A method for improving thermal deformation properties of titanium matrix composites

A titanium-based composite material and thermal deformation technology, which is applied in the field of improving the thermal deformation performance of titanium-based composite materials, can solve the problems of high deformation resistance and many deformation defects, and achieve improved thermal deformation performance, reduced thermal deformation resistance, and reduced deformation The effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

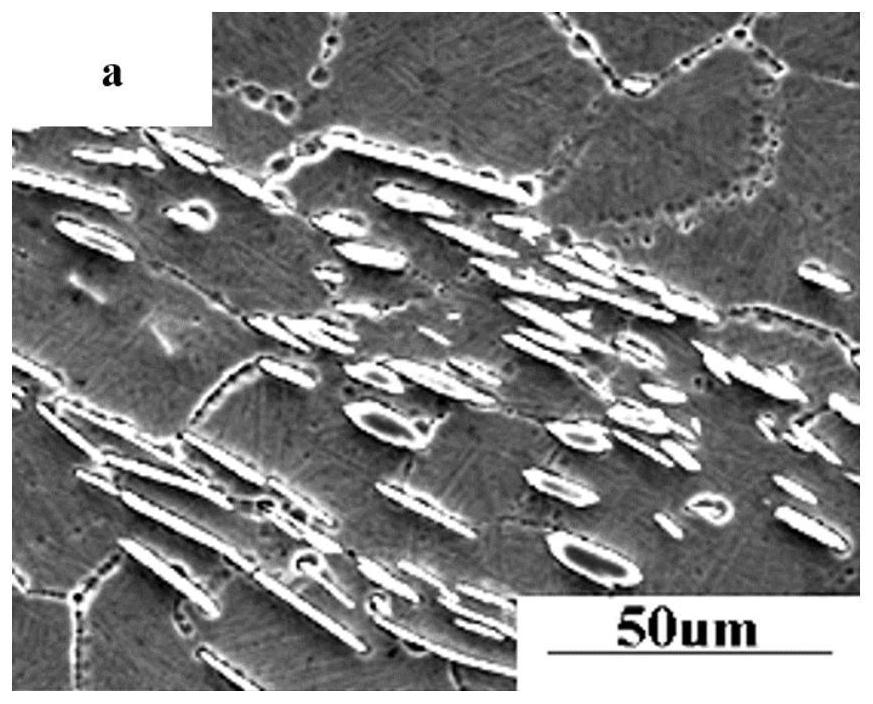

[0025] (1) Use acetone and anhydrous ethanol to ultrasonically clean industrial titanium sponge in turn, dry at 100°C for 4h in a drying oven, add TiB 2 Powder, TiB 2 The powder mass was 1.25% of the total mass of the composite material and was placed in a water-cooled crucible in a vacuum non-consumable arc furnace.

[0026] (2) Vacuuming to achieve a vacuum degree of 3 × 10 -3 After Pa, 99.999% pure argon gas and 99.999% pure hydrogen gas were introduced, and the flow ratio of hydrogen gas and argon gas was 2:3. After melting all the raw materials under the current of 150A, the current was increased to 500A, the current was kept unchanged, and the smelting was stopped after 10 minutes. After the composite material was solidified and cooled, it was turned upside down and placed in a water-cooled copper crucible, and the smelting operation was repeated for a total of 6 times to obtain TiB Reinforced Ti-based composites.

Embodiment 2

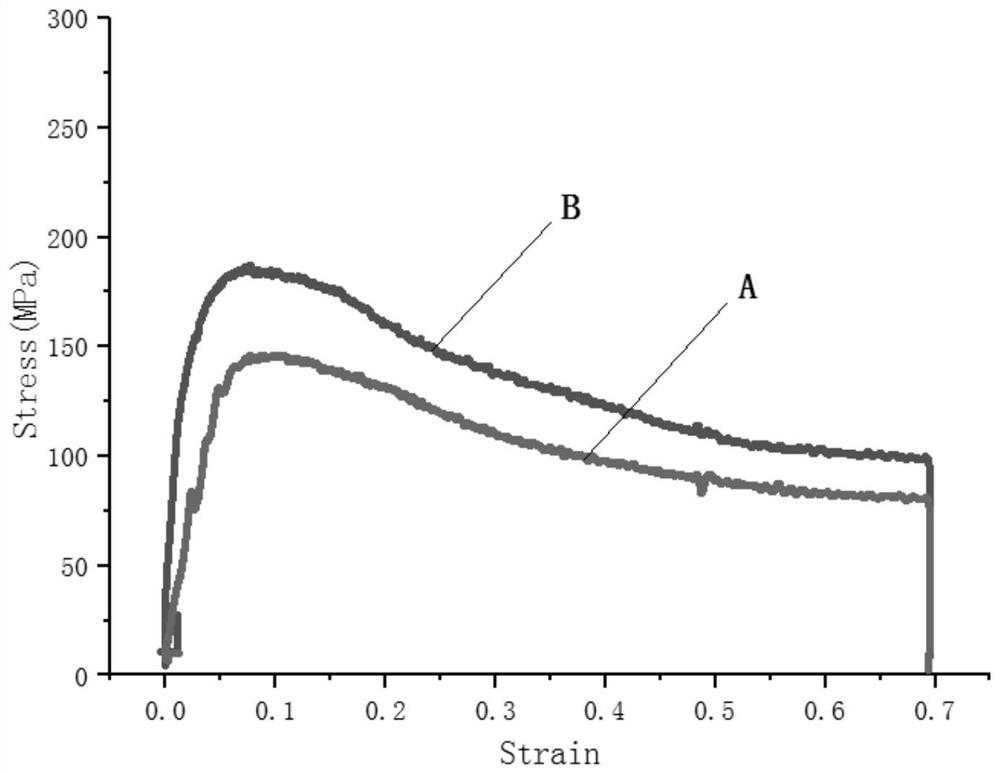

[0028] The difference between this example and Example 1 is: raw material titanium sponge, pure Mo particles and TiB 2 The mass of the powder is 62.25%, 33%, and 4.75% of the total mass of the composite material, and the rest of the operation steps are exactly the same as in Example 1, and the TiB-reinforced Ti-33Mo matrix composite material is obtained.

Embodiment 3

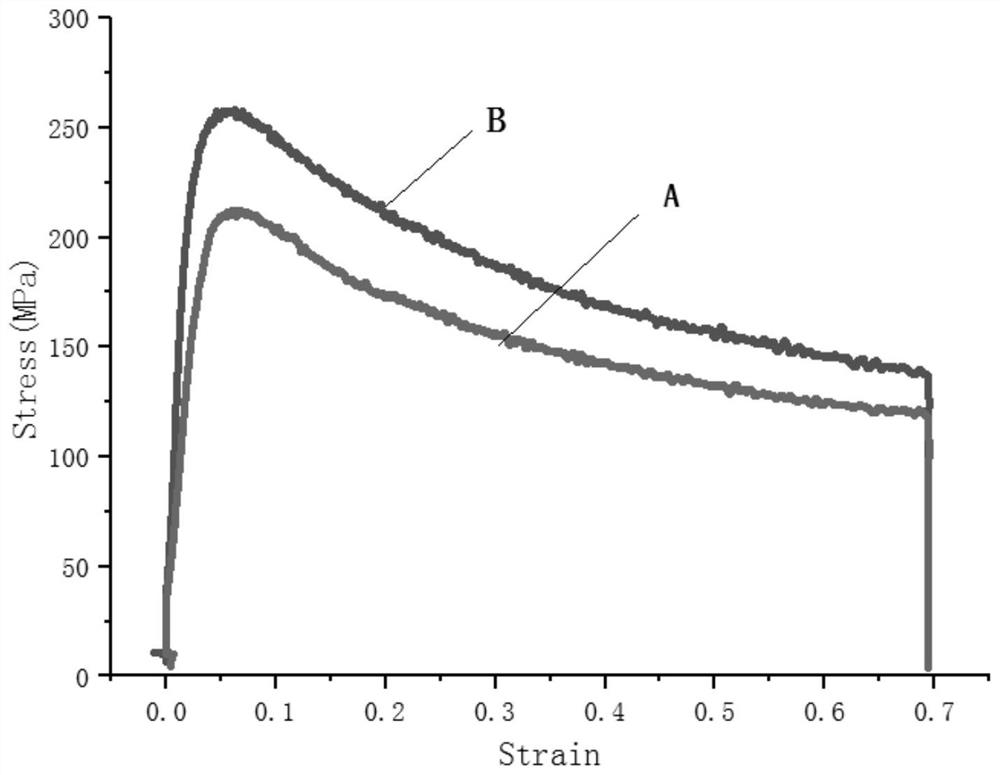

[0030] The difference between this example and Example 1 is: the raw materials are sponge titanium, aluminum element and aluminum-vanadium master alloy; the quality of aluminum-vanadium master alloy is weighed according to the mass ratio of vanadium element in the prepared composite material; The mass ratio of the prepared composite material is 6%. If the quality of aluminum element in the aluminum-vanadium alloy does not meet the quality requirements of the composite material, use aluminum element to make up; add TiB 2 The mass of the powder is 2.5% of the total mass of the composite material, and the rest of the operation steps are exactly the same as in Example 1 to obtain a TiB-reinforced Ti-6Al-4V-based composite material, which is marked as composite material A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com