Antibacterial, mildewproof, self-cleaning, air cleaning and environment-friendly spray coating liquid and preparation and application thereof

An antibacterial, mildew proof, air purification technology, applied in antifouling/underwater coatings, coatings, alkali metal silicate coatings, etc. Difficulty and other problems, to achieve the effect of excellent stability, stable spray coating and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

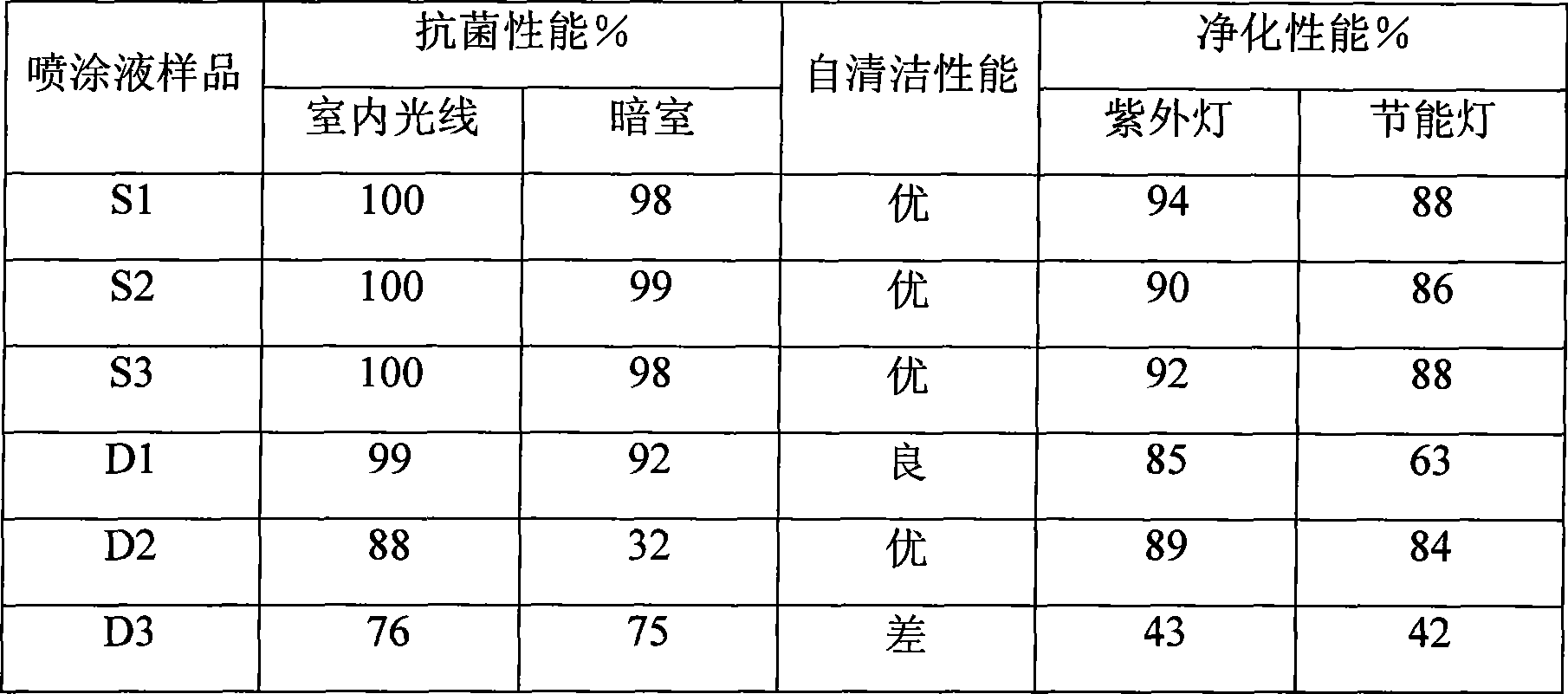

Examples

Embodiment 1

[0051] (1) Weigh 1.0 grams of titanium dioxide photocatalyst with a primary particle diameter of 18 nanometers and 1.0 gram of iron oxide photocatalyst powder with a primary particle diameter of 26 nanometers, add 150 grams of deionized water, and adjust the suspension with hydrochloric acid under stirring conditions The pH is 2.2, continue stirring to make photocatalyst sol.

[0052] (2) weigh 0.2 gram of silver nitrate, 0.2 gram of zinc chloride and 0.2 gram of copper sulfate, dissolve in 150 gram of deionized water, make the mixed solution of antibacterial and antifungal ion; 3.0 gram of montmorillonite and 3.0 gram of beta zeolite Add the molecular sieve powder into the mixed solution, stir for 2 hours, and obtain the antibacterial and antifungal ion slow-release modified adsorbent suspension through impregnation and ion exchange.

[0053] (3) Add 4.0 g of water glass and 1.0 g of sodium hexametaphosphate dropwise into the modified adsorbent suspension under stirring to fo...

Embodiment 2

[0059] (1) Weighing 2.0 grams of titanium dioxide photocatalyst with a primary particle diameter of 18 nanometers and 1.0 gram of iron oxide photocatalyst powder with a primary particle diameter of 12 nanometers, add 150 grams of deionized water, and adjust the suspension with sulfuric acid under stirring conditions The pH is 2.6, continue stirring to make photocatalyst sol.

[0060] (2) Weigh 0.1 gram of silver nitrate, 0.1 gram of zinc sulfate and 0.3 gram of copper chloride, and dissolve them in 150 gram of deionized water to make a mixed solution of antibacterial and antifungal ions; 3.0 gram of bentonite, 1.0 gram of active alumina powder and 1.0 gram of diatomaceous earth were added into the mixed solution, stirred for 1.5 hours, and obtained by impregnation and ion exchange, to obtain the antibacterial and antifungal ion slow-release modified adsorbent suspension.

[0061] (3) Add 5.0 g of water glass, 0.8 g of sodium hexametaphosphate and 0.5 g of sodium trimetaphospha...

Embodiment 3

[0067] (1) Weigh 3.0 grams of titanium dioxide photocatalyst with a primary particle size of 25 nanometers and 1.5 grams of iron oxide photocatalyst powder with a primary particle size of 32 nanometers, add 150 grams of deionized water, and adjust the suspension with nitric acid under stirring conditions The pH is 1.8, continue to stir to make photocatalyst sol.

[0068] (2) Weigh 0.3 grams of silver nitrate and 0.4 grams of copper sulfate, dissolve them in 150 grams of deionized water to make a mixed solution of antibacterial and mildew-proof ions; add 4.0 grams of bentonite, 2.0 grams of zeolite molecular sieve and 3.0 grams of silica gel to the mixed solution , stirred for 2.5 hours, and obtained the antibacterial and anti-mildew ion slow-release modified adsorbent suspension by impregnation and ion exchange.

[0069](3) Under the condition of stirring, 3.5 grams of water glass, 3.5 grams of magnesium aluminosilicate, and 2.0 grams of sodium hexametaphosphate were added dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com