A kind of EPDM composition, rubber air filter tube and preparation method thereof

A technology of EPDM rubber and composition is applied in the preparation of EPDM rubber composition and rubber air filter tube, and the preparation field of automobile air filter hollow filter tube, which can solve the problem of poor tearing performance of product rubber tube. , prone to bending or tearing, not suitable for industrial production and other problems, to achieve the effect of improving hot tearing performance and thermal deformation performance, improving cross-linking degree and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

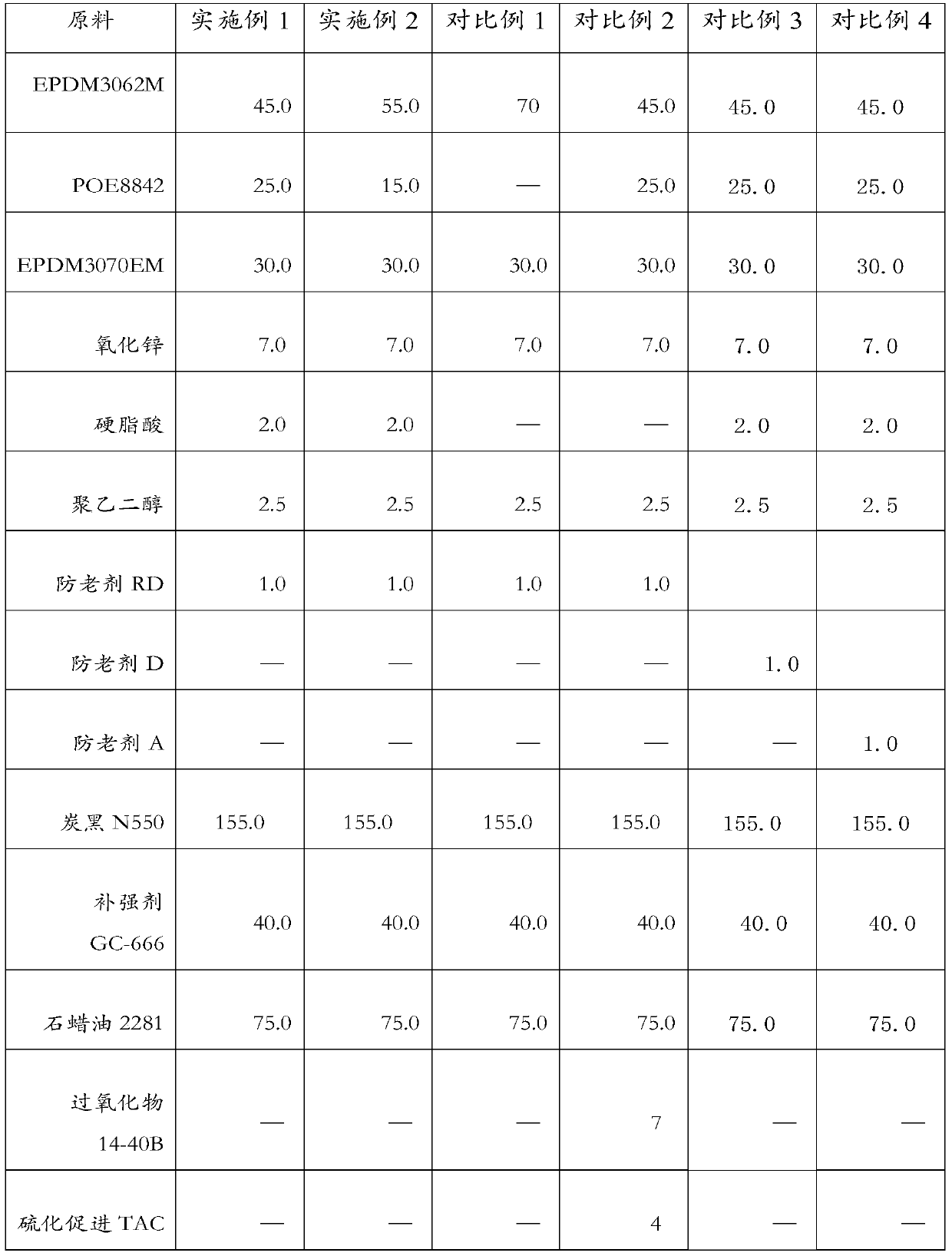

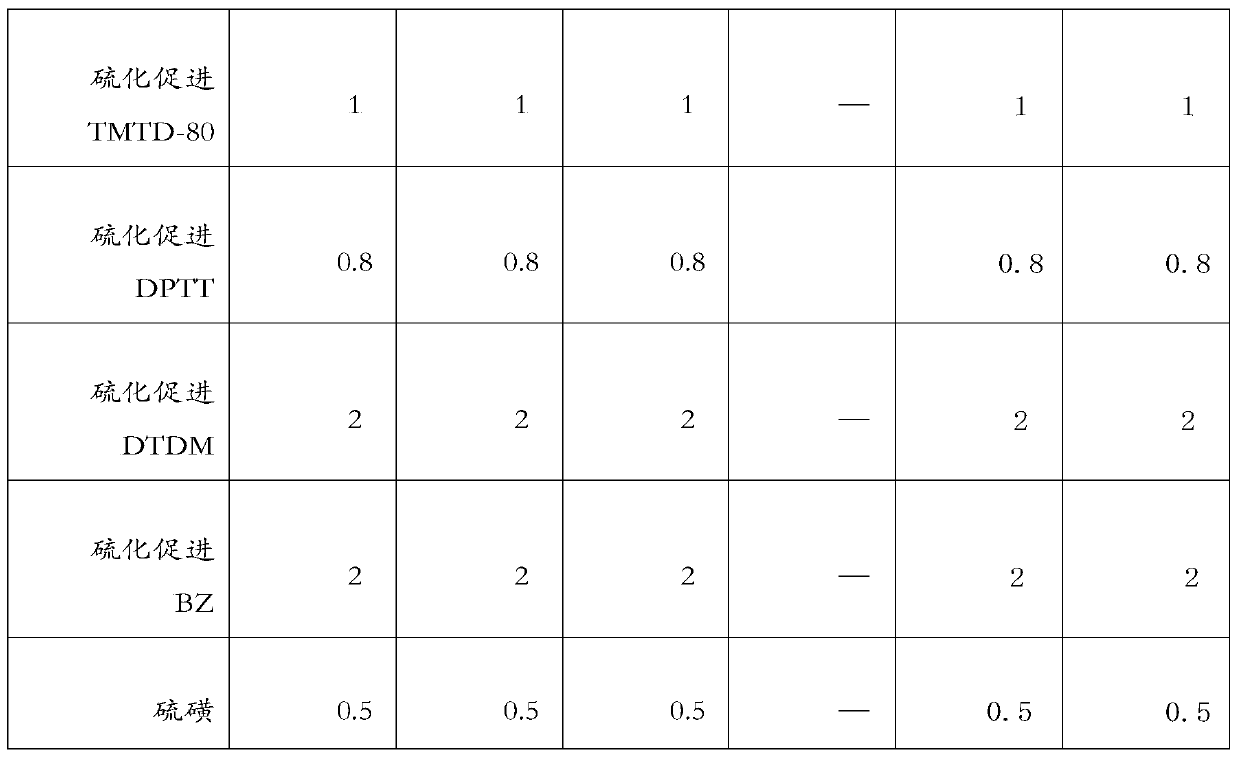

[0052] According to the ratio of raw materials shown in Table 1 below, the weight of the raw materials in grams was weighed to obtain the EPDM rubber formulations described in Examples 1-2 and Comparative Examples 1-4.

[0053] Table 1 embodiment 1-2 and comparative example 1-4 EPDM formula (unit gram)

[0054]

[0055]

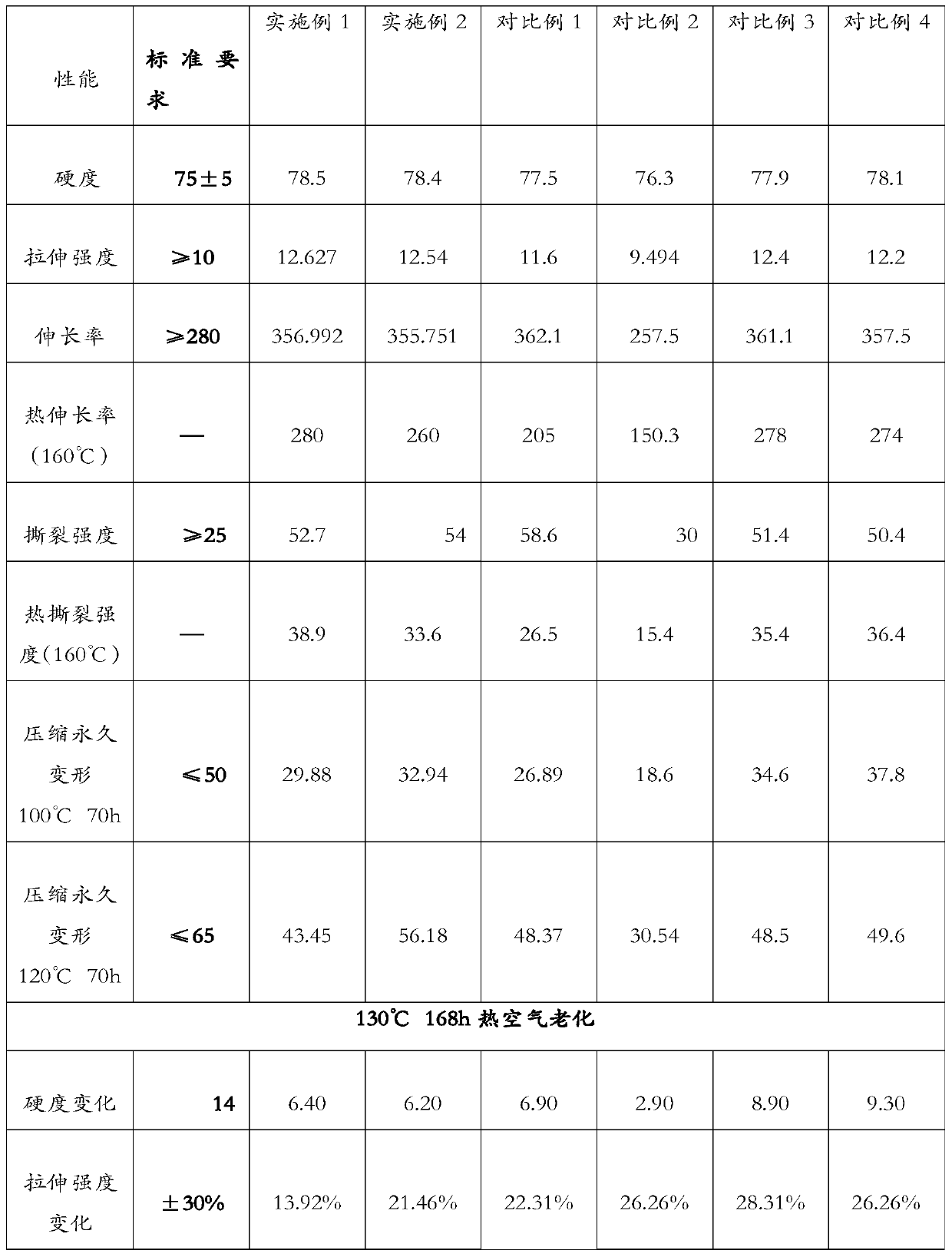

[0056] In the EPDM rubber formula shown in the above-mentioned Examples 1-2 and Comparative Examples 1-4, the vulcanizing agent (peroxide 14-40B / sulfur) and the vulcanization accelerator (TAC, TMTD-80, After the other components except DPTT, DTDM and BZ) are mixed separately, the first stage of mixing is carried out in the internal mixer. After the mixed rubber obtained after the first stage of mixing is cooled at room temperature, a vulcanizing agent and a vulcanization accelerator will be added to the mixed rubber; Under the temperature of ℃, the EPDM rubber material was obtained, and its performance was tested.

[0057] Weigh an appropriate amount ...

Embodiment 3

[0062] In embodiment 3, take 30.0gEPDM3095, 45.0gEPDM3072 as raw material EPDM rubber and take 25.0gDF610 as raw material polyolefin elastomer;

Embodiment 4

[0063] In embodiment 4, take 30.0gEPDMS505, 45.0gEPDMS512 as raw material EPDM rubber and take 25.0gPOE8200 as raw material polyolefin elastomer;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com