Titanium alloy capable of resisting high temperature higher than 600 DEG C

A titanium alloy, high temperature technology, applied in the field of high temperature resistant titanium alloy, can solve the problems of unstable structure, unstable alloy surface and high hot working temperature, and achieve simple and easy processing, meet performance requirements and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

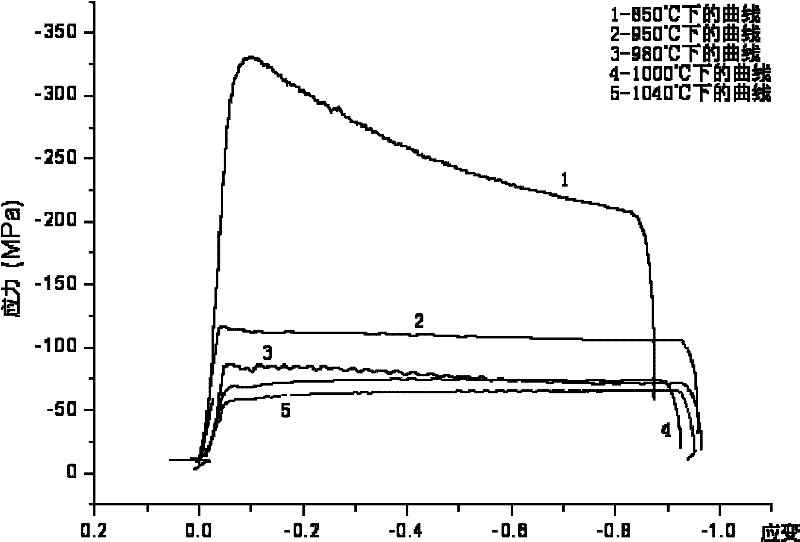

[0028] When mixing materials, add the required master alloy in proportion, the rare earth element Ce is added in the form of Al-Ce master alloy, Ta is added in the form of master alloy, C is added in the form of graphite powder, B is added in the form of B powder or B 4 C powder is added, mixed well, pressed into electrodes, and smelted three times in a vacuum consumable electric arc furnace. Then through rapid forging, radial forging and rolling, a titanium alloy rod with a diameter of 25 mm is obtained. Table 1 is the chemical composition content table of each titanium alloy in Examples 1-5.

[0029] Table 1. (weight percentage)

[0030] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com