Hydrolysis reaction tower for producing bio diesel fuel

A hydrolysis reaction and biodiesel technology, which is applied in the preparation of biological raw materials, biofuels, and liquid hydrocarbon mixtures, etc., can solve the problems of oil foot pollution, large investment, low hydrolysis rate, etc., so as to reduce production costs and reduce environmental pollution. , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

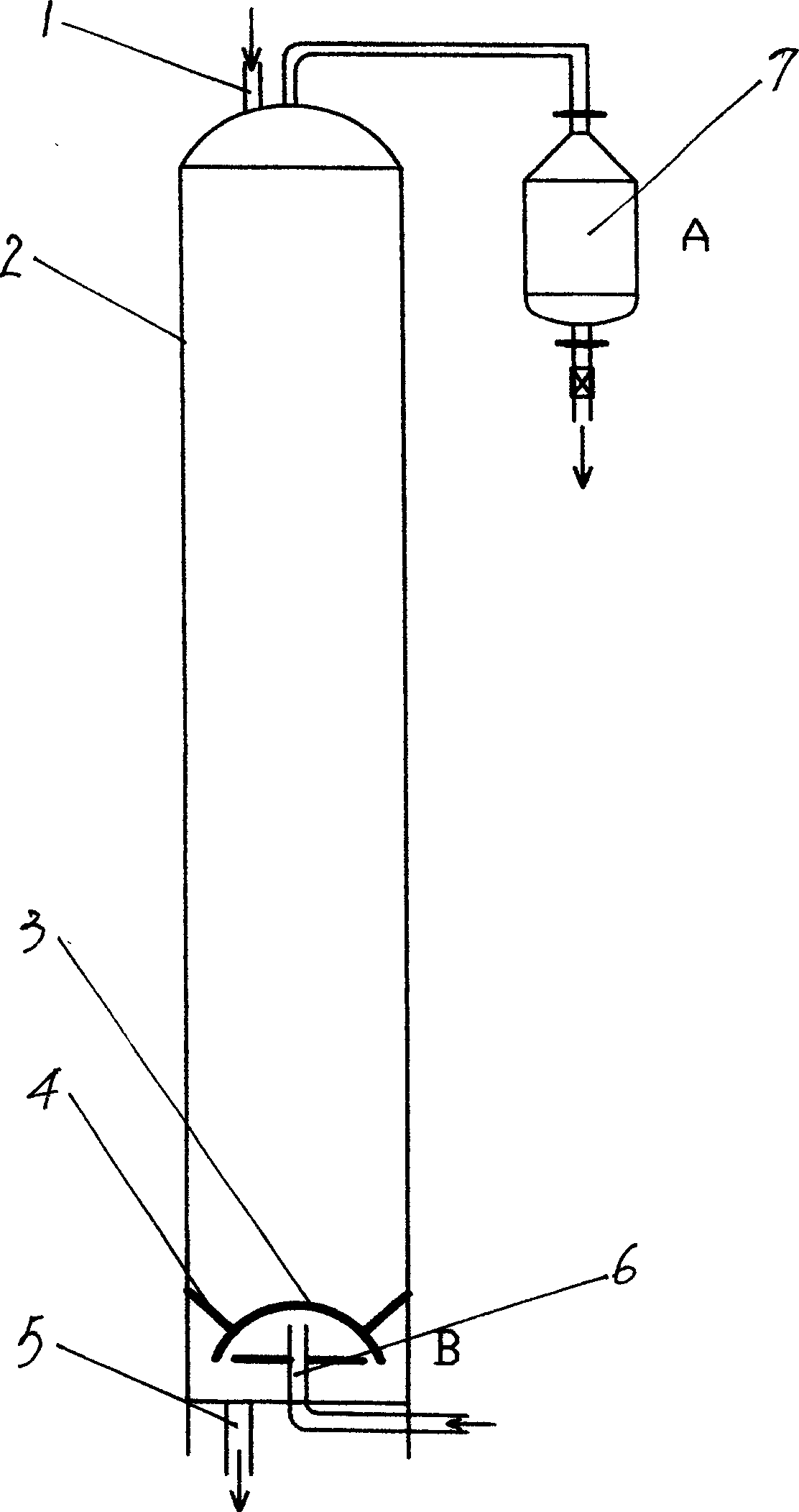

[0009] Use a Gr18Ni9Ti plate with a thickness of 14mm to weld a hydrolysis tower with a diameter of 1000mm and a tower height of 12000mm. A steam distributor 3 is installed at the bottom of the tower body 2. The steam distributor 3 is an arc-shaped plate structure, with the arc upward and the mouth facing Bottom, fixed on the inner wall of the tower body 2 by ribs 4, there is a gap around the bottom of the steam distributor 3 and the inner wall of the tower, and the outlet of the steam input pipe 6 is located below the steam distributor 3 and is perpendicular to the steam distributor. 3; the top of the tower body 2 is externally connected with a steam-water separator 7; The pressure inside the hydrolysis tower is designed to be 25kg / cm 2 .

[0010] The working principle of this hydrolysis tower is: first mix the oil to be hydrolyzed with one-third of the water, enter from the top of the tower, after the oil enters, turn on the steam, the steam enters from the bottom of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com