Method for preparing lamella silicate modified ethylene-vinyl acetate copolymer

A technology of vinyl acetate copolymerization and layered silicate, which is applied in the field of manufacturing layered silicate modified ethylene-vinyl acetate copolymer, and achieves the effects of simple and reasonable process, low cost and improved thermal deformation

Inactive Publication Date: 2008-09-17

NINGBO NENGZHIGUANG NEW MATERIALS TECH

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

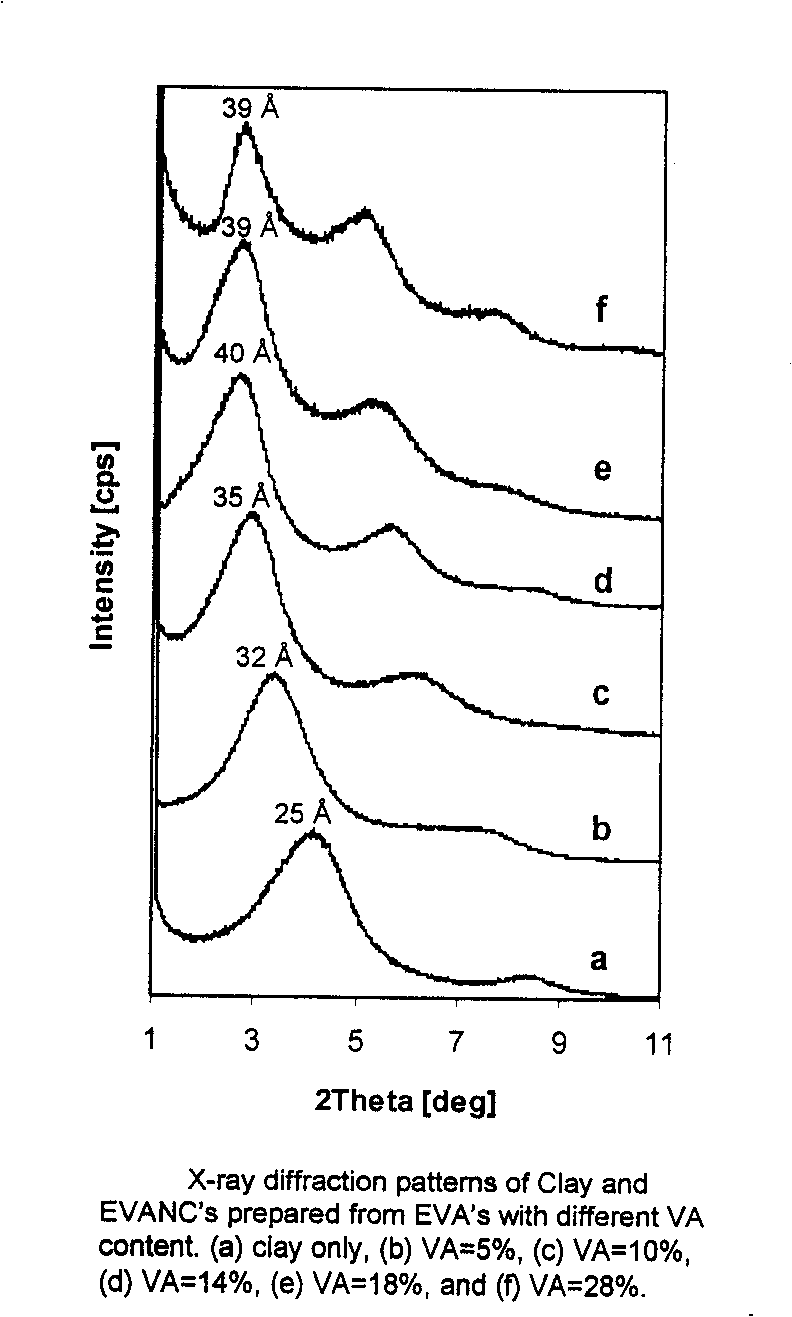

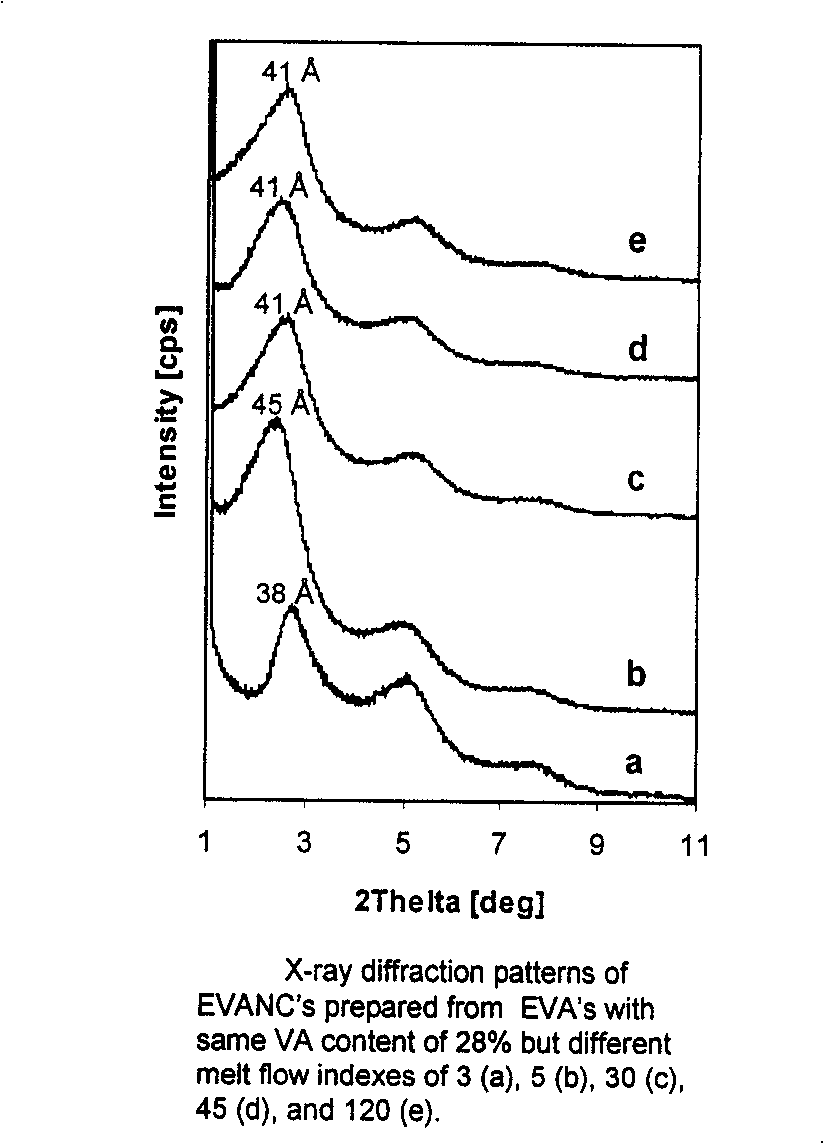

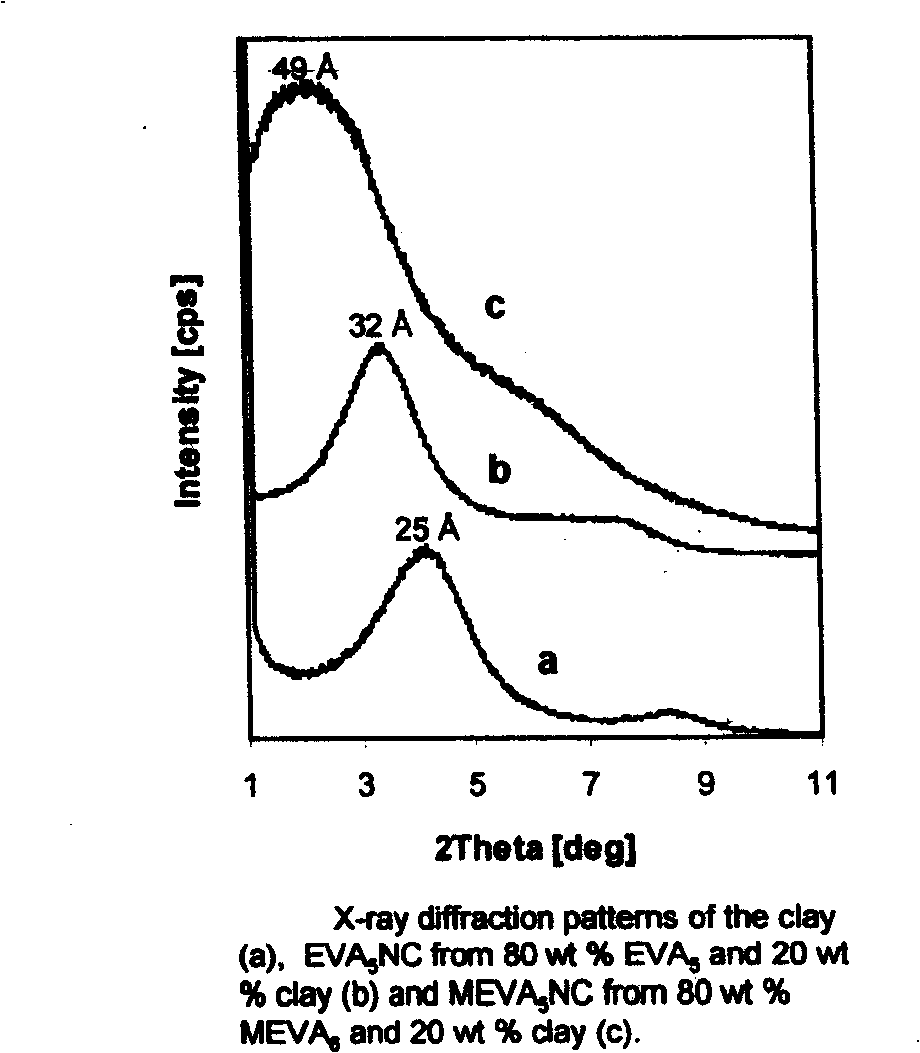

A manufacturing method for a kind of copolymer of laminated silicate and modified ethylene-vinyl acetate characterizes that the organic clay and polyethylene-vinyl acetate are melted and extruded out on the screw extruder according to the mass ratio of 1~10:99~90, the polyethylene-vinyl acetate contains vinyl acetate 5~28% and its melt index is 1~120g / 10min, extrusion temperature is 160-180 deg.C, screw speed is 160~300rpm, mean detention time is 2 ~ 10min, the interaction between EVA and the laminated silicates is promoted through the grafting of the EVA, then the nano-EVA is inserted between the layers of molten state silicates and the silicate layers begin swelling until they are scattered as single nano-layer state in the EVA-base, then the laminated structure is realized.

Description

technical field [0001] The invention relates to a preparation method of layered silicate modified ethylene-vinyl acetate copolymer. Background technique [0002] Nano layered silicate modified plastic is a kind of nanocomposite material prepared by intercalation compounding of layered silicate and plastic. This new type of nano-modified material perfectly combines the rigidity, dimensional stability and thermal stability of inorganic substances with the toughness and processability of polymers, showing excellent hybrid performance. Compared with ordinary plastics, this nano-modified plastic has high elastic modulus and strength, high barrier and flame retardancy, good thermal stability, etc. Nanoplastics have become a hotspot in the field of new materials research and development in recent years because they can be applied practically and have the most industrialization prospects in nanomaterial technology. [0003] Layered silicates are clay minerals widely distributed in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F210/02C08K3/34B29C47/38B29C48/395

CPCB29C2947/92704B29C2947/92561B29C2947/9259B29C2948/92561B29C2948/9259B29C2948/92704

Inventor 张发饶

Owner NINGBO NENGZHIGUANG NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com