Patents

Literature

177results about How to "Production conditions are easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation process of fluorescent powder for white light LED excited by blue light

InactiveCN100999662ASimple preparation processProduction conditions are easy to controlGas discharge lamp usageLuminescent compositionsCruciblePhosphor

The present invention is preparation process of phosphor powder for blue light excited white light LED. The phosphor powder has the chemical formula of (R3-x-yCexLny)A5O12, where, R is at least one of Y, La, Gd, Tb, Lu and Sc; Ln is at least one of Pr, Dy, Nd, Sm, Dy and Bi; A is at least one of B, Al, Ga, Si, Mn and Mg; x is 0.01-1.2; and y is 0-0.2. The preparation process of the phosphor powder includes mixing oxides, hydroxides or salts corresponding to the elements in the formula and proper amount of flux; setting the mixture into the inner crucible with an unsealed cover, setting graphite or carbon between the outer crucible and the inner crucible, and covering the outer crucible with sealing cover; igniting inside a high temperature furnace at 1350-1700 deg.c, for 1-8 hr; cooling, crushing, washing and stoving to obtain the phosphor powder.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

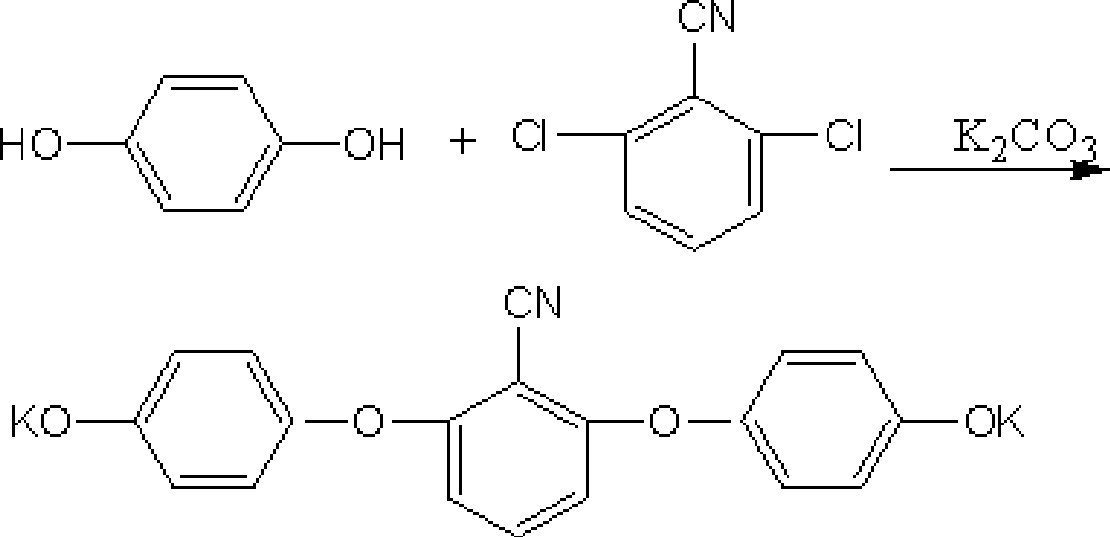

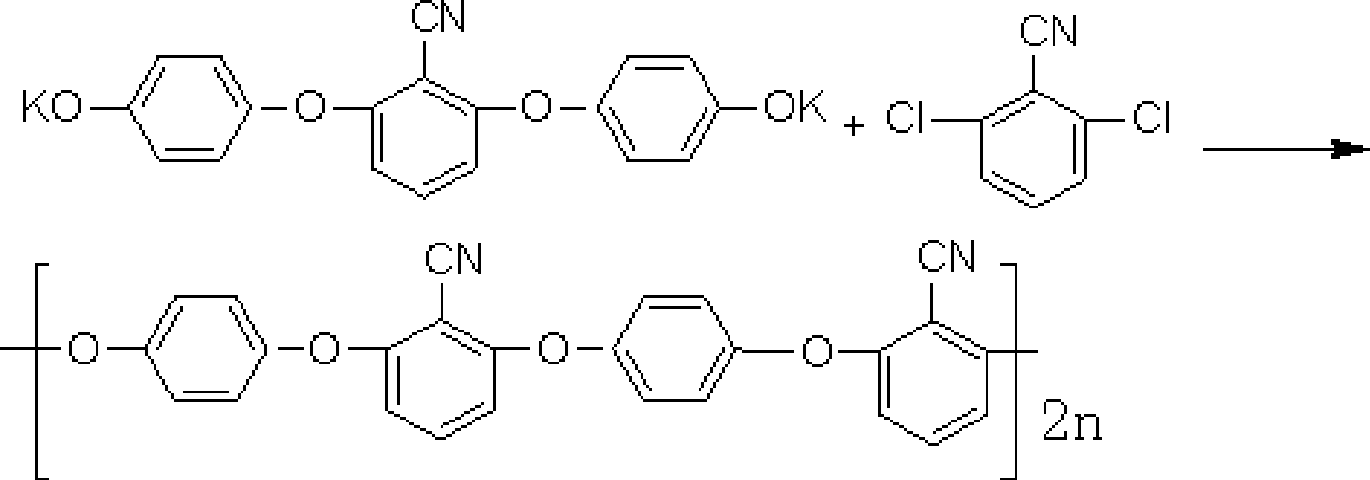

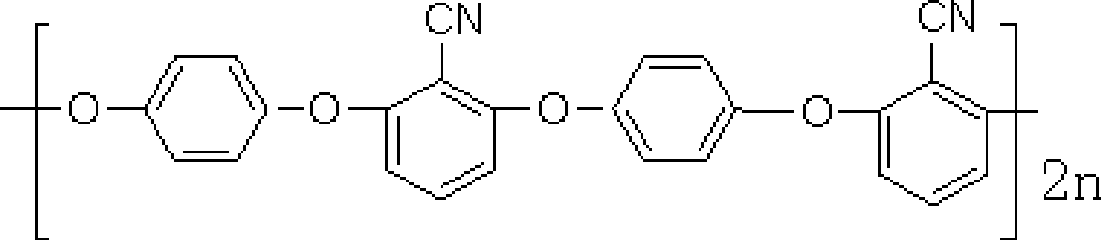

Method for preparing poly(arylene ether nitrile) resin

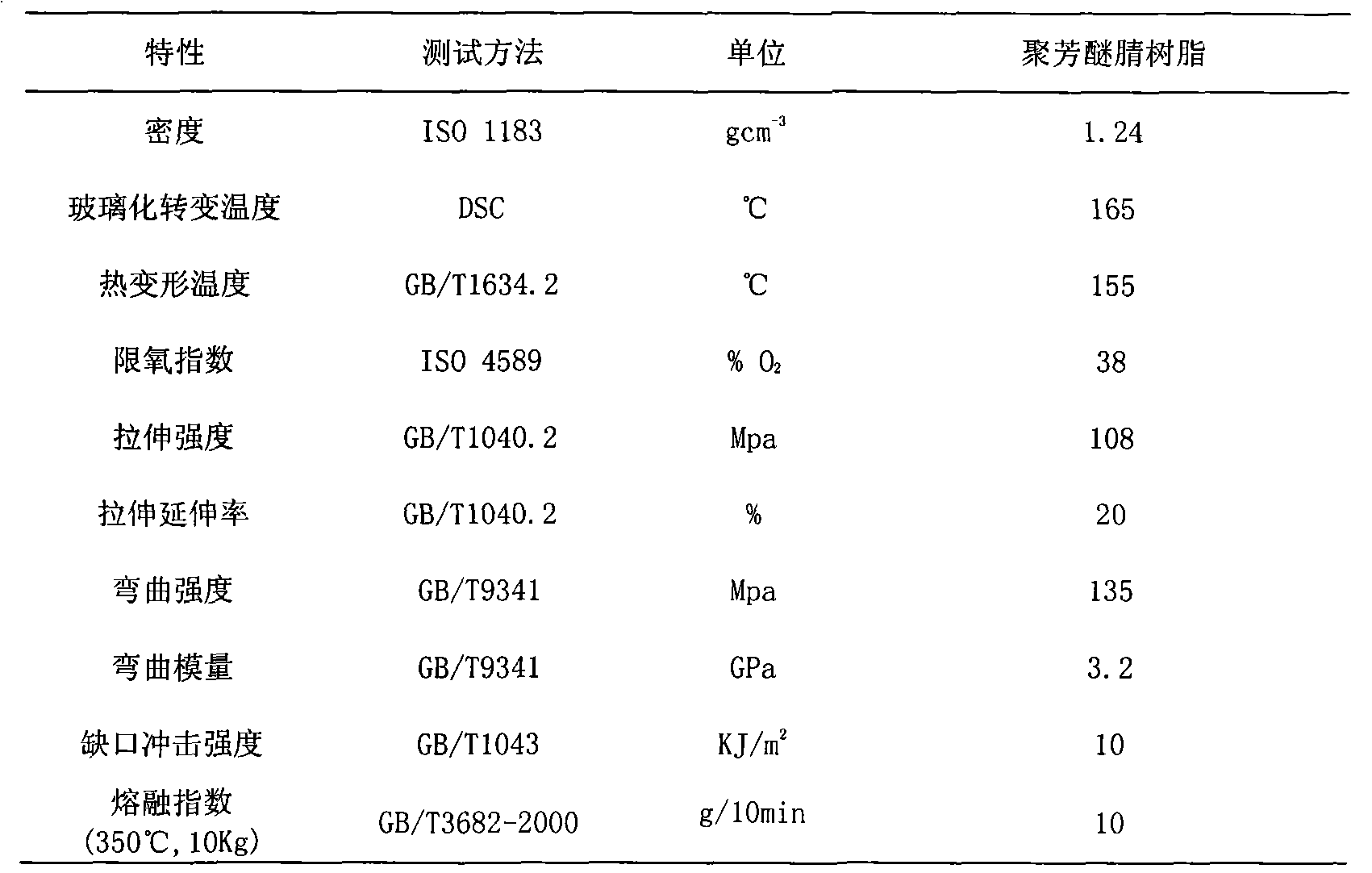

The invention discloses a method for preparing poly(arylene ether nitrile) resin, which belongs to the technical field of high polymer materials. The method comprises the following steps of: finishing a reaction in a reaction kettle under normal pressure under the actions of a catalyst and a dehydrating agent by taking 2,6-dichlorobenzonitrile and aromatic dicarboxylic phenol as raw materials and taking N-methyl pyrrolidone as a solvent; pressurizing and atomizing solution after dilution to a precipitating agent for precipitating; after heating, stirring and refluxing a precipitate and the precipitating agent to finish solvent extraction, performing solid-liquid separation by using a centrifugal machine; allowing liquid to enter a rectifying tower for rectifying and recovering the solvent; and drying solid after washing with boiling water to obtain the poly(arylene ether nitrile) resin of the invention. The method has the characteristics of easily implemented production conditions, and safe and environmentally-friendly production process. The poly(arylene ether nitrile) resin prepared by adopting the method of the invention has the characteristics of high purity and stable performance, and can be applied to the field of aerospace, electronics, machinery, medical treatment, chemical industry and the like.

Owner:SICHUAN FEIYA NEW MATERIAL

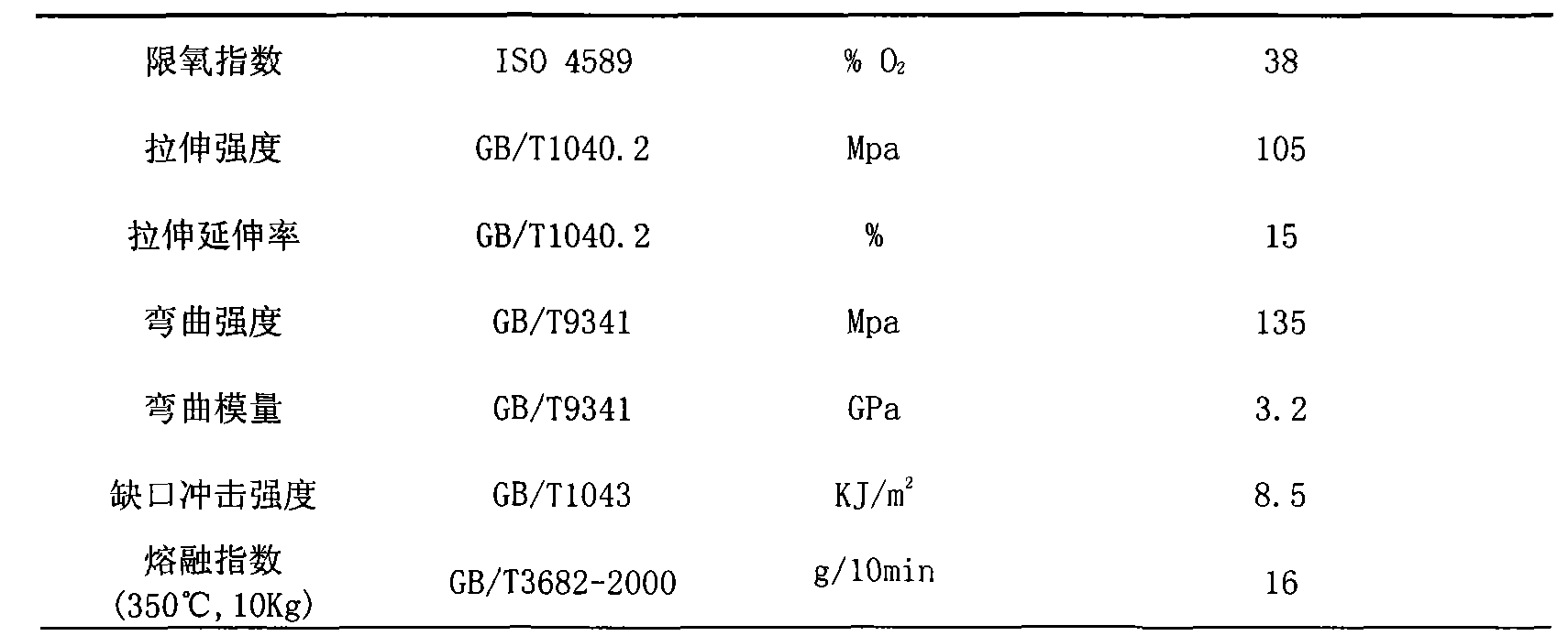

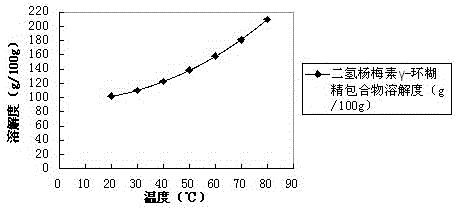

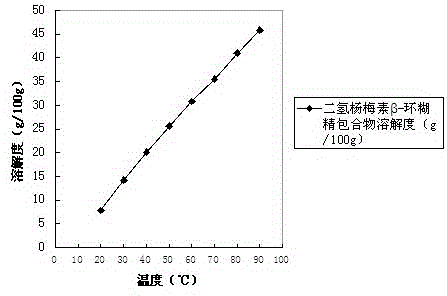

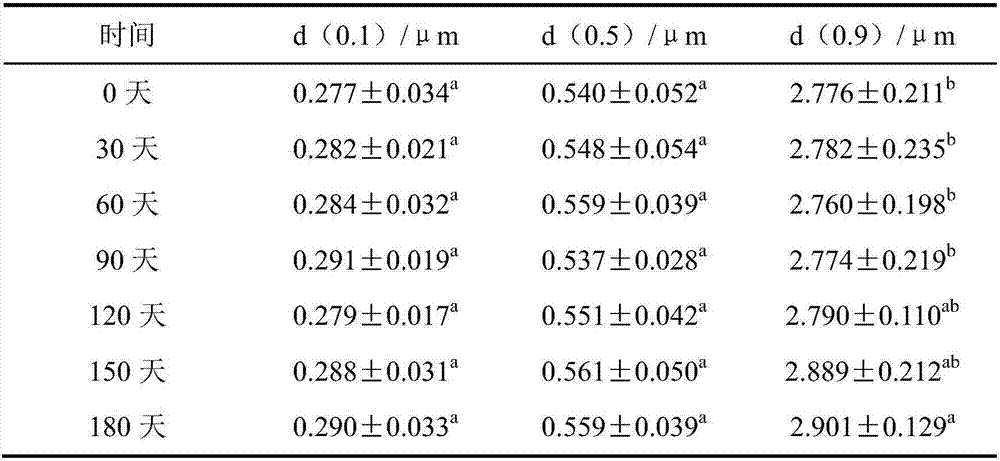

Dihydromyricetin cyclodextrin inclusion compound and preparation method thereof

InactiveCN104666293AImprove solubilityImprove stabilityAntibacterial agentsOrganic active ingredientsSolubilityNatural substance

The invention discloses a dihydromyricetin cyclodextrin inclusion compound, which comprises cyclodextrin and dihydromyricetin, wherein the dihydromyricetin is embedded into a cyclodextrin cavity; and the inclusion compound employing the cyclodextrin as a host molecule and dihydromyricetin as a guest molecule is formed. The dihydromyricetin cyclodextrin inclusion compound has the beneficial effects that 1 the dihydromyricetin cyclodextrin inclusion compound is embedded by the cyclodextrin, and the solubility, the stability and the bioavailability of the dihydromyricetin are improved; 2 the preparation method of the dihydromyricetin cyclodextrin inclusion compound disclosed by the invention is simple in process and suitable for industrialized production; 3 a spray drying process is adopted, the process from spray drying to dust collection is finished within 20 seconds, the problem of product oxidation in the drying process is avoided, the method is simple in process, simple and convenient to operate; the production conditions are easy to control, and the inclusion rate of the dihydromyricetin is high; and 4 the dihydromyricetin used by the dihydromyricetin cyclodextrin inclusion compound is extracted from vitaceae ampelopsis, and the dihydromyricetin in the vitaceae ampelopsis is high in content, and is a natural substance and free of toxicity.

Owner:江苏丰园生物技术有限公司

Method for preparing blue luminescent powder of aluminate activated by vacuum ultraviolet radiation

InactiveCN1415695ASimple preparation processProduction conditions are easy to controlLuminescent compositionsAluminateNoble gas

A vacuum ultraviolet ray activated blue fluorescent aluminate powder has a formula. Ba1-xEuxMgAl10O17, where x=0.02-0.2, and is prepared by choosing raw materials and coflux, generating reduction atmosphere, and controlling reaction temp and time. It can be used for plasma flat display or gas lamp.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for producing fruit juice of germinant unpolished rice and ganoderma lucidum, and production

InactiveCN1759760ASimple processing methodHigh degree of industrializationFood preparationPlant ingredientsFruit juiceAdditive ingredient

A nutritive health-care fruit juice is prepared through choosing Korean ganoderma as bacterial strain, preparing culture medium from germinated long-grained non-glutinous rice mild, malt juice and germinated soybean juice for deep ferment, slant culture, stage-one shaker culture, stage-two seeding tank culture, deep fermenting, mixing the fermented liquid with grape jice, apple juice and orange juice, homogenizing, degassing, sterilizing and cooling. Its advantage is rich bioactive substances (ganoderma polyose, gamma-aminobutanoic acid, etc).

Owner:SUZHOU JINJI FOODS

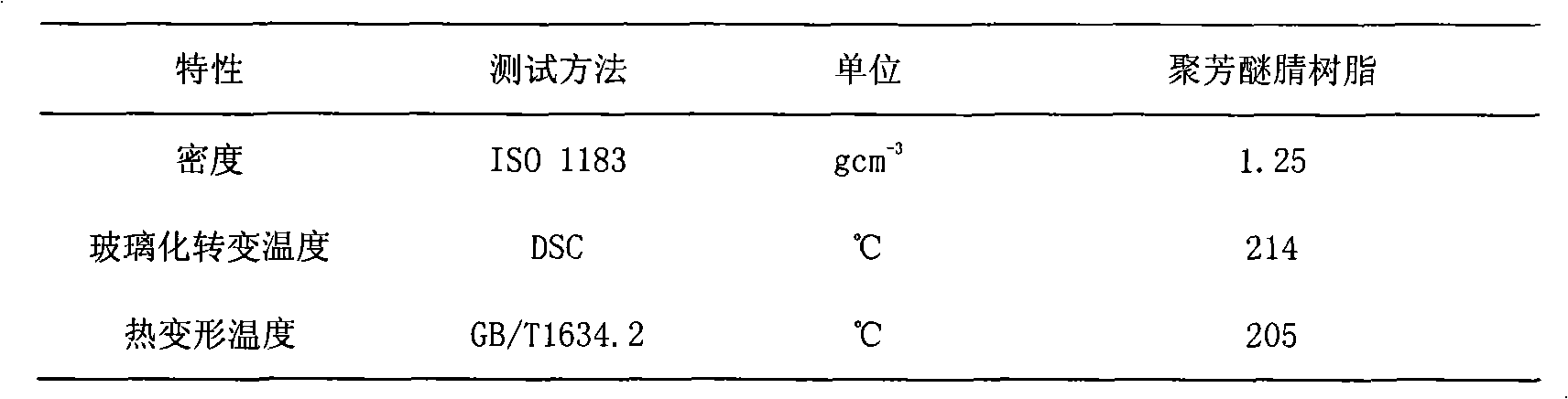

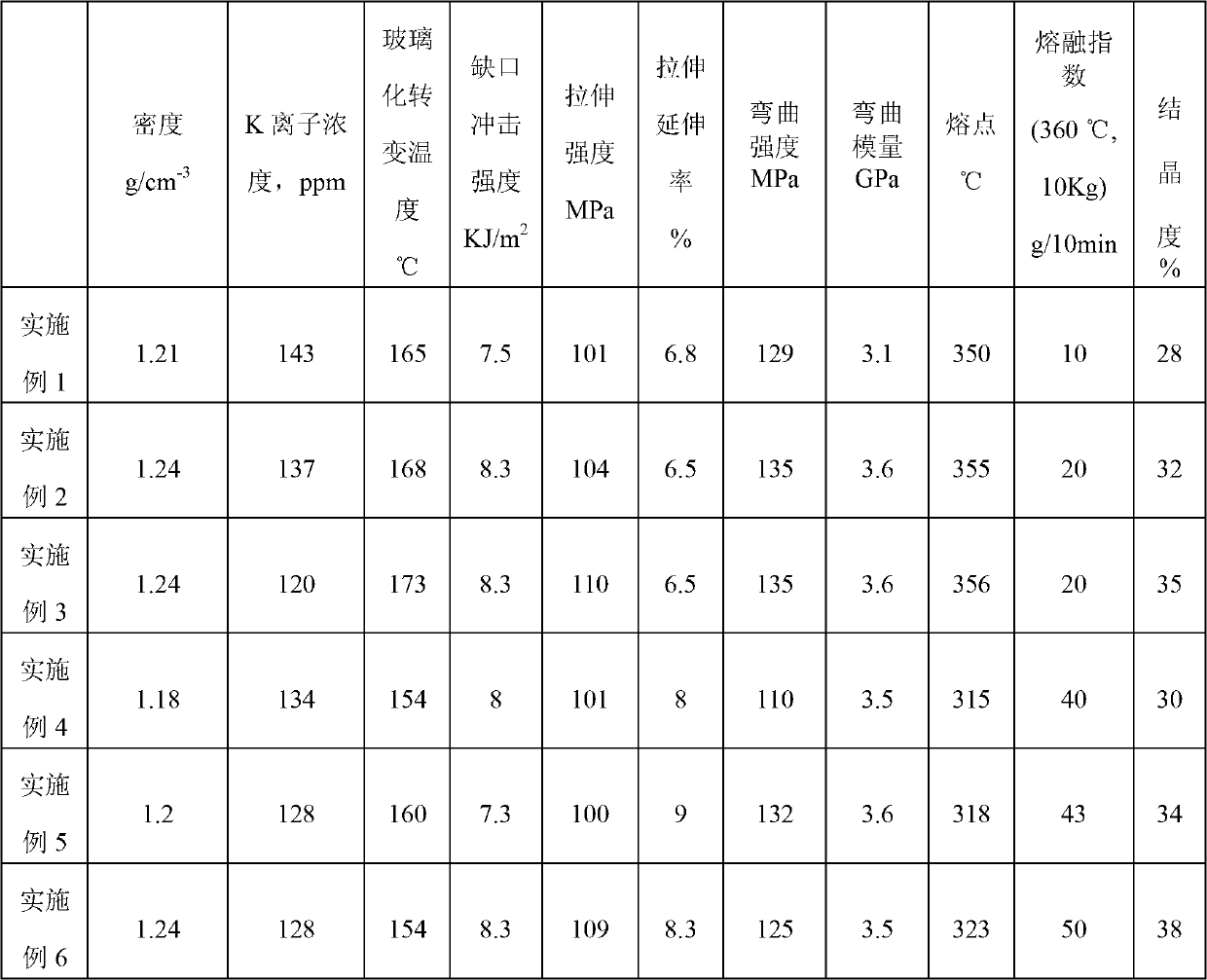

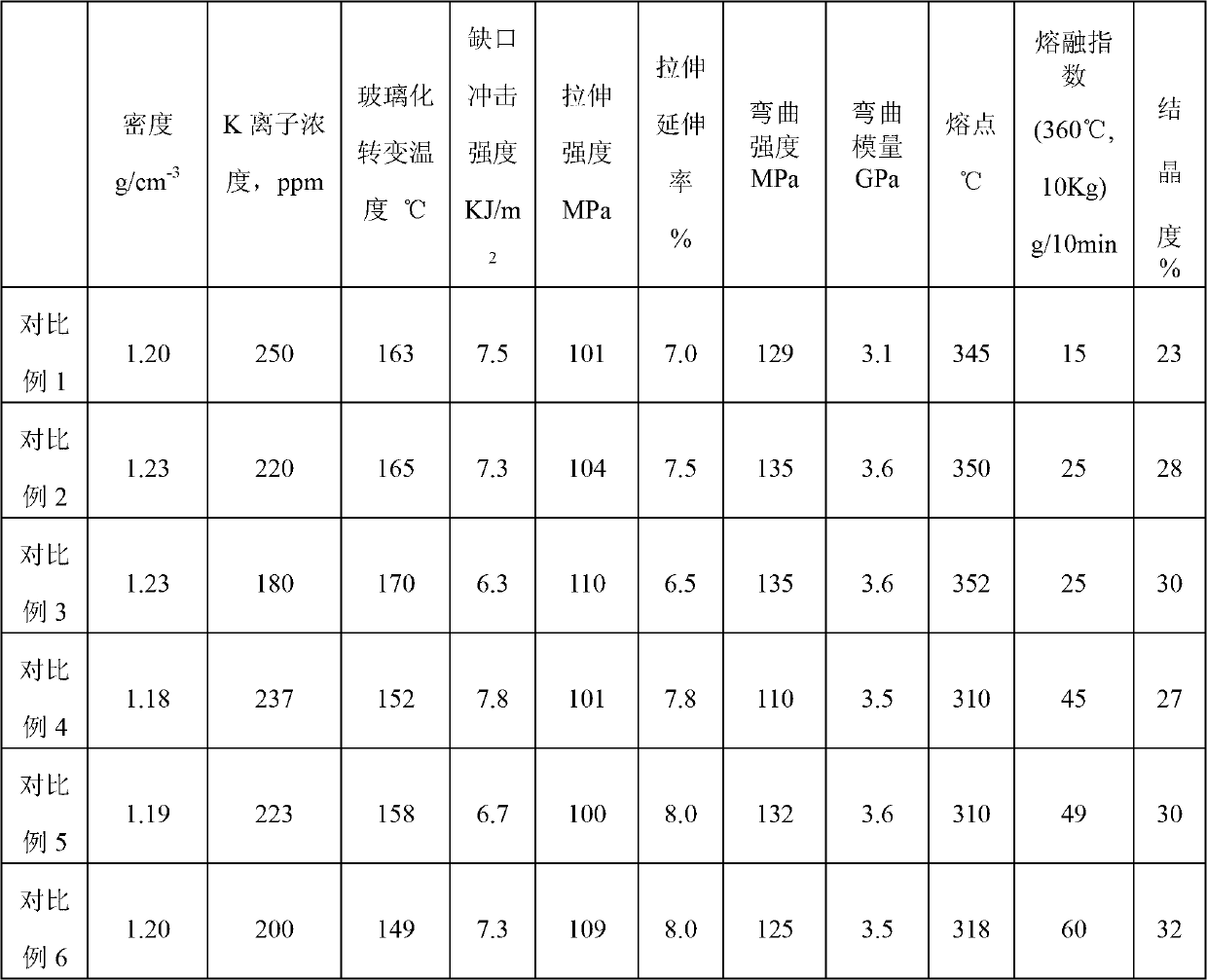

Industrial production method of semi-crystalline poly aryl ether nitrile

The invention relates to an industrial production method for semi-crystal poly(aromatic ether nitrile), which belongs to the field of polymer material. The method comprises the following steps: 2, 6-dichloro benzonitrile and hydroquinone are taken as raw materials; anhydrous potassium carbonate is taken as a catalyst; in the presence of a solvent and a dehydrating agent, the raw materials and the catalyst react under atmospheric pressure to obtain the poly(aromatic ether nitrile) homopolymer with low molecular weight and regular chain segments; and then the molecular weight of polymer is increased through pressurization, so as to obtain the semi-crystal poly(aromatic ether nitrile) polymer with high molecular weight. Due to the increase of crystallinity and molecular weight, the mechanical properties and heat resistance of the semi-crystal poly(aromatic ether nitrile) polymer are obviously improved.

Owner:SICHUAN FEIYA NEW MATERIAL

Method for preparing okra polysaccharide and pectin as well as pill preparation thereof

The invention relates to a method for preparing an okra polysaccharide and pectin as well as a pill preparation thereof, belonging to the technical field of health foods. The method comprises the steps of: in the extraction of the okra polysaccharide and the pectin, drying and grinding young fruits of the okra as raw materials into coarse powders, carrying out percolation extraction, and concentrating a percolation extracting solution with a vacuum film to obtain a concentrated solution; carrying out alcohol precipitation on the concentrated solution to obtain a polysaccharide and pectin precipitate, transferring to a refrigerator for cooling, staying overnight, and then pouring an upper-layer solution to obtain a polysaccharide and pectin extractum object; freeze-drying or spray-drying the extractum object to obtain an okra polysaccharide and pectin dry powder; and mixing the okra polysaccharide and pectin dry powder as the raw material with a mixed substrate according to the ratio of 1:1-1:3 to prepare the pill preparation. The prepared product has the health care efficacy of resisting fatigue, delaying aging, improving digestion, invigorating the stomach, moistening the intestine, protecting the liver, strengthening the kidney, reducing the blood fat, enhancing the human endurance and the immunity of the organism, and the like and has the advantages of high bioavailability, quick oral-taking absorption, high content of functional components, remarkable health care function and convenience eating and carrying.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Industrial production method for ethylene propylene diene rubber molded sealed cell sponge rubber

ActiveCN101724172AProduction conditions are easy to controlStable productionPolymer scienceFoaming agent

The invention discloses an industrial production method for ethylene propylene diene rubber molded sealed cell sponge rubber and, relates to an industrial preparation method for a foaming material with a high foaming ratio. The method comprises the following steps of performing plastication, mixing, refining, and foaming and vulcanization molding on raw rubber, and is characterized in that carbon black, naphthenic oil, a blowing promoter, a vulcanization accelerator and an anti-aging agent are added in the mixing process to perform the mixing; a foaming agent Ac and a vulcanizing agent are added in the refining process to perform the refining; and the vulcanization conditions in the foaming and vulcanization molding process are that: the pressure is 15 to 20 MPa; the temperature is 160 to 180 DEG C; and the vulcanizing time is 3,000 to 3,500 seconds. The industrial production method is researched and developed based on market demands to turn laboratory researches to industrialized researches, ensure that the production condition can be controllable and the production process is stable. The industrial production method selects homemade rubber masses, selects the foaming agent Ac to replace the foaming agent H, and prepares an EPDM molded sponge rubber product in accordance with the requirements on the industrial production by adjusting the mixture ratio of various auxiliary agents in a formula and controlling process conditions.

Owner:连云港冠泰汽车配件有限公司

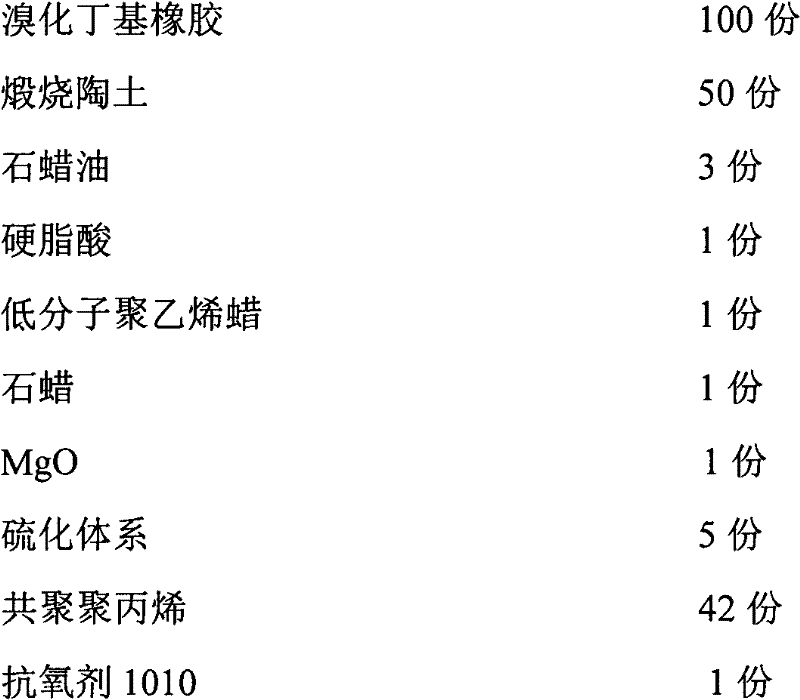

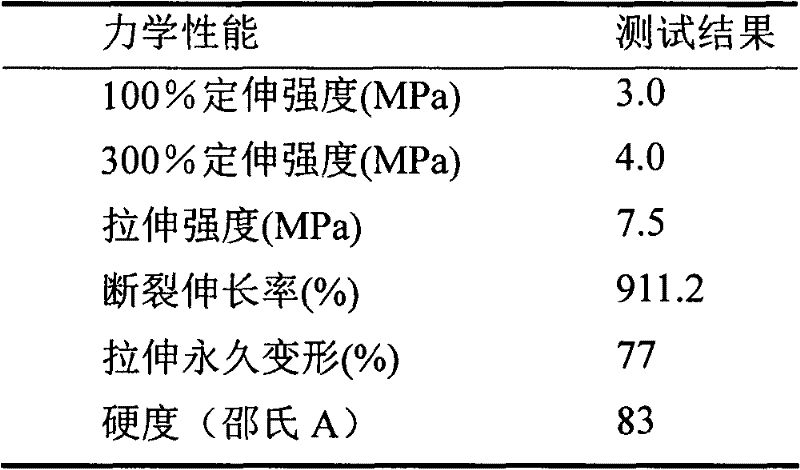

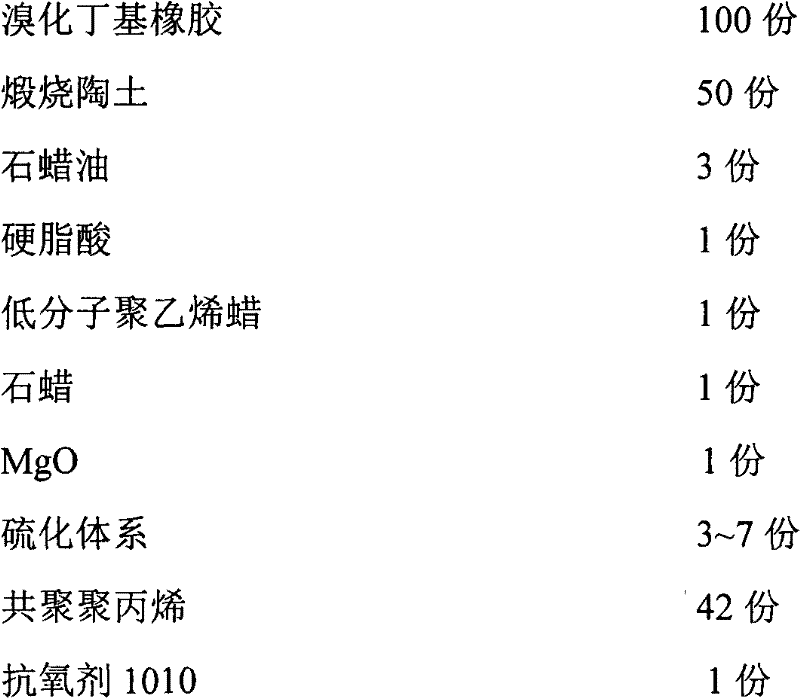

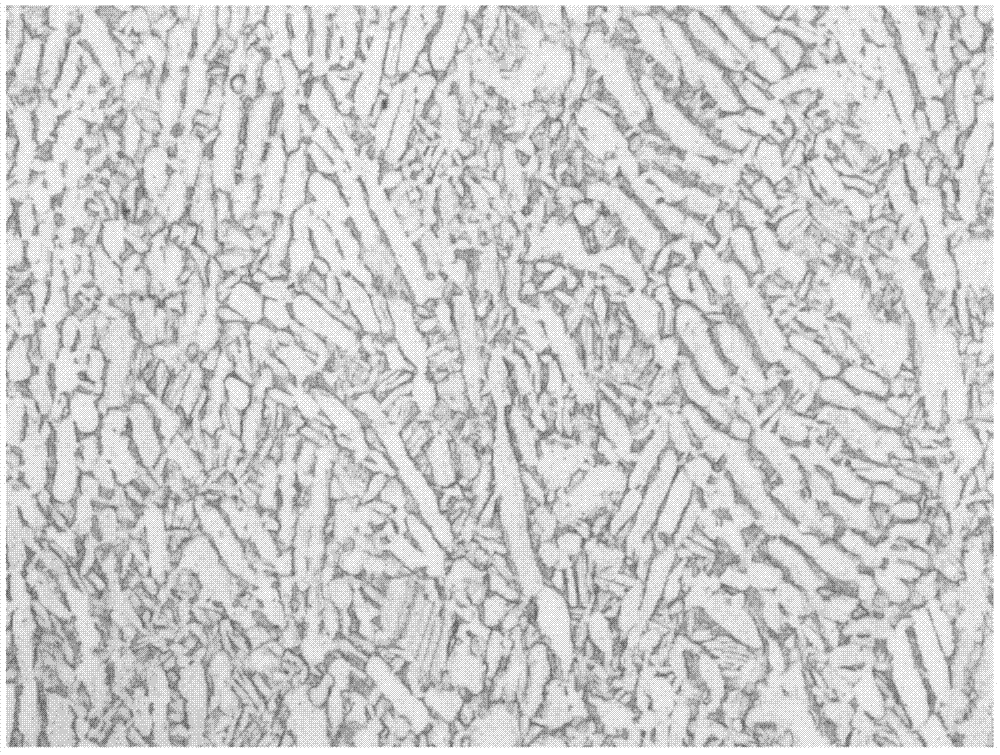

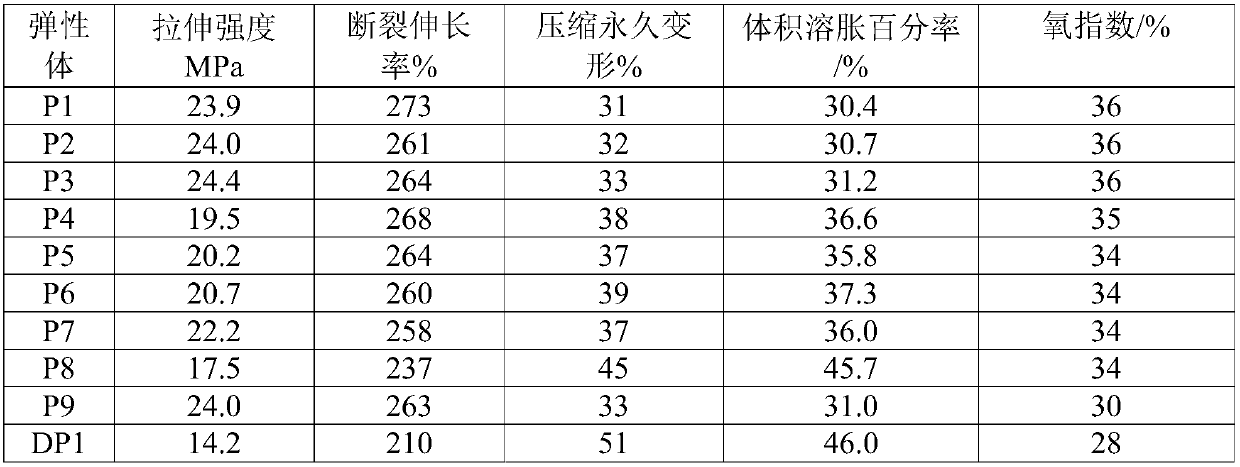

Vulcanizing system of brominated butyl rubber/ polypropylene thermoplastic elastomer sealing material and preparation method for sealing material

InactiveCN102585319APlay a role in vulcanizationHigh elongation at breakOther chemical processesCross-linkPolymer science

The invention provides a vulcanizing system of a brominated butyl rubber / polypropylene thermoplastic elastomer sealing material and a preparation method for the sealing material. The vulcanizing system comprises a vulcanizing agent, a catalyst and an active agent. The vulcanizing agent is a sulfur-free vulcanizing system, is granular and dustless, and is easy to weigh, calculate and disperse and safe in operation. The preparation method is a dynamic vulcanizing blending method, and can comprise injection and extrusion molding; the cross-linked rubber phase is dispersed uniformly in a plastic phase; and the preparation method has the advantages of simple process, a small amount of waste, high production efficiency and the like. The performance of the prepared sealing material meets the requirement of national standard YBB00232004. The vulcanizing system can substitute brominated butyl vulcanized rubber and can be applied in various fields.

Owner:EAST CHINA UNIV OF SCI & TECH

Production method of titanium alloy seamless tubes used for tubing coupling

ActiveCN104259206AReduce manufacturing costSimple production methodMetal rolling arrangementsCouplingHeating furnace

The invention discloses a production method of titanium alloy seamless tubes used for tubing coupling. According to the production technology of annular furnace heating, cross piercing, non-mandrel tube rolling, heating furnace heating and sizing, the special titanium alloy seamless tubes with the specifications being different and the performance meeting the requirements can be produced by using an existing mandrel mill set and dies of the existing mandrel mill set and adjusting technology parameters according to requirements. The special titanium alloy seamless tubes can be directly used for machining a tubing coupling machine without being subject to thermal treatment. The production method is simple, production conditions are easy to control, the yield is higher than 95%, mass production can be realized, and large scale benefits can be produced.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Synthesis method of cefepime hydrochloride

InactiveCN102408440AReduce the impactReduce degradationOrganic chemistryCefepime hydrochlorideSynthesis methods

The invention belongs to the field of medical intermediate and particularly relates to a synthesis method of cefepime hydrochloride. The method comprises the following steps: adding (6R,7R)-7-amino-3-[(1-methyl-1-pyrrolidine)methyl]cef-3-ene-4-carboxylic acid hydrochloride and AE active ester in a mixed solvent of water and a water-soluble organic solvent; adjusting the pH value to 5.5-7.5, and performing an acylation reaction while keeping the temperature; extracting after the reaction, and recycling the organic phase through reduced pressure distillation; and adjusting the pH value of the water phase with hydrochloric acid, and crystallizing to prepare cefepime hydrochloride. The reaction is milder and adopts an acidic or nearly neutral environment, the influence of the reaction on cefepime is lower, the reaction is easier to control, the degradation probability and ring opening probability can be reduced, the purity of the finished product can be increased, the yield of cefepime can be increased, the quality of cefepime can be increased and the purity is above 99.5% through high performance liquid chromatography (HPLC) detection.

Owner:YIYUAN XINQUAN CHEM

Improved preparing method for soy sauce and sauce

The invention relates to the preparative way of flavoring, especially the way of producing a kind of improved soy sauce or / and catsup. The main procedures go as follows: first, conduct conventional alcohol fermentation or pre-fermentation to part of the starches leaven or the starches; second, add salt to the wine mash to make ready-made wine mash; third, mix the rest leaven with ready-made wine mash, conduct the mid-fermentation and after-fermentation to get the soy sauce and / or catsup.

Owner:SHIJIAZHUANG DINGXIN FERMENTATING FOOD SCIRES INST

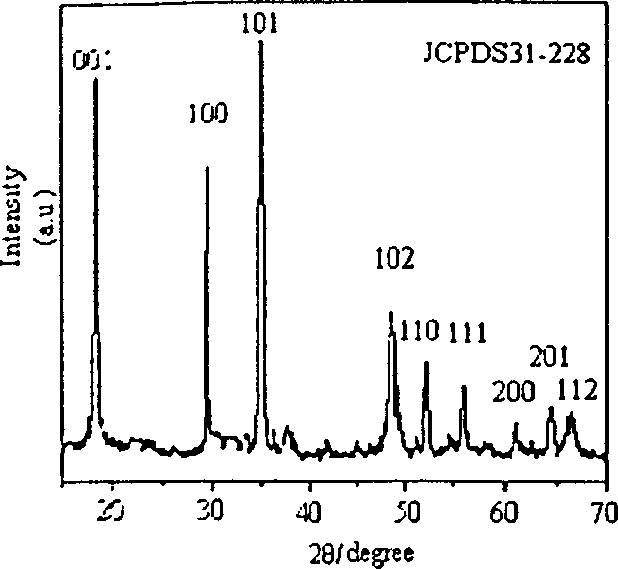

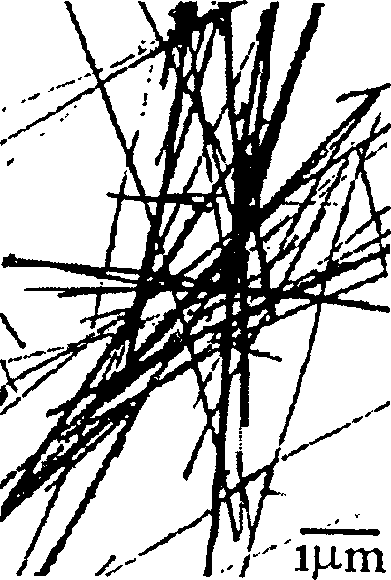

Method for synthesizing cadmium hydroxide single-crystal nanowire

InactiveCN1546382ASimple processProduction conditions are easy to controlCadmium compoundsInorganic saltsNanowire

The invention provides a process for preparing cadmium hydroxide single-crystal nanowires comprising the steps of, (1) dissolving soluble cadmium salt in deionized water, slowly charging alkali or ammonia solution till the pH is 10-14, stiring to produce white Cd(OH)2 deposition, (2) centrifugally scouring the white Al(OH)2 till pH is neutral, (3) redepersing the scoured white Cd(OH)2 deposition into deionized water, charging right amount of inorganic salt, (4) hot reaction 10-15 hours in air-tight container at 200-250 deg. C, thus obtaining cadmium hydroxide single crystal nanowires.

Owner:SHANDONG NORMAL UNIV

Preparation method of ferronickel residue sintered water-permeable bricks

InactiveCN106045477AReduce typesSimple processCeramic materials productionClaywaresBrickNational standard

The invention provides a preparation method of ferronickel residue sintered water-permeable bricks, and belongs to the technical field of building materials. The preparation method is characterized by adopting the following steps that firstly, ferronickel residues are smashed and sieved, and particles with the particle size of 1 mm-3 mm are taken as ferronickel residue raw materials; secondly, 70%-80% of the ferronickel residue raw materials, 10%-15% of clay and 10%-15% of a bonding agent are weighed by mass for batching, mixed and then stirred to be uniform by adding water, and a uniformly-stirred mixture is subjected to pressurization molding under the pressure of 30 MPa-50 MPa in a brick press to prepare green bricks; finally, the green bricks are dried and then sintered at the temperature of 1,050 DEG C-1,200 DEG C, heat preservation is conducted for 3-6 h, and then the ferronickel residue sintered water-permeable bricks are prepared. According to the preparation method, the industrial waste residues-ferronickel residues are maximumly utilized, the waste materials are changed into things of value, environmental pollution is reduced, and the performances of the ferronickel residue sintered water-permeable bricks meet the relevant requirements of the national standard.

Owner:SHANDONG UNIV OF TECH

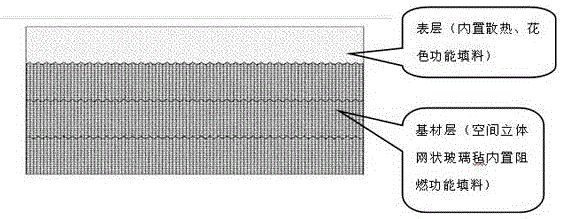

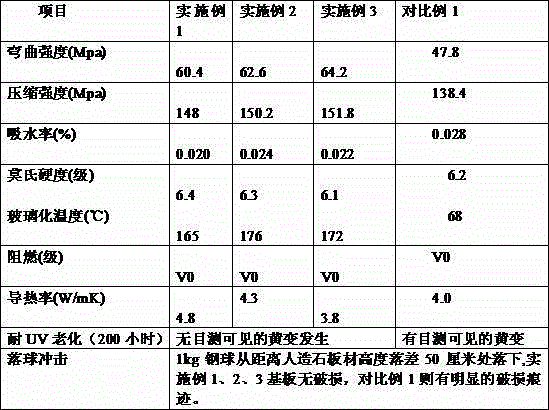

Composite artificial stone table board and preparation method thereof

ActiveCN105060776ANo cracking problemImprove the decorative effectLayered productsEpoxySurface layer

The invention discloses a composite artificial stone table board and a preparation method thereof. The composite artificial stone table board comprises a surface layer and a base material layer, wherein the surface layer is prepared from raw materials, namely, quartz sand, quartz powder, a curing agent, an accelerant, a solvent, multifunctional epoxy resin, a coupling agent, a pigment and heat-conducting powder; the base material layer is prepared from raw materials, namely, aluminum hydroxide powder, quartz powder, a curing agent, an accelerant, a solvent, multifunctional epoxy resin, a coupling agent and a glass mat. The composite artificial stone table board has the advantages that the table board is high in strength, high in torsion and bending deformation resistance, high in heat conductivity coefficient, quick in heat dissipation, good in heat resistance and flame-retardant, does not age and yellow easily and the like, and the table board is suitable for popularization and application.

Owner:来宾环球经典新型建材有限公司

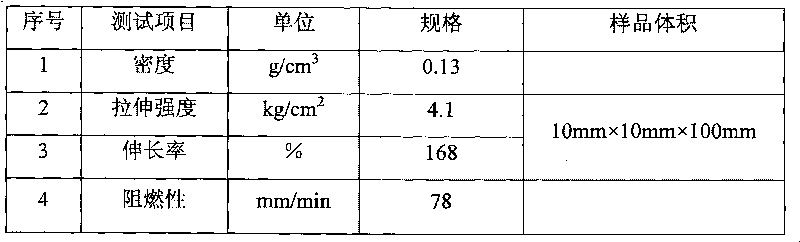

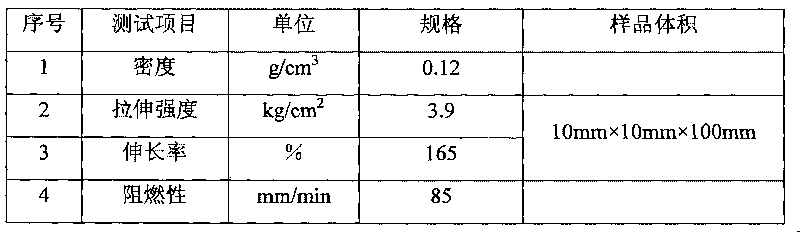

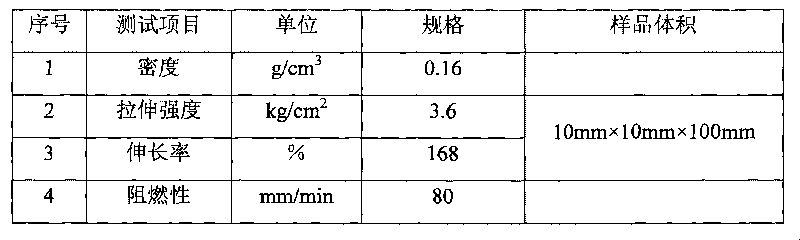

Polyetheramine toughened phenol formaldehyde foam and preparation method thereof

The invention discloses a polyetheramine toughened phenol formaldehyde foam and a preparation method thereof. The polyetheramine toughened phenol formaldehyde foam comprises the following components in parts by weight: 100 parts of polyetheramine modified phenol formaldehyde resin, 3-10 parts of surfactant, 5-15 parts of foaming agent and 5-20 parts of curing agent. The preparation method comprises the following steps: after sequentially adding the curing agent, surfactant and foaming agent into the polyetheramine modified phenol formaldehyde resin, stirring at high speed, injecting into a mold, and heating to foam and form, thereby obtaining the polyetheramine toughened phenol formaldehyde foam, which has the advantages of less shedding and high toughness and is a heat insulating material with excellent properties.

Owner:SHANGHAI INST OF TECH

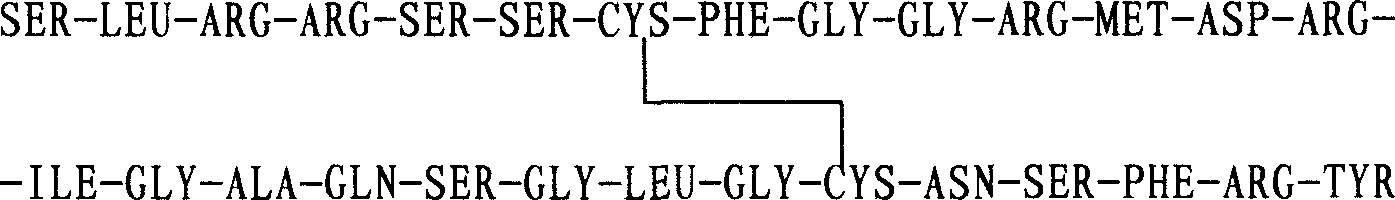

Method for preparing recombined human atrial natriuretic peptide rhANP by using ferment in high density

This invention relates to microorganism fermentation domain, is a method of preparing rhANP by the way of high density fermentation. This invention uses PCW112-ANP / DH5 alpha , through expand seed culture medium solution talus bacterium, high density fermentation, separation and purity e.g. craft procedure, we prepares the rhANP. This invention dissolves the problem of ANP express and difficulty of purity which has imprisoned the industrial application of it. Its production condition is easy to control and the material of bacterium is easy to obtain, with good repeat activity, low cost, and product can be applied to biology pharmacy.

Owner:SHENZHEN STATE BIOCHEM ENG TECHDEV CENT

Polyaryl ether nitrile resin and industrialized synthetic method thereof

The invention belongs to the technical field of polymer materials, and especially relates to a polyaryl ether nitrile resin and an industrialized synthetic method thereof. The structural unit of the polyaryl ether nitrile resin is one of units shown in the specification, and the crystallinity degree of the polyaryl ether nitrile resin is 28-38%. The polyaryl ether nitrile resin prepared by the invention is high in purity and high in crystallinity degree (28-38%); the glass transition temperature is 150-180 DEG C, the melting point is 310-355 DEG C, and the initial decomposition temperature is more than 450 DEG C; the resin has higher mechanical strength, the tensile strength is 100-120Mpa, the tensile modulus is 2.4-3.6GPa, and the bending strength is 100-140Mpa; and therefore, the polyaryl ether nitrile resin prepared by using the method disclosed by the invention can be applied to the fields such as aerospace, electronics, machinery, medical treatment, chemical engineering and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for producing chlorinated butyl rubber

The invention discloses a method for producing chlorinated butyl rubber which comprises the steps of dissolving, chloridizing, neutralizing and charging adjuvant. The invention realizes simple process, easy processing, easy production condition control, and better product quality.

Owner:NANTONG DONGTENG SPECIAL SYNTHETIC RUBBER

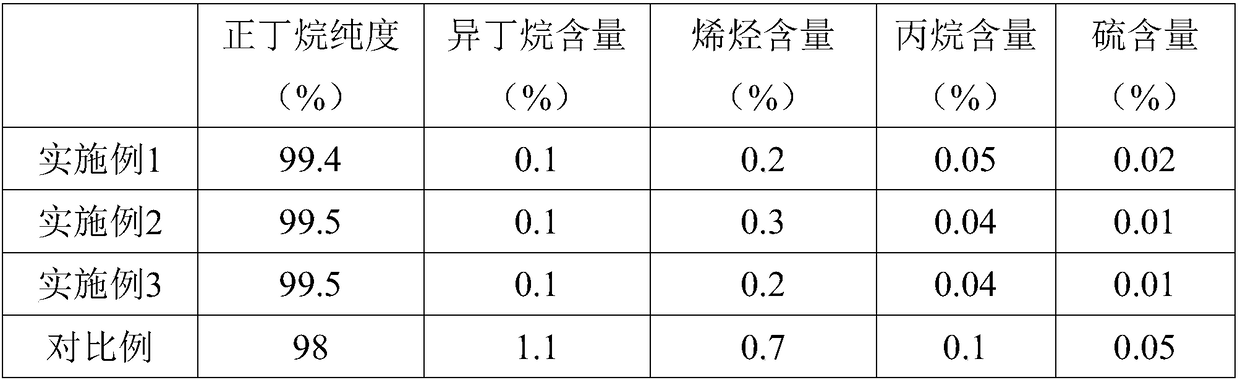

Method for preparing n-butane from mixed butane

InactiveCN108530254AHigh catalytic activityShorten the hydrogenation reaction timeHydrocarbon by isomerisationHydrocarbon by hydrogenationFixed bedPetroleum

The invention discloses a method for preparing n-butane from mixed butane, and relates to the technical field of n-butane synthesis. The method includes placing the butane in a fixed-bed reactor, adding hydrogenation catalysts into the fixed-bed reactor, circularly filling the fixed-bed reactor with hydrogen and carrying out hydrogenation reaction; uniformly mixing reaction products and desulfurizing agents with one another to obtain mixtures and feeding the mixtures into a distillation tower; feeding desulfurized products into a rectification tower, collecting propane from the top of the rectification tower, collecting the n-butane from the bottom of the rectification tower and collecting isobutane in the middle of the rectification tower; carrying out normalization reaction on the collected isobutane under the effects of catalysts to generate the n-butane. The butane which is about to be placed in the fixed-bed reactor is a byproduct generated in production procedures for refining petroleum, preparing ethylene by means of steam cracking, preparing olefin from methanol and the like. The method has the advantages that the method includes chemical processes, accordingly, operation such as repeated fractional distillation and rectification required by conventional physical methods can be omitted, production processes can be simplified, conditions can be controlled in production procedures, the n-butane prepared by the aid of the method is high in purity, and byproducts rarely can be generated.

Owner:陈久仓

High-performance spherical ultrafine silver powder for solar cell electric conduction silver paste and preparation method thereof

InactiveCN108941609AEasy to separateHigh densityTransportation and packagingMetal-working apparatusSilver pasteFiltration

The invention discloses high-performance spherical ultrafine silver powder for solar cell electric conduction silver paste and a preparation method thereof. The method comprises the following steps: (1) silver nitrate is dissolved in distilled water for uniform stirring; and a dispersing agent and a pH value adjusting agent are added; (2) hydroquinone is dissolved in the distilled water to obtainhydroquinone solution; and under the stirring condition, the obtained hydroquinone solution is quickly added in silver nitrate solution for reaction; and (3) after the reaction is finished, the staticsettlement and the suction filtration are performed; anhydrous ethanol is used for repeated washing and precipitation; and finally, the silver powder is obtained by drying. The invention further provides the high-performance spherical ultrafine silver powder for the solar cell electric conduction silver paste, which is prepared by the method. The sigh-performance spherical ultrafine silver powderfor the solar cell electric conduction silver paste and the preparation method thereof are easy to control the process conditions; and the performances of the prepared silver powder with high densityand easy dispersibility meet the production requirements of the solar cell electric conduction silver paste.

Owner:河南金渠银通金属材料有限公司

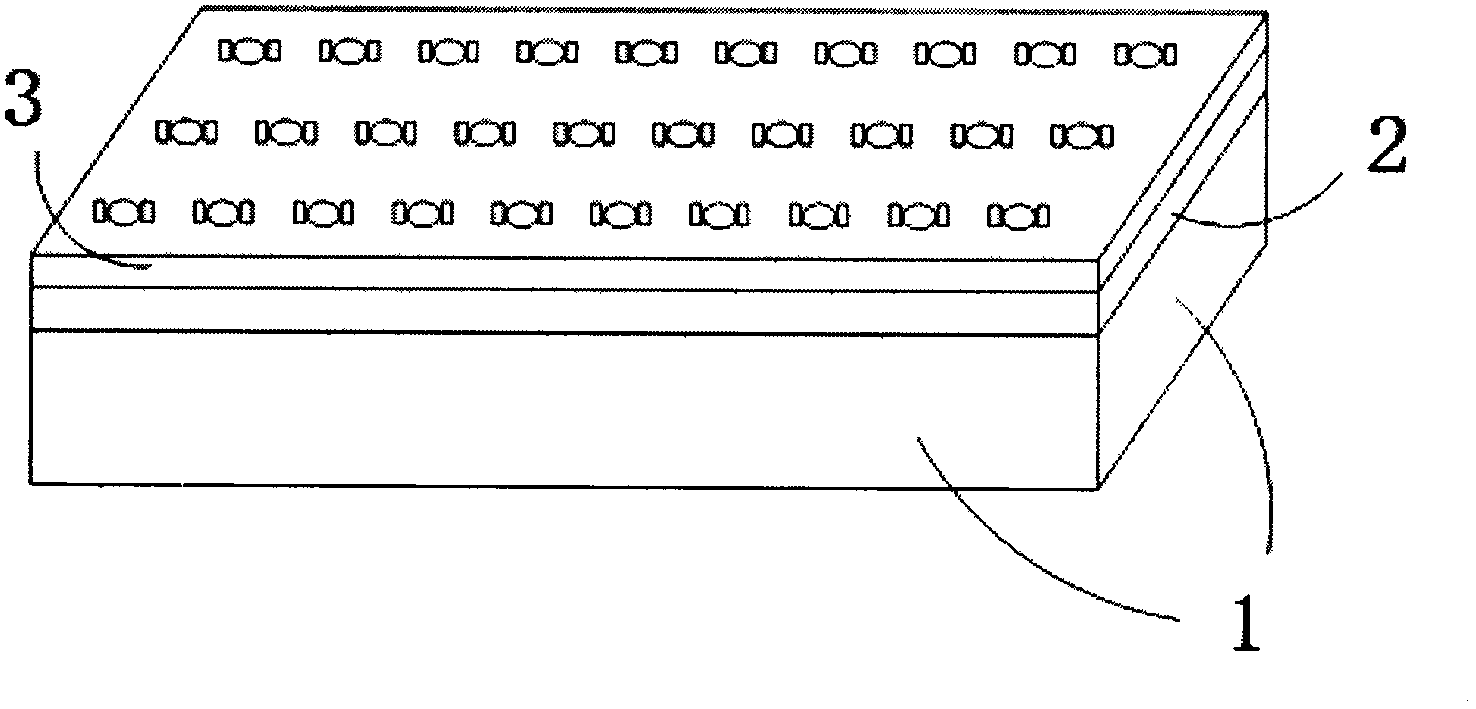

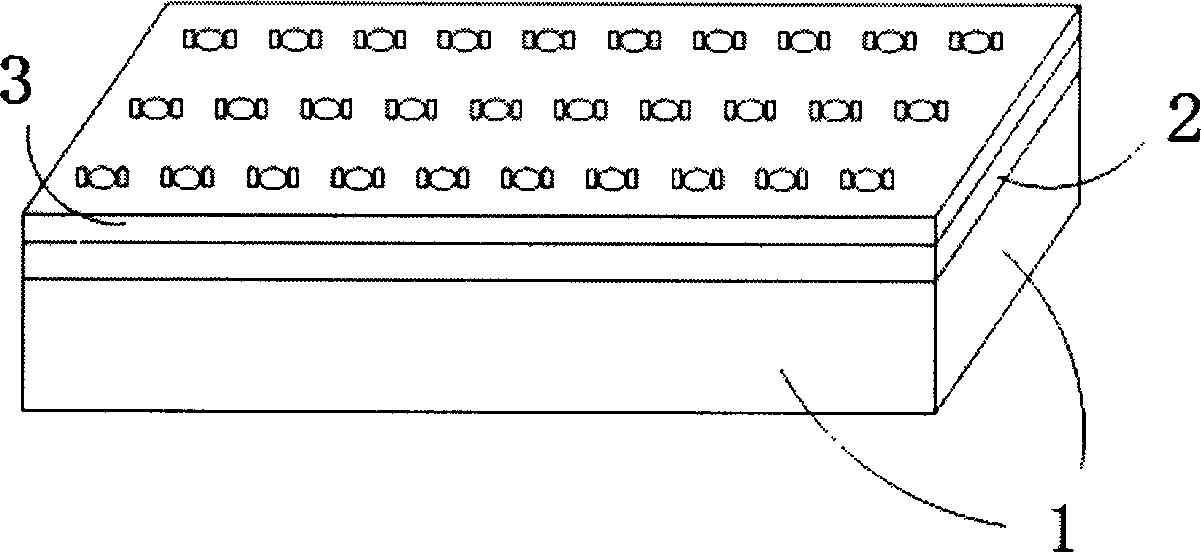

Graphite base plate for LED (light emitting diode) high-power illumination module and manufacturing technology of graphite base plate

InactiveCN102692000AReduce weightImprove heat transfer performanceCarbon compoundsPoint-like light sourceInsulation layerManufacturing technology

The invention discloses a graphite base plate for an LED (light emitting diode) high-power illumination module and a manufacturing technology of the graphite base plate. The graphite base plate comprises a high heat-conduction graphite base layer, a heat-conduction insulation layer and a circuit layer. The heat-conduction graphite base layer is formed by the steps of sintering WT70 % of fine graphite powder, WT5 % of copper powder, WT5% of aluminium powder, WT14 % of silane coupling agent, WT6 % of titanate coupling agent under the condition of high temperature of 1000-1200 DEG C to obtain a graphite composite, and manufacturing the graphite composite into a high heat-conduction graphite sheet-shaped base material by graphite coiled material production equipment. The heat-conduction insulation layer is made from a ceramic-filled polymer. The circuit layer is manufactured by a copper foil with thickness being 35-280 Mu m through a PCB (printed circuit board) technology. The main component of the graphite base plate is carbon material which is easy and convenient to obtain, and therefore the graphite base plate is low in cost and has strong resistance to corrosion, acid and alkali, oxidation and aging; and the waste does not pollute environment.

Owner:SHANXI SHANDI XINYUAN TECH

Preparation method of forsterite refractory brick prepared from nickel-iron slag

The invention discloses a preparation method of a forsterite refractory brick prepared from nickel-iron slag. The nickel-iron slag is used as a raw material, and fine magnesite powder is added; the generation amount of a liquid phase in a firing process is controlled by regulating and controlling the mass ratios of all components, so that the volume density and the compression strength of the refractory brick are improved, and the sintering temperature is reduced; the mass ratios of all the components are controlled to meet the following conditions that the mass ratio of MgO to SiO2 is 0.98 to 1.67, the mass ratio of MgO to FeO is 5.87 to 7.71, the mass ratio of MgO to Al2O3 is 11.23 to 17.6, the mass ratio of Al2O3 to SiO2 is 0.087 to 0.095, and the sum of MgO and CaO to the sum of SiO2 and Al2O3 is 0.95 to 1.59; meanwhile, the preparation method comprises the following steps: additionally adding water and a binding agent, uniformly mixing, and carrying out compression moulding and drying treatment; after treatment, roasting at the temperature of 1200 to 1350 DEG C for 2 to 3.5 hours; adopting an oxidizing atmosphere in the firing process, thus obtaining the forsterite refractory brick. The preparation method disclosed by the invention has the advantages of high resource utilization rate, environment friendliness, simple process, low production cost and the like; the forsterite refractory brick prepared from the nickel-iron slag has the advantages of high compression strength, high volume density, low porosity and good thermal shock resistance.

Owner:CENT SOUTH UNIV

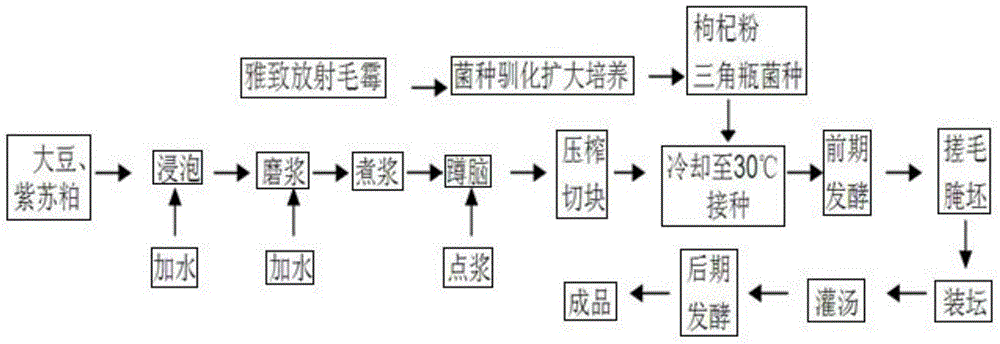

Preparation method of fermented bean curd with purple perilla flavor

InactiveCN104351355AHigh nutritional valueHigh health valueCheese manufactureFood scienceAdditive ingredientPerilla oil

The invention relates to a preparation method of fermented bean curd with purple perilla flavor, belonging to the field of agriculture product processing technology. The preparation method comprises the steps of carrying out ultraviolet irradiation on actinomucor elegans strains, adding with purple perilla meal and lycium barbarum powder for habituated culture, manufacturing a bean curd base, fermenting in earlier stage and fermenting in later period; particularly, the preparation method comprises the following specific steps of soaking purple perilla meal and soybeans grinding, then carrying out residue filtering, solidifying, standing, squeezing and slicing to obtain the bean curd base; dipping the bean curd base into seed solution added with lycium barbarum powder to be inoculated, and then carrying out early-stage fermentation to form a blank; then carrying out later-stage fermentation on the blank and filling into a pot, then adding soup base to obtain the fermented bean curd with purple perilla flavor. According to the preparation method of the fermented bean curd with purple perilla flavor, purple perilla meal is added in the soybean raw material of the traditional fermented bean curd, the flavor of the traditional fermented bean curd taking the soybeans as raw materials is kept, the fermented bean curd also has the purple perilla flavor; the fermented bean curd is rich in alpha-linolenic acid and flavonoids, the nutrition value, the health value and the edible value of the fermented bean curd are improved, protein, residual perilla oil and functional ingredients in purple perilla meal can be effectively utilized and waste resources are effectively utilized.

Owner:JILIN BUSINESS & TECH COLLEGE

Preparation method of high temperature resistant forsterite type refractory material

The invention discloses a preparation method of a high temperature resistant forsterite type refractory material. The method comprises the following steps: using nickel-iron slag as raw materials and magnesia powder as additives, wherein the ratio of [w (MgO) + w (FeO)] to [w (Al2O3)+w (Cr2O3)] is 10.50 to 13.57, the ratio of w (MgO) to w (Cr2O3) is 34.90 to 48.12 and the ratio of w (MgO) to w (SiO2) is 1.19 to 1.61, adding binding agents and controlling calcination temperature to be 1360 DEG C to 1450 DEG C, inducing mineral phase reconstruction of the nickel-iron slag, optimizing transformation process of refractory crystal form (Mg2SiO4, MgO.Fe2O3, MgO.Al2O3, MgO.Cr2O3) to increase refractoriness of the refractory material. The refractoriness of the obtained refractory material is 1700 to 1800 DEG C, and the refractory material also has the advantages of high compressive strength, large bulk density, low apparent porosity, and can fully meet the industrial need of the refractory material. The preparation method of the high temperature resistant forsterite type refractory material has the advantages of high utilization rate of resources, high production efficiency, high added value, environment friendliness, easiness in process control, low production cost and the like.

Owner:CENT SOUTH UNIV

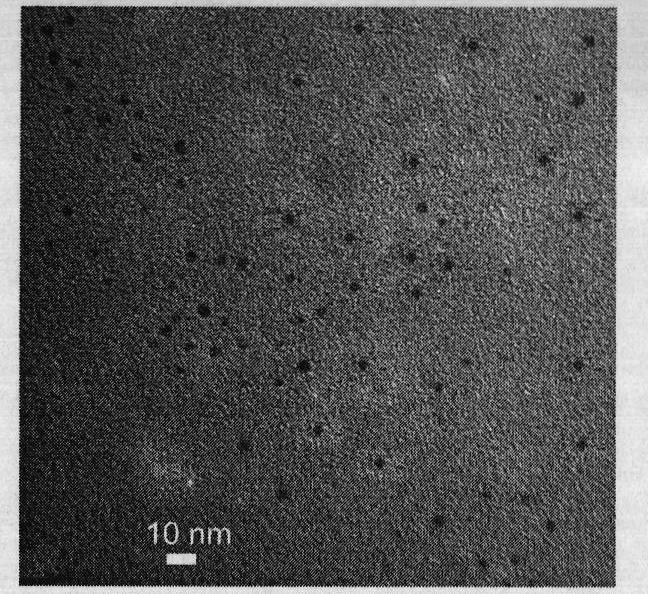

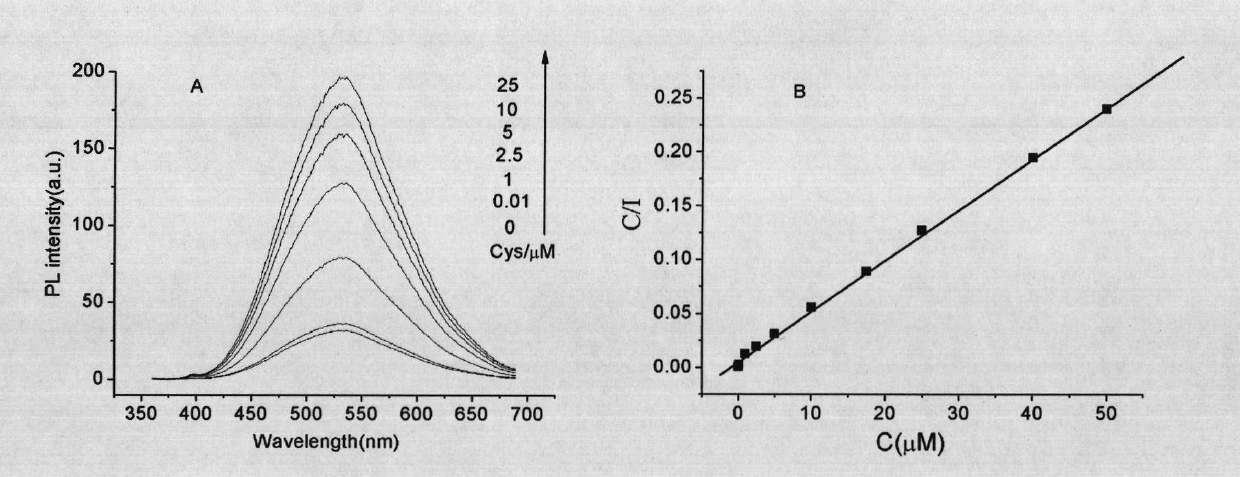

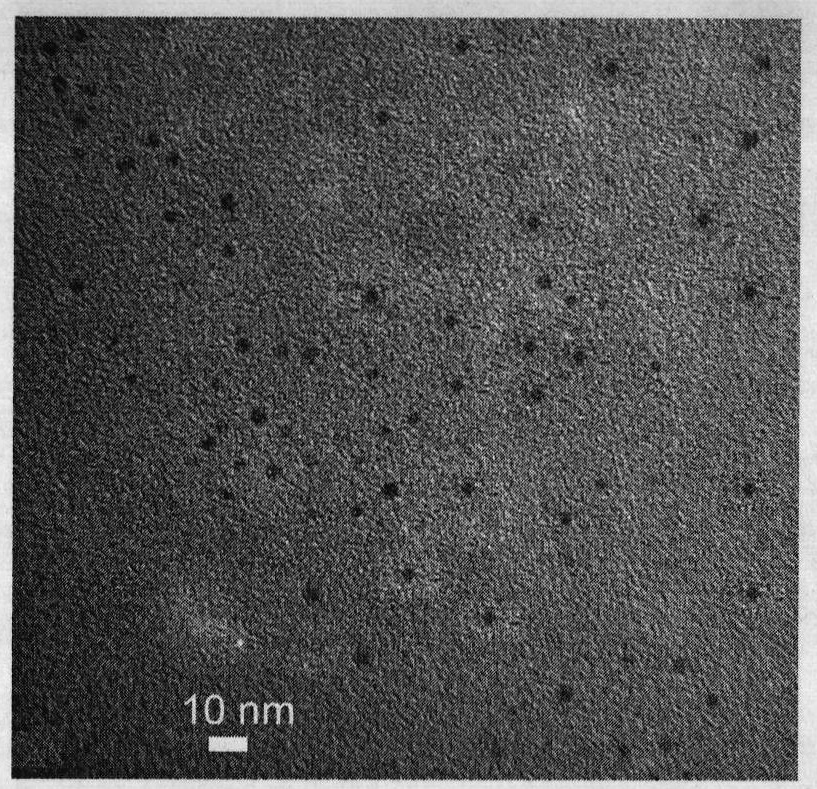

Synthesis and application of citrate-covered water soluble CdS nanomaterial

InactiveCN101948685ASensitive selective responseImprove luminosityFluorescence/phosphorescenceLuminescent compositionsFluorescenceSynthesis methods

The invention provides a synthesis method and application of a citrate-covered water soluble CdS nanomaterial. The synthesis method comprises the following steps of: a, adding soluble citrate into solution of soluble salt in which cadmium ions are dissolved to prepare precursor solution of Cd-Cit; b, adjusting the pH value of the precursor solution with solution of sodium hydroxide, and removing oxygen from mixed solution by introducing an inert gas; and c, adding sodium sulfide into the mixed solution, and reacting for a certain period of time to obtain the citrate-covered water soluble CdS nanomaterial. A water soluble quantum dot with high dispersibility and high fluorescent performance can be obtained under mild conditions. The obtained quantum dot can be used for analysis and measurement of cysteine.

Owner:JIANGNAN UNIV

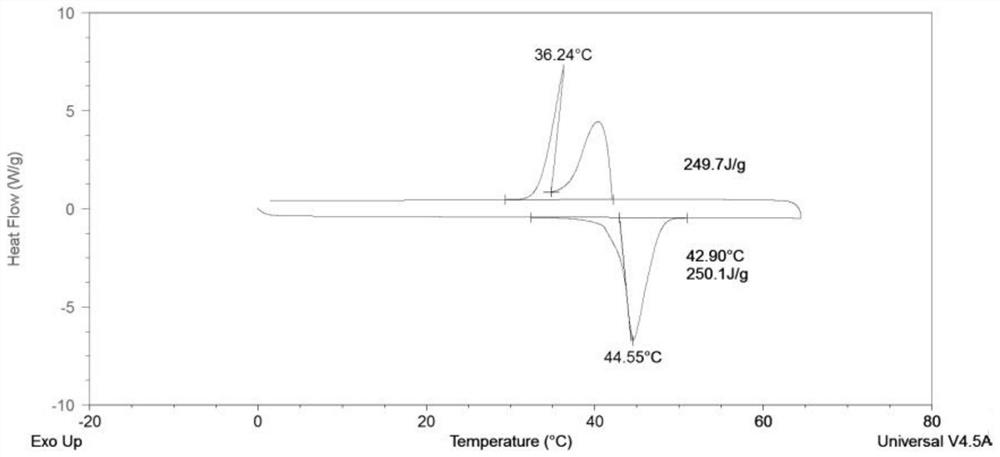

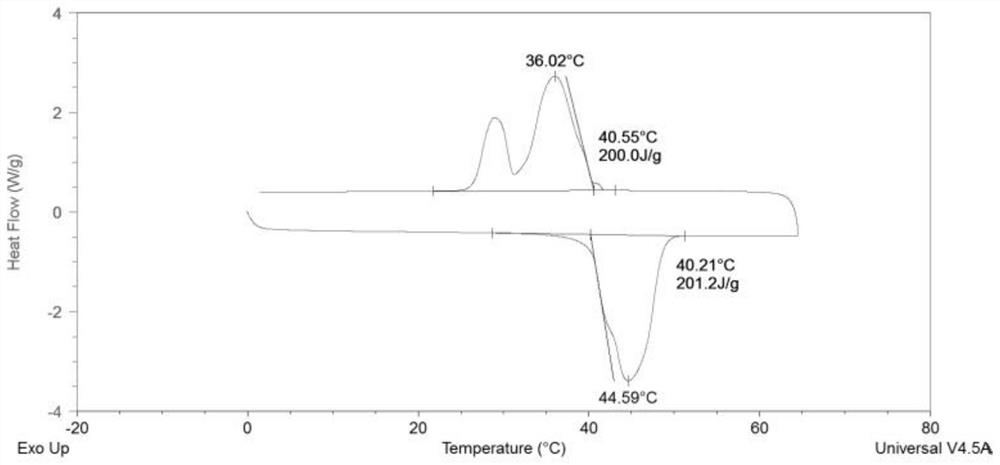

Phase change energy storage microcapsule and preparation method thereof

InactiveCN112592696AImprove compactnessHigh mechanical strengthHeat-exchange elementsMicroballoon preparationAlkanePolymer science

The invention provides a phase change energy storage microcapsule and a preparation method thereof, and belongs to the technical field of phase change energy storage. A shell material of the phase change energy storage microcapsule provided by the invention is polyimide resin, and a core material of the phase change energy storage microcapsule is an n-alkane phase change material. According to thephase change energy storage microcapsule disclosed by the invention, the polyimide resin is used as the shell material, and the n-alkane phase change material is used as the core material, so that the shell material of the phase change energy storage microcapsule is ultrathin, good in compactness, good in mechanical strength and thermal stability, controllable in particle size and high in phase change latent heat value; wide application prospects are realized in the fields of electronic device thermal interface materials, textile and clothing, solar energy storage and the like. The phase-change energy-storage microcapsules are prepared by adopting a solvent evaporation method, the operation is simple and convenient, the experiment and production conditions are easy to control, and the method has the advantages of stable system, small temperature change, recyclable solvent, low residue and the like, and is convenient for realizing large-scale production.

Owner:合肥瑞雪新材料科技有限公司

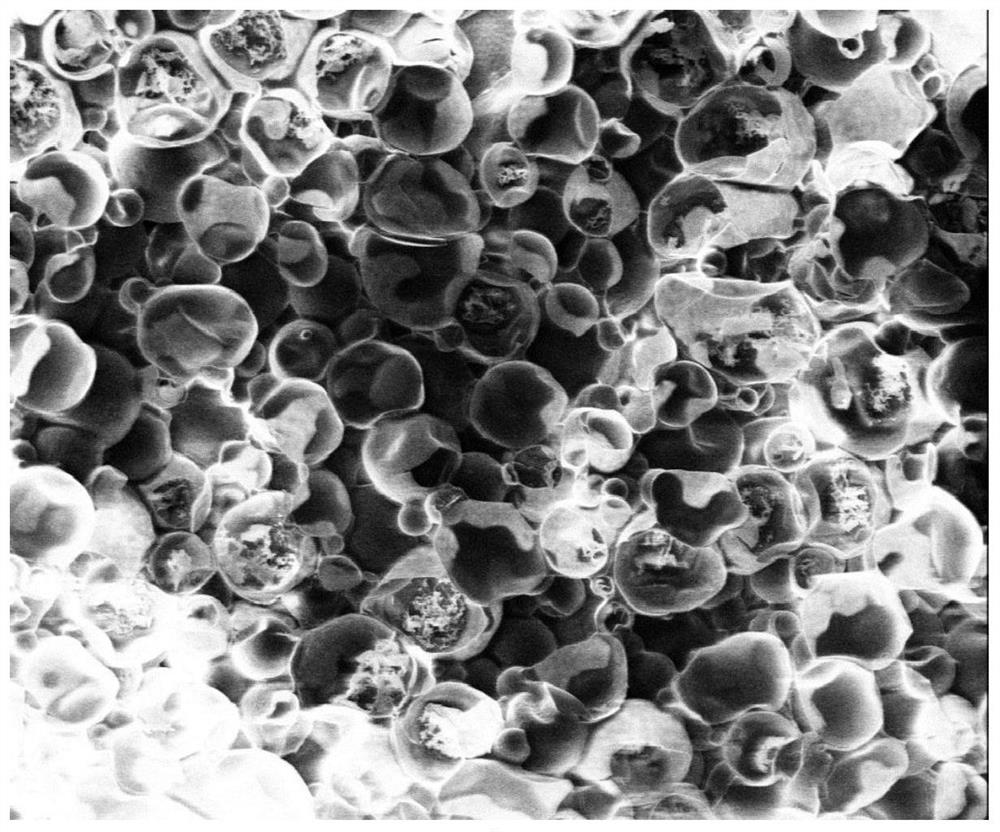

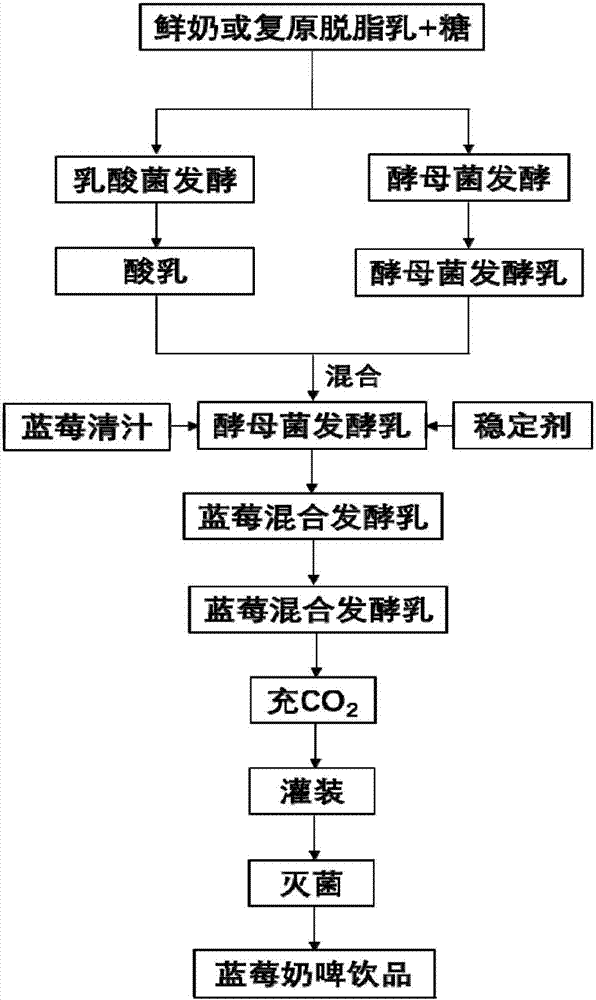

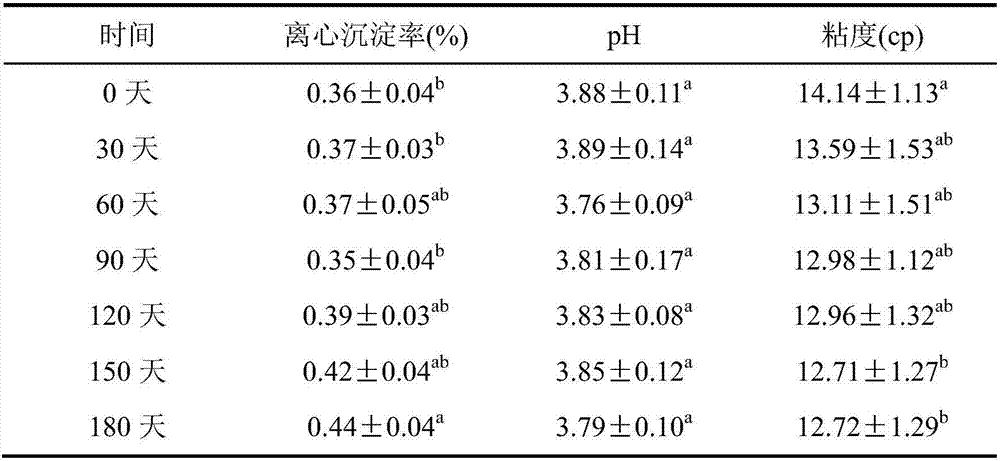

Blueberry milk-beer drink and production method thereof

InactiveCN107372825AShorten the production cycleChange conditionsMilk preparationOther dairy technologyFlavorLactobacillus

The invention discloses blueberry milk-beer drink and a production method thereof. The production method comprises the steps of fermenting by using lactic acid bacteria and saccharomycetes so as to respectively prepare lactic acid bacteria fermented milk and saccharomycete fermented milk, and mixing the prepared lactic acid bacteria fermented milk and saccharomycete fermented milk so as to prepare mixed fermented milk; after that, adding clear blueberry juice, a sweetener and a compound stabilizer into the mixed fermented milk to obtain blueberry mixed fermented milk; carrying out two-stage high-pressure homogenization, injecting CO2, filling, and sterilizing to obtain a blueberry milk-beer drink finished product. The production method provided by the invention is simple in technology and short in production cycle, can shorten the production cycle to 12h or less, is high in production efficiency and product stability, low in equipment requirements and less in production investment, and can greatly reduces the production cost. The obtained product not only has the unique characteristics of milk flavor, low alcohol, tongue astringency, nutrition and health care of milk-beer, but is also endowed with special blueberry flavor due to the addition of the blueberry juice; therefore, the nutritional and health care functions of the milk-beer are further improved, and the blueberry milk-beer drink is suitable for home, sports, travel and meeting with friends and has wide market prospect.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Production and preparation process for fulvic acid

The invention relates to the field of chemical product production, in particular to a production and preparation process for fulvic acid. The production and preparation process is characterized in that a raw material lignite for preparing the fulvic acid is smashed into 80 mesh and added into warm water at the temperature of 49 DEG C to 51 DEG C, and the ratio of the dry weight of the lignite powder to the weight of the water is 1:(18-22), H2O2 is slowly added in a stirring state, the adding rate of H2O2 is limited by the reaction temperature lower than 65 DEG C, and the mass ratio of the lignite powder to H2O2 is 1:(0.68-0.72); after lignite is subjected to an oxydrolysis reaction, the mixture is subjected to solid-liquid separation and dried, and a fulvic acid product is obtained. The production and preparation process has the advantages that the leonardite is adopted as the raw material, so that the production cost is low; hydrogen peroxide is adopted as an oxidizing agent, so that environmental friendliness is achieved, and pollution is avoided; adopted equipment is simple, the production conditions are easy to control, the process route is feasible, the technical index is stable, the production and preparation process is suitable for large-scale industrial production, and the fulvic acid is high in yield and purity; compared with an imported product, the cost is greatly reduced, and conditions are created for full utilization of low-quality coal resources and substituting for imported goods.

Owner:王墨林

Halogen-free flame-retardant nitrile rubber/nylon thermoplastic elastomer and preparation method thereof

The invention relates to the field of thermoplastic elastomers, and discloses a halogen-free flame-retardant nitrile rubber / nylon thermoplastic elastomer and a preparation method thereof, wherein thethermoplastic elastomer contains a nitrile rubber, nylon, a flame retardant, a vulcanizing agent, an anti-aging agent, an antioxidant and an auxiliary agent, the vulcanizing agent is an organic peroxide, and the organic peroxide is at least one selected from dicumyl peroxide, bis(t-butylperoxyisopropyl)benzene, t-butyl cumene peroxide, 2,5-bis(t-butyl peroxy)-2,5-dimethyl-3-hexyne, 2,5-bis-(tert-butyl peroxy)-2,5-dimethyl hexane, dibenzoyl peroxide, tert-butyl peroxybenzoate, and di-tert-butyl peroxide. According to the present invention, the nitrile rubber / nylon thermoplastic elastomer has characteristics of high elasticity, easy processing, repeated processing, good flame retardant performance and the like, and can be used for vehicle oil pipelines and sealing members.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com