Camera cover plate and camera

A camera and head cover technology, applied in image communication, optical filters, instruments for photography, etc., can solve the problems of affecting the shooting effect, loss of anti-fog, limited water absorption capacity of the hydrophilic film, etc., to ensure the camera effect, Guaranteed transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

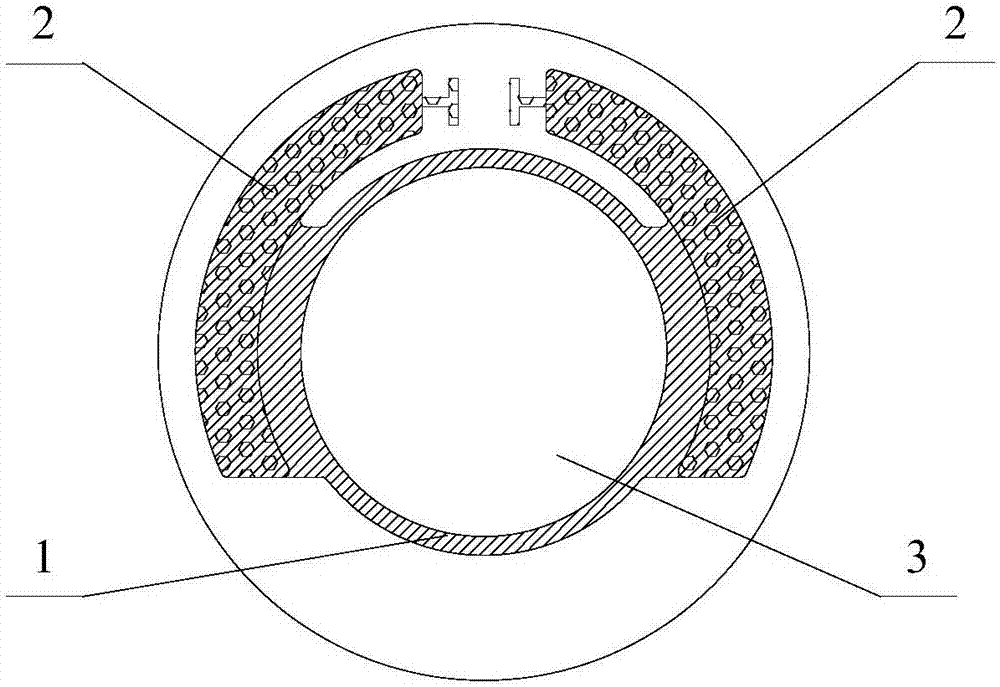

[0021] The core of this specific embodiment is to provide a camera cover, which can ensure the light transmittance of the camera cover and at the same time play an anti-fog effect without affecting the overall appearance of the camera. field problems.

[0022] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

[0023] The camera cover plate provided in this specific embodiment may include an indium tin oxide layer 1 and two conductive layers 2; wherein, the indium tin oxide layer 1 and the two conductive layers 2 are all arranged on the non-imaging area of the camera cover plate, and the two Each conductive layer 2 is in communication with the indium tin oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com