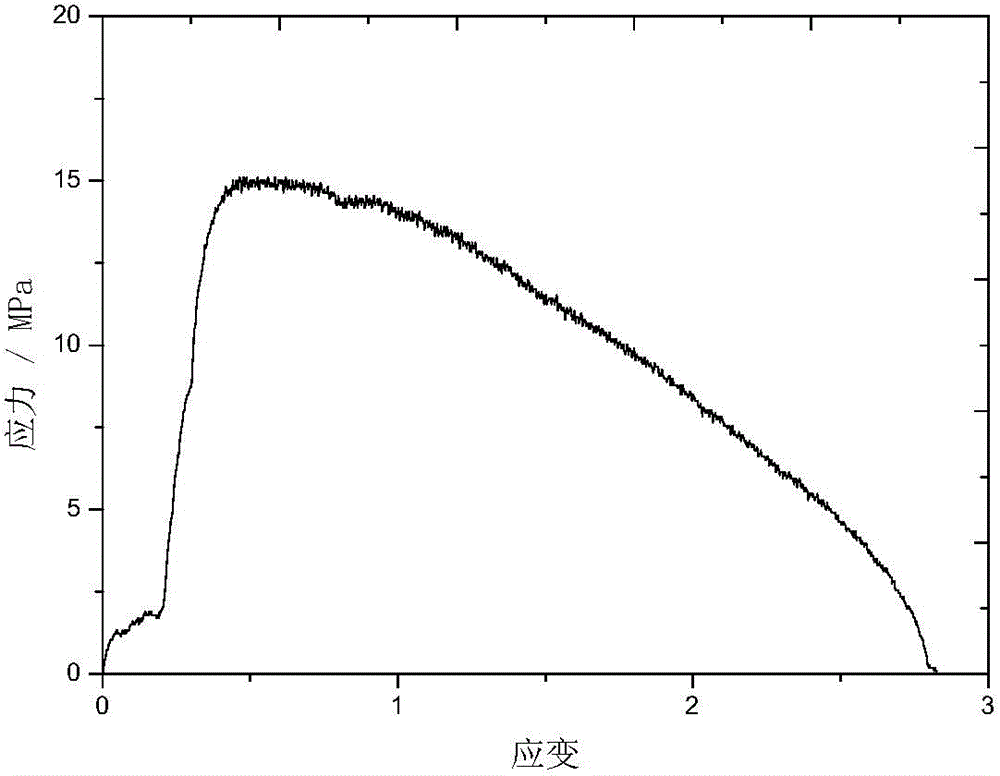

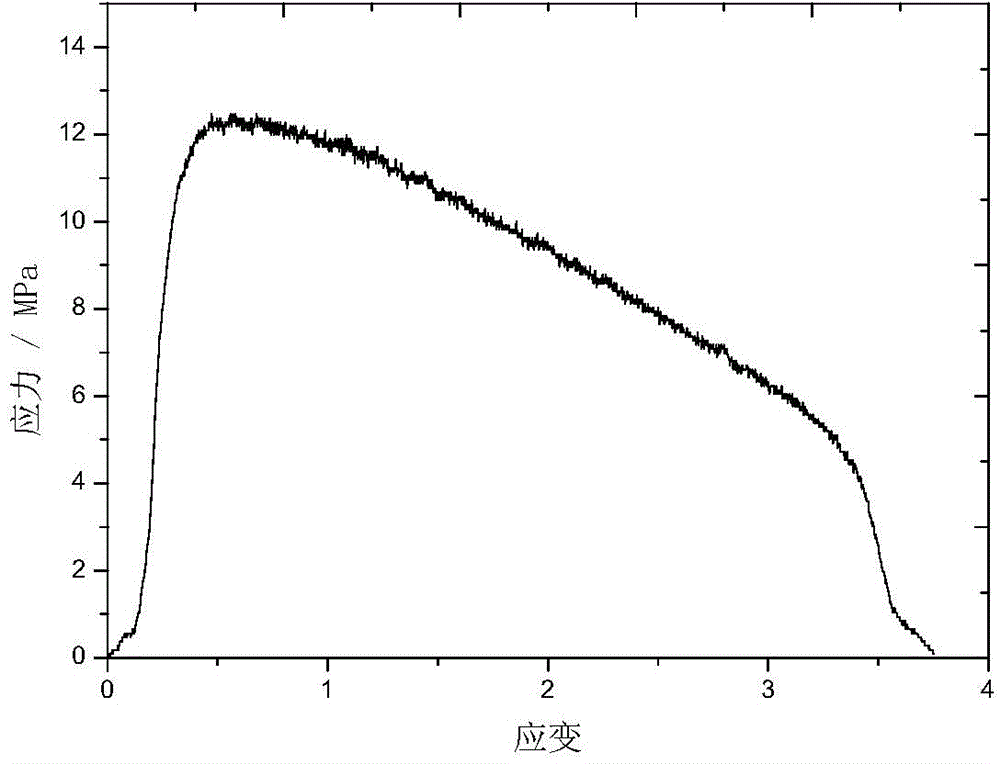

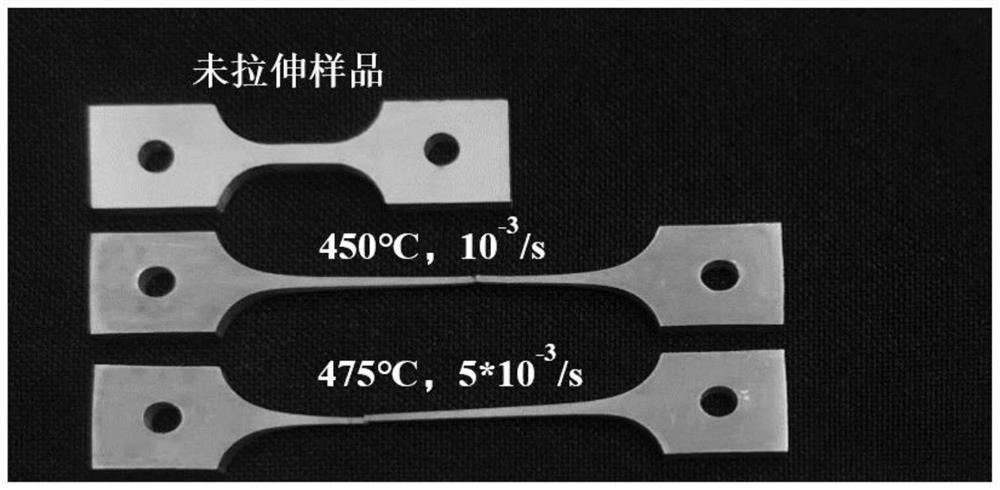

The invention discloses a preparation method of a superplastic aluminum-based composite material plate. The method comprises the following steps: carrying out pre-rolling heat treatment including solid solution and overaging on a to-be-processed aluminum-based composite material, and turning and peeling the surface of the aluminum-based composite material after heat treatment until the surface is flat; and then carrying out multi-pass medium-temperature rolling, conducting homogenizing heat treatment before each pass of rolling, and stretching and straightening the rolled plate. According to the method, heat treatment before rolling and medium-temperature rolling machining forming are combined so that matrix grains are substantially refined, and the material forming rate is increased; the in-situ nano-particle reinforced phase TiB2 is added into aluminum alloy for pinning and rolling a grain boundary to prevent grain growth, the thermal stability is good, and the effect of suppressing the grain growth and cavity generation of grains in high-temperature deformation is achieved; and the longitudinal elongation of the plate can reach 350%-600% under the deformation process conditions of 400-475 DEG C and 10<-3>-10<-4> / s, and the high-temperature superplasticity is excellent.

Owner:SHANGHAI JIAO TONG UNIV +1

Dental restoration photocuring ceramic material and application thereof

InactiveCN106580715AHigh strengthIncreased biaxial flexural strengthImpression capsDentistry preparationsCalcium biphosphateRepair material

The invention relates to the field of dental restoration materials, in particular to a dental restoration photocuring ceramic material and application thereof. The material is used for restoration of dental caries and tooth defects. The dental restoration photocuring ceramic material is prepared from, by weight, 166-187 parts of nanometer ceramic powder, 5-8 parts of a dispersing agent, 1-2 parts of a photoinitiator, 15-45 parts of a main monomer, 15-45 parts of a diluting monomer, 1-2 parts of a coloring agent, 27-55 parts of fillings and 0.5-1 part of a fluorine ion source, wherein the fillings are prepared from silanized and zirconated calcium phosphate, nano-zirconia and nano-diamond. The material has the advantages of being high in strength and curing speed, stable in curing effect and capable of effectively prolonging the service life.

Owner:东莞市永嘉义齿有限公司

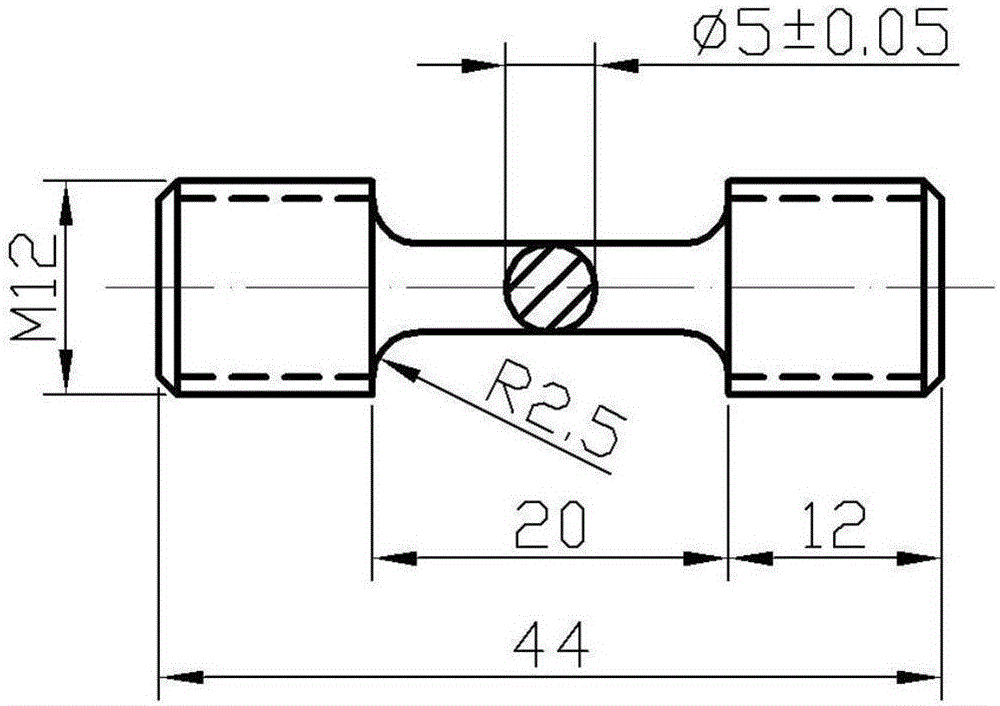

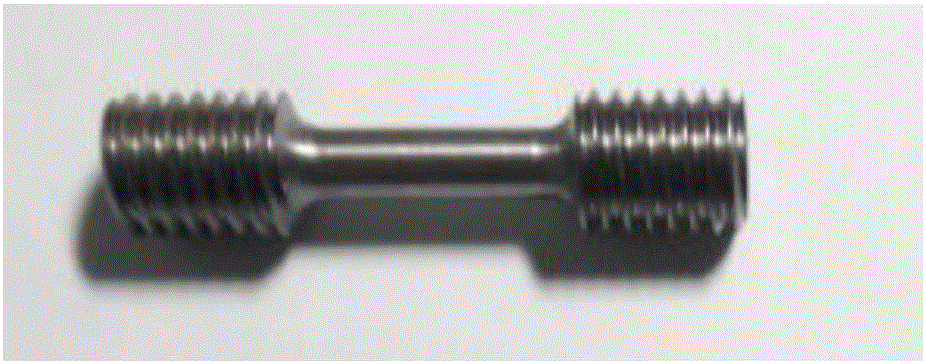

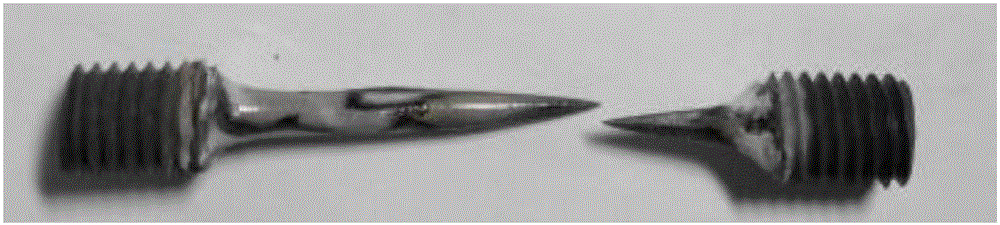

Method for improving superplasticity of semi-stable beta titanium alloy

The invention provides a method for improving superplasticity of a semi-stable beta titanium alloy. The method is used for preageing treatment of the semi-stable beta titanium alloy. According to the method, the semi-stable beta titanium alloy is subjected to preageing treatment for 20-70 min at the temperature of 440-545 DEG C, a certain quantity of alpha phases are separated out from the semi-stable beta titanium alloy, the alpha phases are separated out in a beta crystal boundary position firstly, the hardness of the alpha phases is higher than that of beta phases, the alpha phases with high hardness perform stress concentration relative to matrix beta phases, beta-phase grains are fined to a certain extent, the finer the crystal grains are, the better the superplasticity is, and the superplasticity of the semi-stable beta titanium alloy is further improved. The elongation of the treated semi-stable beta titanium alloy reaches 361.8% and is increased by 167.8% by comparison with the elongation of an untreated semi-stable beta titanium alloy.

Owner:江西景航航空锻铸有限公司 +1

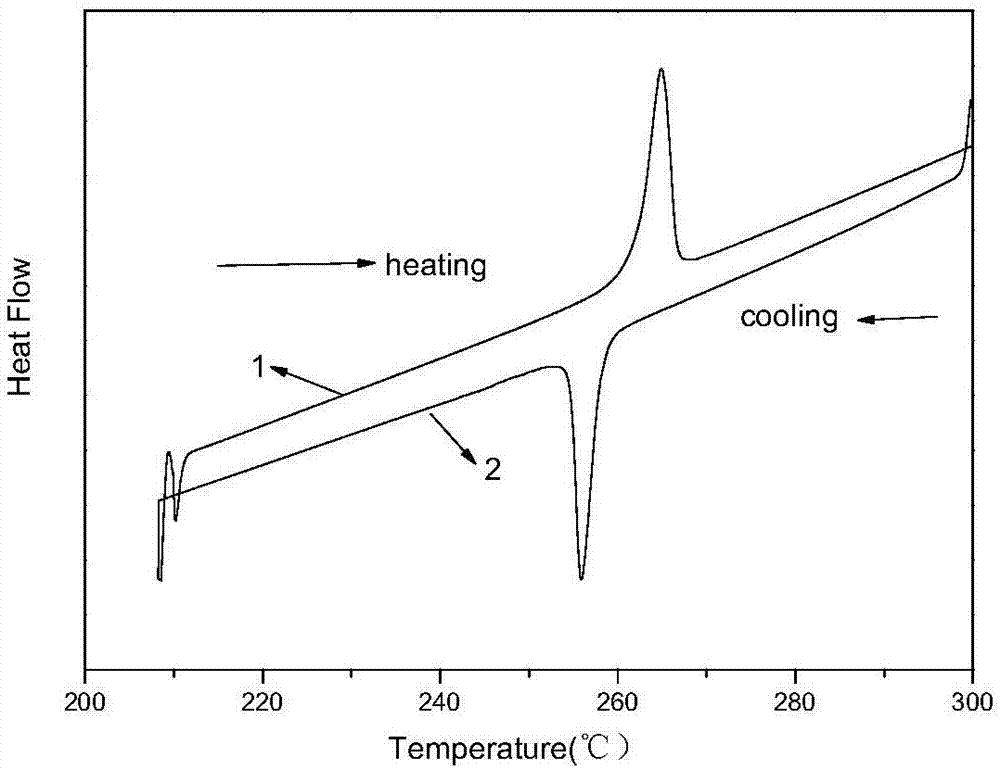

Preparation method of superplastic Ni-Mn-Ga-Ta high-temperature memory alloy

ActiveCN107345279AThe problem of ensuring that the phase transition temperature does not drop too lowHigh ionic field strengthShape-memory alloyHigh intensity

The invention relates to a preparation method of a high-temperature memory alloy, in particular to a preparation method of a superplastic Ni-Mn-Ga-Ta high-temperature memory alloy. According to the method, the high-temperature superplastic Ni53Mn25Ga21Ta1 alloy is obtained by material taking, vacuumizing, smelting, adding of an Mn element for continuous smelting, cleaning, heat insulation and quenching in water. The Ni53Mn25Ga21Ta1 alloy prepared through the preparation method has the advantages of high toughness, high intensity, high phase change temperature and the like, and a new idea is expanded for application of high-temperature and high-plasticity shape memory alloys.

Owner:DALIAN UNIV

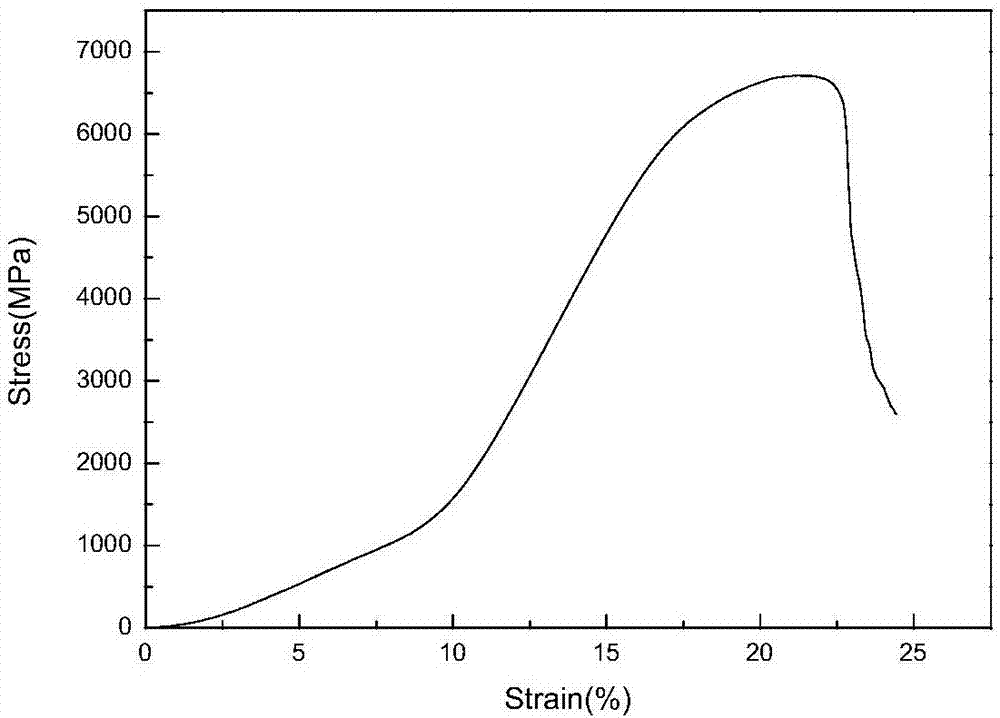

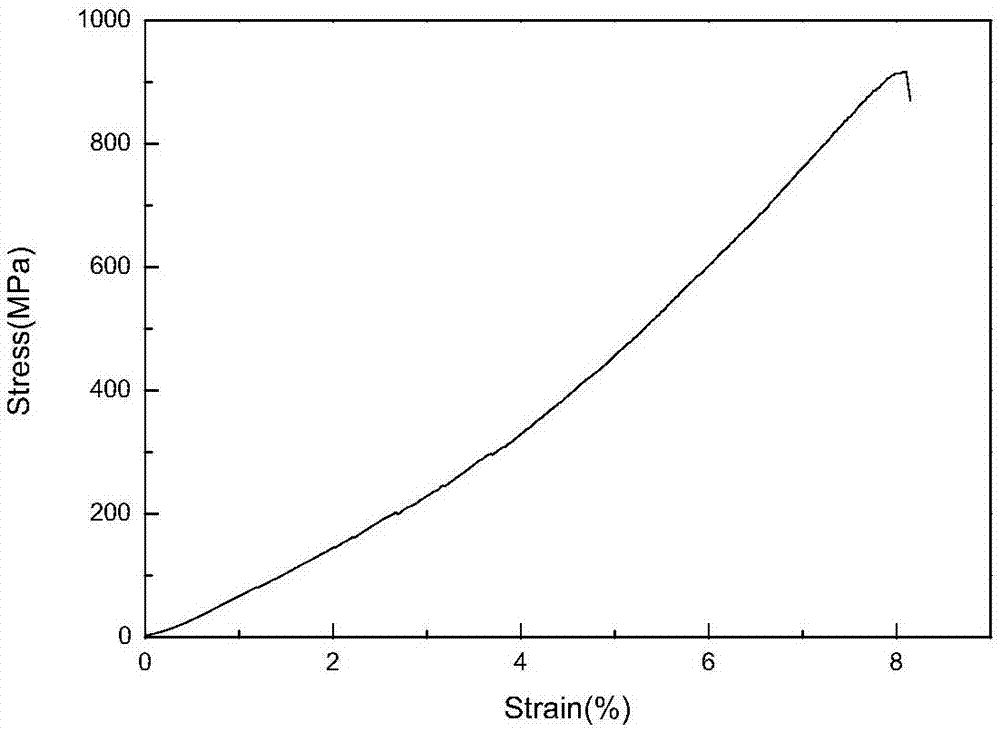

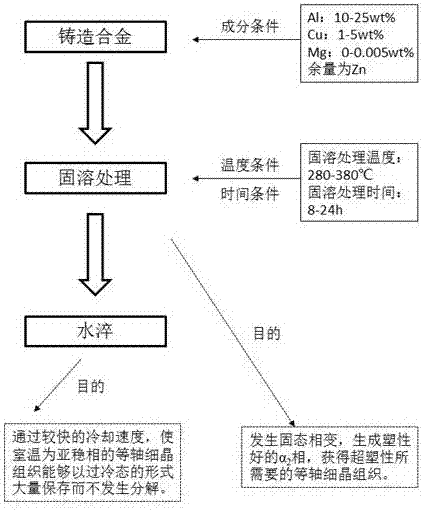

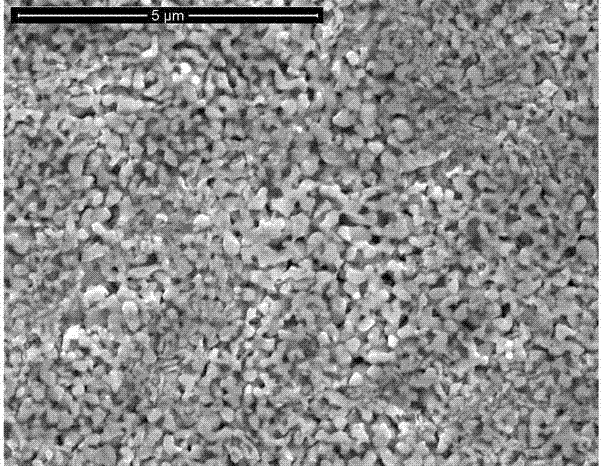

Method for improving superplasticity of zinc-aluminum alloy through heat treatment

InactiveCN107058925AIncreased superplasticityHigh elongation after breakSolution treatmentTime range

The invention discloses a method for improving superplasticity of a zinc-aluminum alloy through heat treatment. The provided method comprises the following steps that the zinc-aluminum alloy is subjected to solution treatment at the temperature ranging from 280 DEG C to 380 DEG C; the solution treatment time ranges from 8 h to 24 h; and water quenching is conducted after solution treatment is finished. By means of the above manner, the zinc-aluminum alloy can obtain an equiaxial fine grain structure composed of a large number of metastable alpha 2 phase grains with good plasticity, and accordingly the superplasticity of the alloy is greatly improved. The post-fracture elongation percentage of the zinc-aluminum alloy treated through the provided method reaches 1,970%; and compared with 200% which is the post-fracture elongation percentage of the zinc-aluminum alloy not treated through the method, the post-fracture elongation percentage of the alloy is greatly improved.

Owner:ANYANG INST OF TECH

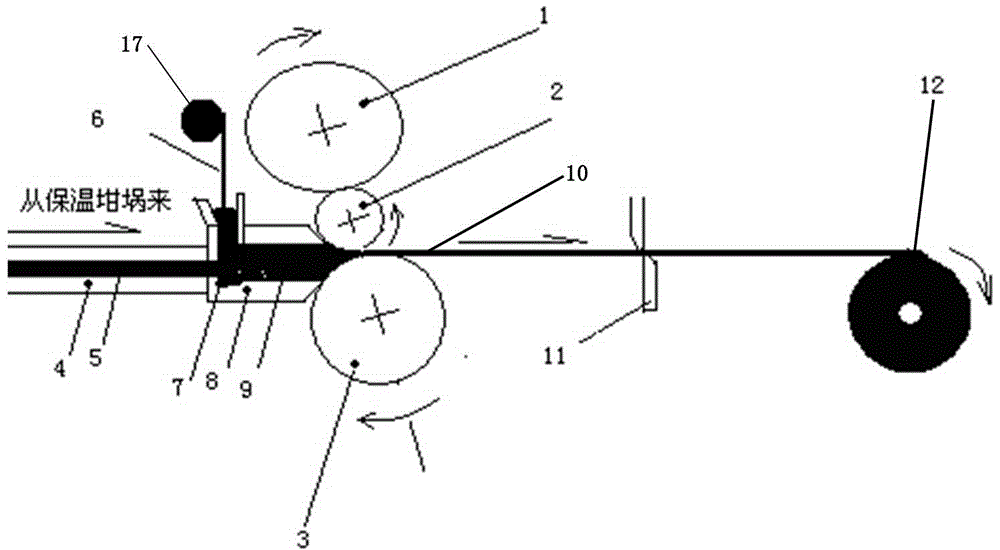

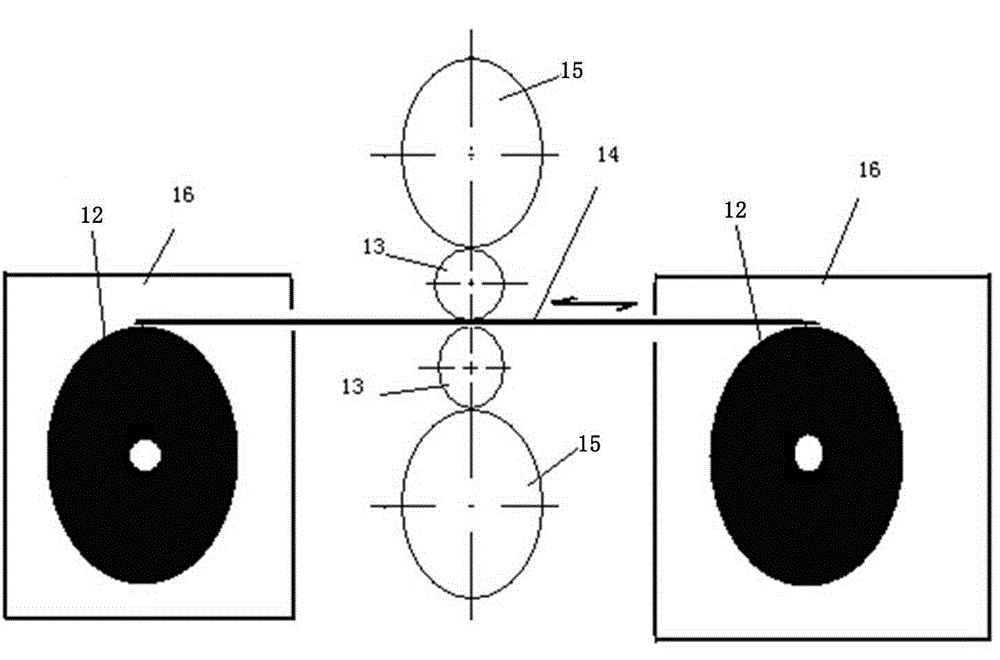

Producing method of hot-rolled alloy plate for automobile body

ActiveCN104550231AImprove performanceMeet the requirementsMetal rolling arrangementsAuto industryManufacturing technology

The invention relates to a magnesium alloy plate manufacturing technology. Based on existing mature conventional magnesium alloy which is good in comprehensive performance but cannot completely meet the plate requirement of an automobile body, a micron quasi-crystal intermediate alloy online mixed melting technology, a magnesium alloy plate cast rolling technology and a dynamic recrystallization hot rolling technology are adopted to modify the magnesium alloy and enable the performance of the magnesium alloy to be improved. By means of the producing method, the production cost can be remarkably reduced, the performance of the plate can be improved, and index can be closer to the requirement for sheet metal parts in the automobile industry.

Owner:山西银光华盛镁业股份有限公司

Manufacturing process for superfine fine steel

InactiveCN1490417AImprove refinementThe refinement effect is easy to achieveUltimate tensile strengthMartensite

Owner:潘龙修

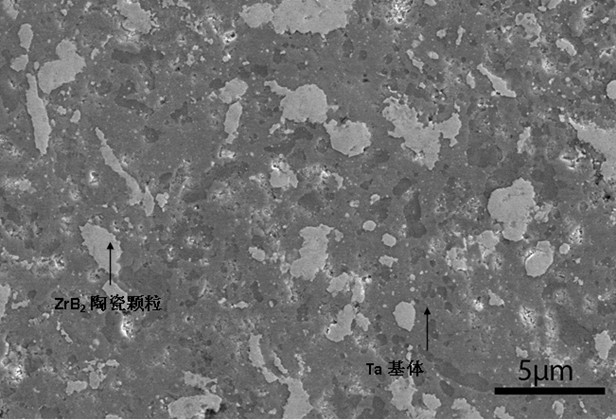

Ta-Hf-Zr-ZrB2 alloy bar and preparation method thereof

ActiveCN112281039AApplications with tubingImprove mechanical propertiesOxidation resistantUltimate tensile strength

The invention provides a Ta-Hf-Zr-ZrB2 alloy bar. The Ta-Hf-Zr-ZrB2 alloy bar is prepared from the following raw materials in percentage by mass: 3-9% of Hf, 4-8% of Zr, 3-7% of ZrB2, and the balanceTa and inevitable impurities. The invention further provides a method for preparing the alloy bar. The method comprises the following steps that: (1) all the raw materials are weighed according to themass percentages, and are ball-milled and uniformly mixed under argon protection to obtain mixed powder; (2) the mixed powder is pressed to obtain a blank; (3) the blank is put in a shell; and the shell is sealed after vacuumizing; (4) the hot isostatic pressing sintering is performed to obtain a Ta-Hf-Zr-ZrB2 alloy sintered body; and (5) the hot extrusion is performed to obtain the Ta-Hf-Zr-ZrB2alloy bar. The alloy bar is excellent in high-temperature oxidation resistance, room-temperature plasticity and tensile strength and excellent in fatigue strength, high-temperature strength and superplasticity, and can be applied to high-temperature structural parts.

Owner:西安鑫昌机电设备有限责任公司

Mg-XAl-YCa-ZZn alloy low in cost, high in performance and high in Ca/Al ratio and preparation method

The invention discloses an Mg-XAl-YCa-ZZn alloy and a preparation method. The alloy comprises, by weight percentage, 2-4% of Ca, 2-4% of Al, 2.9-6% of Zn and the balance Mg or an Mg solid solution, wherein the mass ratio of the Ca to the Al in the alloy is 0.8-1.2. According to the preparation method of the alloy, direct water-cooling semicontinuous casting is conducted, so that a microscopic structure which surrounds an Mg substrate and is of a solid solution structure containing a netlike Al2Ca phase and a granulous MgZn phase is obtained; and the extrusion mode is adopted for further refining crystalline grains, and meanwhile the netlike structure of Al2Ca and Ca2Mg6Zn3 is fully crushed into micron grains and submicron grains, so that a composite uniform in structure, fine in crystalline grain and obvious in reinforcing effect is obtained. The Mg-XAl-YCa-ZZn alloy is low in cost; the obtained composite is small in weight and excellent in mechanical performance, flame retardation performance, corrosion resistance and processing performance; and the defects that existing magnesium alloys are easy to corrode and combust, difficult to process and the like are overcome. The Mg-XAl-YCa-ZZn alloy has extremely high industrial application value in all fields.

Owner:HUNAN UNIV

Processing method for realizing super high plasticity performance of titanium alloy welded joint

ActiveCN109702317AReduce flow stressHigh superplastic properties with low flow stressOther manufacturing equipments/toolsNon-electric welding apparatusFriction weldingHydrogen atmosphere

The invention discloses a processing method for realizing super high plasticity performance of a titanium alloy welded joint, and belongs to the technical field of titanium alloy welding. The processing method includes the steps that firstly, hydrogenation treatment is conducted on a titanium board to be welded in a pure hydrogen atmosphere; then stirring friction welding is conducted on the titanium board subjected to the hydrogenation treatment to make a welding nugget to be of a tiny laminated structure; and super plasticity tensile deformation is conducted on a joint welding nugget after stirring friction welding, a part of a base metal and the entire welded joint, so that entire super plasticity processing of a titanium alloy workpiece is realized. Through the processing method for realizing the super high plasticity performance of the titanium alloy welded joint, the super plasticity of the titanium alloy welded joint can be obviously improved, the super plasticity temperature and flow stress are lowered, the difficulty of super plasticity forming and the welding cost are lowered greatly, the mechanical performance of a super plasticity forming component is improved, and thesuper plasticity forming of the whole joint is realized; and the processing method for realizing the super high plasticity performance of the titanium alloy welded joint particularly adapts to the super plasticity forming and high temperature forming of the titanium alloy welded joint, and can be applied to manufacture large-scale titanium alloy entire components, partial forming components and the like in space flight and aviation field.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

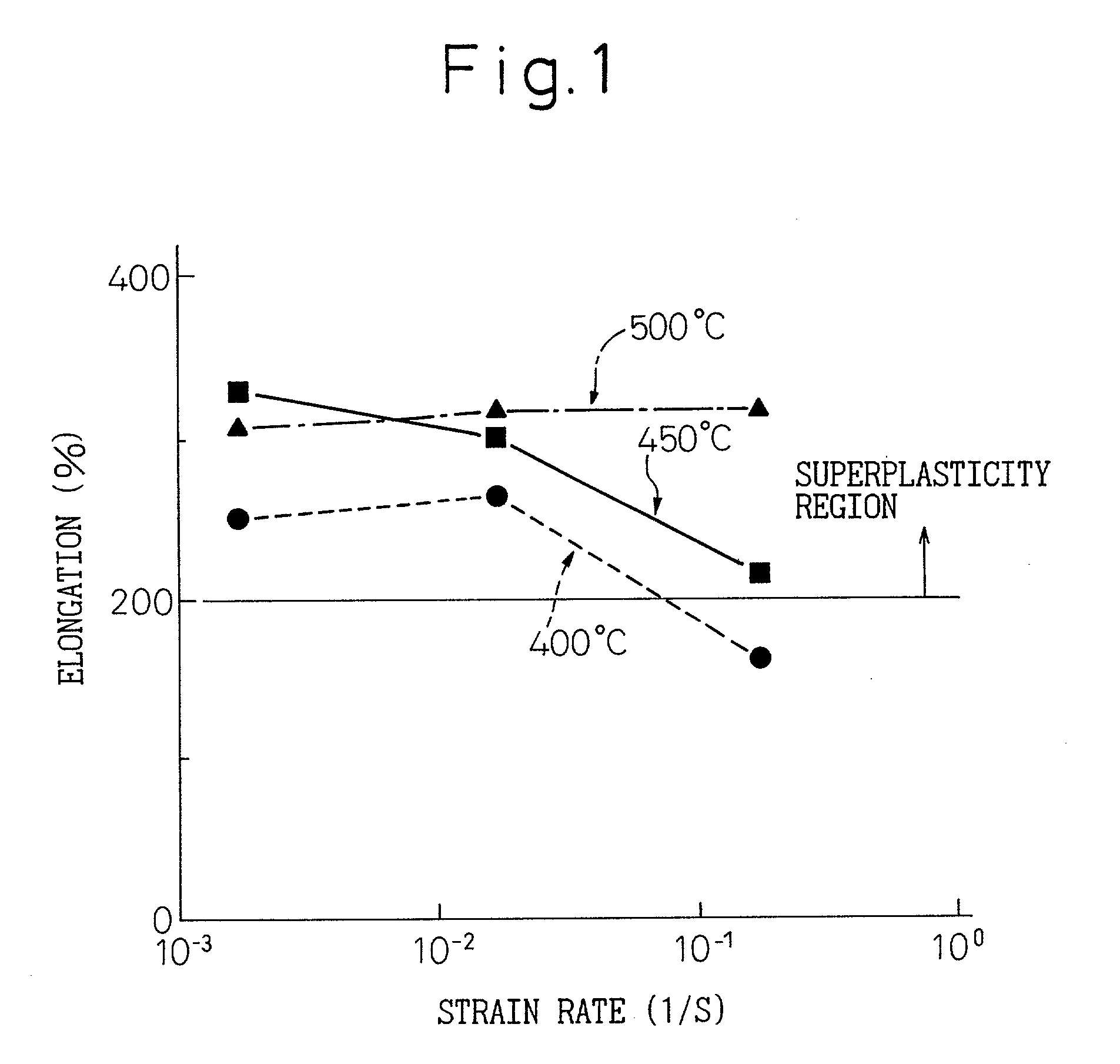

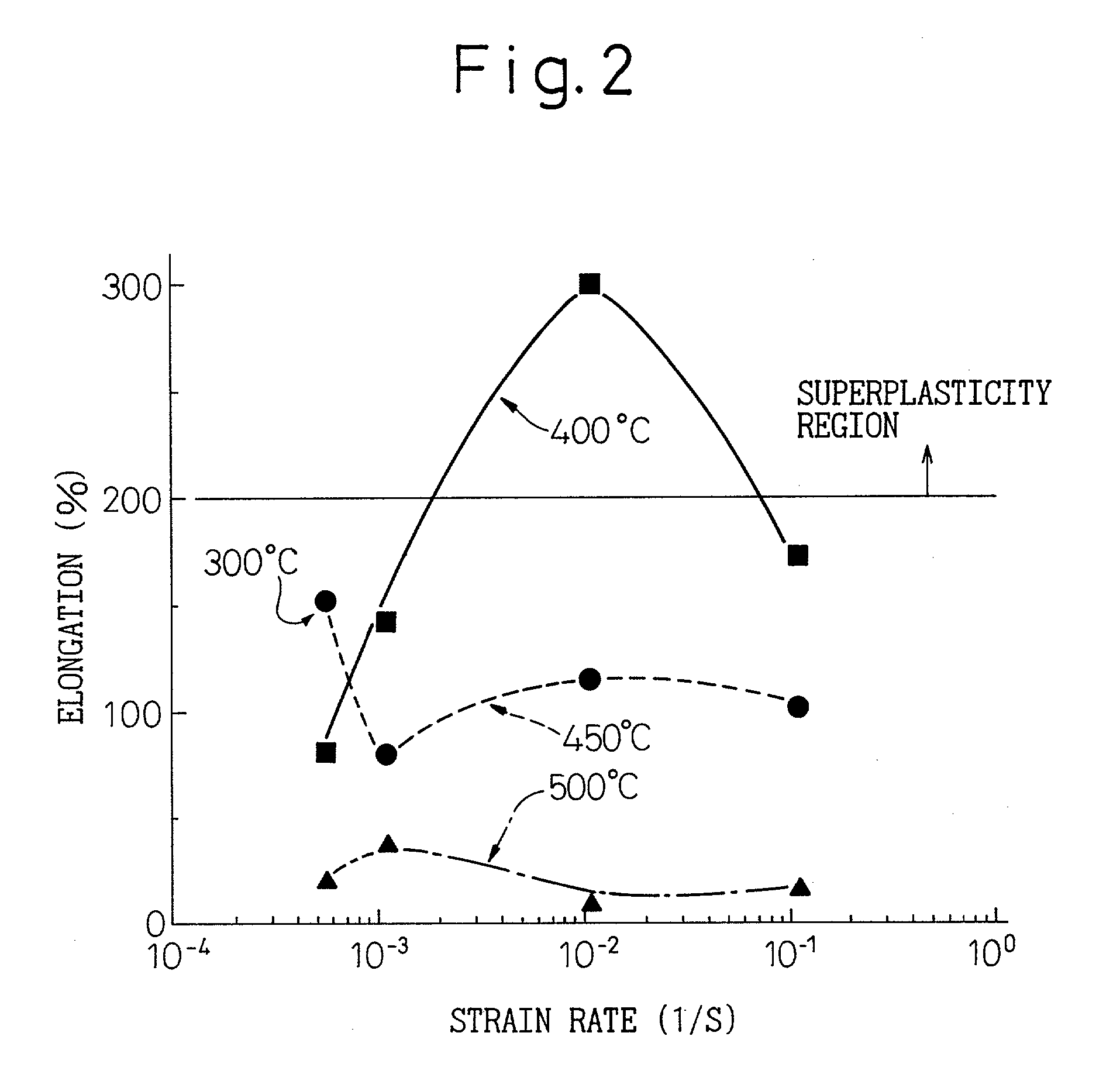

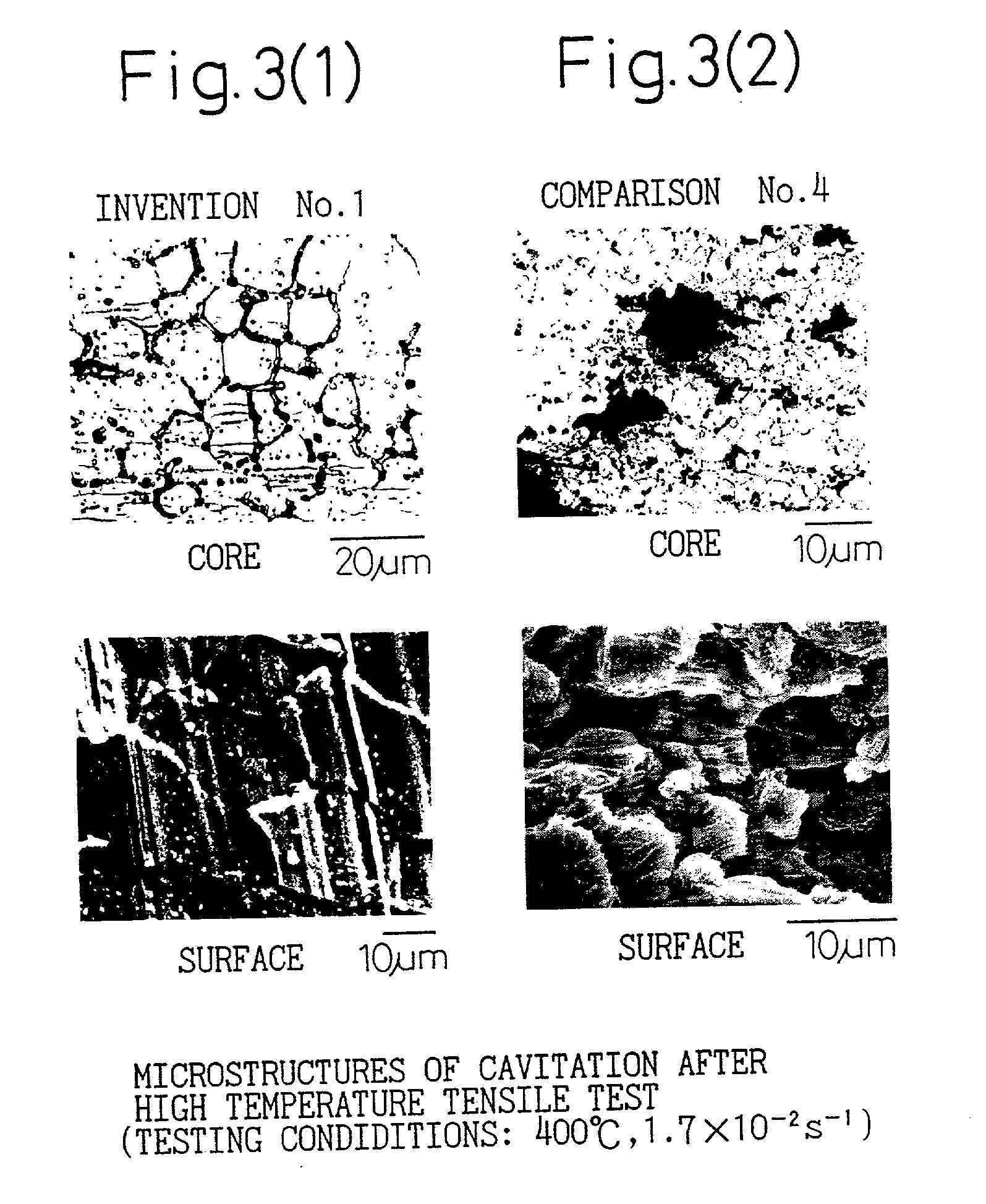

Superplastic aluminum alloy and process of producing same

InactiveUS20010014404A1Improve the immunityDecrease in cross slipThin material handlingCores/yokesWorking temperatureIngot

The present invention provides a superplastic aluminum alloy in which fine particles not substantially dispersion hardening are dispersed in a sufficient amount to effect grain boundary pinning to suppress crystal grain growth during hot working thereby ensuring manifestation of superplasticity over wide ranges of working temperature and strain rate. According to the present invention, a superplastic aluminum alloy contains ceramic particles having an average particle size of from 10 nm to 500 nm in an amount of from 0.1 vol % to 5 vol % and a process of producing a superplastic aluminum alloy, comprises the steps of: hot working an aluminum alloy ingot containing ceramic particles having an average particle size of from 10 nm to 500 nm in an amount of from 0.1 vol % to 5 vol % with a working degree of from 10% to 40% at a temperature of 400° C. or higher; heat-treating at a temperature of 400° C. or higher; and hot-working with a working degree of 40% or more at a temperature of lower than 400° C.

Owner:TOYOTA JIDOSHA KK

Preparation method of aluminum-based composite material

The invention provides a preparation method of an aluminum-based composite material. The preparation method of the aluminum-based composite material comprises the following steps that a to-be-machinedaluminum-based composite material plate after being subjected to pretreatment is horizontally placed on a cushion plate and is clamped and fixed; a stirring head of friction stir welding is insertedinto the surface of the aluminum-based composite material plate at a rotating speed of 10-2000 rpm until the lower end of a shaft shoulder is in tight contact with the upper surface of the aluminum-based composite material plate, and the aluminum-based composite material plate is preheated; and transverse friction stir welding and longitudinal friction stir welding are carried out to the surface of the aluminum-based composite material plate through the stirring head at a certain walking speed until the whole aluminum-based composite material plate is machined completely. According to the preparation method of the aluminum-based composite material, the hardness of an in-situ nanoparticle reinforcing phase TiB2 added into an aluminum alloy is high, the heat stability is good, inhibiting effects on grain growth and void formation in high-temperature deformation of crystalline grains are achieved, and thus the material can have excellent superplasticity.

Owner:SHANGHAI JIAO TONG UNIV

Coarse-grain magnesium alloy board with superplasticity and preparation method thereof

The invention relates to a coarse-grain magnesium alloy board with superplasticity and a preparation method thereof, and belongs to the technical field of magnesium alloys. An alloy comprises the following components in percentage by mass: 7.6-8.9% of aluminum, 0.02-0.70% of silver, 0.35-0.55% of zinc, 0.15-0.35% of manganese, 0.02-0.08% of rare earth, 0.001-0.02% of calcium, and the balance of magnesium. The preparation method comprises the steps of smelting, casting, turning and peeling, uniform annealing and extrusion. The grain size of the obtained coarse-grain magnesium alloy board is 45-60 microns; the transverse ductility of the board can reach 420-550%; the longitudinal ductility can reach 640-730%; excellent high-temperature superplasticity is achieved; and superplastic forming can be directly performed without needing complicated thermal mechanical grain refining treatment, so that the production cost can be effectively reduced.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com