Polyaryl ether nitrile resin and industrialized synthetic method thereof

A polyarylether nitrile and synthesis method technology, applied in the field of polymer materials, can solve the problems of low purity of recovered solvent, low efficiency of recovered solvent, poor reuse effect, etc., achieve significant economic and social benefits, and easy to realize production conditions , The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides the industrial synthesis method of polyarylether nitrile resin, comprises the following steps:

[0038] (1) Polymerization reaction:

[0039] Using 2,6-dihalobenzonitrile and aromatic dihydric phenol as reaction raw materials, react under the action of aprotic strong polar solvent, catalyst and dehydrating agent to obtain polyarylether nitrile solution; then the obtained polyarylether nitrile The solution is processed by flash evaporation to obtain polyarylether nitrile powder; wherein, the aromatic dihydric phenol is at least one of hydroquinone or resorcinol;

[0040] (2) post-processing

[0041] Grinding the above polyarylether nitrile powder into a powder with a particle size of ≤0.1 mm, soaking the powder in an organic solvent, separating the solid from the liquid, recycling the liquid, washing the solid with boiling water, filtering, and drying to obtain the polyarylether nitrile resin of the present invention.

[0042] The fl...

Embodiment 1

[0049] The preparation and performance thereof of embodiment 1 high crystallinity polyarylether nitrile

[0050] At 10m with separator, condenser, agitator and heater 3 Weigh the raw materials in the reaction kettle according to the following molar ratio: 2,6-dichlorobenzonitrile: resorcinol / hydroquinone: potassium carbonate: N-methylpyrrolidone: toluene=1:1:1.1~1.5 ︰6~8︰1.2~1.5, wherein the molar ratio of resorcinol to hydroquinone is 1:9; start stirring, raise the temperature to 150°C for dehydration reaction for 2 hours, steam the toluene through the water separator, and raise the temperature to 180-200°C, after 3 hours of reaction, inject 400kg of N-methylpyrrolidone solvent into the reactor so that the reactants can be quickly put into the 18m 3 In a flash kettle with a pulverizing blade stirrer, steam N-methylpyrrolidone under reduced pressure at 160-180°C under strong stirring. The above-mentioned fine powder of solid matter is ground into a fine powder with a size of...

Embodiment 2-6

[0052] Preparation and properties of embodiment 2-6 high crystallinity polyarylether nitrile

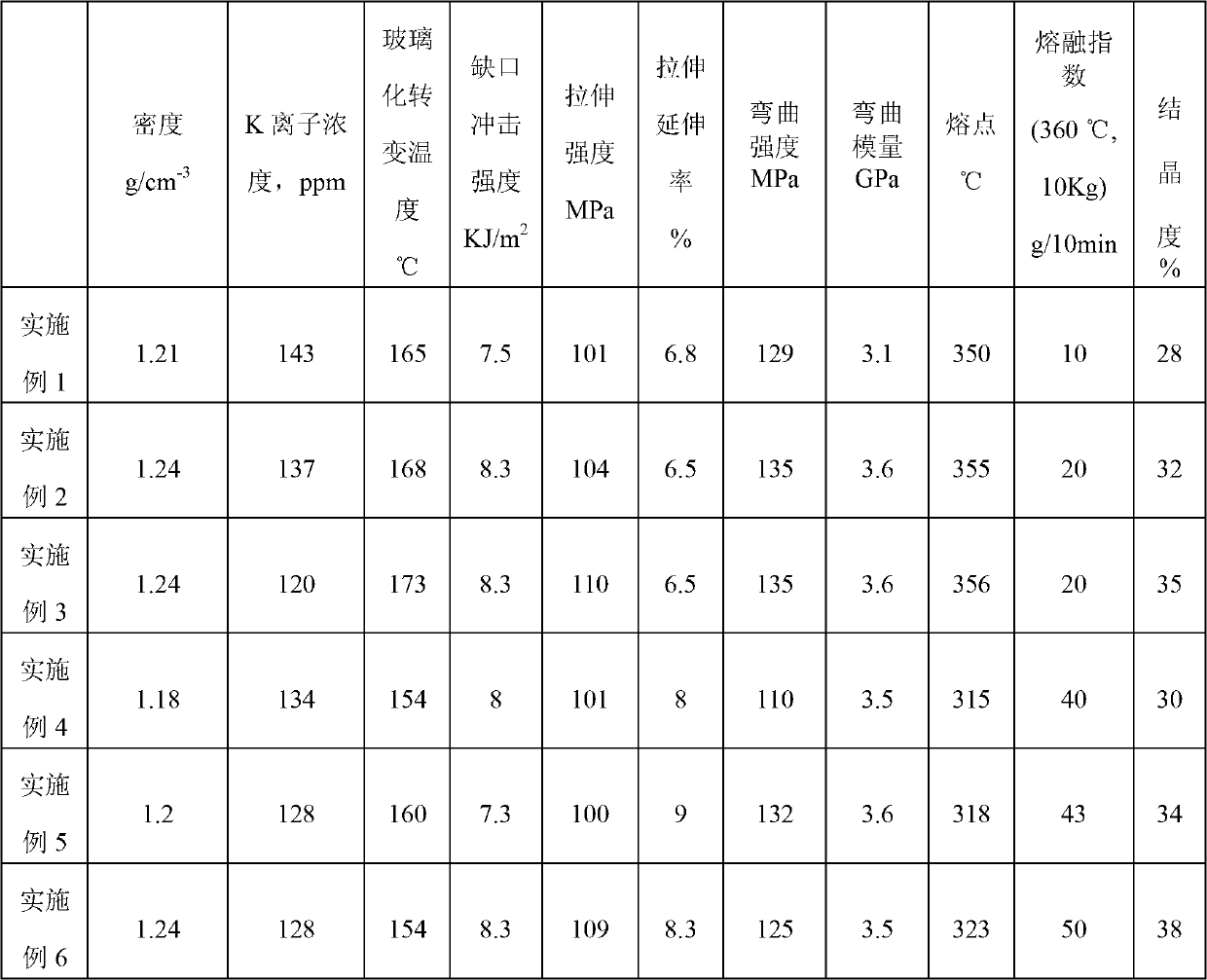

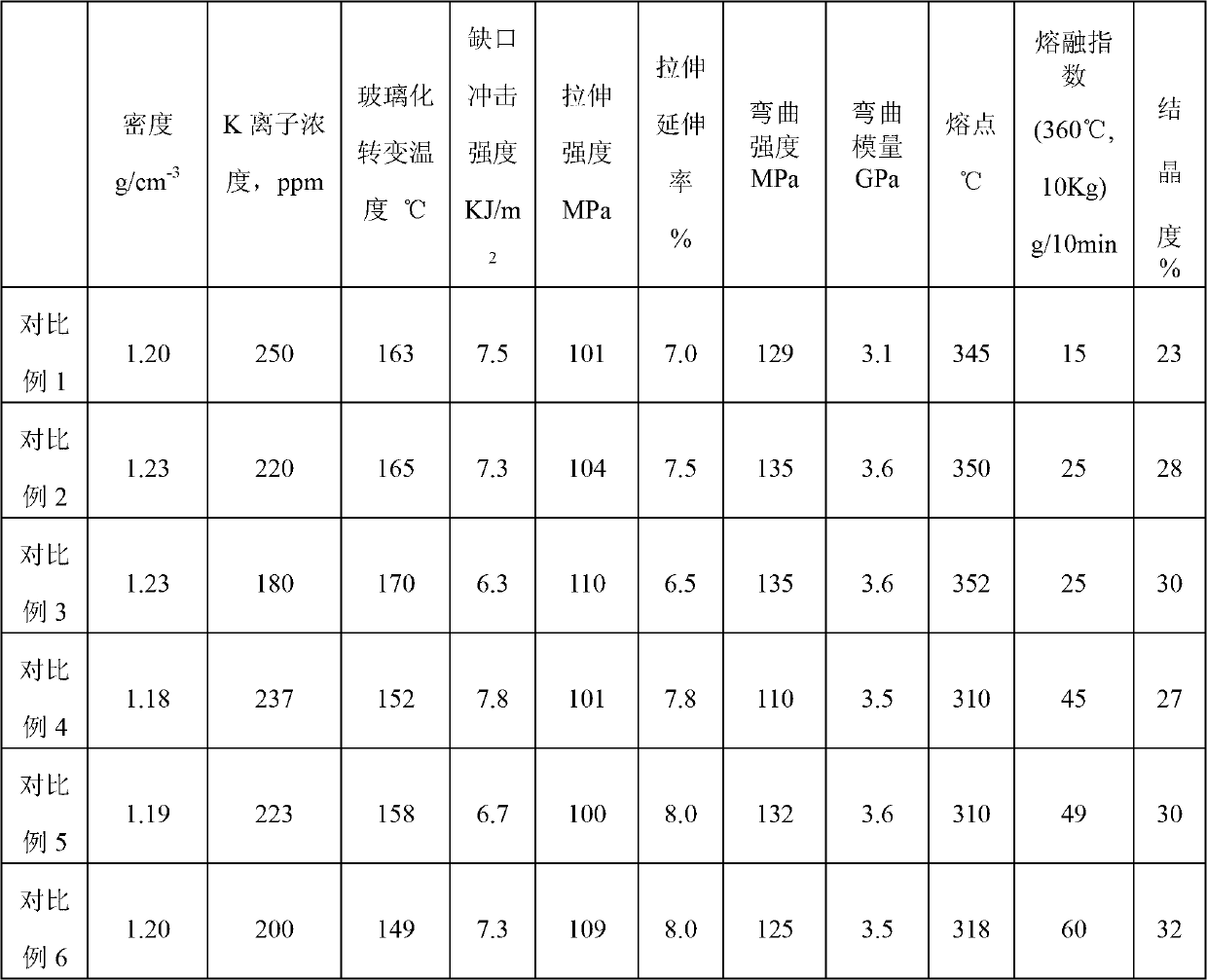

[0053] Change the resorcinol and hydroquinone molar ratios in Example 1 to 0.5:9.5 (Example 2), 0:10 (Example 3), 9:1 (Example 4), 9.5:0.5 (embodiment 5), 10:0 (embodiment 6), others are all with embodiment 1; The performance of gained resin is shown in Table 1.

[0054] Table 1 High Crystalline Polyether Nitrile Resin Properties

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com