Patents

Literature

38 results about "Industrial benefit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial Benefits. The H2O ENERGIZER is good business. It reduces scale buildup for cleaner, more efficient pipes. It increases flow, reduces maintenance, and eliminates the need for chemicals.

Antibacterial, mildewproof, self-cleaning, air cleaning and environment-friendly spray coating liquid and preparation and application thereof

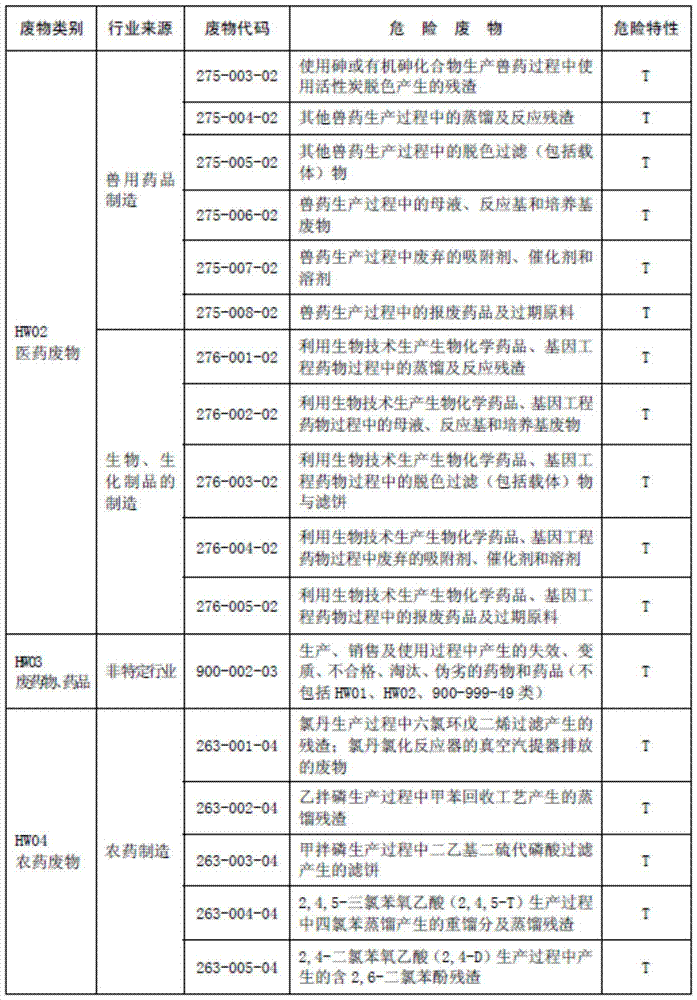

InactiveCN101544854AEasy to operateGood industrial efficiencyAntifouling/underwater paintsAlkali metal silicate coatingsFiltrationSpray coating

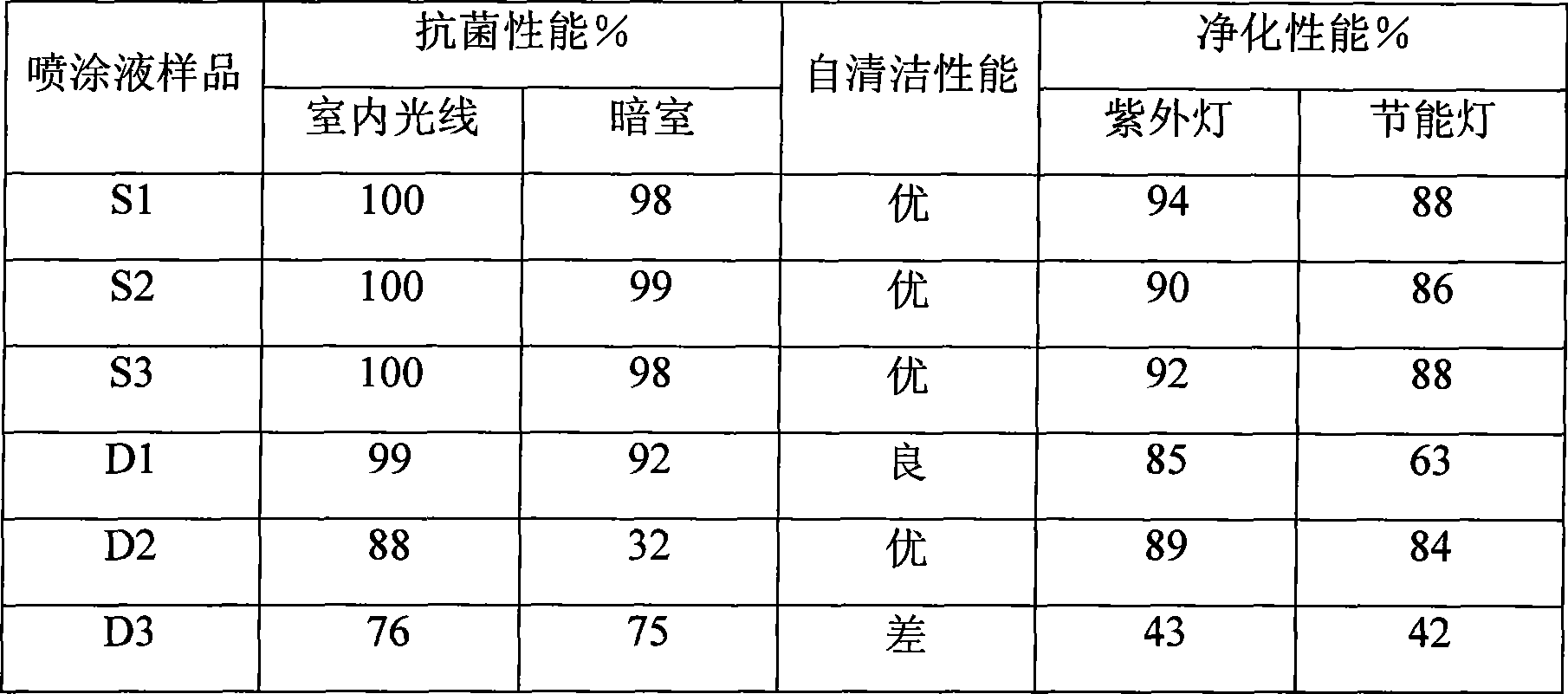

The invention relates to an antibacterial, mildewproof, self-cleaning, air cleaning and environment-friendly spray coating liquid, which comprises the following raw materials in percentage by weight: 0.5 to 20 percent of modified adsorbent, 0.1 to 10 percent of nano photocatalyst, 0.1 to 10 percent of binding and film forming agent, 0.01 to 5 percent of dispersant, and the balance of deionized water. The preparation method comprises that: photocatalyst powder is subjected to acid soluble treatment by inorganic strong acid and prepared into sol; adsorbent is immerged in a soluble salt mixture solution of antibacterial and mildewproof ions, subjected to ion exchange treatment and prepared into the modified adsorbent which is mixed with the binding and film forming agent and the dispersant; two types of solutions are mixed and a spray coating liquid precursor is obtained; and the antibacterial, mildewproof, self-cleaning, air cleaning and environment-friendly spray coating liquid is obtained after distributed processing and filtration. The antibacterial, mildewproof, self-cleaning, air cleaning and environment-friendly spray coating liquid can be applied to antibacterial, mildewproof and self-cleaning treatment of buildings or articles. The antibacterial, mildewproof, self-cleaning, air cleaning and environment-friendly spray coating liquid realizes synergetic and reinforced combination of three functions through the composition of multi-functional compositions, and the preparation method is simple and environment-friendly, has good industrial benefit and can realize industrialized production.

Owner:SHANGHAI VEASON TECH

Environment-friendly air freshener and preparation method thereof

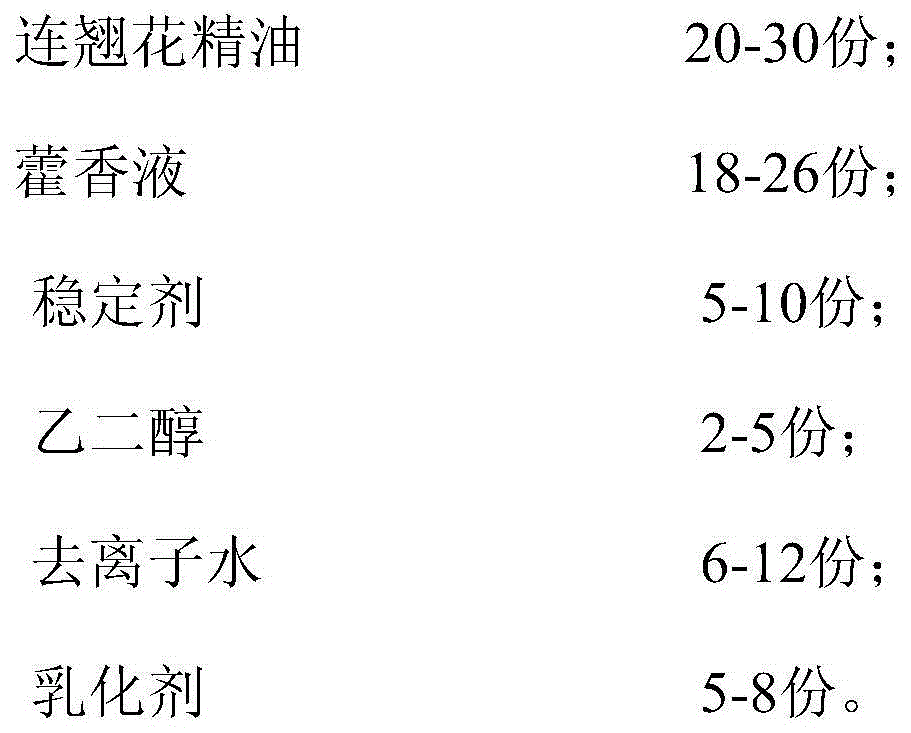

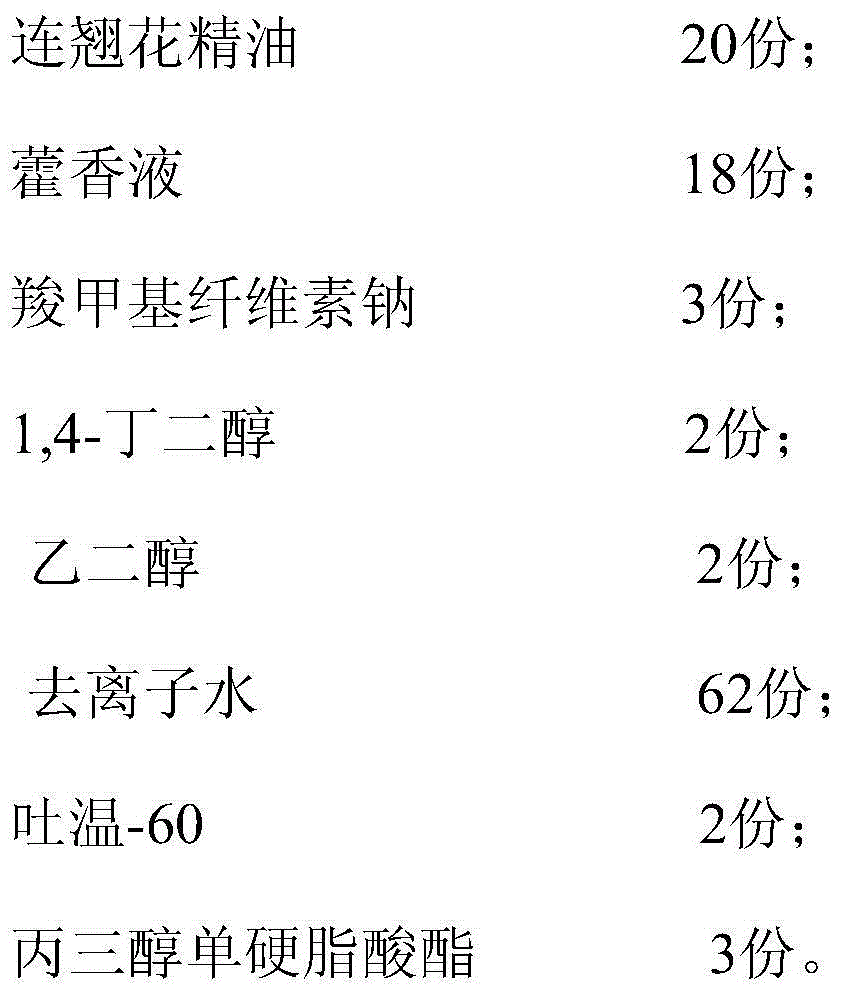

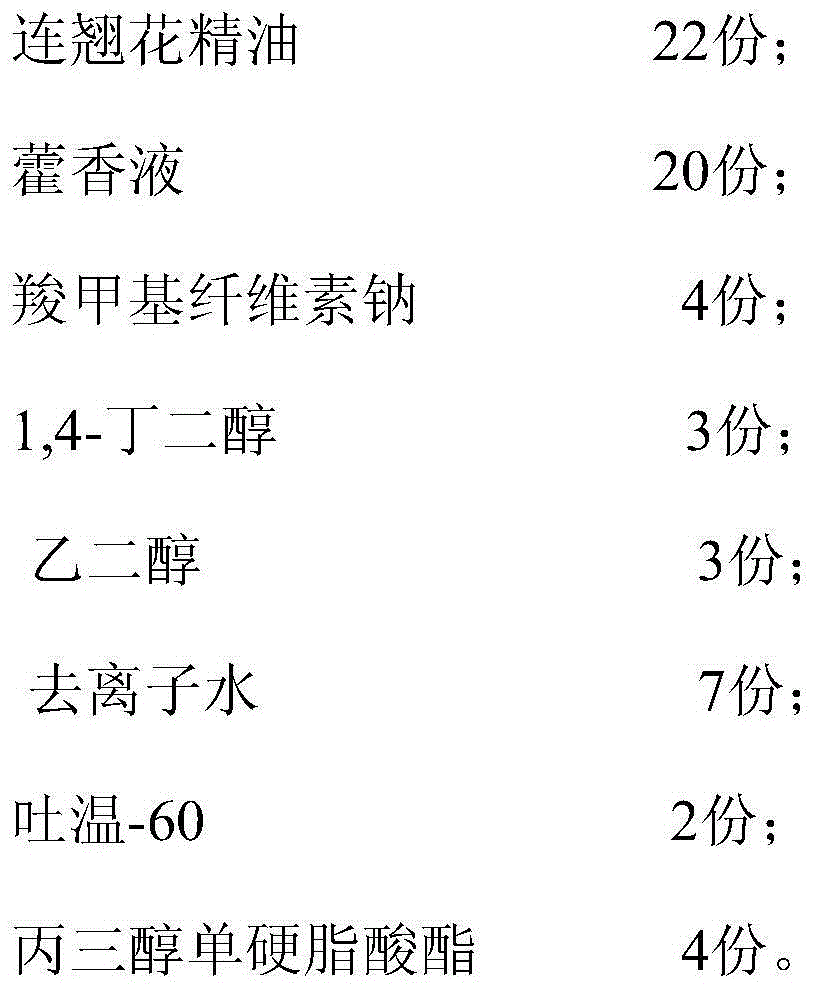

An environment-friendly air freshener belongs to the field of air purification. The environment-friendly air freshener provided by the invention employs an agastache rugosa extract and forsythia flower essential oil. When used by people, the environment-friendly air freshener cannot pollute the environment, has a certain environmental protection property and can achieve the purpose of refreshing and preventing diseases such as cold, pneumonia and enteritis; the environment-friendly air freshener doesn't contain synthetic chemical components such as chemical essences and chemical bactericides and thus cannot cause man-made pollution to the environment; the environment-friendly air freshener fits the needs of different crowds and different places, meets different requirements of various people and has a better development prospect and better industrial benefits; and plant components employed in the environment-friendly air freshener have relatively lower market prices, are used commonly and have remarkable antimicrobial effects, and the environment-friendly air freshener is lower in cost and has a high market development value.

Owner:SHANDONG YONGTAI CHEM GROUP

Extraction method of high-purity gold

The invention relates to the field of gold silver refining technique, more particularly to an extraction method of high-purity gold. The inventive extraction method of high-purity gold comprises the following steps of: 1) gold dissolution; 2) reagent preparation; 3) extraction; 4) acid adjustment; 5) reduction; 6) drying to obtain the product. The inventive extraction method has the following beneficial effects that: the inventive method avoids impurities in chemical reagents like ether entering into an organic phase with osylates, improves quality of high-purity sponge gold, saves one-step extraction process, avoids the conditions like complex operations and abominable working environment resulted from nitrate removal, and has good working conditions and outstanding environment; storage conditions of Na2So3 are not so strict as those of SO2. The invention is simple in operation and easy in control. Added value of industrial benefit of 99.999-99.9999% of gold is several times, even more than ten times than that of 99.99% of gold, thus meeting the industrial demands.

Owner:宋裕华

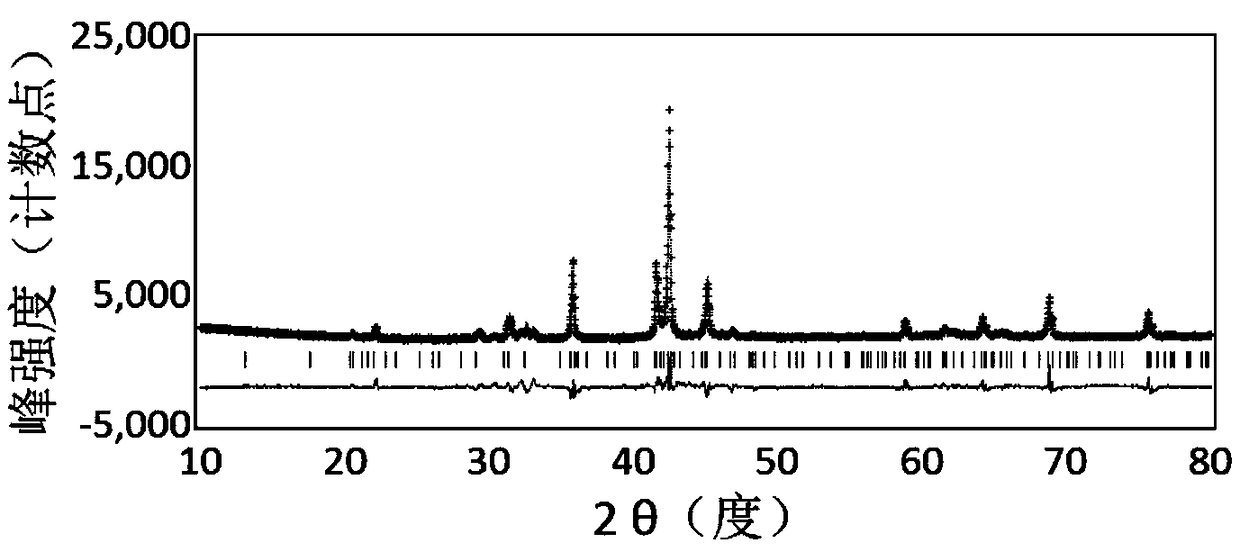

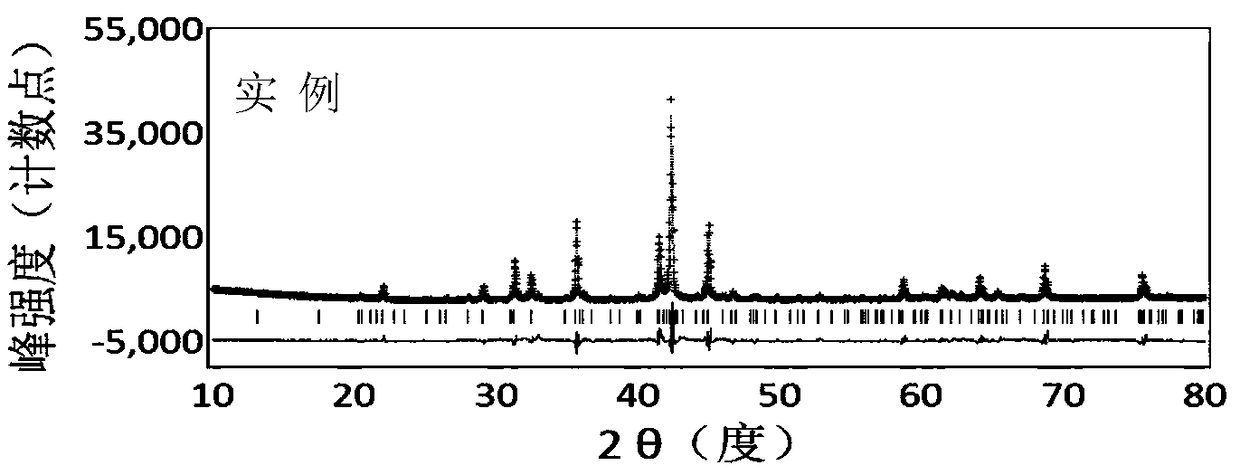

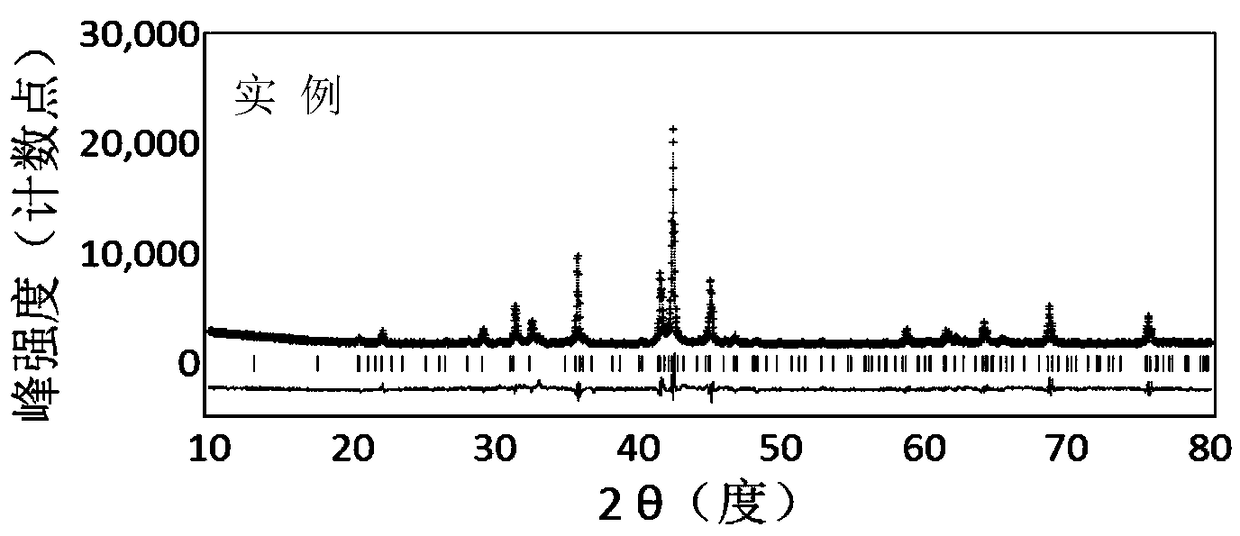

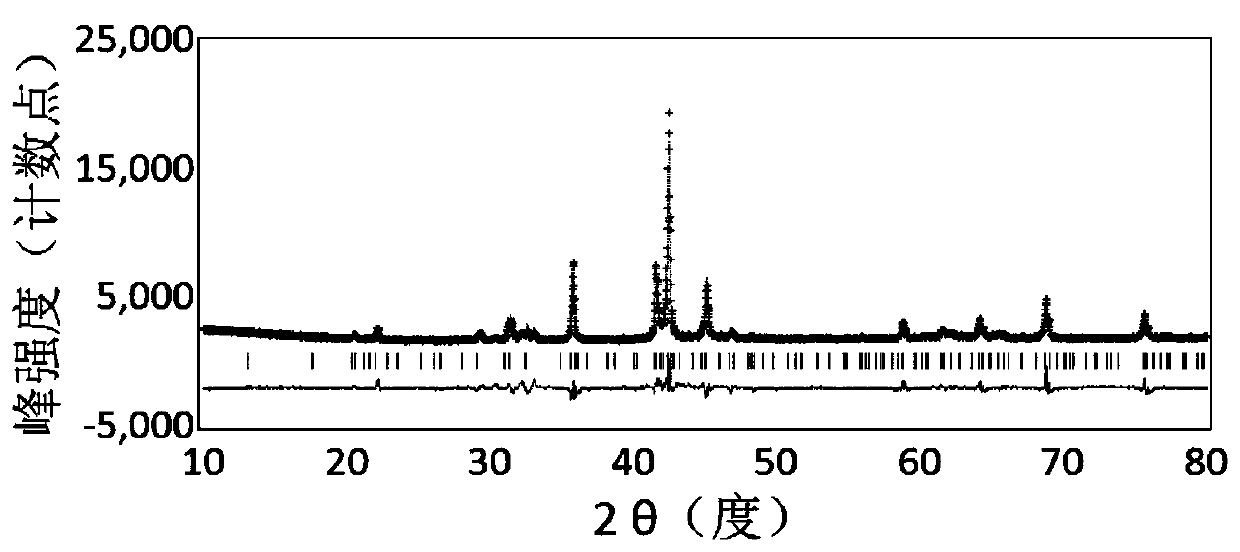

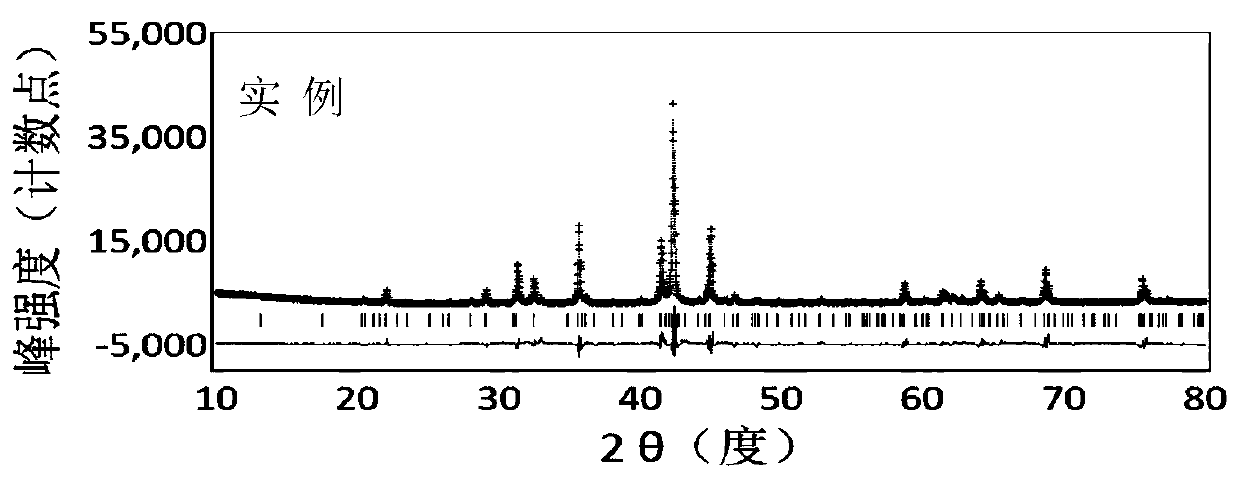

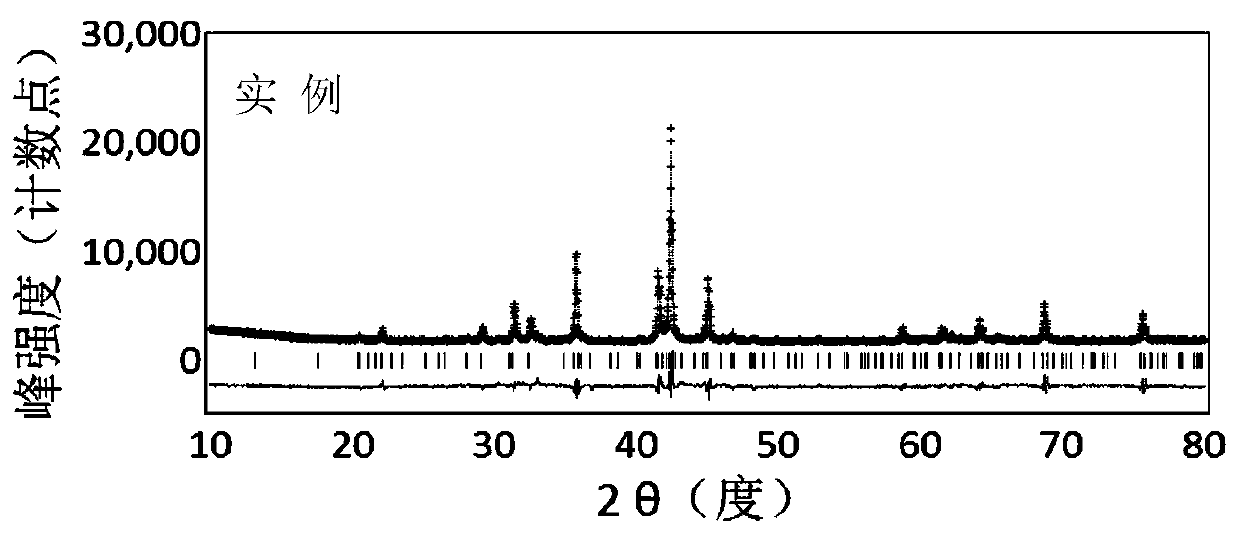

3R type AB4 hydrogen storage alloy as well as preparation method and application thereof

ActiveCN108977676AEasy to prepareEasy to operateCell electrodesNickel accumulatorsHigh rateElectrochemistry

The invention provides a 3R type AB4 hydrogen storage alloy. Nd, Gd, Y or Pr replaces La in La-Mg-Ni-series alloy, and Co, Mn or Al replaces Ni in the La-Mg-Ni-series alloy, and adding amount of ND, Gd, Y or Pr as well as Co, Mn or Al is controlled, so that comprehensive electrochemical properties of the alloy are improved to certain extent. According to the record of the embodiment, the 3R type AB4 hydrogen storage alloy has only a 3R type super-stack structure. High-rate discharge performance and cycling stability of the La-Mg-Ni-series alloy are improved. The invention further provides a preparation method for the 3R type AB4 hydrogen storage alloy, and the preparation method is simple, is convenient to operate, is easy in production condition control, is suitable for large-scale production, and industrial benefits are realized.

Owner:YANSHAN UNIV

Positive electrode material used for lithium ion secondary battery,, and manufacturing method thereof

The invention discloses a positive electrode material used for a lithium ion secondary battery, and a manufacturing method thereof. The positive electrode material used for the lithium ion secondary battery is shown as a general formula of LixNi1-y-zCoyMnzMgaTibAlcO2, wherein 0.95 =< x <= 1.30; 0 =< y <= 0.6; 0 =< z <= 0.8; y + z < 1; 0 =< a <= 0.1; 0 =< b <= 0.1; and 0 =< c <= 0.1. A positive electrode active material used for a lithium nickel cobalt and manganese composite oxide lithium secondary battery capable of giving extremely excellent cycle characteristics to the lithium secondary battery, a method for manufacturing the positive electrode active material by an industrial benefit method and the lithium secondary battery applying the positive electrode active material particularly the lithium secondary battery with the excellent cycle characteristics are provided by the invention.

Owner:NANTONG RESHINE NEW MATERIAL

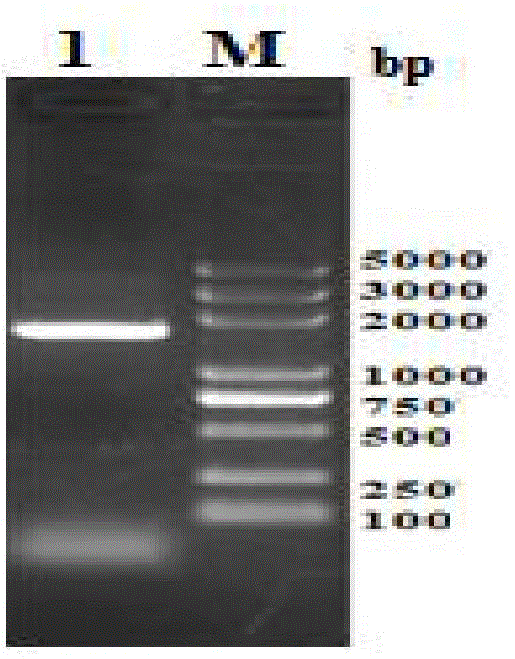

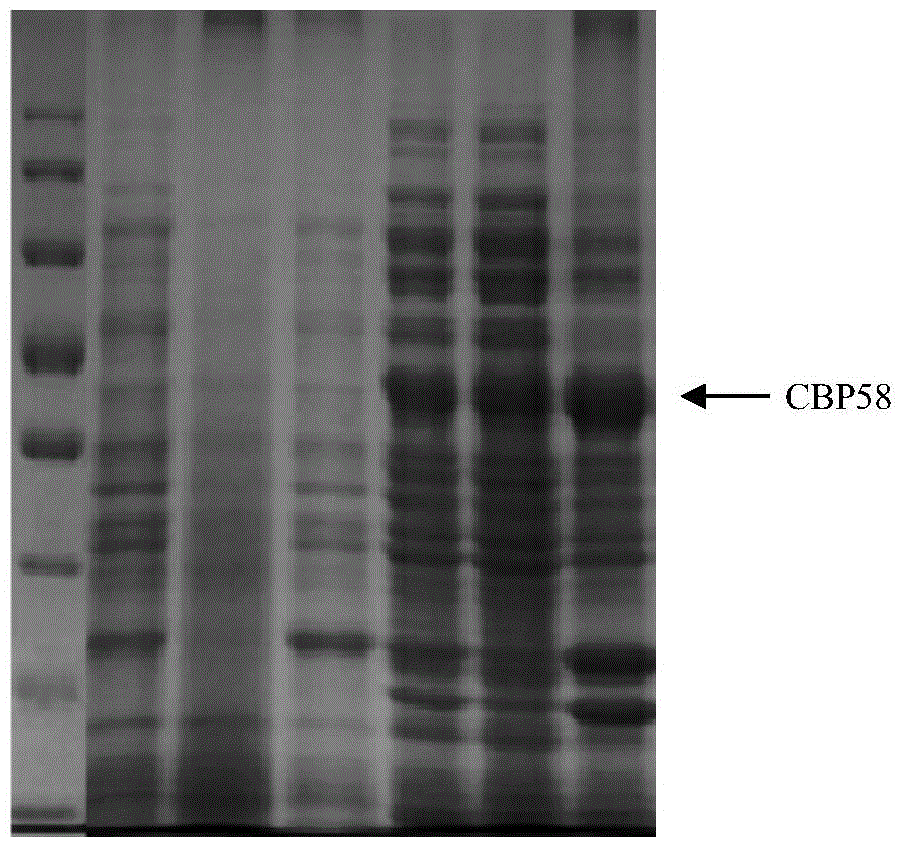

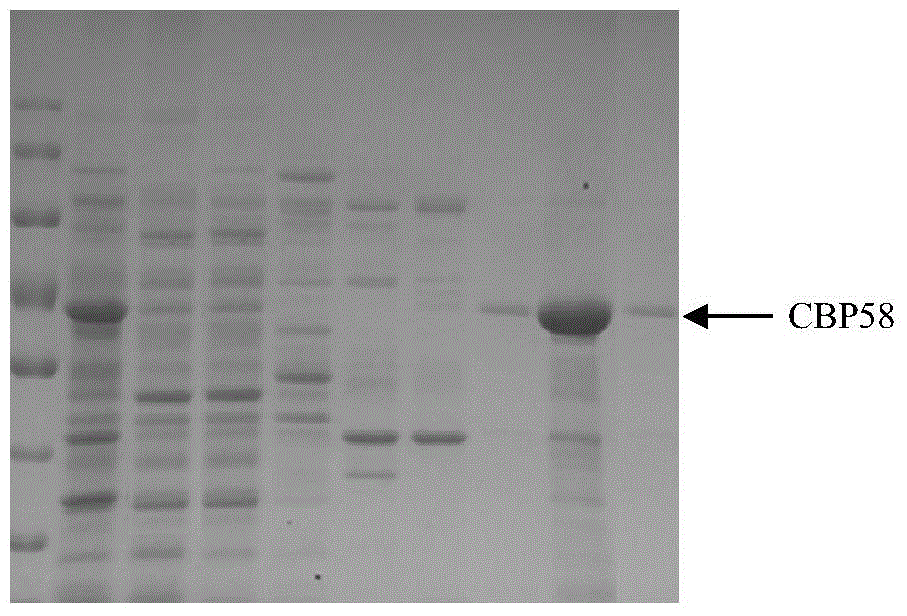

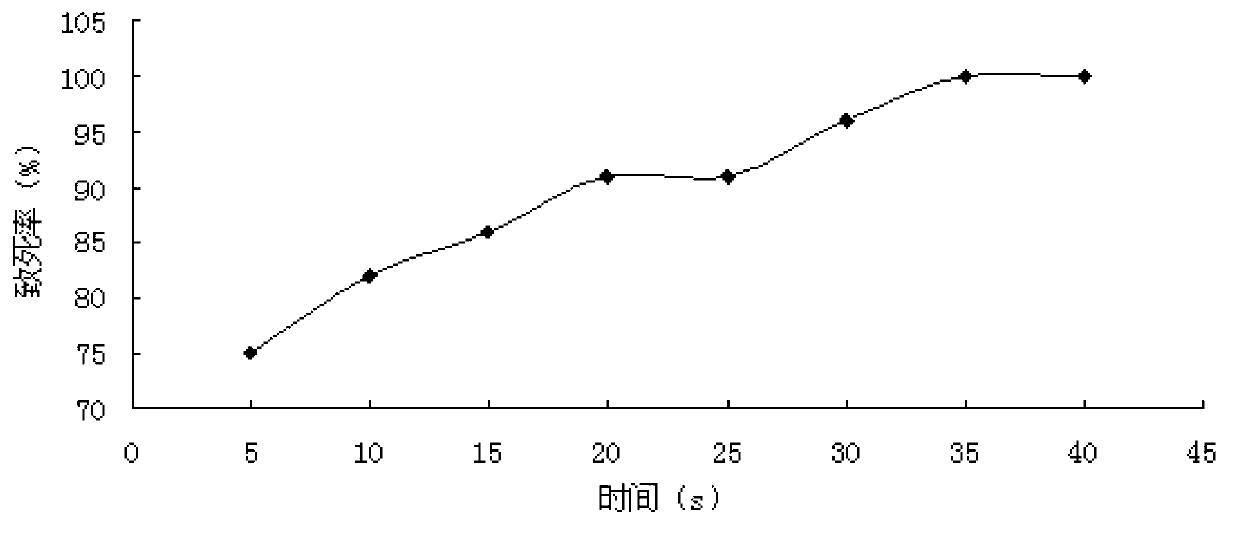

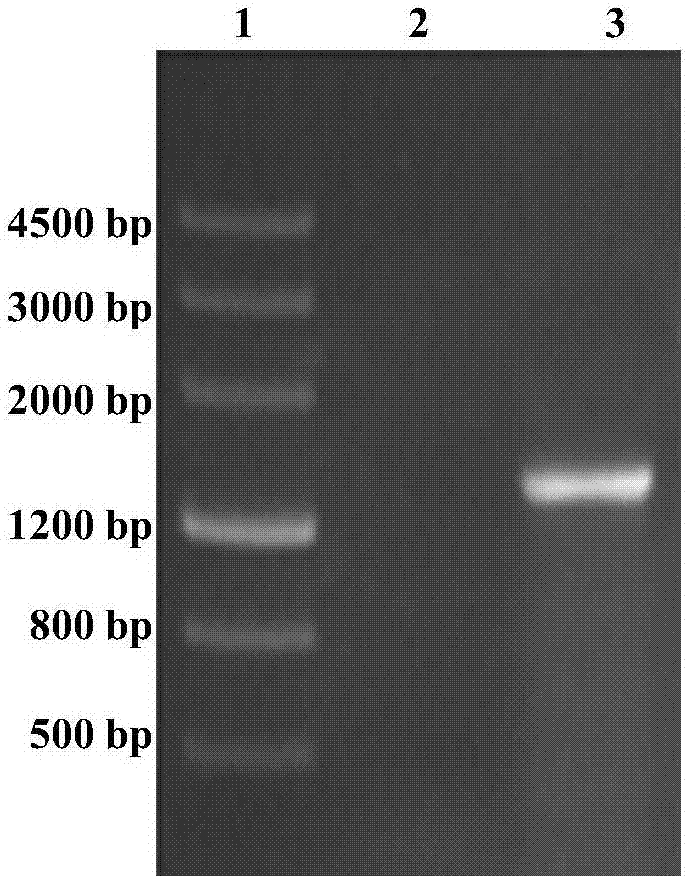

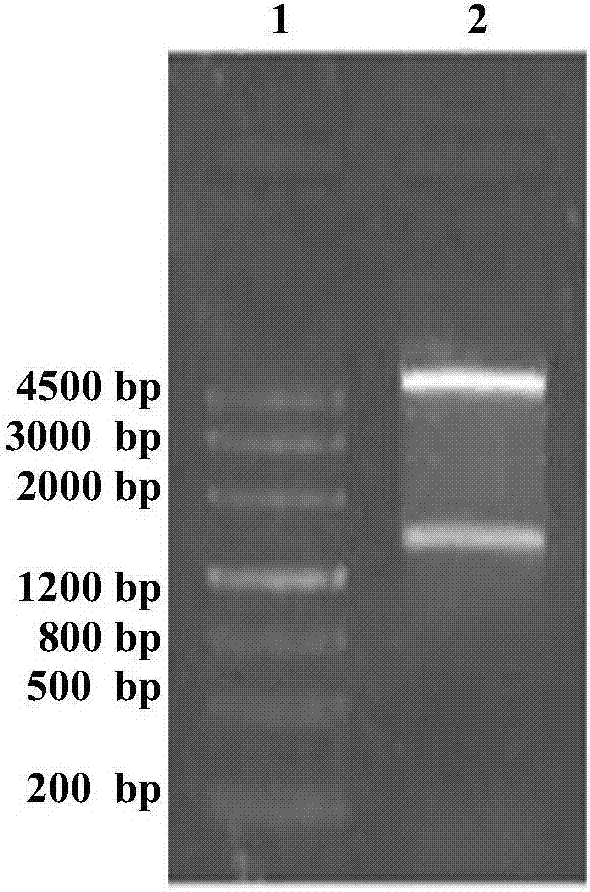

Chitin binding protein CBP58, and encoding gene and application thereof

InactiveCN104877018AHigh activityEasy to makeMicroorganism based processesFungicidesAntifungalHigh activity

The invention relates to a chitin binding protein CBP58, and an encoding gene and an application thereof, and belongs to the technical field of gene engineering. The encoding gene of the chitin binding protein CBP58 is cloned from a strain pseudoalteromonas sp.DL-6 for the first time; and a high-activity expression product is obtained by construction of a prokaryotic expression vector and imidazole elution. The preparation process is simple; a simple and convenient method is provided for subsequent research on the chitin protein CBP58; the chitin protein CBP58 is low in production cost and easy to store, has a chitin binding function, is applied to purification and auxiliary identification of chitin, has a good inhibiting effect on aspergillus niger (Aspergillus niger) and cytospora mandshurica miura (Cytospora mandshurica miura), has a potential biological control function and has wide application value; a novel research direction is provided for research and development of anti-fungal medicines in the field of agriculture; and great industrial benefits and economic value are generated.

Owner:DALIAN UNIV

Aspergillus oryzae strain and method for producing fungal alpha-amylase by liquid-state fermentation of aspergillus oryzae strain

The invention discloses an aspergillus oryzae strain MFA-AO-3 with the collection number of CGMCC No. 6834 and a method for producing fungal alpha-amylase by taking the aspergillus oryzae strain as the strain for liquid-state fermentation. The aspergillus oryzae strain can be used for realizing high yield of the fungal alpha-amylase; and the method for producing the fungal alpha-amylase by liquid-state fermentation of the aspergillus oryzae strain, disclosed by the invention, comprises the following step: on the basis of taking the aspergillus oryzae strain as the strain, performing fermentation and culture at the stirring rate of 500-1000 rpm (revolutions per minute) under the conditions that the ventilation quantity calculated by feed liquid volume is as follows: the air volume per minute is 1:(1.5-2) and the dissolved oxygen accounts for 20-25%, thereby preparing the fungal alpha-amylase. According to the method for producing the fungal alpha-amylase, disclosed by the invention, the enzyme production level is high and the industrial benefits are great.

Owner:意葆(上海)生物科技有限公司

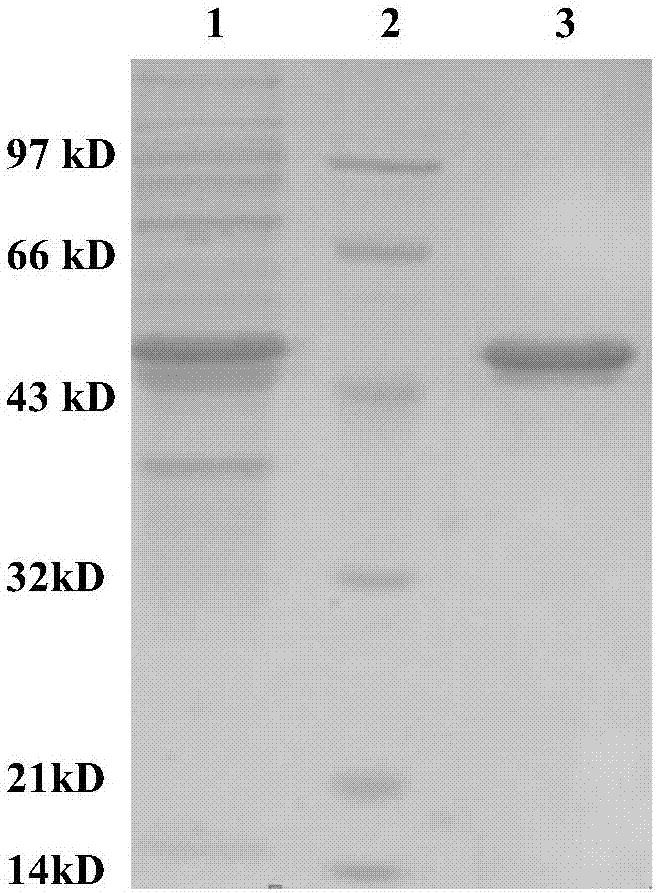

Chitin binding protein Bt-CBP, and coding gene and preparation method and application thereof

InactiveCN107098953AHigh activityEasy to makeBiocideMicrobiological testing/measurementEscherichia coliFusarium oxysporum

The invention relates to a chitin binding protein Bt-CBP, and a coding gene and a preparation method and an application thereof and belongs to the technical field of gene engineering. The coding gene of the chitin binding protein is cloned from bacillus thuringiensis for the first time, and an expression product with high activity is obtained by constructing a prokaryotic expression vector and expressing the gene in escherichia coli. The chitin binding protein Bt-CBP has a good inhibiting effect on cucumber gray mold and fusarium oxysporum. In addition, the chitin binding protein Bt-CBP has a synergic effect on catalytic activity of chitin ChiB, can promote ChiB to efficiently degrade chitin, can remarkably enhance the inhibiting effect of ChiB on cucumber gray mold, has a good biological control function, provides a novel research direction for research of antifungal drugs in the agricultural field, has wide application value and generates a huge industrial benefit and economical value.

Owner:NANKAI UNIV

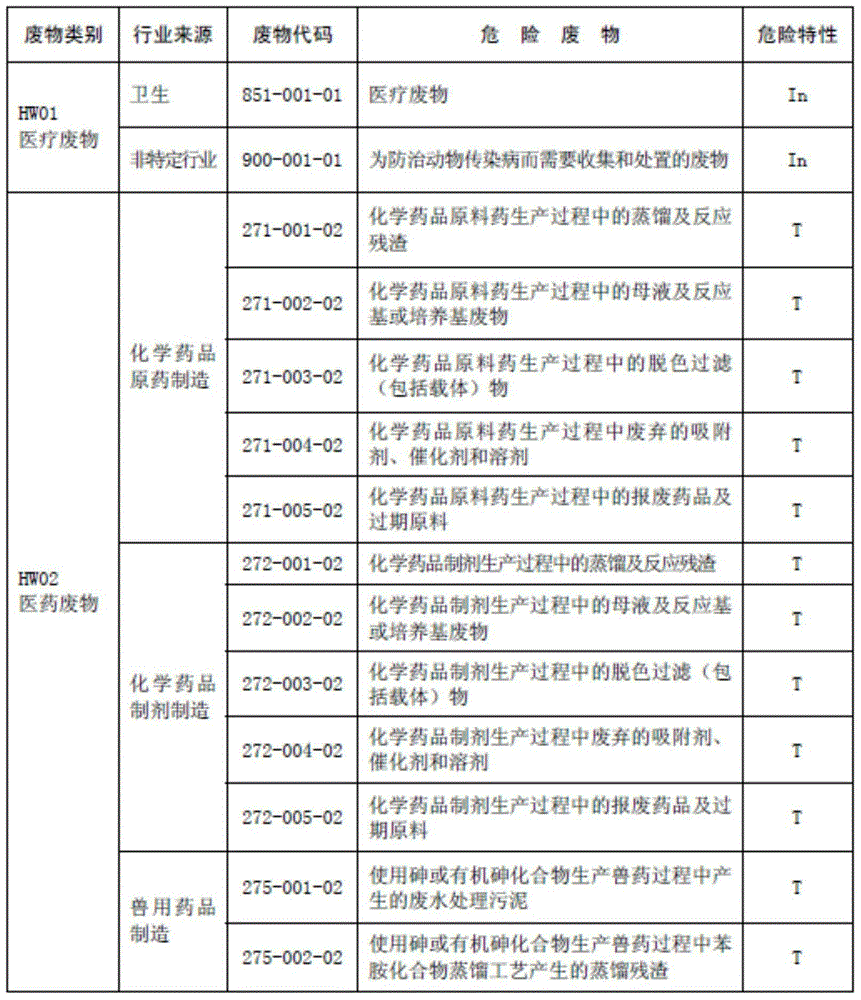

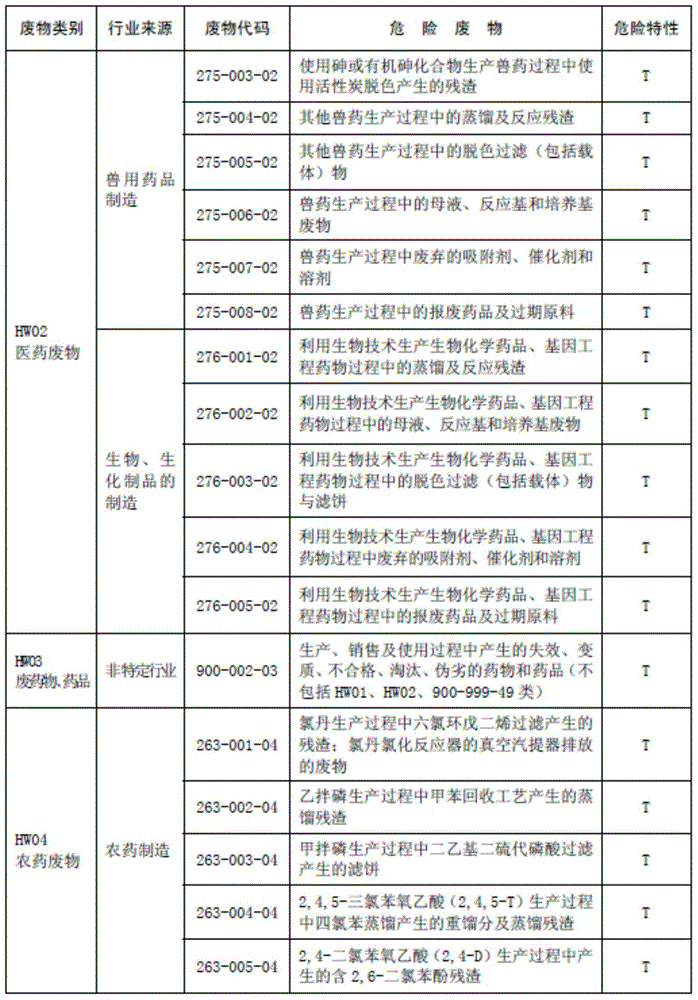

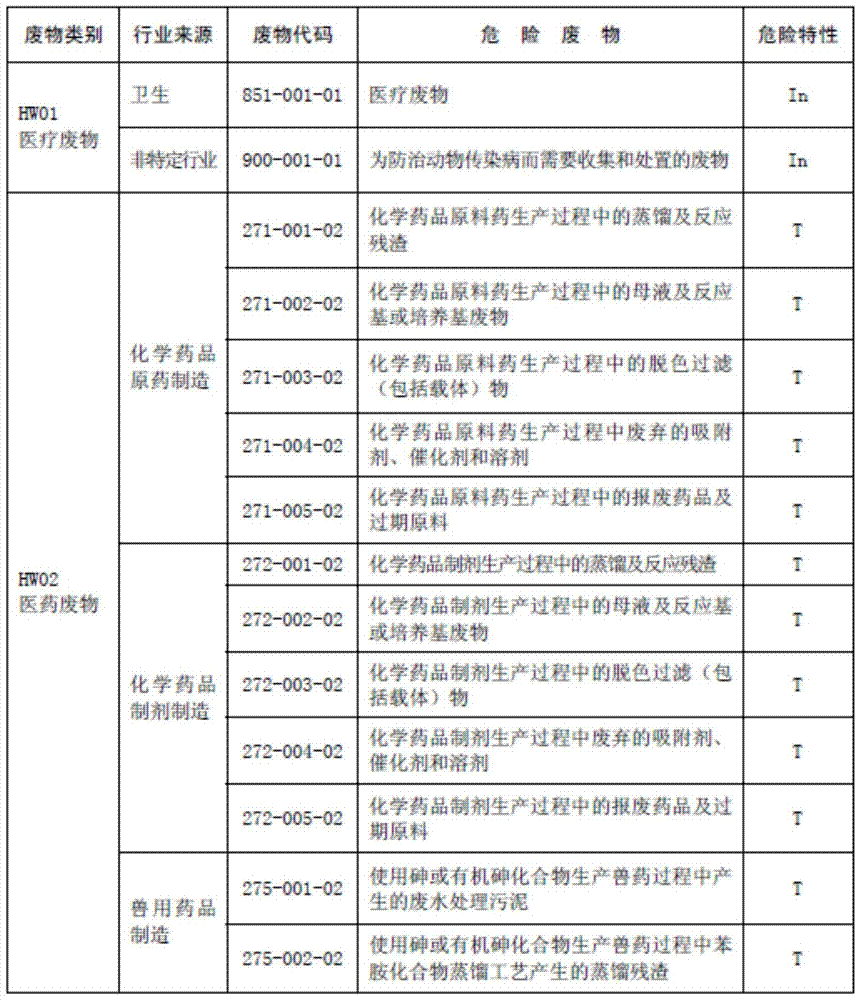

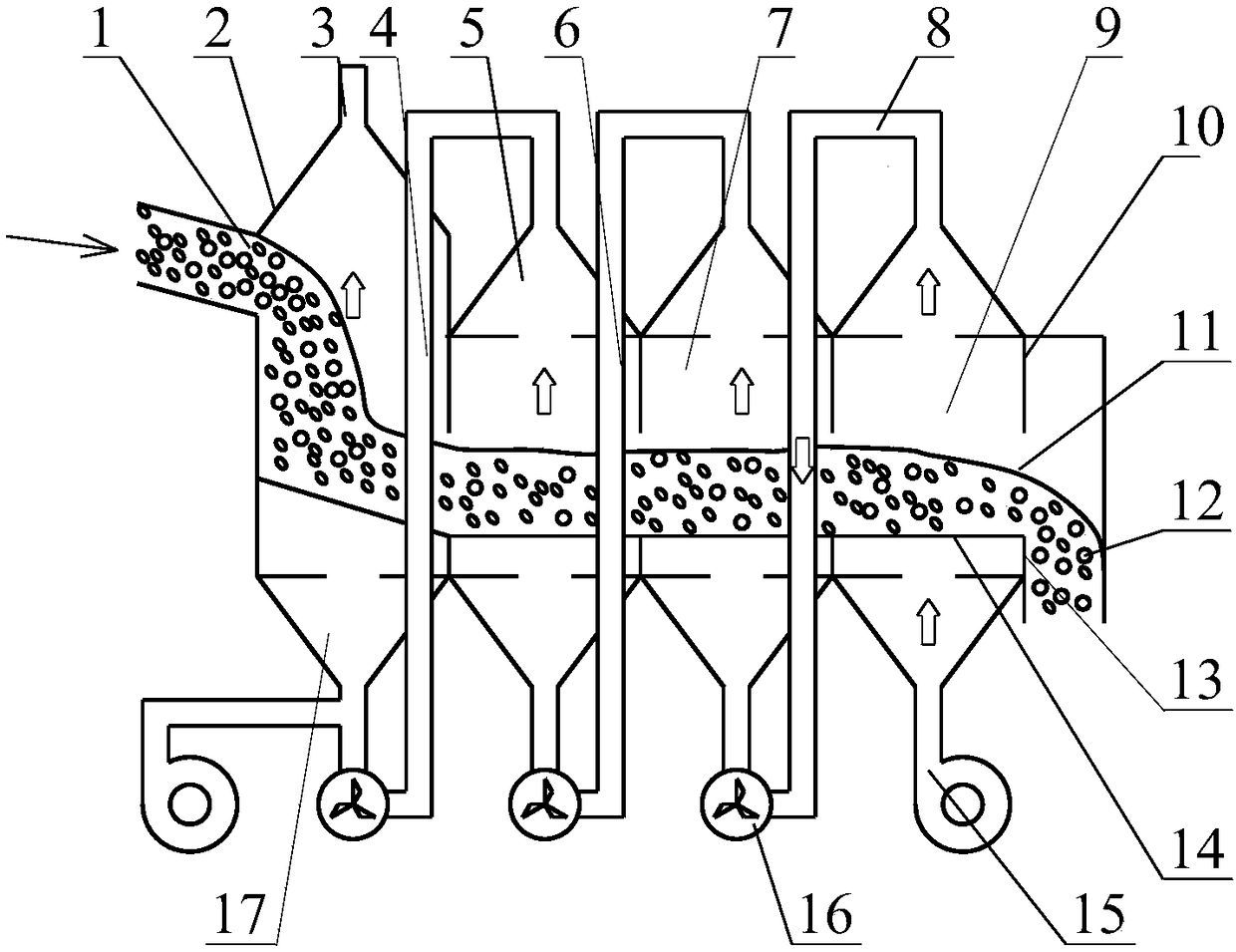

Synchronous recycling method with high-calorific-value dangerous waste and municipal solid waste

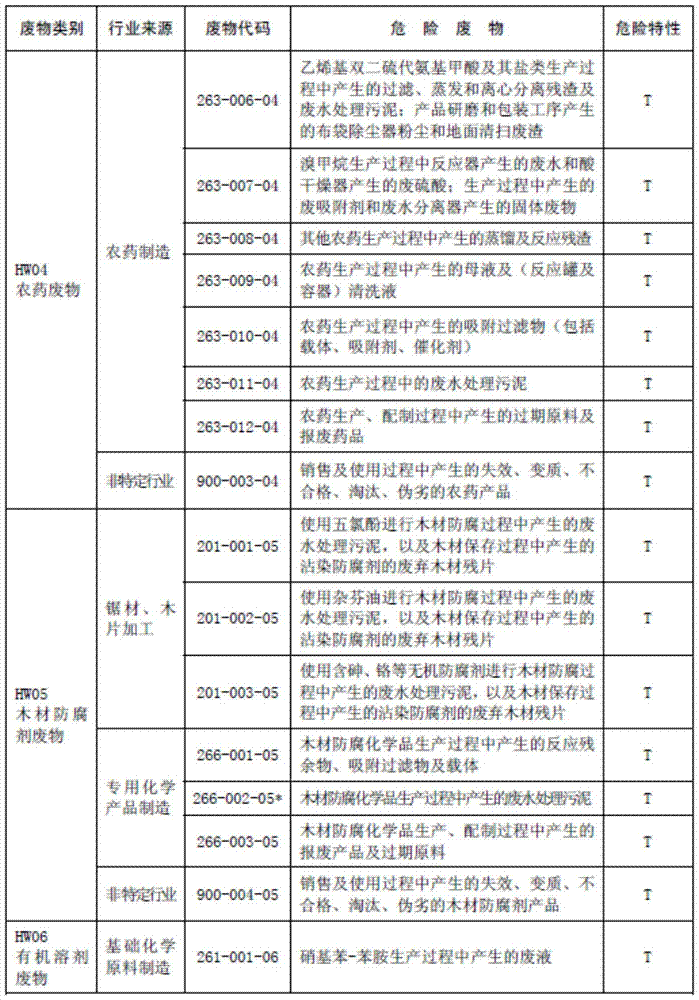

ActiveCN104818064ALower viscosity coefficientHigh compressive strengthGaseous fuelsCeramicwarePower stationMass ratio

The invention provides a synchronous recycling method with high-calorific-value dangerous wastes and municipal solid wastes, which includes following steps: (1) mixing dewatered sludge, building solid wastes and fuel residues from power plants according to the mass ratio of (3-5):(2-4):(1-3), and aging the mixture for 20-30 days to obtain a stacked material; (2) mixing dangerous wastes and homogenizing and crushing the dangerous wastes, anaerobic pyrolyzing the dangerous wastes at higher than 1500 DEG C for 1-2 h to obtain pyrolyzed gas and pyrolyzed residue, performing plasma gasification to the pyrolyzed gas at a temperature of higher than 5000 DEG C for 5-10 s to obtain artificial flammable gas; (3) water-quenching the pyrolyzed residue and mixing the pyrolyzed residue with the stacked material according to the volume ratio of 1:(60-80) uniformly, and performing granulation to obtain raw material granules; and (4) sintering and moulding the raw material granules and cooling the moulded granules to obtain a finished product of ceramic granules. The synchronous recycling method can reduce exploitation of primary energy resource and primary resources, can reduce damage on natural environment, is beneficial to maintenance and optimization of original ecologic system and can increase industrial benefit.

Owner:山东兴硕环保科技有限公司 +1

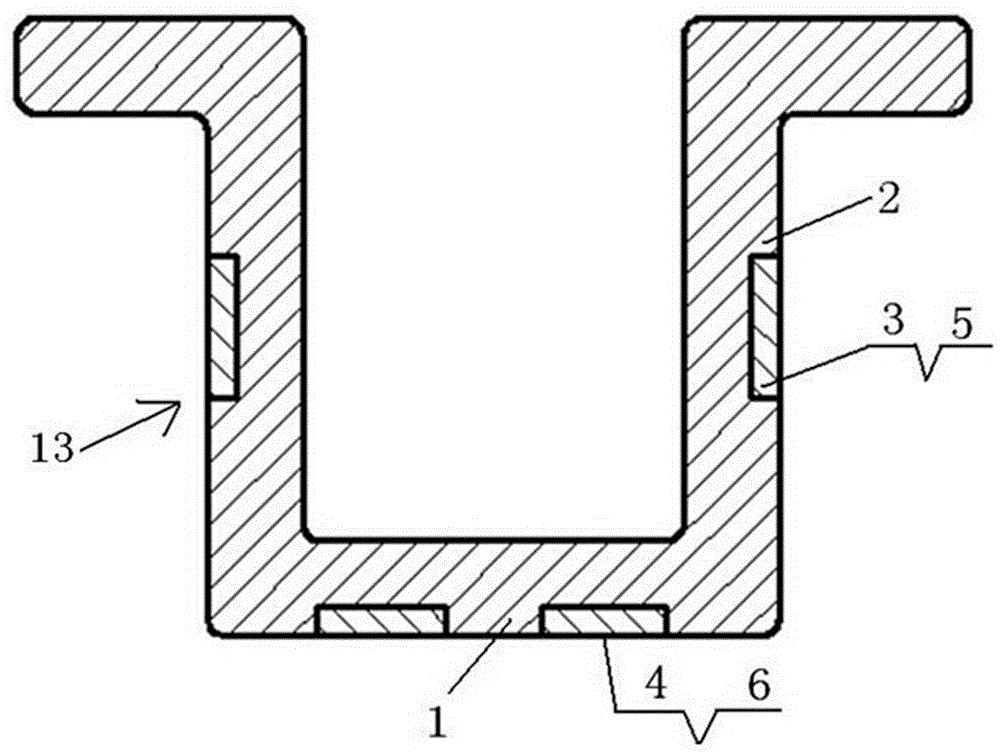

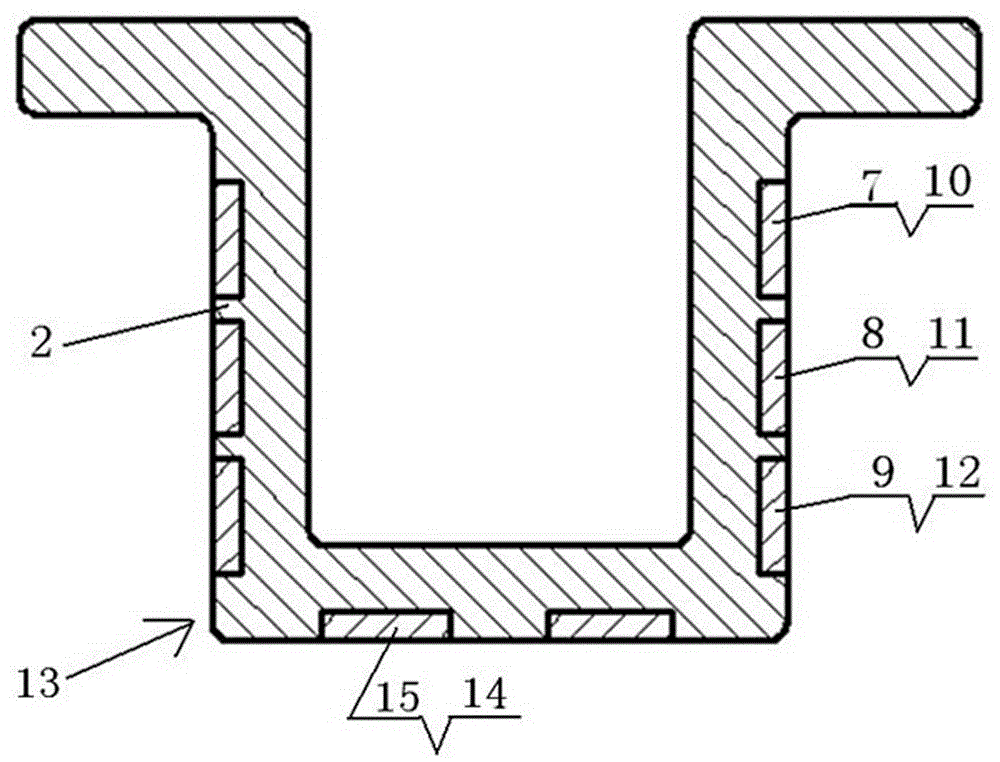

Vacuum skull furnace crystallizer and preparation method thereof

InactiveCN104525925AHigh strengthReduce distortionMolten metal conveying equipmentsMetallurgyIndustrial benefit

The invention provides a vacuum skull furnace crystallizer and a preparation method thereof. The vacuum skull furnace crystallizer comprises a crucible body and is characterized in that a third annular slot, a fourth annular slot and a fifth annular slot are formed in the waist part of the crucible body; a third copper alloy ring, a fourth copper alloy ring and a fifth copper alloy ring are respectively arranged in the third annular slot, the fourth annular slot and the fifth annular slot and are integrated with the crucible body by the brazing method; a sixth annular slot in which a sixth copper alloy ring is arranged is formed in the bottom part of the crucible body and is integrated with the crucible body by the brazing method. The vacuum skull furnace crystallizer is difficultly deformed, long in service life, and low in cost of device repair, so that the industrial benefit is increased.

Owner:沈阳和泰冶金设备有限公司 +1

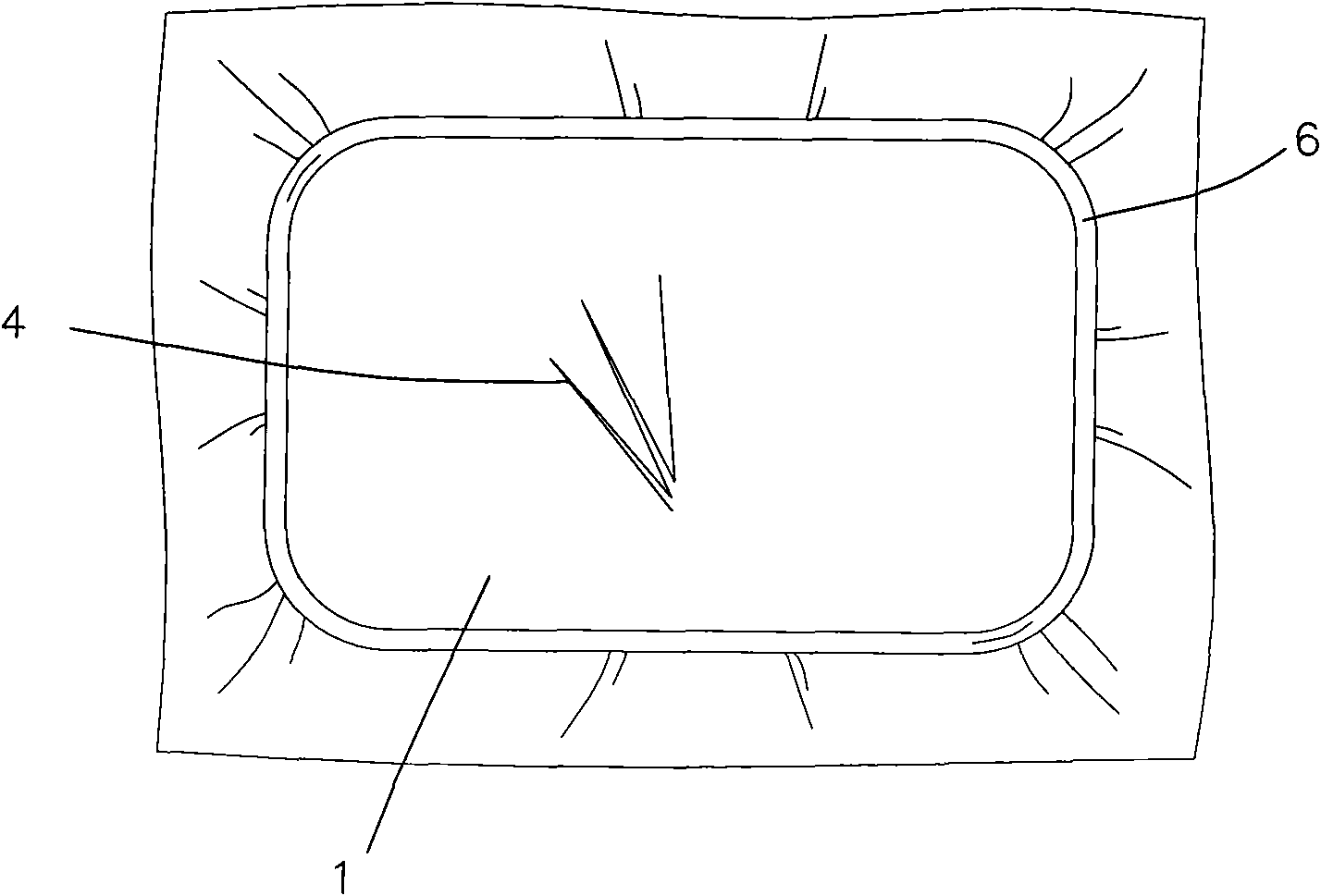

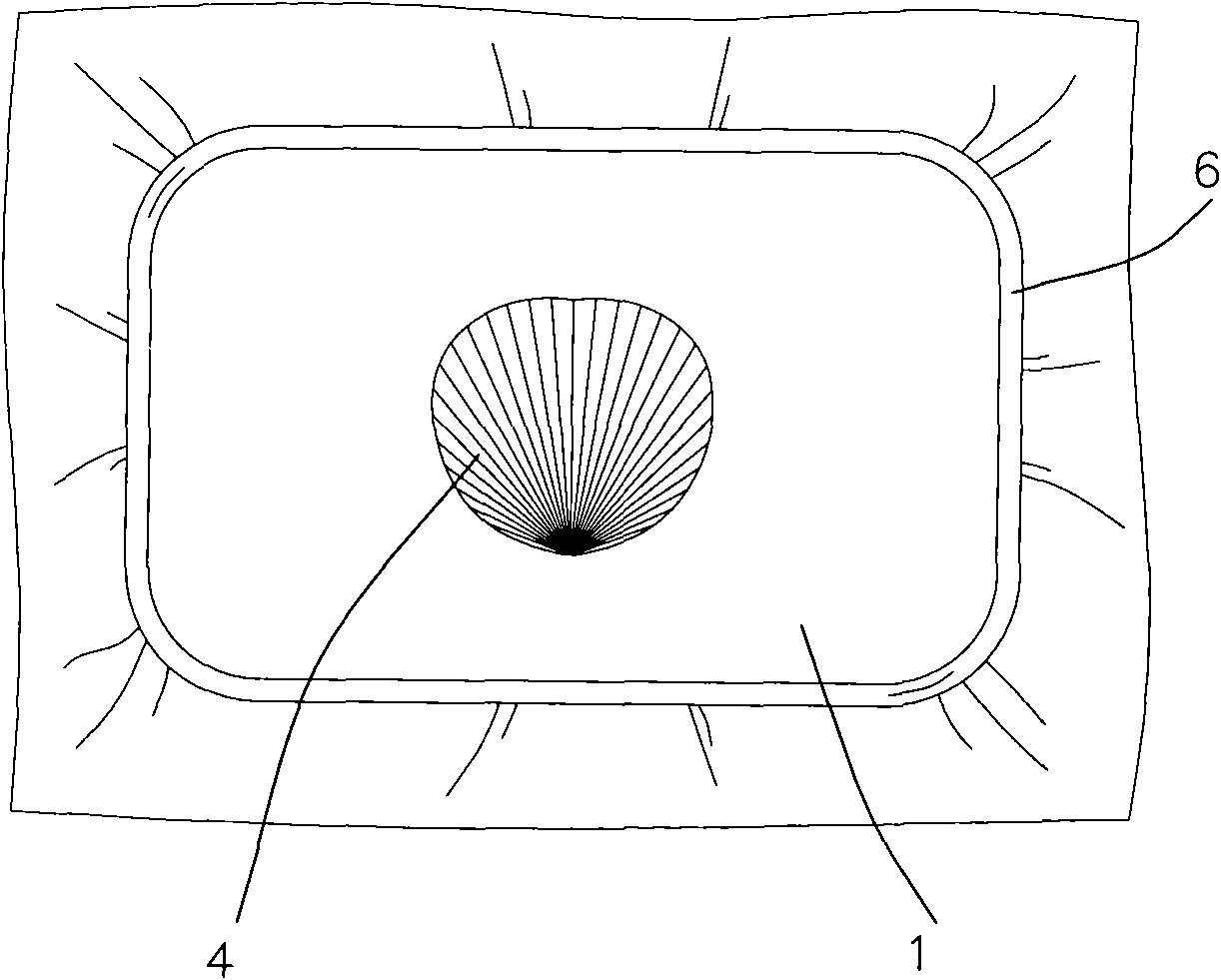

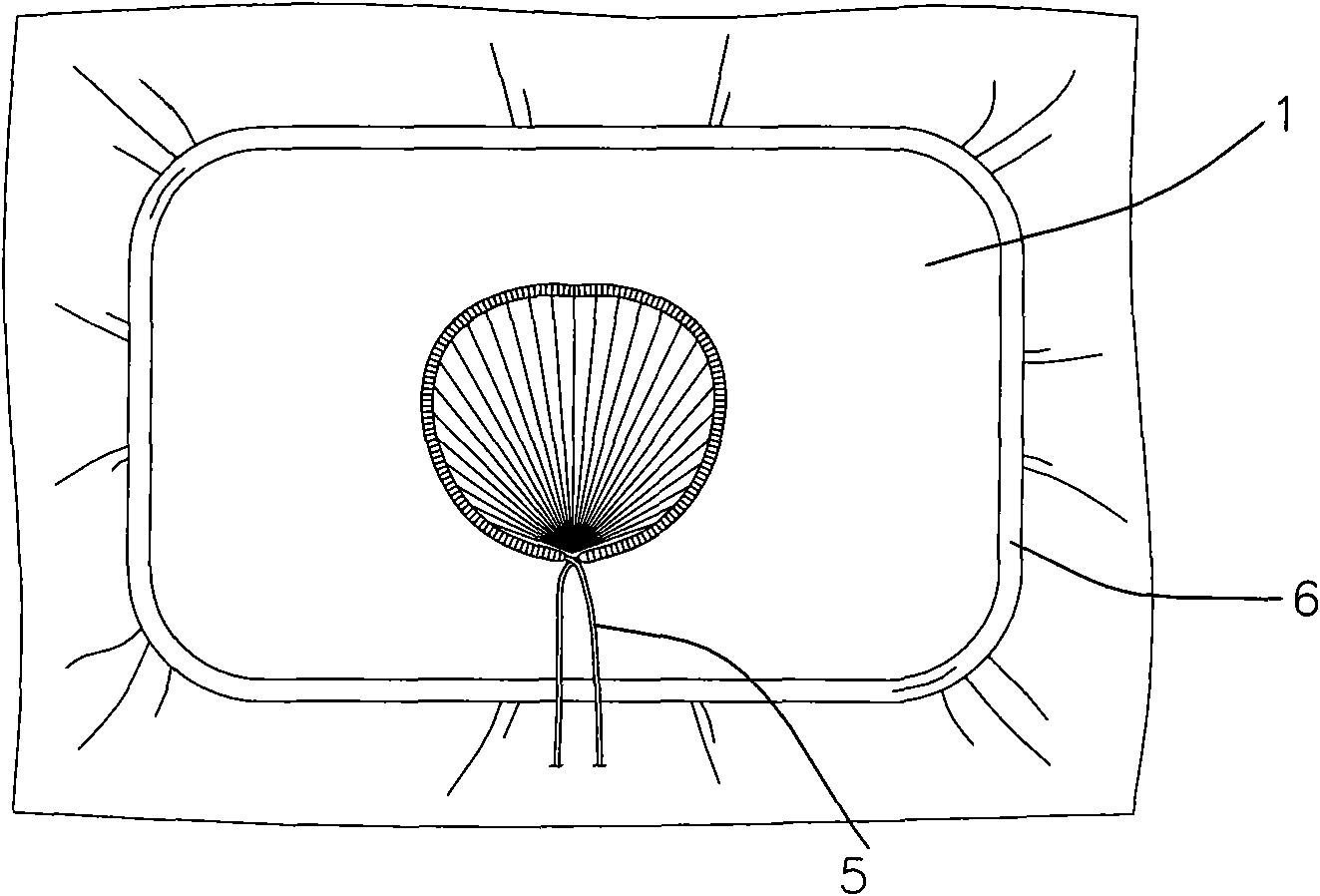

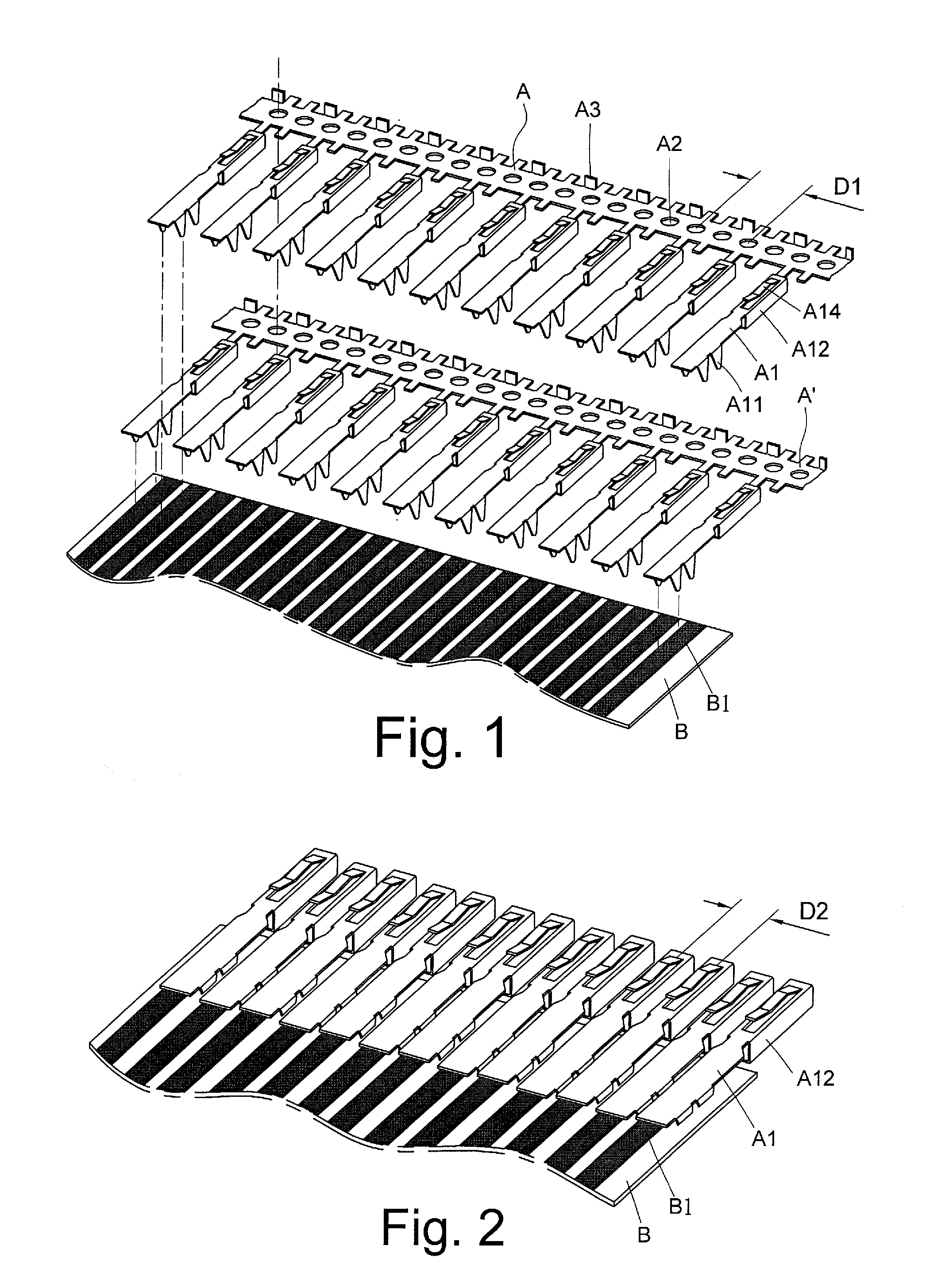

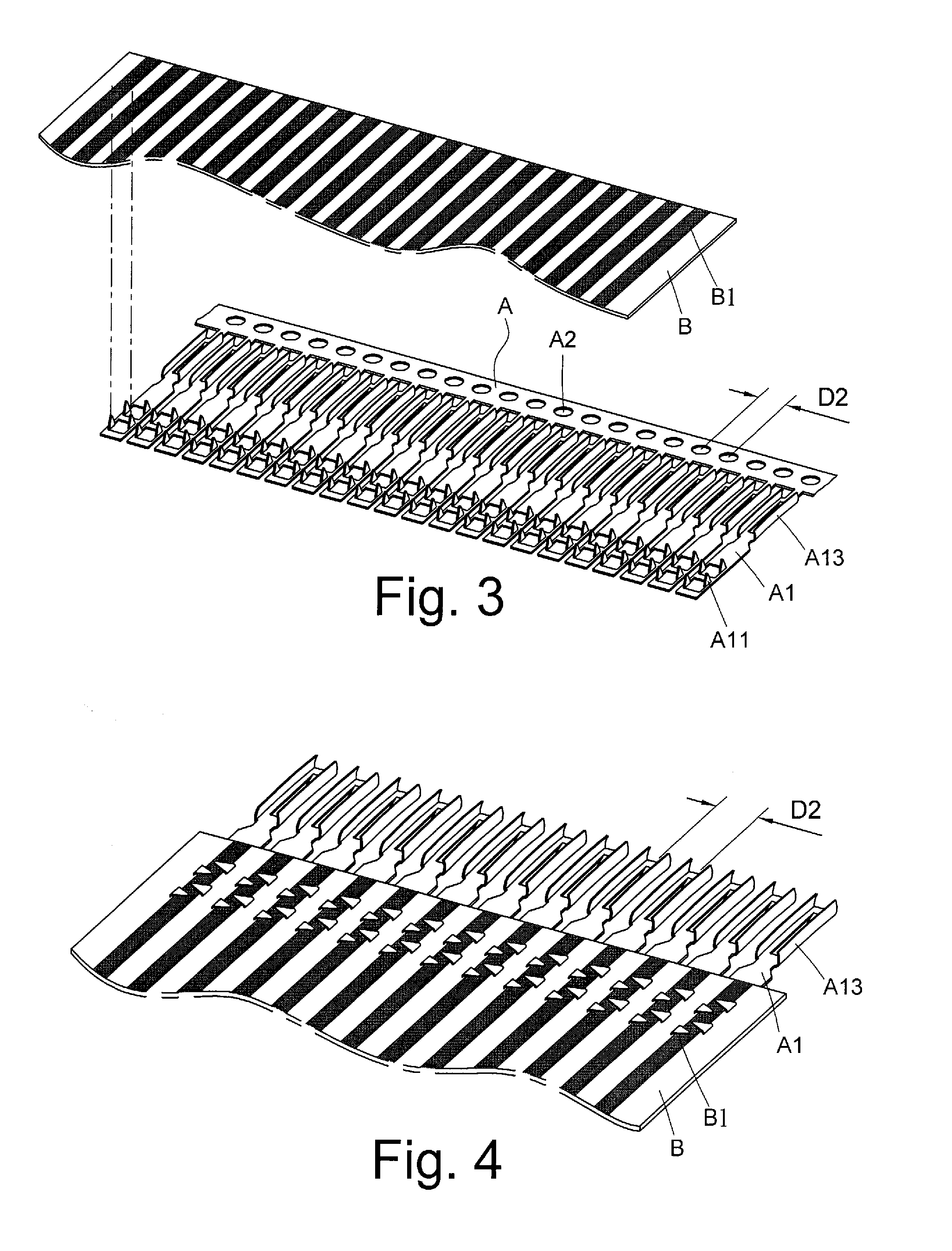

Suite of modular three-dimensional embroidery article and manufacturing method thereof

The invention relates to a suite of a modular three-dimensional embroidery article and a manufacturing method thereof. The suite is automatically processed in combination with an electronic embroidery sewing machine. The suite comprises a cloth serving as a substrate, a line material, accessories serving as functional ornaments, a memory device and an accommodating device, wherein the line material is used for embroidering the profile of the embroidery article; the memory device stores the pattern and the manufacturing process of the embroidery article; and the accommodating device is used for accommodating and integrating the members. During the manufacturing, the data of the memory device is read by using the electronic embroidery sewing machine, each component is accordingly manufactured, each finished component is laminated and combined and the components are ornamented so as to manufacture the three-dimensional embroidery article. The suite and the manufacturing method have simple and quick manufacturing and volume production and can maintain the industrial benefit of high processing quality.

Owner:台弟工业股份有限公司

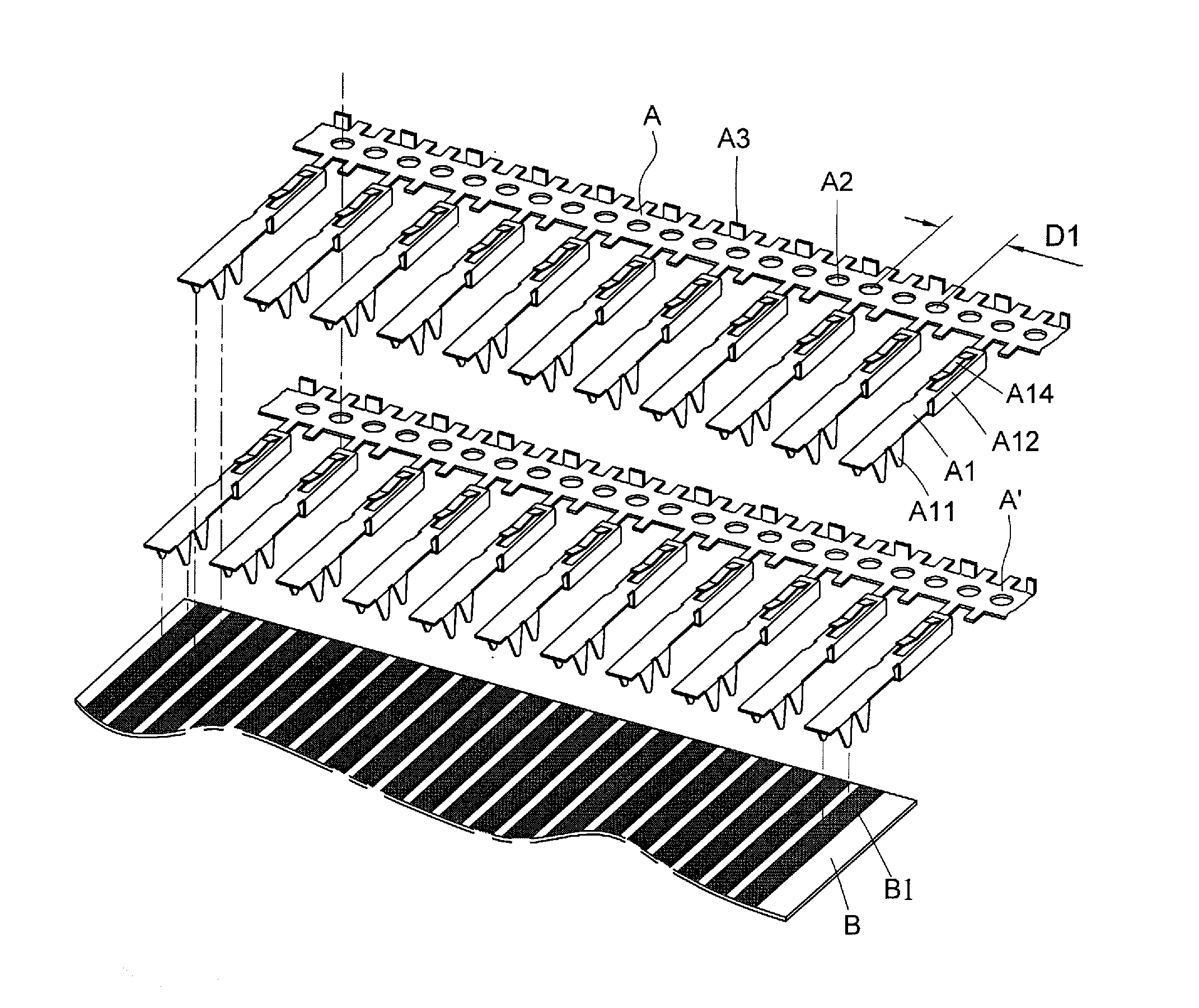

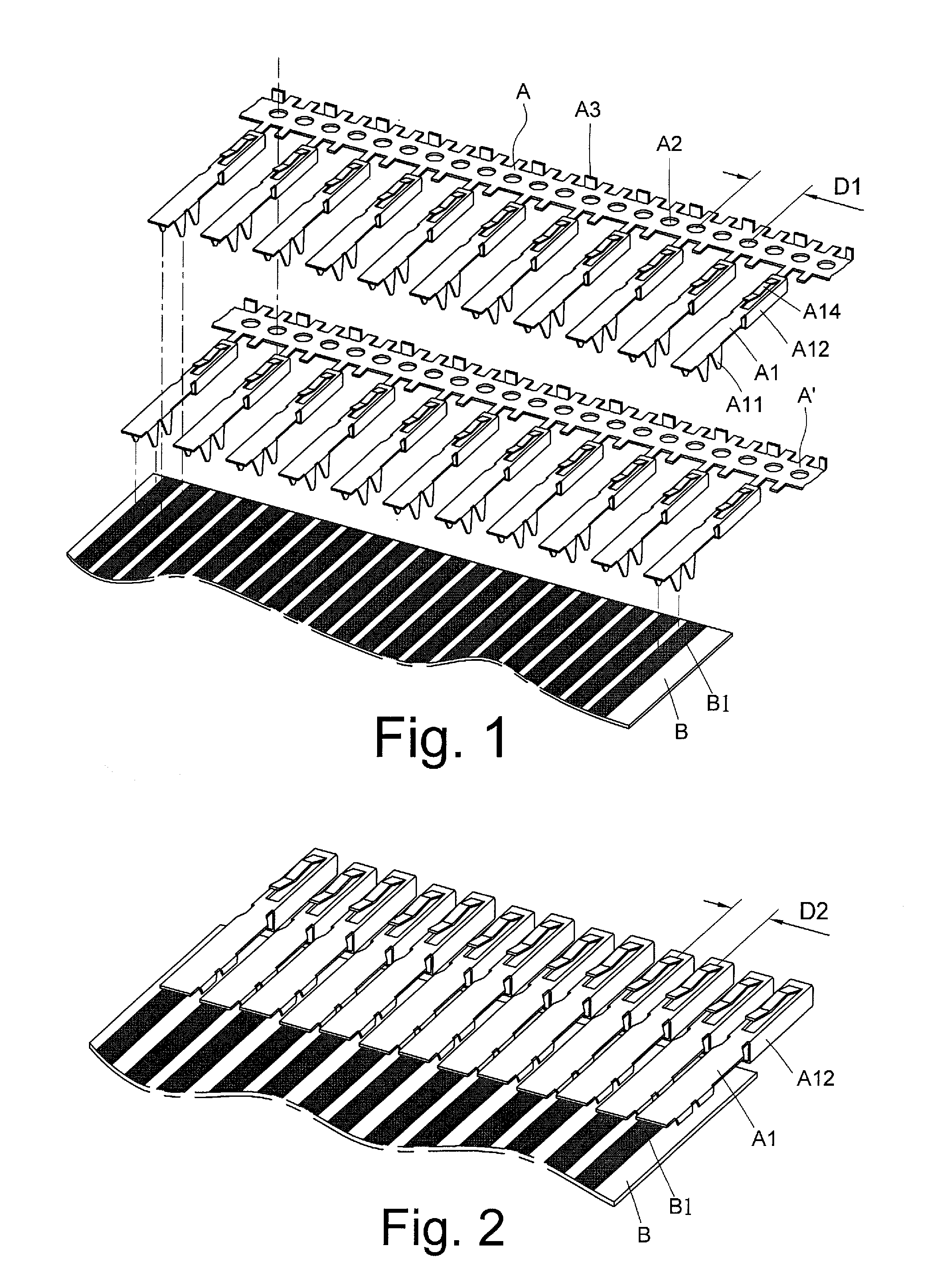

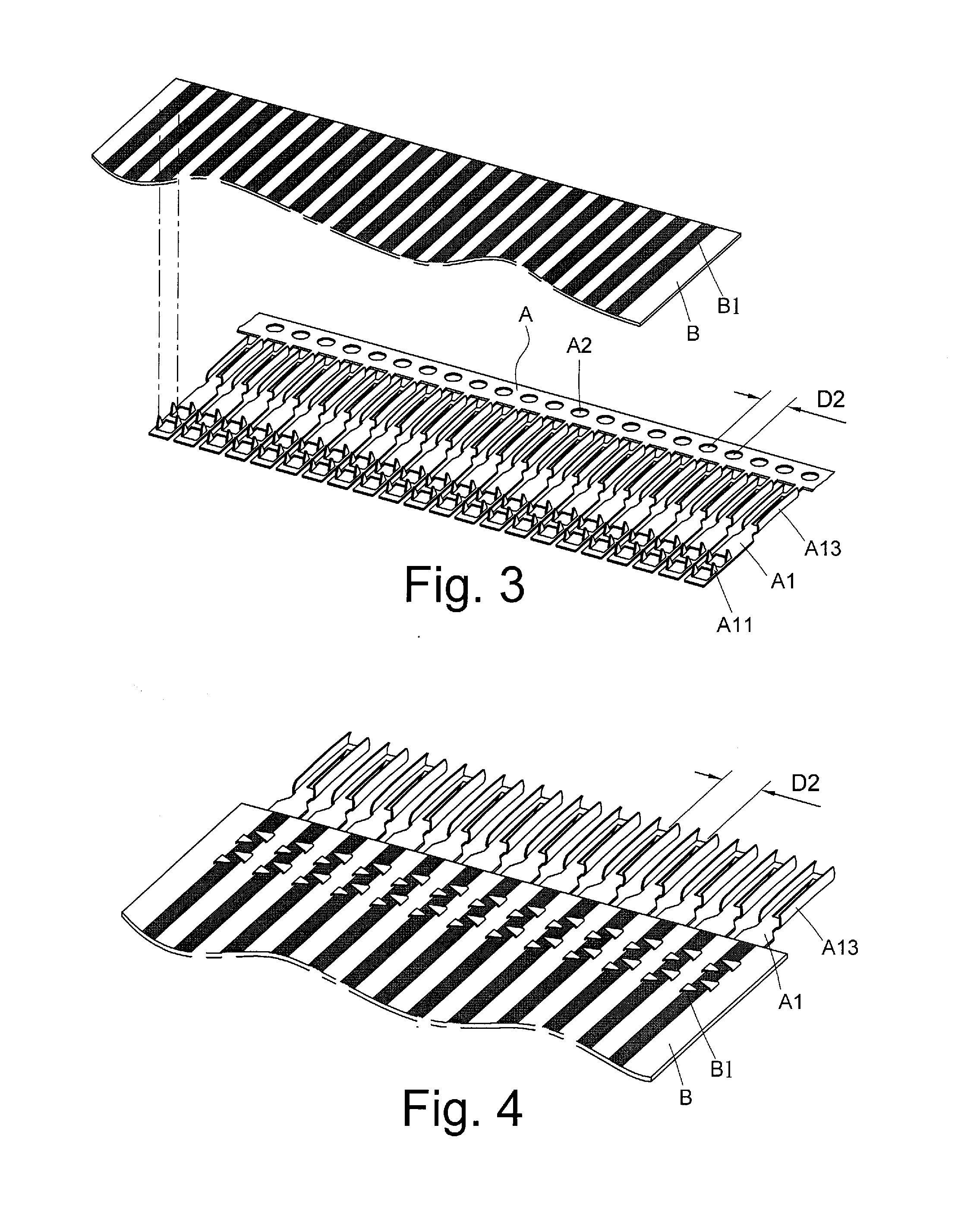

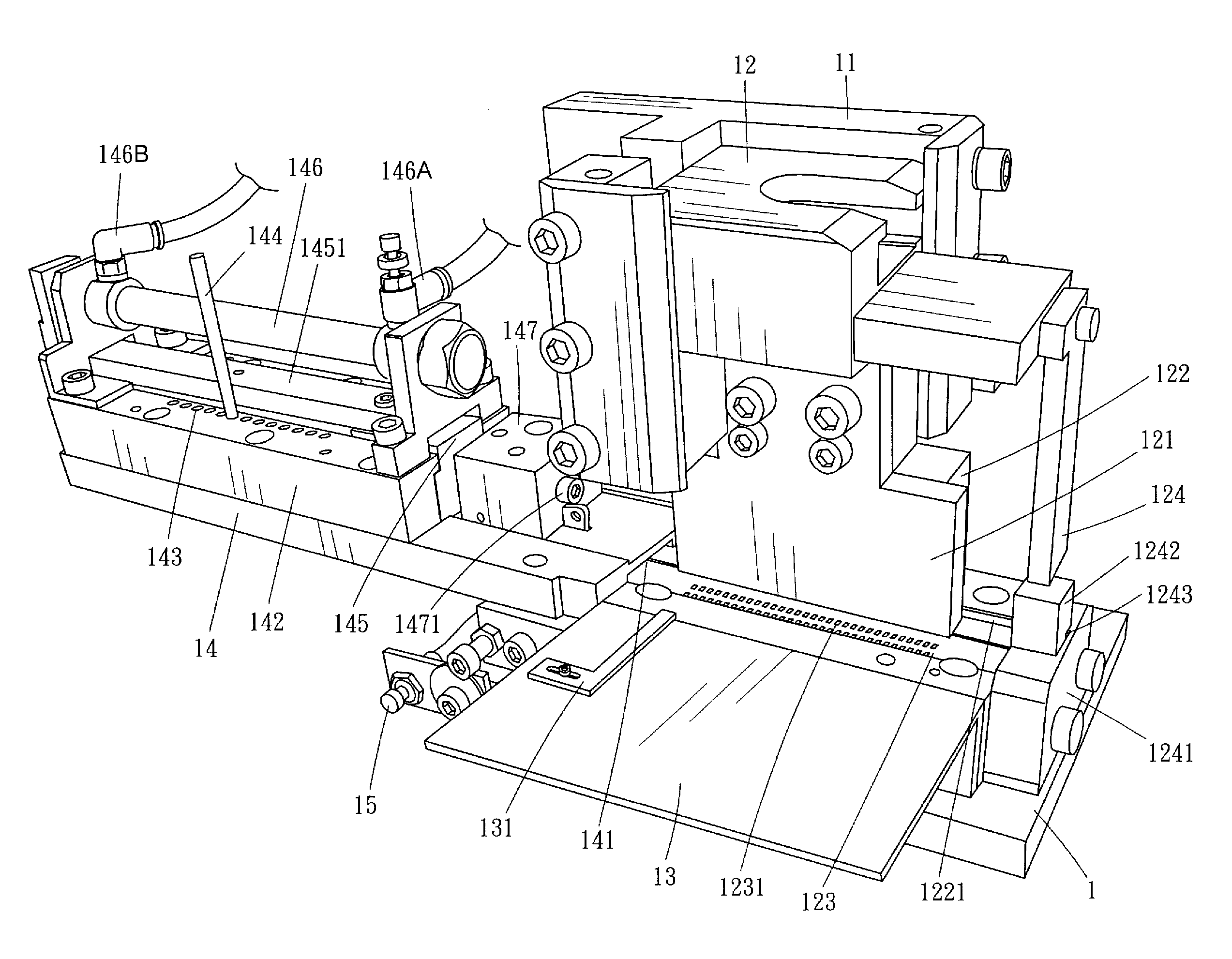

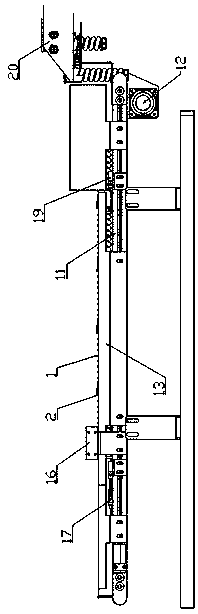

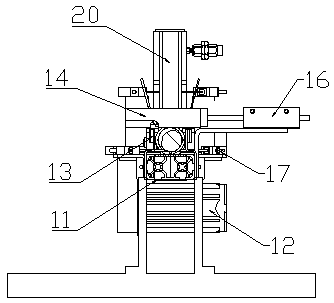

Automatic feeding and crimping device of applicator in terminal making machine for flexible printed circuits, flat cables and cable terminals

ActiveUS20120102727A1Line/current collector detailsFixed connectionsEngineeringMechanical engineering

An automatic feeding and crimping device of an applicator in a terminal making machine for flexible printed circuits, flat cables and cable terminals allows easy adjustment of a feed number of terminals and serves to automatically feed the terminals for the applicator to crimp the terminals with a flexible printed circuit, a flat cable or other cable terminals, thereby providing industrial benefits related to fast and precise terminal processing and flexible feed pitches.

Owner:TIEN CHENG JEN

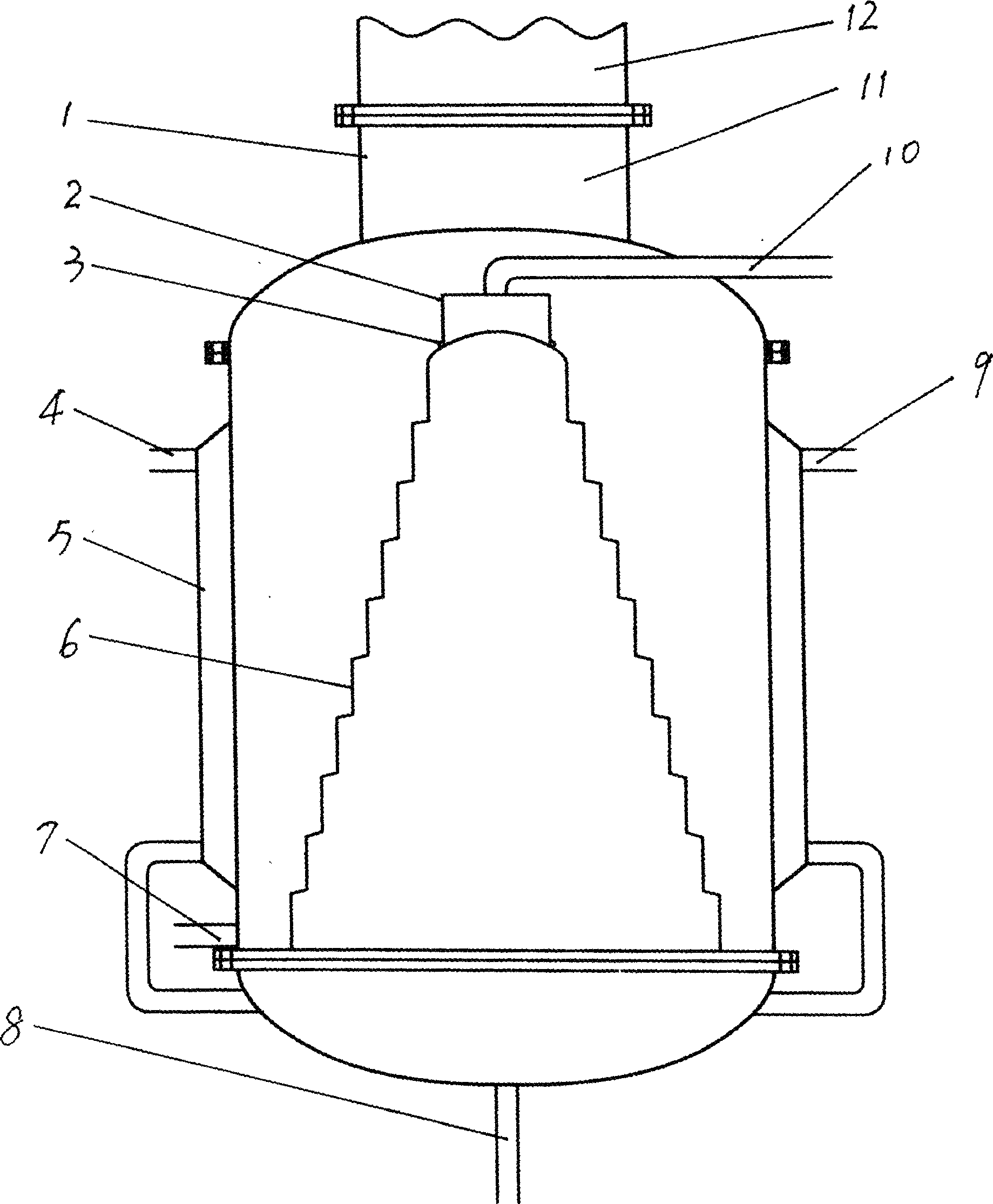

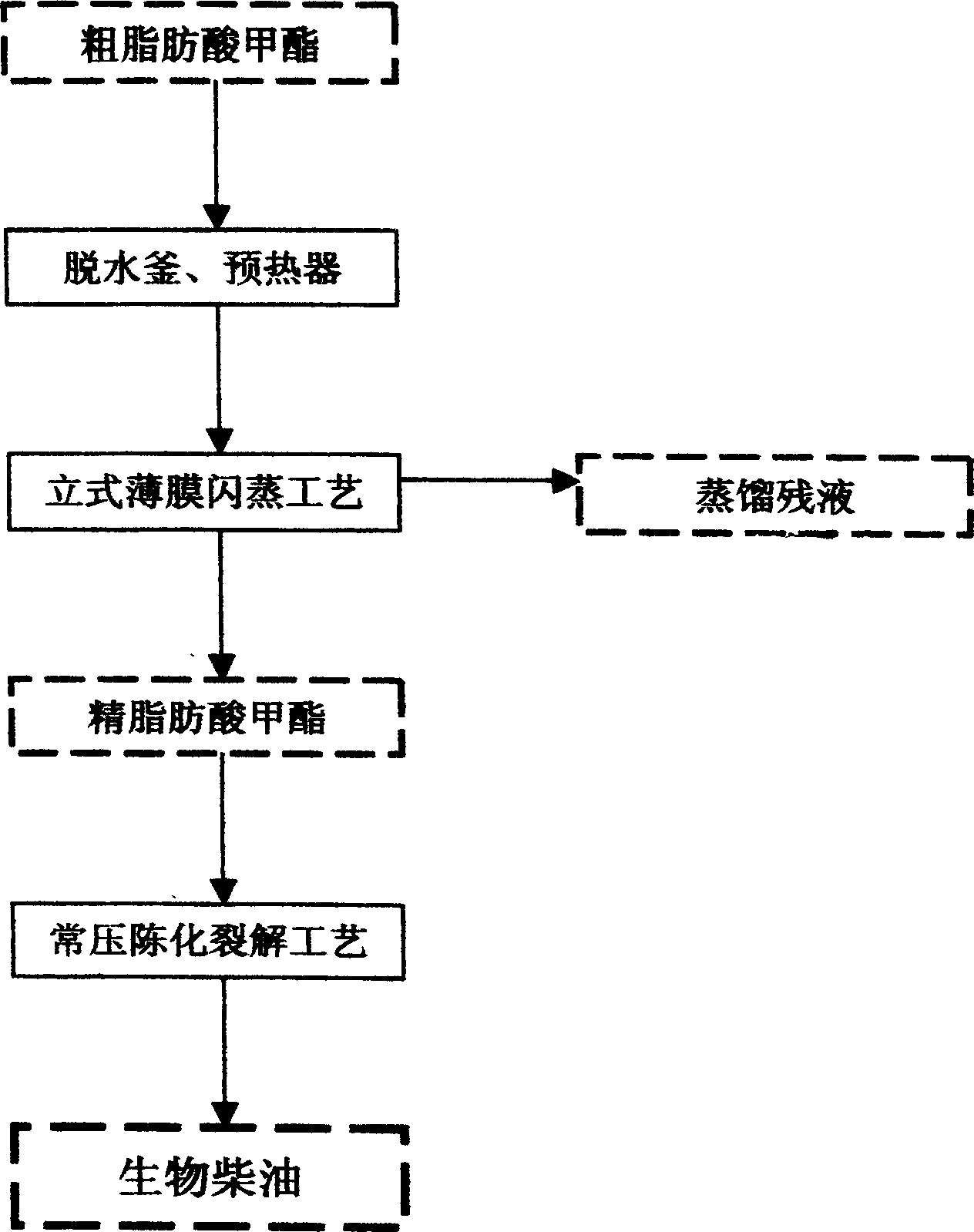

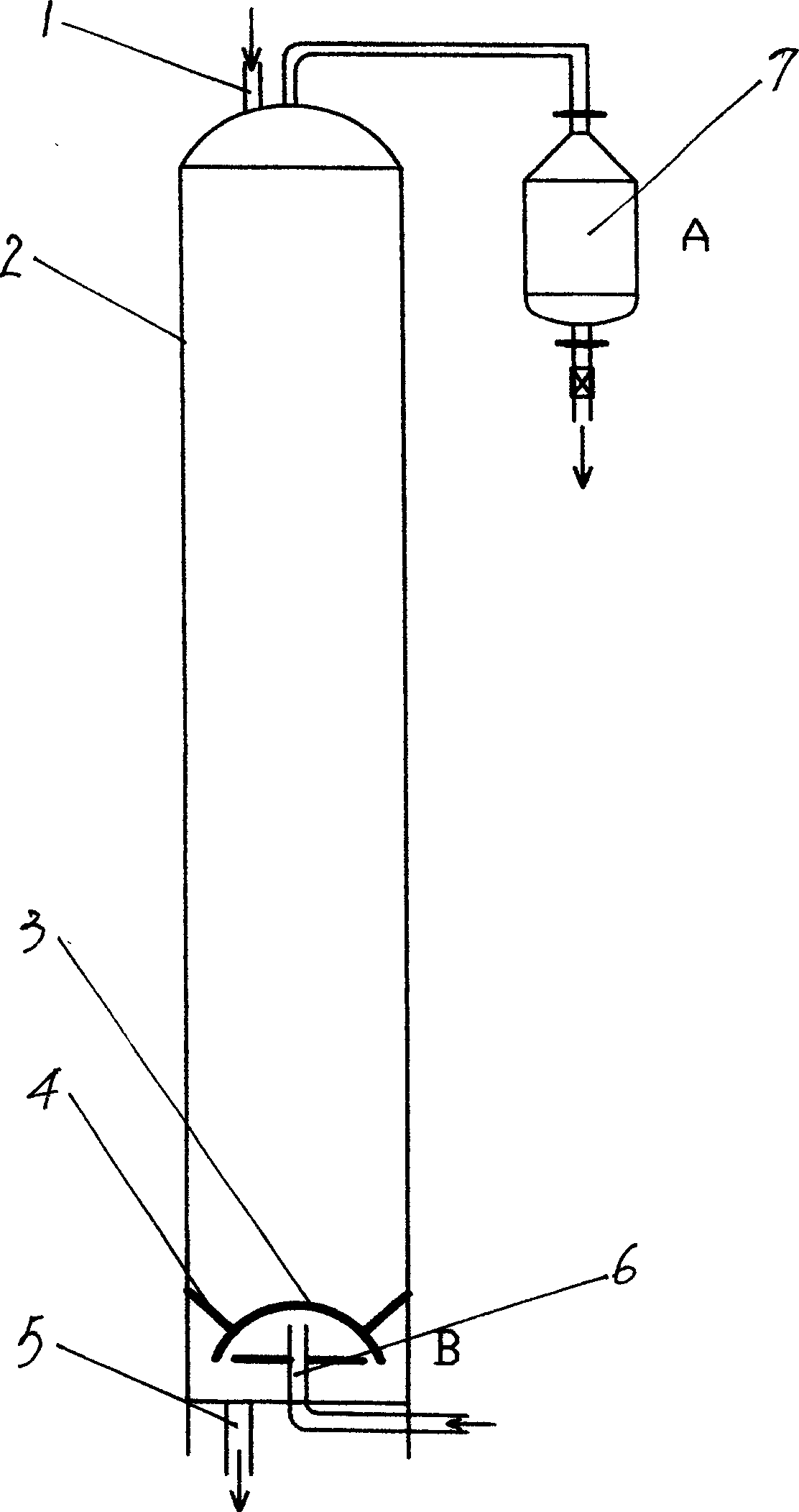

Vertical film flash distillation rectifying still for producing bio diesel fuel

InactiveCN101007958AShort stayReduce lossBiofuelsLiquid hydrocarbon mixture productionHeat carrierBiodiesel

The invention relates to a vertical film flash evaporation and distillation device for biodiesel production, mainly comprising rectifying still and film evaporator. The inside of annular tube around of rectifying still outer wall and inside of film evaporator are filled with heat conductive oil; the top of evaporator is equipped with a current limiter, all- around of bottom of current limiter is equipped with a plurality of eyelets, top of current limiter is connected with coarse methyl ester inlet; the coarse methyl ester enters into current limiter from inlet and flows out through said eyelets to heating wall of film evaporator and gasified instantly because of the high temperature of 300 Deg. C in the heating wall; gasified methyl ester enters into chiller and getting fine methyl ester. The invention is characterized in that it can greatly reduce the retention time for coarse methyl ester in rectifying still, reduces polymerzation; reduces fat consumption by over 10%, the continuous feed is possible and mass production is feasible; the heat carrier can be coal or electricity, heat availability ratio is increased by over 8%, the energy consumption is reduced and industrial benefit is increased.

Owner:河南省商丘油脂化学厂

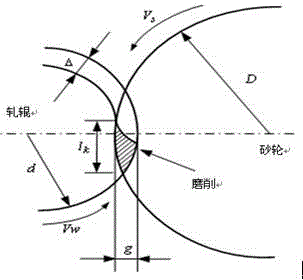

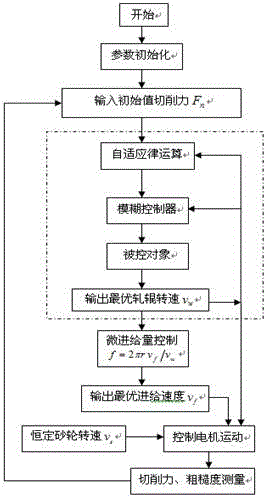

Self-adaptive fuzzy control roller variable-speed grinding method

InactiveCN105215800AGuaranteed stabilityImprove grinding accuracyRevolution surface grinding machinesGrinding feed controlData informationEngineering

The invention aims at providing a roller variable-speed grinding scheme, particularly a self-adaptive micro-feeding roller variable-speed grinding intelligent control scheme. On the basis of analysis of the relationship between a variable-speed grinding mechanism, the variable-speed grinding and grinding chatter suppression, and the grinding precision, the invention provides a variable-speed grinding technological strategy based on self-adaptive fuzzy control, and the variable-speed grinding technological strategy is used for reasonably determining the characteristic and grinding technological parameters of a grinding wheel according to the texture and the structure of a roller. The method has the advantages that direct self-adaptive control is adopted, a fuzzy logic system for a self-adaptive learning algorithm is provided, the learning algorithm adjusts the parameters of the fuzzy logic system according to data information, the stability and the approximate intelligence of a control system can be guaranteed, and the grinding precision of the surface of a roller grind is effectively improved; the system is simple, operation is convenient, application and popularization are easy, the practicability is high, and good industrial benefits and social benefits are achieved.

Owner:高庆

Use of vertical film flash distillation rectifying process in producing bio diesel fuel

InactiveCN101007960AReduce the occurrence of polymerization reactionsReduce lossHydrocarbon distillationBiofuelsHeat carrierBiodiesel

The invention relates to a vertical film flash evaporation and distillation device for biodiesel production, which is mainly used for coarse methyl ester distillation. The esterified or transesterified coarse methyl ester erters into dewatering still and preheating device for hydrolysis and preheating, then comes into vertical film flash evaporation and distillation device for gasification; the methyl ester gas is fed into chiller through ester gas inlet under vaccum being 5 mmHg / cm2 and getting fine methyl ester. The invention is characterized in that it can greatly reduce the retention time for coarse methyl ester in rectifying still which is only 3 minutes, reduces polymerzation; reduces fat consumption by over 10%, the continuous feed is possible and mass production is feasible; the heat carrier can be coal or electricity, heat availability ratio is increased by over 8%, the energy consumption is reduced and industrial benefit is increased.

Owner:河南省商丘油脂化学厂

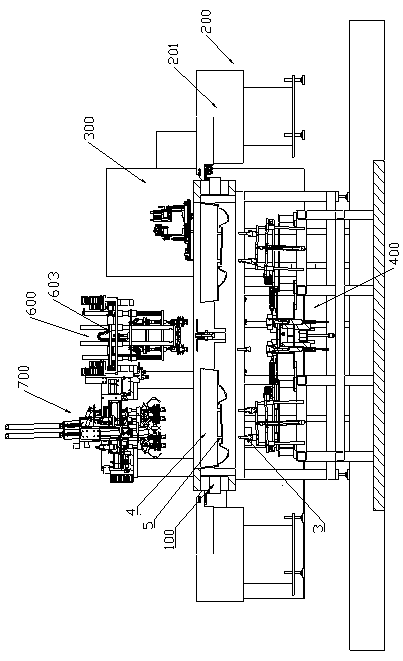

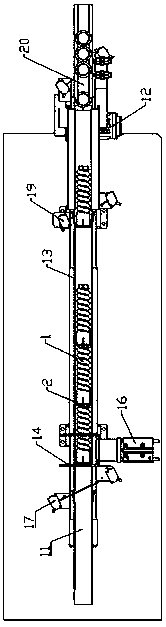

Automatic assembling system for sleeper casing

PendingCN109895237AImprove assembly efficiencySave human effortCeramic shaping apparatusAgricultural engineeringIndustrial benefit

The invention discloses an automatic assembling system for a sleeper casing. The automatic assembling system comprises an assembling platform; a tray translation rail is arranged on the assembling platform; a tray is connected onto the tray translation rail in a sliding manner; a plurality of casing positioning pins are arranged on the tray; casing fixtures are arranged on two sides of each casingpositioning pin; a first driving cylinder used for driving the tray translation rail to move is arranged on the assembling platform; a spiral reinforcement feeding mechanism is arranged on one side of the assembling platform; a casing feeding mechanism is arranged on the other side of the assembling platform; a positioning shaft feeding mechanism is also arranged on the other side of the assembling platform; a casing and spiral reinforcement assembling mechanism is arranged above the assembling platform, and is used for transporting a casing and spiral reinforcements and assembling the casingand the spiral reinforcement in a screwing manner; and a casing and positioning shaft assembling mechanism is arranged on one side of the casing and spiral reinforcement assembling mechanism, and isused for assembling the assembled casing and positioning shafts on dies. The automatic assembling system can automatically finish feeding and assembling of the casing, the spiral reinforcements and the positioning shafts, the assembling efficiency is high, manpower is saved, the production cost is beneficially reduced, and the industrial benefits are improved.

Owner:北京好运达智创科技有限公司

Automatic feeding and crimping device of applicator in terminal making machine for flexible printed circuits, flat cables and cable terminals

An automatic feeding and crimping device of an applicator in a terminal making machine for flexible printed circuits, flat cables and cable terminals allows easy adjustment of a feed number of terminals and serves to automatically feed the terminals for the applicator to crimp the terminals with a flexible printed circuit, a flat cable or other cable terminals, thereby providing industrial benefits related to fast and precise terminal processing and flexible feed pitches.

Owner:TIEN CHENG JEN

Hydrolysis reaction tower for producing bio diesel fuel

InactiveCN101007959AReduce pollutionSimple structureBiofuelsLiquid hydrocarbon mixture productionBiodieselEngineering

The invention relates to hydrolysis tower for biodiesel production. The bottom of tower is equipped with a steam distributor and fixed with rib to tower inner wall; there is space between all- around of steam distributor and tower inner wall, the outlet of steam inlet pipe is fixed below steam distributor; the top of tower is connected to a water separator; oil inlet is located on the top of tower, and the hydrolyized material outlet is at the bottom of tower. The invention is characterized by simple structure, easy production, high oil availability ratio of over 98.5%, increased biodiesel productivity by more than 30%, reduced production cost and environmental pollution, and increased industrial benefit.

Owner:河南省商丘油脂化学厂

Treatment and machining process for steel piece casting and rust and corrosion prevention

The invention discloses a treatment and machining process for steel piece casting and rust and corrosion prevention. The treatment and machining process for steel piece casting and rust and corrosion prevention belongs to the comprehensive technical field of mechanical manufacturing processes and corrosion prevention treatment, and comprises the following steps: firstly, casting a steel piece blank; eliminating the internal stress of the blank after cooling and then performing corrosion and rust prevention treatment on the surface of the blank; specifically, the surface of the blank is treated by using an acid-alkali-salt mixed method; a scavenger can be isolated from contacting with the steel piece, such that occurrence of over-corrosion of the steel can be prevented; the process is low in cost, simple, convenient and feasible, low in investment, applicable to coating pretreatment of steel pieces of various shapes and sizes, high in benefit and power-saving, and further capable of enabling the steel pieces to be high in resistance to bending, good in abrasion resistance and improved in corrosion resistance; meanwhile, the process enables cores of the steel pieces to be high in toughness, good in flexibility and fine in heat dissipation; as a result, the service life of the steel pieces is greatly prolonged, and the added value and industrial benefits thereof are high.

Owner:WUXI QIAOYANG MACHINERY MFG

Plantation method for pitaya family potting

InactiveCN106538203AIncrease breadthEasy to viewPlant cultivationCultivating equipmentsMaintenance managementPotting soil

The invention discloses a plantation method for pitaya family potting and belongs to the technical field of fruit plantation. The method specifically comprises container selection, preparation and sterilization of potting soil, transplantation and maintenance management, disease control, management after fruit harvesting, winter passing, etc. Through application of the potting plantation technology, a balcony and a roof can be used rationally to increase industrial benefits and promote sustainable development. The method is simple and can be operated conveniently, so that plantation demands of public people can be satisfied, universality and ornamental values of pitaya plantation can be enhanced, and income of orchard workers can be increased.

Owner:蔡凤文

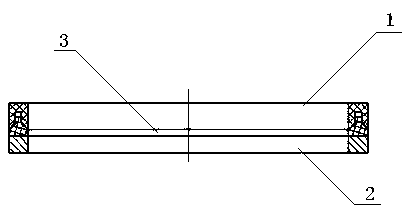

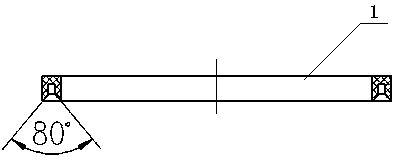

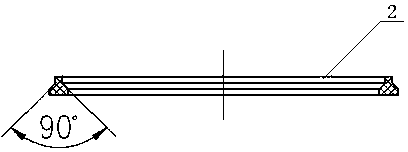

Sealing device of supercritical carbon dioxide extraction kettle

InactiveCN103851191AEasy to openNo frequent replacementEngine sealsSolvent extractionEngineeringIndustrial benefit

The invention discloses a sealing device of a supercritical carbon dioxide extraction kettle. The sealing device comprises an upper sealing piece, a lower sealing piece and a gasket sequentially from top to bottom. An angle of a groove of the upper sealing piece is 80 degrees, and an angle of a slope of the lower sealing piece is 90 degrees. During assembling, compression force is applied from the upper and the lower ends of the sealing device, and since the angle of the groove of the upper sealing piece is 80 degrees and the angle of the slope of the lower sealing piece is 90 degrees, upper parts can be strutted, and sealing is achieved. By the aid of the sealing device, the extraction kettle is easy to open, and sealing pieces need not to be changed frequently, so that cost is saved, working efficiency is improved, and industrial benefit is increased.

Owner:NANTONG HUAXING OIL EQUIP

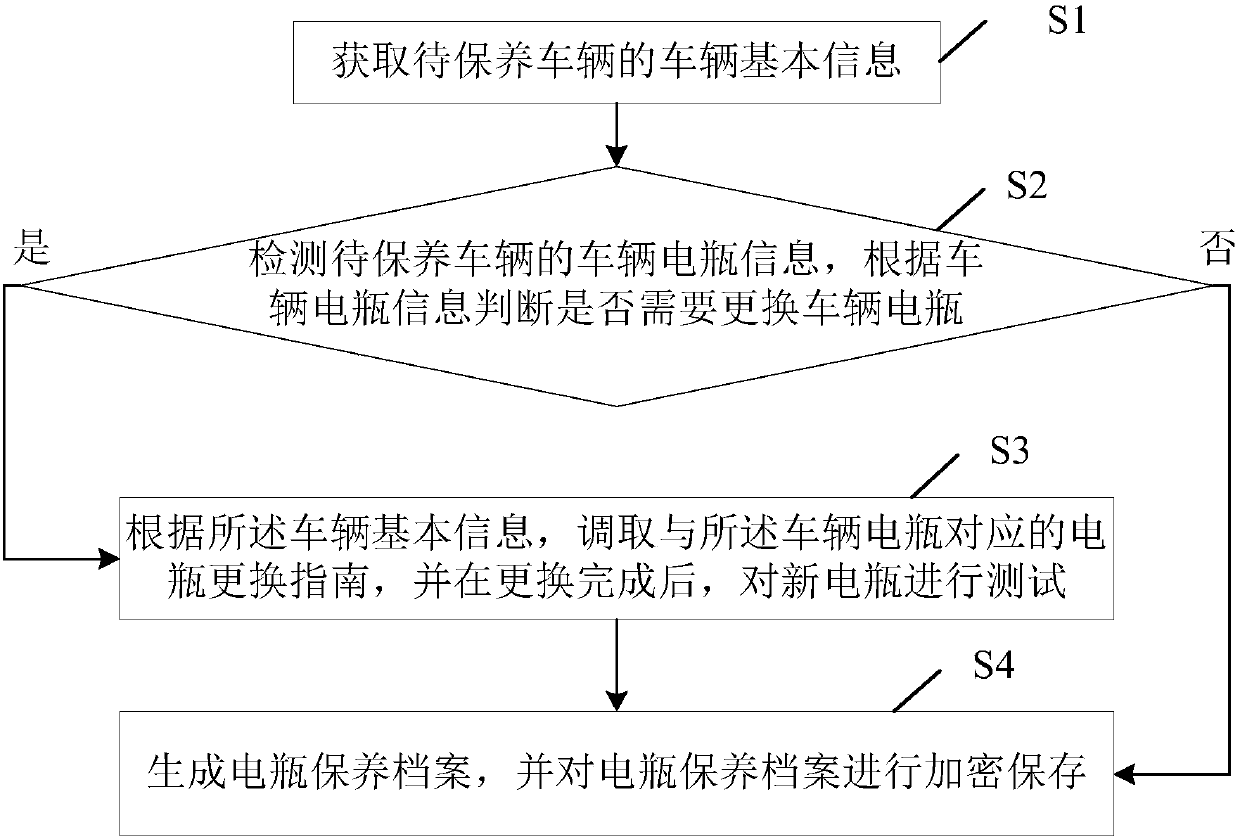

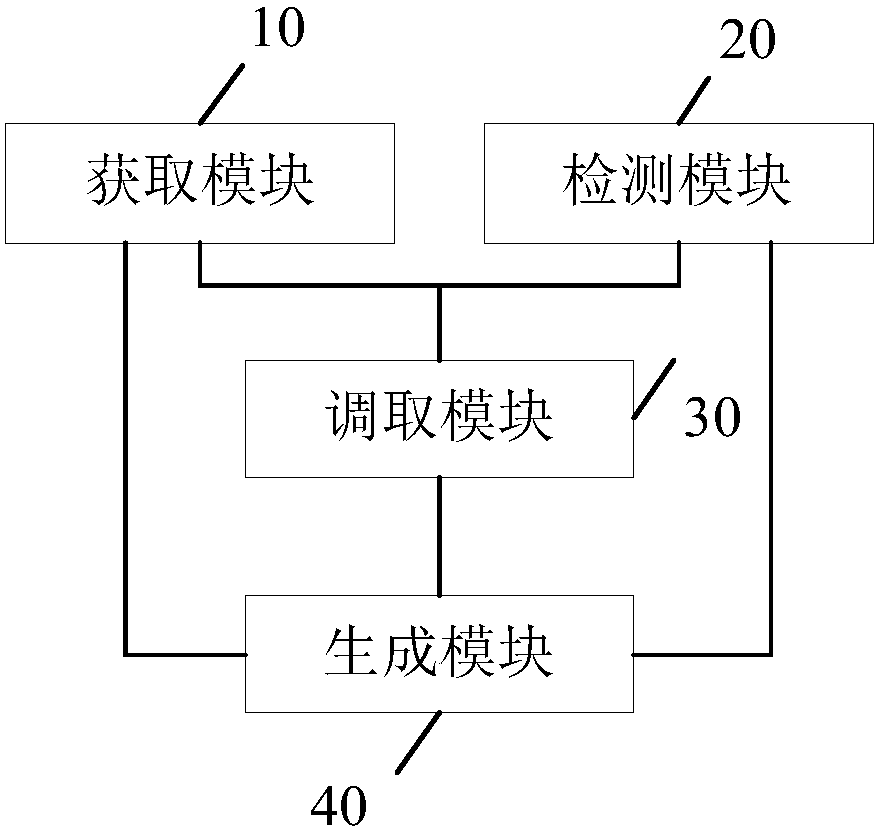

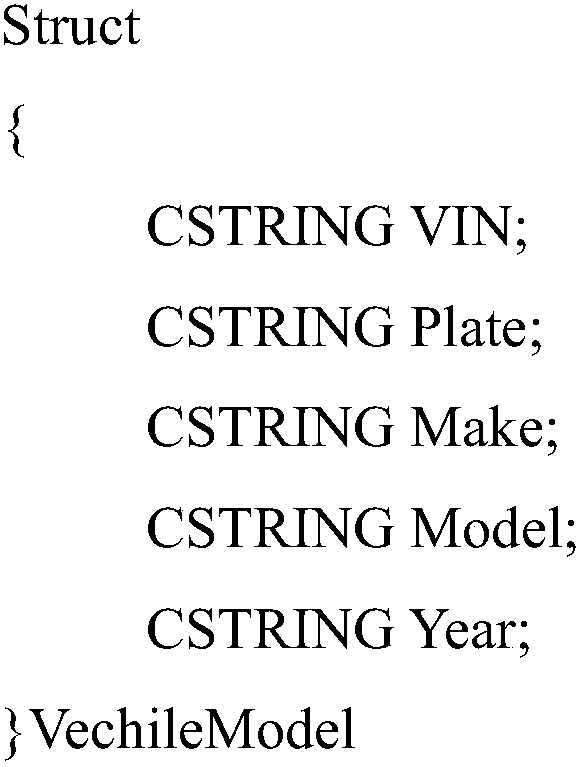

Vehicle storage battery maintenance file generation method and system

InactiveCN107622095AImprove efficiencyHigh transparencyEncryption apparatus with shift registers/memoriesDigital data protectionEconomic benefitsEngineering

The invention discloses a vehicle storage battery maintenance file generation method. The method comprises the following steps of S1. acquiring basic vehicle information of a to-be-maintained vehicle;S2. detecting vehicle storage battery information of the to-be-maintained vehicle, determining whether to replace the vehicle storage battery according to the vehicle storage battery information, ifthe vehicle storage battery needs to replace, executing S3, and if the vehicle storage battery does not need to replace, executing S4; S3. according to basic vehicle information, invoking a storage battery replace guide corresponding to the vehicle storage battery, after replacement, testing the new storage battery; and S4. generating a storage battery maintenance file, and encrypting and storingthe storage battery maintenance file. Through adoption of the method, the storage battery maintenance process is standardized, working time is reduced, secondary faults are prevented, the industrial economic benefit and transparence are improved, and the built files provide basis for enterprises of the industry, help increase the industrial benefit, and provide standard reference information for government in managing the enterprises of the industry.

Owner:深圳众为智慧技术有限公司

Mushroom residue feed and preparation method

The invention discloses a mushroom residue feed and a preparation method, and relates to the technical field of feed preparation. The mushroom residue feed is prepared from, by weight, 50-70 parts ofmushroom residue ferments, 5-15 parts of potato residue powder, 5-15 parts of rice bran, 15-20 parts of wheatmeal, 10-15 parts of bean pulp, 8-15 parts of fishmeal, 10-15 parts of meat and bone meal,0.5-2.5 parts of salt and 15-25 parts of green feed meal. Mushroom residues can be effectively utilized, the feed cost is lowered, the fermented mushroom residues can remove a large number of impurities, fiber lignin and other anti-nutritional factors in mushroom residues, and mycelium protein, various animo acids, polysaccharide substances, nucleic acid and other active substances are reserved tothe maximum extent. The feed resources in the region are saved, the problem that people and livestock fight for feed is solved, edible mushroom industrial benefits are improved, and the industry is continuously and healthily developed. A new way is developed for rural characteristic terrain economic development.

Owner:姚丁元

Aspergillus oryzae strain and method for producing fungal alpha-amylase by liquid-state fermentation of aspergillus oryzae strain

The invention discloses an aspergillus oryzae strain MFA-AO-3 with the collection number of CGMCC No. 6834 and a method for producing fungal alpha-amylase by taking the aspergillus oryzae strain as the strain for liquid-state fermentation. The aspergillus oryzae strain can be used for realizing high yield of the fungal alpha-amylase; and the method for producing the fungal alpha-amylase by liquid-state fermentation of the aspergillus oryzae strain, disclosed by the invention, comprises the following step: on the basis of taking the aspergillus oryzae strain as the strain, performing fermentation and culture at the stirring rate of 500-1000 rpm (revolutions per minute) under the conditions that the ventilation quantity calculated by feed liquid volume is as follows: the air volume per minute is 1:(1.5-2) and the dissolved oxygen accounts for 20-25%, thereby preparing the fungal alpha-amylase. According to the method for producing the fungal alpha-amylase, disclosed by the invention, the enzyme production level is high and the industrial benefits are great.

Owner:意葆(上海)生物科技有限公司

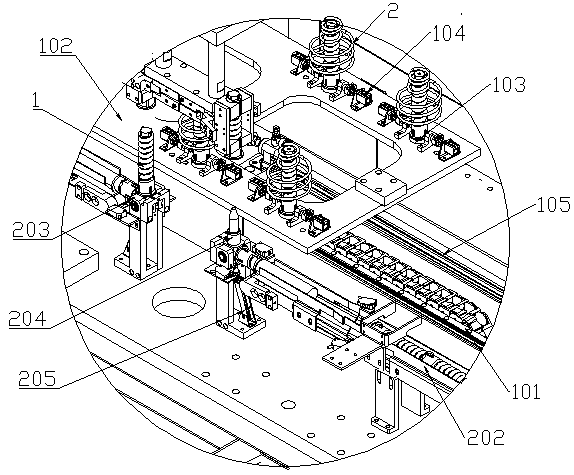

Electrolysis capacitor pin defect detection apparatus

InactiveCN105115977AReduce human errorImprove work efficiencyOptically investigating flaws/contaminationElectrolysisGas cylinder

The present invention relates to an electrolysis capacitor pin defect detection apparatus, which comprises a transfer mechanism, an execution mechanism and a detection mechanism, wherein the transfer mechanism comprises a guide rail, a guide rail bracket, a pin plate seat, a pin bracket, a small gas cylinder, a small gas cylinder frame, a single pin plate and a double pin plate, the execution mechanism comprises a pneumatic finger, a pneumatic finger frame, a medium gas cylinder, a medium gas cylinder frame, a large gas cylinder and a large gas cylinder frame, the pneumatic finger is arranged on the pneumatic finger frame, the terminal end of the pneumatic finger frame is arranged on the medium gas cylinder, the lateral movement of the pneumatic finger frame is controlled by the medium gas cylinder, the medium gas cylinder is arranged on the medium gas cylinder frame, the medium gas cylinder frame is arranged on the large gas cylinder frame, the longitudinal movement of the medium gas cylinder frame is controlled by the large gas cylinder, the large gas cylinder is arranged on the large gas cylinder frame, the detection mechanism comprises a camera assembly and a camera frame, the camera assembly is arranged on the camera frame, and the camera frame is vertically fixed on the ground through ground screws. The electrolysis capacitor pin defect detection apparatus of the present invention has advantages of human error reducing, work efficiency improving, labor cost reducing, and industrial benefit increasing.

Owner:NANTONG DILONG KNITTING GARMENT

A method for synchronous recycling of hazardous waste with high calorific value and municipal solid waste

ActiveCN104818064BAchieve recyclingImplement resourcesGaseous fuelsCeramicwareResource utilizationMass ratio

A method for synchronous recycling of hazardous waste with high calorific value and municipal solid waste according to the present invention comprises the following steps: (1) dewatering sludge, construction dregs, and power plant fuel residues according to (3-5): (2-4 ): (1~3) mixed in mass ratio, stale for 20~30 days to obtain composted materials; (2) after mixing hazardous waste and homogenizing and pulverizing, anaerobic pyrolysis at a temperature above 1500°C for 1~2h, Pyrolysis gas and pyrolysis slag are obtained; pyrolysis gas is plasma gasified at a temperature above 5000°C for 5‑10s to obtain artificial combustible gas; ‑80) The volume ratio is mixed evenly, and granulated to obtain raw material balls; (4) The raw material balls are sintered and formed, and cooled to obtain the finished product of ceramsite. The invention reduces the exploitation of primary energy and resources, reduces the damage to the natural environment, is beneficial to the maintenance and optimization of the original ecological system, and improves the industrial income.

Owner:山东兴硕环保科技有限公司 +1

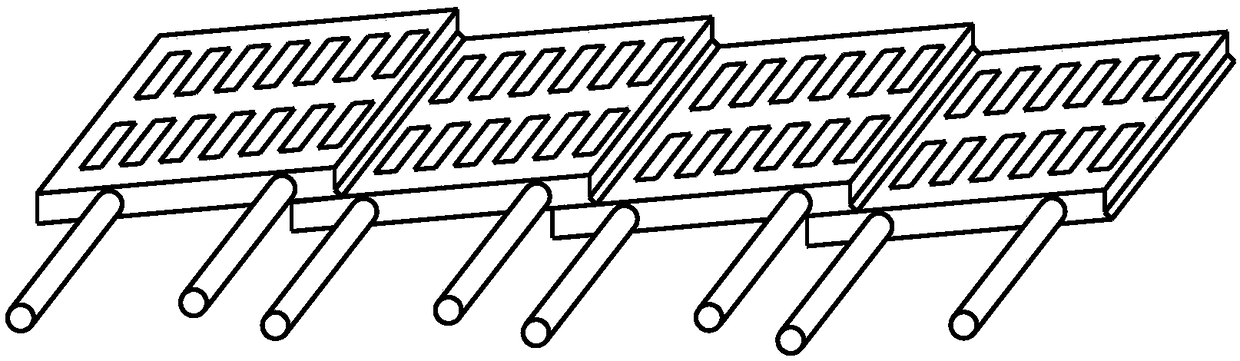

Closed type cooling and waste heat recovery device for sintering ores

InactiveCN108302944AEliminate distractionsImprove heat transfer effectIncreasing energy efficiencyHandling discharged materialWaste heat recovery unitAir cycle

The invention discloses a closed type cooling and waste heat recovery device for sintering ores. The cooling and waste heat recovery device is characterized by comprising a feeding port, a dischargingport, fans, conveying plates, air circulating pipes and cooling chambers; and shells of the cooling chambers are in a closed type, the conveying plates are arranged in the cooling chambers, the conveying plates are used for conveying the sintering ores to the discharging port from the feeding port, and the fans comprise induced draft fans and air blowers. According to the cooling device for the sintering ores, a ring type cooling machine in the past is changed into the novel closed cooling device, a cooling system adopts a gradient heat exchange mode to achieve approximate countercurrent heatexchange, the interference of dynamic sealing is eliminated, the heat exchange rate and the waste heat quality are improved, the waste heat recovery efficiency is improved, energy is saved, primary screening can be carried out on the return sintering ores, and the industrial benefit is improved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

A type 3r ab 4 Hydrogen storage alloy and its preparation method and application

ActiveCN108977676BEasy to prepareEasy to operateCell electrodesNickel accumulatorsHigh rateElectrochemistry

Owner:YANSHAN UNIV

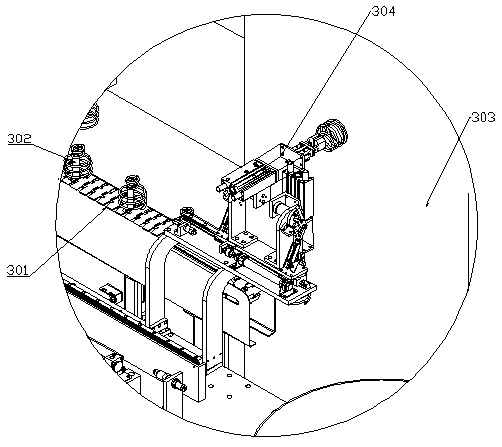

Sleeve guide groove of automatic assembly system for sleeper sleeve

PendingCN109941707ASave human effortReduce manufacturing costControl devices for conveyorsCeramic shaping apparatusReciprocating motionThreaded pipe

The invention discloses a sleeve guide groove of an automatic assembly system for a sleeper sleeve. The sleeve is a threaded pipe. An outer step is arranged outside of one end of the threaded pipe. The guide groove comprises a conveyor belt and a driving motor driving the conveyor belt to convey; side plates are correspondingly arranged on both sides of the conveyor belt; a sleeve conveying passage is formed between the side plates; the height of the side plates is greater than the outer diameter of the threaded pipe and less than the outer diameter of the outer step; a baffle is arranged at the upper end of the middle of each side plate to block the passage of the sleeve; a notch is formed in one side of the lower end of each baffle to release the sleeve; the baffles are driven by a cylinder and move back and forth in the width direction of the conveyor belt; a first inductor is arranged between the exit end of the conveying passage and the baffles for sensing the passage of the sleeve; and when the first inductor senses the passage of the sleeve, the cylinder repositions the baffles to block the passage of the next sleeve. The sleeve guide groove can be used for the automatic assembly system of the sleeper sleeve, can complete the automatic feeding of the sleeper sleeve, and is beneficial to saving manpower, reducing production cost and improving industrial benefit.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +3

Heat treatment and rust and oil prevention method for surfaces of steel and iron parts

InactiveCN104294289AImprove wear resistanceExtend your lifeMetallic material coating processesHeat treatment bathsEnvironmental resistancePhosphate

The invention discloses a heat treatment and rust and oil prevention method for surfaces of steel and iron parts, and belongs to the technical field of steel and iron. Firstly, the quenching treatment is performed for the steel and iron parts; the rust and oil prevention treatment is performed after the pretreatment; and then, the electroplating treatment is performed, so that the rust and oil prevention time is longer, and the surfaces of steel and iron materials can be prevented from forming rust spots again; and an antirusting agent contains no phosphate, and contains no nitrite harmful to human bodies and environment, so that the discharge treatment of the antirusting agent is convenient, the environment is not polluted, the antirusting agent is green and environment-friendly, is suitable for the coating pretreatment of steel parts with various shapes and sizes, can enable the surfaces of steel products to have good wear resistance and improved corrosion resistance, and enable the heart parts to have high roughness, good flexibility and strong insulativity, high-temperature impact resistance and bending resistance, therefore, the service life of the steel products is largely prolonged, and the added value and the industrial benefit of the steel products are largely improved.

Owner:WUXI HUAYE IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com