Processing method for realizing super high plasticity performance of titanium alloy welded joint

A technology for welding joints and processing methods, applied in the field of titanium alloy welding, can solve the problems of increasing the difficulty of superplastic forming of joints, increasing the difficulty of welding, affecting the quality of joints, etc., and achieves increased mechanical properties, reduced oxidation degree, and low superplastic temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A 2 mm thick TC4 titanium alloy plate was used, 0.2 wt% hydrogen was placed in a hydrogen atmosphere, and a stirring head with a shoulder diameter of 11 mm was used for welding. During the welding process, the joint was protected by argon and the weld was rapidly cooled, and the friction stir welding was performed under the welding parameters of the tool rotation speed of 300 rpm and the travel speed of 100 mm / min. The typical lamellar structure of friction stir welding nugget of TC4 titanium alloy is as follows: figure 1 As shown, it can be seen that the grains in the nugget area are uniform and fine lamellar structures. A high-quality welded joint with a lamellar length-to-diameter ratio of 7:1 and a lamellar thickness of 120 nm was obtained.

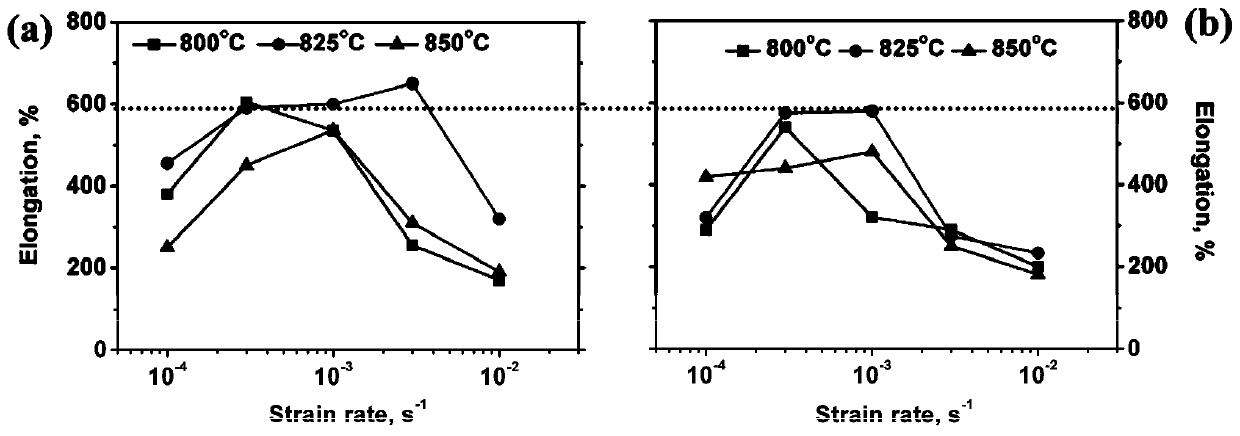

[0038] The high temperature superplasticity tensile test shows that the optimum superplasticity temperature of the weld nugget is 800℃. When the superplastic temperature is 800°C, the strain rate is 1×10 -3 the s -1 , the m...

Embodiment 2

[0042] Use TC4 titanium alloy plate, and use 0.2wt% hydrogen before welding. Use a W-Re stirring head with a shoulder diameter of 11 mm for welding. During the welding process, use argon to protect the joint and rapidly cool the weld. Under the welding parameters, a high-quality welded joint with fine nugget lamellar structure (sheet thickness 80-200 nanometers, aspect ratio 6:1-12:1) is obtained. The high-temperature superplasticity tensile test shows that the optimal superplasticity temperature of the weld nugget at a tool speed of 400 rpm and a travel speed of 100 mm / min is 825 °C. When the superplastic temperature is 825°C and the strain rate is 1×10 -3 the s -1 When the maximum elongation of the weld nugget is 600%, the flow stress is only 28MPa, such as figure 2 shown.

[0043] The sample of the TC4 titanium alloy friction stir welding nugget prepared in this example after being stretched at 825°C is as follows image 3 .

Embodiment 3

[0047] Use a 2mm thick as-rolled annealed TC4 titanium alloy plate with 0.2wt% hydrogen before welding. Welding is carried out with a stirring head with a shoulder diameter of 11 mm, the joint is protected by argon gas during the welding process and the weld is cooled rapidly, and high quality is obtained under the welding parameters of tool rotation speed of 500 rpm and travel speed of 150 mm / min of welded joints. The high-temperature superplastic tensile test shows that when the superplastic temperature is 800°C, the strain rate is 3×10 -3 the s -1 , the maximum elongation of the weld nugget is more than 600%, and the flow stress is only 36MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com