Preparation method of aluminum-based composite material

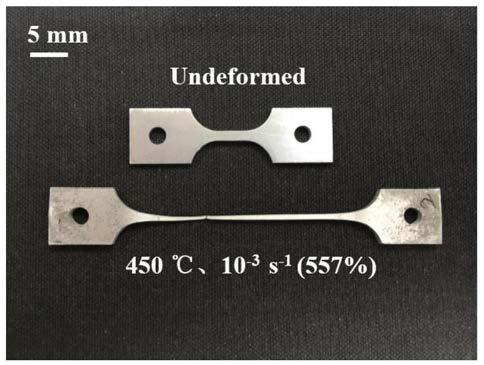

An aluminum-based composite material and composite material technology, applied in the field of material preparation, can solve the problems of low superplastic forming and processing, inability to put into industrial application, and increased material cost, and achieve excellent superplastic performance, high hardness, and crystal grain The effect of growth inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In situ self-generated 5wt.%TiB obtained by casting 2 / 7050Al composite material, the treatment method is as follows: (1) the particle reinforced aluminum matrix composite material obtained by in-situ autogenous casting is subjected to homogenization heat treatment of alloy elements, the heat treatment temperature is 475 ℃, and the heat treatment time is 20h; (2) the uniform The in-situ particle-reinforced aluminum-matrix composite material is subjected to one-way hot extrusion deformation; (3) The plate is subjected to friction stir treatment, and the particle-reinforced aluminum-matrix composite material plate to be processed is placed horizontally on the backing plate and fixed by clamping (4) Insert the stirring head into the surface of the plate at a speed of 600r / min until the lower end surface of the shoulder is in close contact with the upper surface of the plate, then stop the lowering and preheat the material; (5) make the stirring head 80mm / min The walking sp...

Embodiment 2

[0030] In situ self-generated 5wt.%TiB obtained by casting 2 / 7050Al composite material, the treatment method is as follows: (1) the particle reinforced aluminum matrix composite material obtained by in-situ autogenous casting is subjected to homogenization heat treatment of alloy elements, the heat treatment temperature is 475 ℃, and the heat treatment time is 20h; (2) the uniform The in-situ particle-reinforced aluminum-matrix composite material is subjected to one-way hot extrusion deformation; (3) The plate is subjected to friction stir treatment, and the particle-reinforced aluminum-matrix composite material plate to be processed is placed horizontally on the backing plate and fixed by clamping (4) Insert the stirring head into the surface of the plate at a speed of 800r / min until the lower end surface of the shoulder is in close contact with the upper surface of the plate, then stop the lowering and preheat the material; (5) make the stirring head 80mm / min The walking sp...

Embodiment 3

[0032] In situ self-generated 15wt.%TiB obtained by casting 2 / 7050Al composite material, the treatment method is as follows: (1) the particle reinforced aluminum matrix composite material obtained by in-situ autogenous casting is subjected to homogenization heat treatment of alloy elements, the heat treatment temperature is 485 ℃, and the heat treatment time is 24h; (2) the homogeneous The in-situ particle-reinforced aluminum-matrix composite material is subjected to one-way hot extrusion deformation; (3) The plate is subjected to friction stir treatment, and the particle-reinforced aluminum-matrix composite material plate to be processed is placed horizontally on the backing plate and fixed by clamping (4) Insert the stirring head into the surface of the plate at a speed of 1000r / min until the lower end surface of the shoulder is in close contact with the upper surface of the plate, then stop the lowering and preheat the material; (5) make the stirring head 50mm / min The walki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com