Two-stage homogenization heat treatment method for high-strength nickel-based superalloy cast ingot

A nickel-based superalloy, homogenized heat treatment technology, applied in the field of alloy materials, to achieve the effect of eliminating dendrites, eliminating element segregation, and reducing carbide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: The experimental material was processed into a ingot having a diameter of 300 mm for secondary homogenization treatment. CR: 15% ~ 18%, CO: 15% ~ 20%, Ti: 0.5% ~ 1.4%, and W: 5% ~ 8.5%, Si: ≤ 0.5%, Si: ≤ 0.5%, Si: ≤ 0.5%, Si: Mn: ≤0.5%, Nb: 0.5% ~ 1.5%, C: 0.03% ~ 0.08%, the margin is Ni, and the vacuum induction furnace is added, and it is cast into a alloy ingot. The casting process is vacuum induction smelting + electric slag remember + vacuum self-consuming smelting triple process smelting.

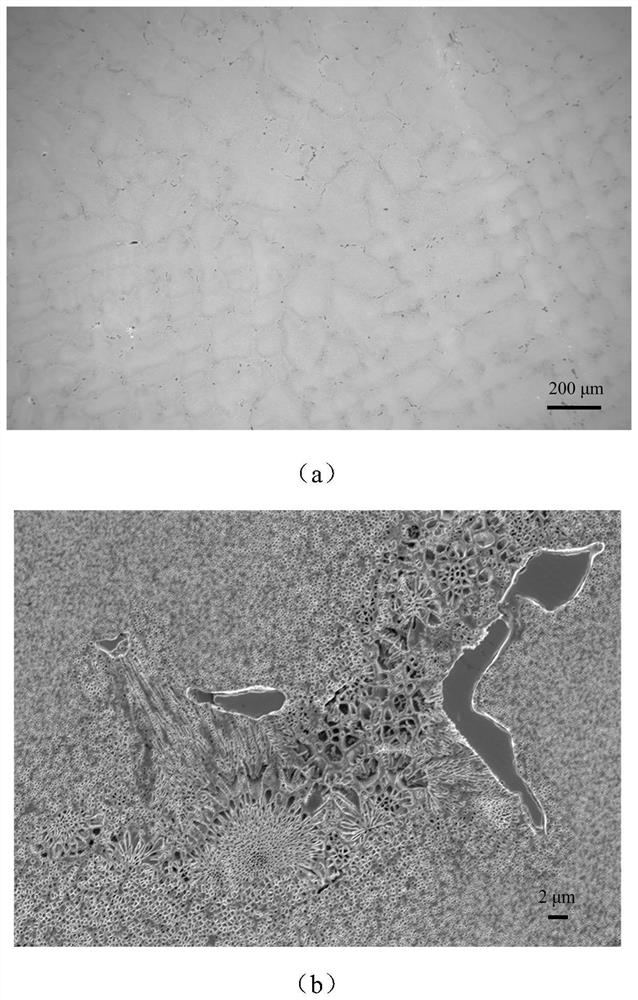

[0027] like figure 1 (a) and 1 (b) show that the cast tissue scanning electron micrograph before the nickel alloy homogenization process of the present embodiment, figure 1 (a) shows that there is a significant dendrite crystal in the ingot tissue, and there is a significant carbide in the branches. figure 1 (b) shows that there is a significant eutectic structure in the dendrites between the ingot tissue and the dendrites.

Embodiment 2

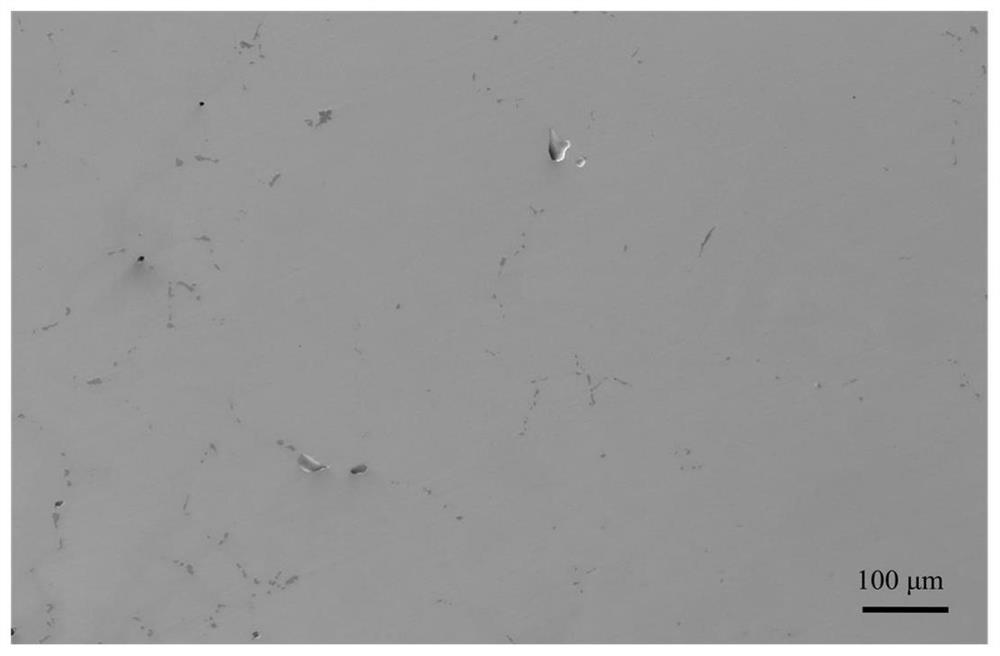

[0028] Example 2: Two-stage homogenization treatment of different processes for different processes of the nickel alloy blank using the method of the present invention, from the room temperature rise to the first stage homogenization temperature of 5 ° C / min The nickel alloy fell in the heat treatment furnace at 1080 ° C for 48 h, complete the first stage homogenization treatment; the first stage homogenized fillar is heated to the second stage homogenization temperature, the heat treatment temperature is 1200 ° C, after insulation 96h, complete the second level homogenization treatment, and the homogenization is completed, and the tissue shape after the two-stage uniform treatment is treated. figure 2 . according to figure 1 and figure 2 After the homogenization of the display, it can be apparent that after the homogenization process produced by the present invention, even if the homogenization process of the blank is also thoroughly thorough, the grain size is about 500 μm, th...

Embodiment 3

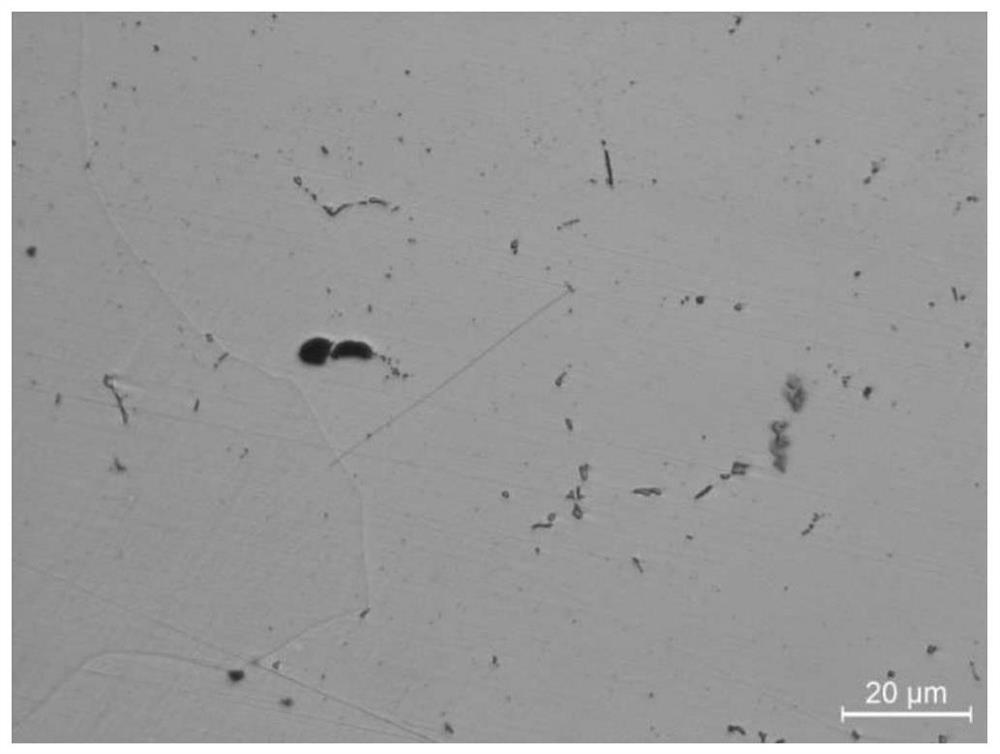

[0031] Example 3: Two-stage homogenization treatment of different processes in different processes by the alloy provided in the present invention, from room temperature rises to the first stage homogenization temperature of 10 ° C / min, The nickel alloy is 1080 ° C for 12 hours in the heat treatment furnace, and the first stage homogenization treatment is completed; the first stage homogeneous embryo is raised to the second stage homogenization temperature, the heat treatment temperature is 1220. EtOAc image 3 . Combine image 3 It can be seen that when the second stage homogenization temperature is 1220 ° C, the alloy is uniform, and the carbide distributed on the grain boundary is dissolved, the mesh structure disappears, and there is only a small amount of carbide left in the substrate. Although this processing system has also achieved homogenization requirements, since the homogenization temperature of the second stage is short, the total temperature is high, but the homogeneo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com