Titanium alloy with excellent hot-workability and preparation method thereof

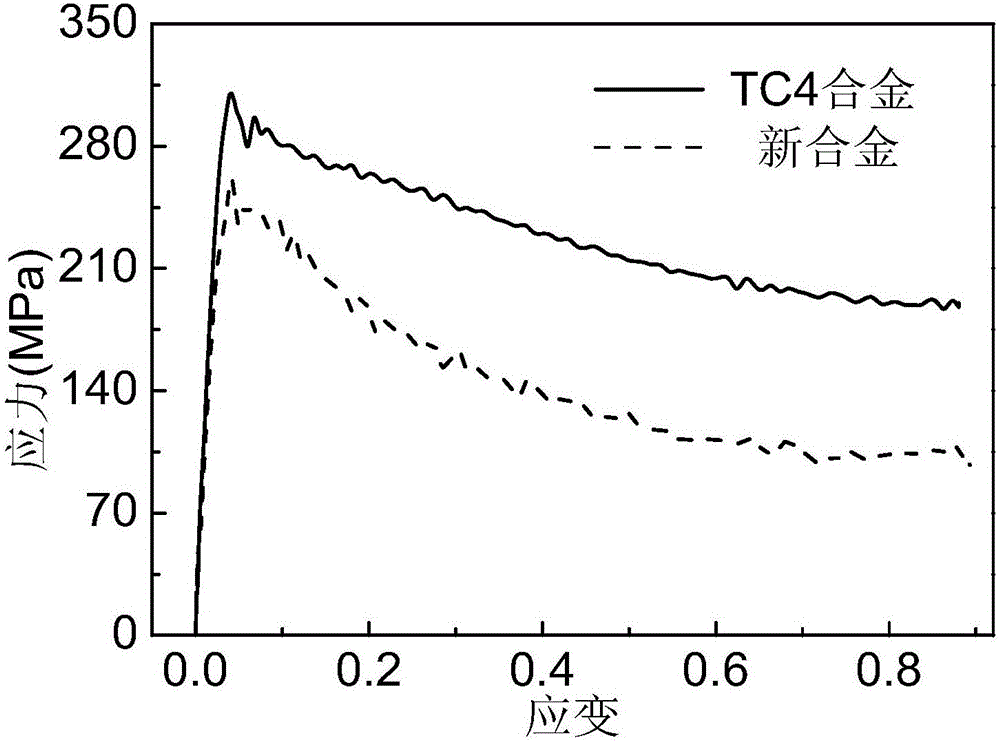

A titanium alloy and thermal processing technology, which is applied in the field of material processing, can solve the problems of large rheological resistance and poor thermal processing performance, and achieve the effect of reducing rheological resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A titanium alloy with excellent hot workability, consisting of 6% Al, 4% V, 0.5% Fe, ≤0.2% O, ≤0.05% C, ≤0.05% N, and ≤0.05% N by weight percentage ≤0.01%, the balance is Ti. Quantitative aluminum beans, aluminum-vanadium alloys, aluminum-iron alloys and TiO 2 The powder is wrapped in aluminum foil and folded to form an alloy package; the alloy package is placed in the sponge titanium and pressed into a dense electrode block by a press, and the welding electrode block is formed by means of argon arc welding; then the arc voltage is 28-30V, Arc current 3~3.6kA and vacuum degree 10 -2 Under the condition of Pa, the above-mentioned welding electrode block is subjected to secondary vacuum smelting, each smelting time is 15-20min, and an ingot with a mass of about 30kg is obtained. Before the ingot is opened and forged, the surface of the ingot is peeled 3-6mm on one side, and the hydrogen-oxygen sample and chip sample are taken at a distance of 150-250mm from the head of ...

Embodiment 2

[0037] A titanium alloy with excellent hot workability, by weight percentage: 6.5% for Al, 4.5% for V, 1.0% for Fe, ≤0.2% for O, ≤0.05% for C, ≤0.05% for N, and ≤0.05% for H ≤0.01%, the balance is Ti; quantitative aluminum beans, aluminum vanadium alloys, aluminum iron alloys and TiO 2 The powder is wrapped in aluminum foil and folded to form an alloy package; the alloy package is placed in the sponge titanium and pressed into a dense electrode block by a press, and the welding electrode block is formed by means of argon arc welding; then the arc voltage is 28-30V, Arc current 3~3.6kA and vacuum degree 10 -2 Under the condition of Pa, the above-mentioned welding electrode block is subjected to secondary vacuum smelting, each smelting time is 15-20min, and an ingot with a mass of about 30kg is obtained. Before the ingot is opened and forged, the surface of the ingot is peeled 3-6mm on one side, and the hydrogen-oxygen sample and chip sample are taken at a distance of 150-250mm...

Embodiment 3

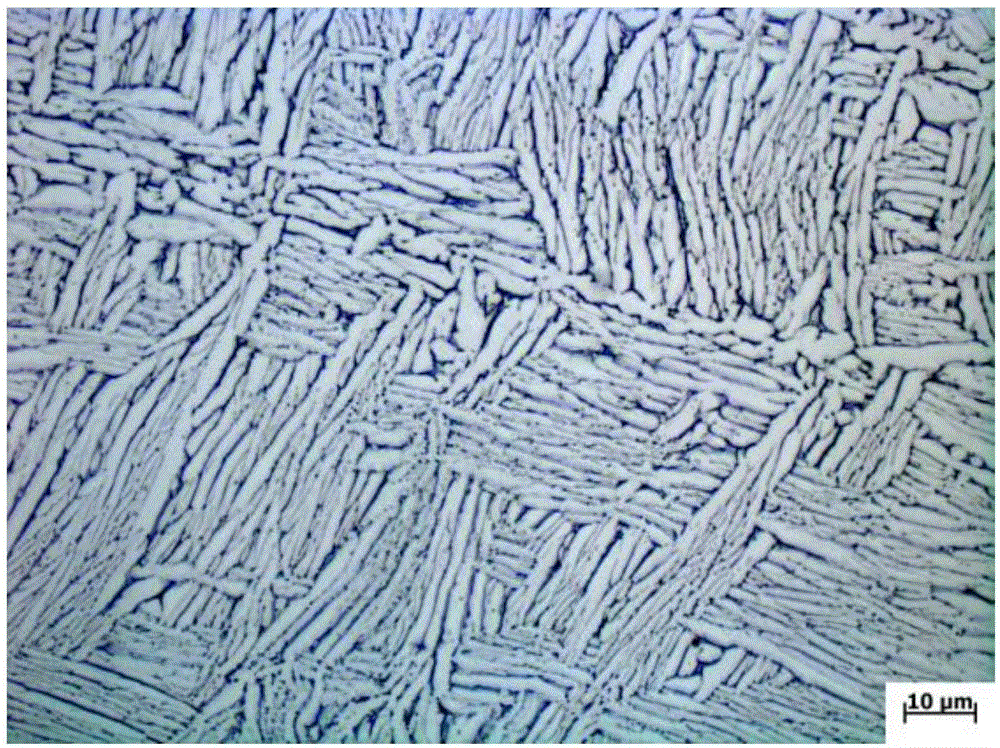

[0039] This example relates to the detection of the microstructure of the titanium alloy of the present application with excellent hot workability.

[0040] Adopt metallographic microscope to magnify 1000 times and observe the titanium alloy with excellent hot workability prepared by embodiment 1, as figure 1 shown by figure 1 It can be seen that the forged structure of the titanium alloy is a large area of Widmanstatten structure and a little basket structure, and the uniform and fine flaky α phase is neatly arranged in the original β grains. Among them, the β phase accounts for about 20%, which is beneficial to the high temperature deformation of the alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com