Preparation method of superplastic Ni-Mn-Ga-Ta high-temperature memory alloy

A memory alloy and superplastic technology, which is applied in the field of high-temperature superplastic Ni-Mn-Ga-Ta memory alloy preparation, can solve the problems of high brittleness and low restoring force of memory alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The high temperature superplastic Ni of this embodiment 53 mn 25 Ga 21 Ta 1 The preparation method of the memory alloy is prepared according to the following method: according to the atomic percentage, 53 parts of Ni, 25 parts of Mn, 21 parts of Ga and 0.5 parts of rare element Ta are put into a vacuum intermediate frequency induction melting furnace, and the order is as follows Place raw materials: first place the rare element Ta, then Ni, and finally Ga. Due to the high volatility of Mn element, when feeding, put the Mn sheet in the feeding device of the vacuum intermediate frequency induction melting furnace for standby, and close the side furnace door. Before smelting, vacuumize to 6.67×10 with mechanical pump and Roots pump -3 Pa, then filled with high-purity argon to 0.5Pa. Start smelting and control the smelting power to 450Kw. Due to the melting principle of the intermediate frequency induction itself, the melted metal liquid will flow and stir under the ac...

Embodiment 2

[0021] The high temperature superplastic Ni of this embodiment 53 mn 25 Ga 21 Ta 1 The preparation method of the memory alloy is prepared according to the following method: according to the atomic percentage, 53 parts of Ni, 25 parts of Mn, 21 parts of Ga and 0.5 parts of rare element Ta are put into a vacuum intermediate frequency induction melting furnace, and the order is as follows Place the raw materials: first place the rare element Ta, then Ni, and finally Ga, put the Mn sheet in the feeding device of the vacuum intermediate frequency induction melting furnace for standby, and close the side furnace door. Before smelting, vacuumize to 6.67×10 with mechanical pump and Roots pump -3 Pa, then filled with high-purity nitrogen to 0.5Pa. Start smelting and control the smelting power to 450Kw. Due to the melting principle of the intermediate frequency induction itself, the melted metal liquid will flow and stir under the action of the electromagnetic field. When the melt...

Embodiment 3

[0023] The high temperature superplastic Ni of this embodiment 53 mn 25 Ga 21 Ta 1 The preparation method of the memory alloy is prepared according to the following method: according to the atomic percentage, 53 parts of Ni, 25 parts of Mn, 21 parts of Ga and 0.5 parts of rare element Ta are put into a vacuum intermediate frequency induction melting furnace, and the order is as follows Place the raw materials: first place the rare element Ta, then Ni, and finally Ga, put the Mn sheet in the feeding device of the vacuum intermediate frequency induction melting furnace for standby, and close the side furnace door. Before smelting, vacuumize to 6.67×10 with mechanical pump and Roots pump -3 Pa, then filled with high-purity argon to 0.5Pa. Start smelting, control the smelting power to 500Kw, and arc smelting for 8-12 minutes. Due to the melting principle of the intermediate frequency induction itself, the melted metal liquid will flow and stir under the action of the electrom...

PUM

| Property | Measurement | Unit |

|---|---|---|

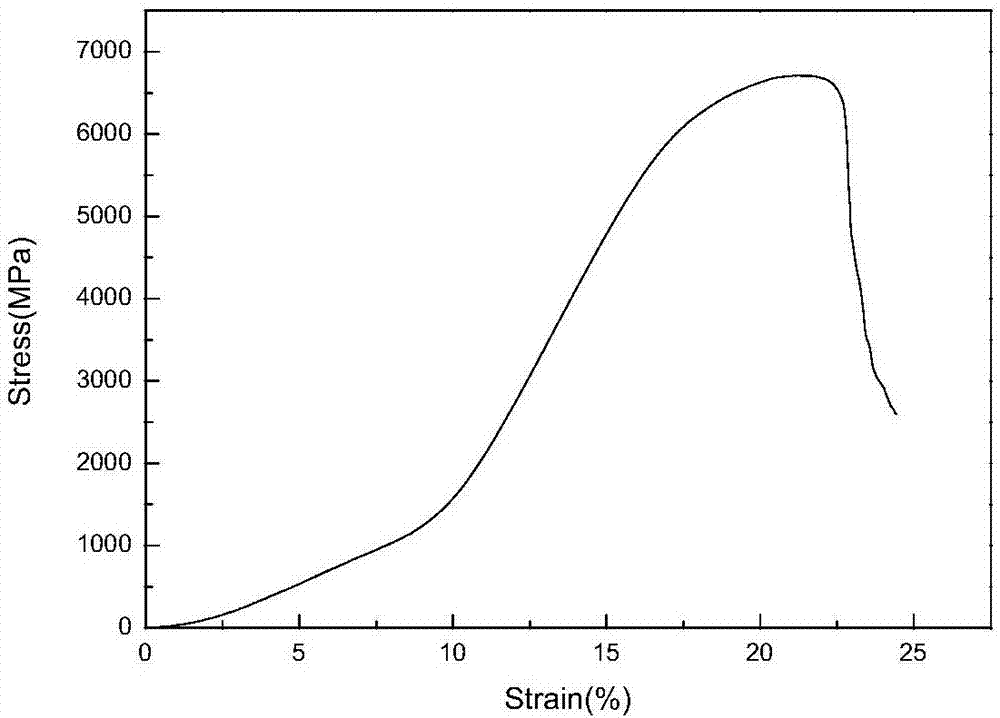

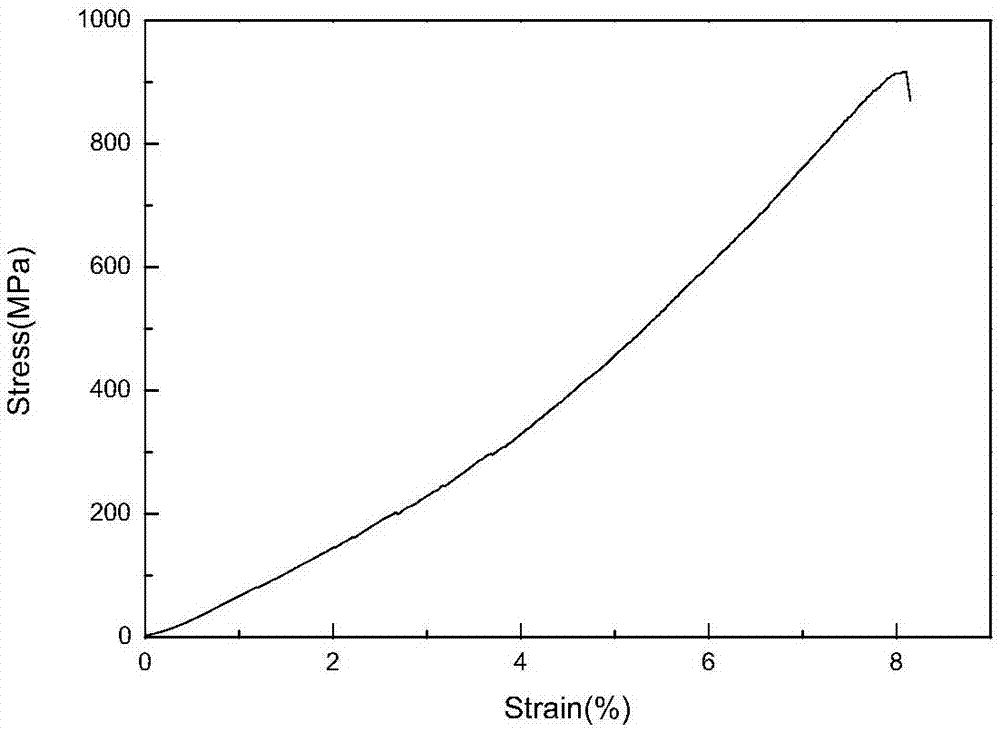

| breaking strength | aaaaa | aaaaa |

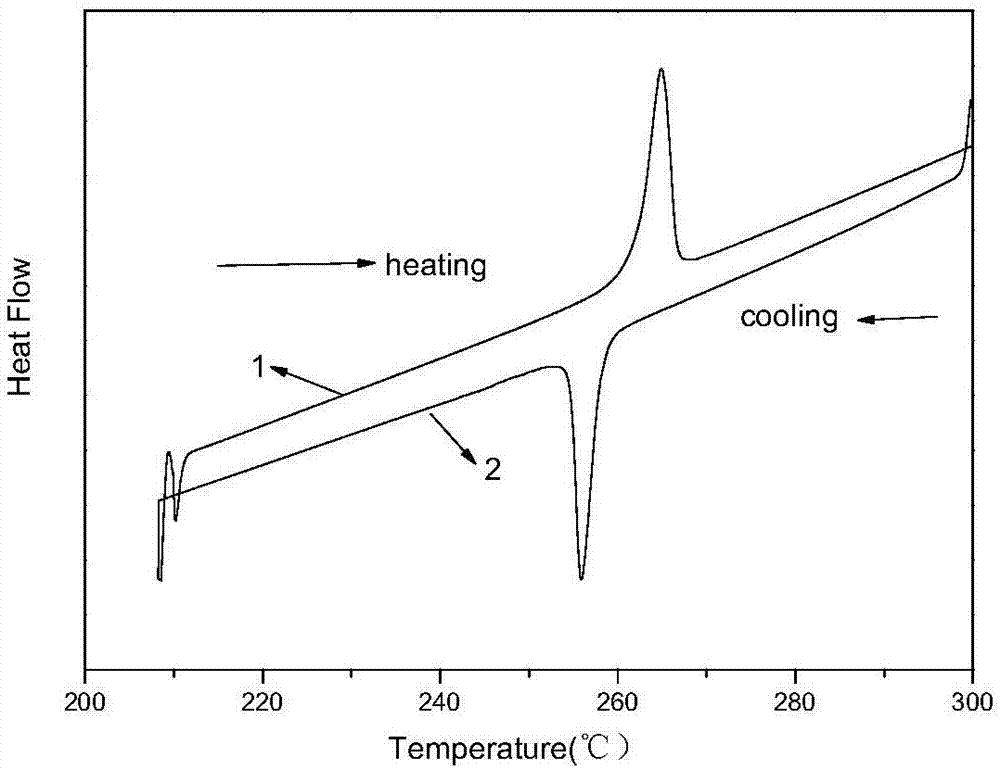

| phase transition temperature | aaaaa | aaaaa |

| fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com