A type 3r ab 4 Hydrogen storage alloy and its preparation method and application

A technology for hydrogen storage alloys and alloys, which can be used in nickel storage batteries, structural parts, circuits, etc., and can solve problems such as poor cycle stability, alloy capacity attenuation, and mismatching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides the described 3R type AB 4 A method for preparing a hydrogen storage alloy, comprising the following steps:

[0039] Mix the metal elements corresponding to the alloying elements and conduct induction melting to obtain multi-element cast alloys;

[0040] Annealing the multi-element as-cast alloy to obtain 3R type AB 4 Hydrogen storage alloys.

[0041] The present invention mixes the metal elements corresponding to the alloying elements and conducts induction melting to obtain a multi-element cast alloy; the present invention does not have any special limitation on the mixing, and the mixing process can be carried out by using a mixing process well known to those skilled in the art.

[0042] In the present invention, when mixing the simple metals corresponding to the alloying elements, it is preferable to weigh an amount slightly higher than the composition of the alloying elements. In the present invention, the amount slightly high...

Embodiment 1

[0059] Press La 0.40 SM 0.30 Mg 0.30 Ni 4.0 The ratio of La, Sm, Mg, Ni was weighed and mixed, and vacuum induction melting was carried out at 1200 ° C to obtain La-Sm-Mg-Ni-based multi-element cast alloy;

[0060] The La-Sm-Mg-Ni-based multi-element cast alloy was placed in a vacuum annealing furnace at 6×10 -3 Under the condition of Pa, the temperature was raised from room temperature to 600°C at a rate of 5°C / min; then the temperature was raised from 600°C to 1000°C at a rate of 1°C / min, and kept for 8 hours; finally, the temperature was lowered to room temperature with the furnace to obtain a 3R super Stacked La 0.40 SM 0.30 Mg 0.30 Ni 4.0 alloy.

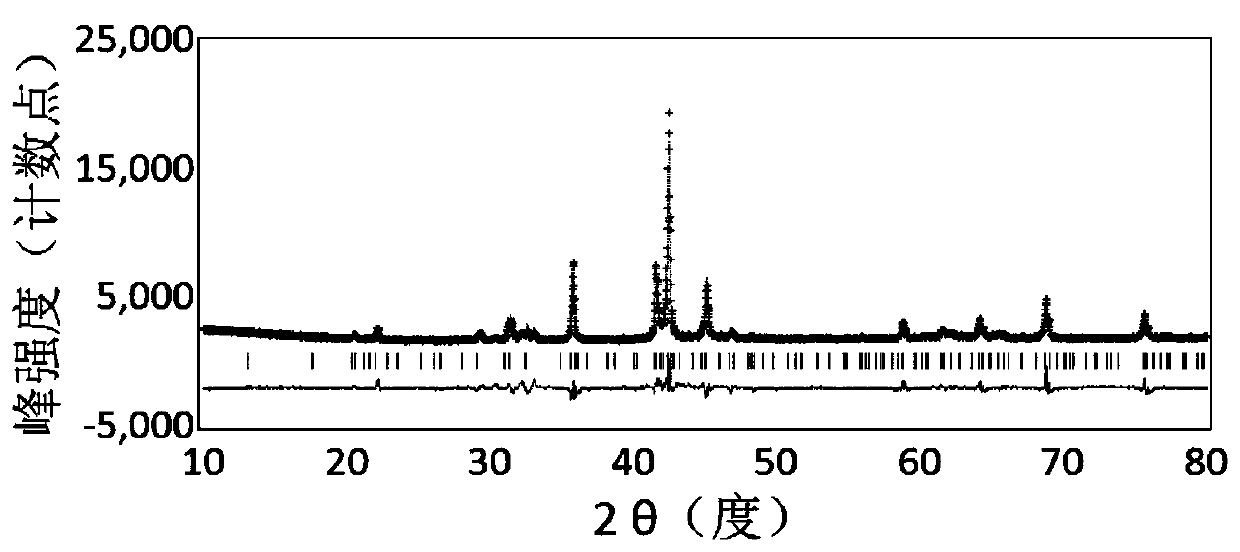

[0061] the La 0.40 SM 0.30 Mg 0.30 Ni 4.0 After the alloy is pulverized, pass through a 400-mesh sieve, and the sieved La 0.40 SM 0.30 Mg 0.30 Ni 4.0 The alloy was tested by XRD. figure 1 In order to adopt the Rietveld method for La 0.40 SM 0.30 Mg 0.30 Ni 4.0 The full-spectrum fitting of the XRD pattern of th...

Embodiment 2

[0064] Press La 0.70 SM 0.05 Mg 0.25 Ni 3.72 al 0.10 The ratio of La, Sm, Mg, Ni, Al was weighed and mixed, and vacuum induction melting was carried out at 1400 ° C to obtain La-Sm-Mg-Ni-Al-based multi-element cast alloy;

[0065] The La-Sm-Mg-Ni-Al based multi-element as-cast alloy was placed in a vacuum annealing furnace at 6×10 -3 Under the condition of Pa, the temperature was raised from room temperature to 600 °C at a rate of 8 °C / min; then the temperature was raised from 600 °C to 1005 °C at a rate of 1 °C / min, and kept for 12 hours; finally, the temperature was lowered to room temperature with the furnace to obtain a 3R super Stacked La 0.70 SM 0.05 Mg 0.25 Ni 3.72 al 0.10 alloy.

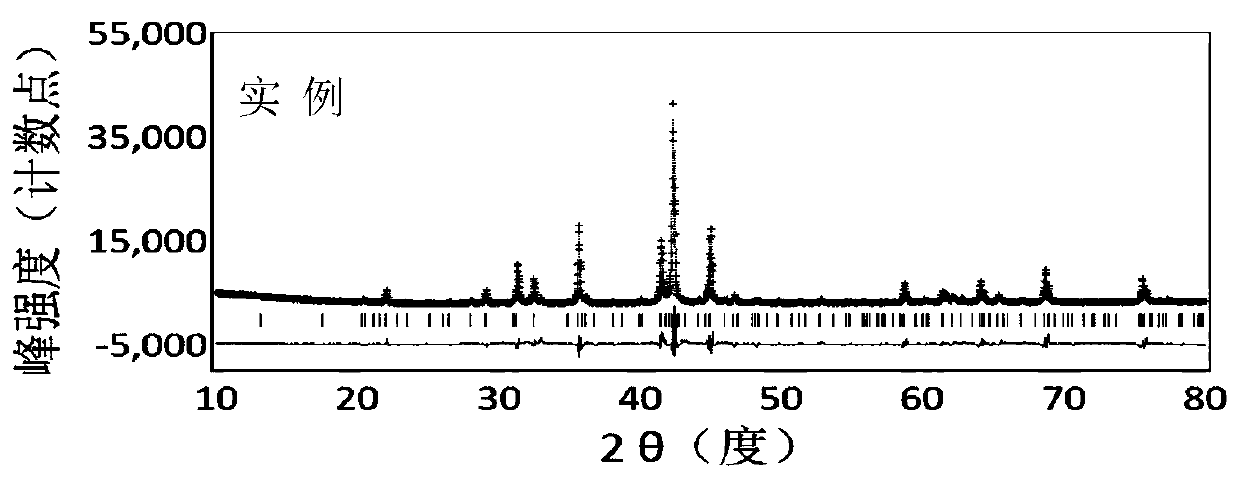

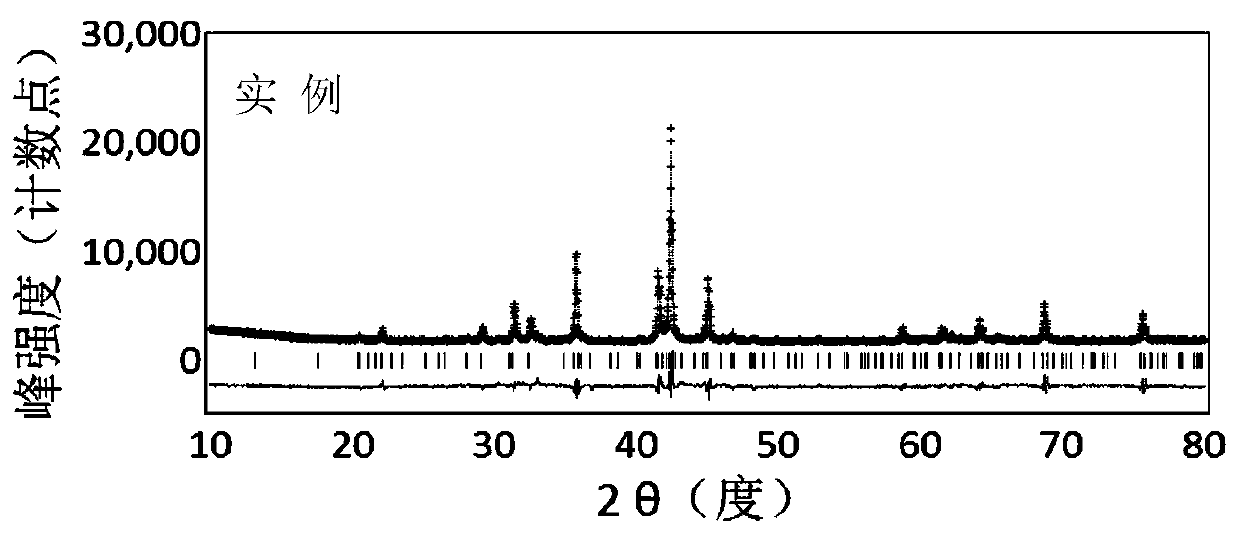

[0066] the La 0.70 SM 0.05 Mg 0.25 Ni 3.72 al 0.10 After the alloy is pulverized, pass through a 400-mesh sieve, and the sieved La 0.70 SM 0.05 Mg 0.25 Ni 3.72 al 0.10 The alloy was tested by XRD. figure 2 In order to use the Rietveld method for La 0.70 SM 0.05 Mg 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com