Method for preparing poly(arylene ether nitrile) resin

A technology of polyarylether nitrile and resin, which is applied in the field of preparation of polyarylether nitrile resin, can solve the problems of solvent not being recovered and recycled by rectification, high reaction temperature and pressure, and limited application range of resin, etc., to overcome side effects Effects of reactions and by-products, stable performance, and easy-to-achieve production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

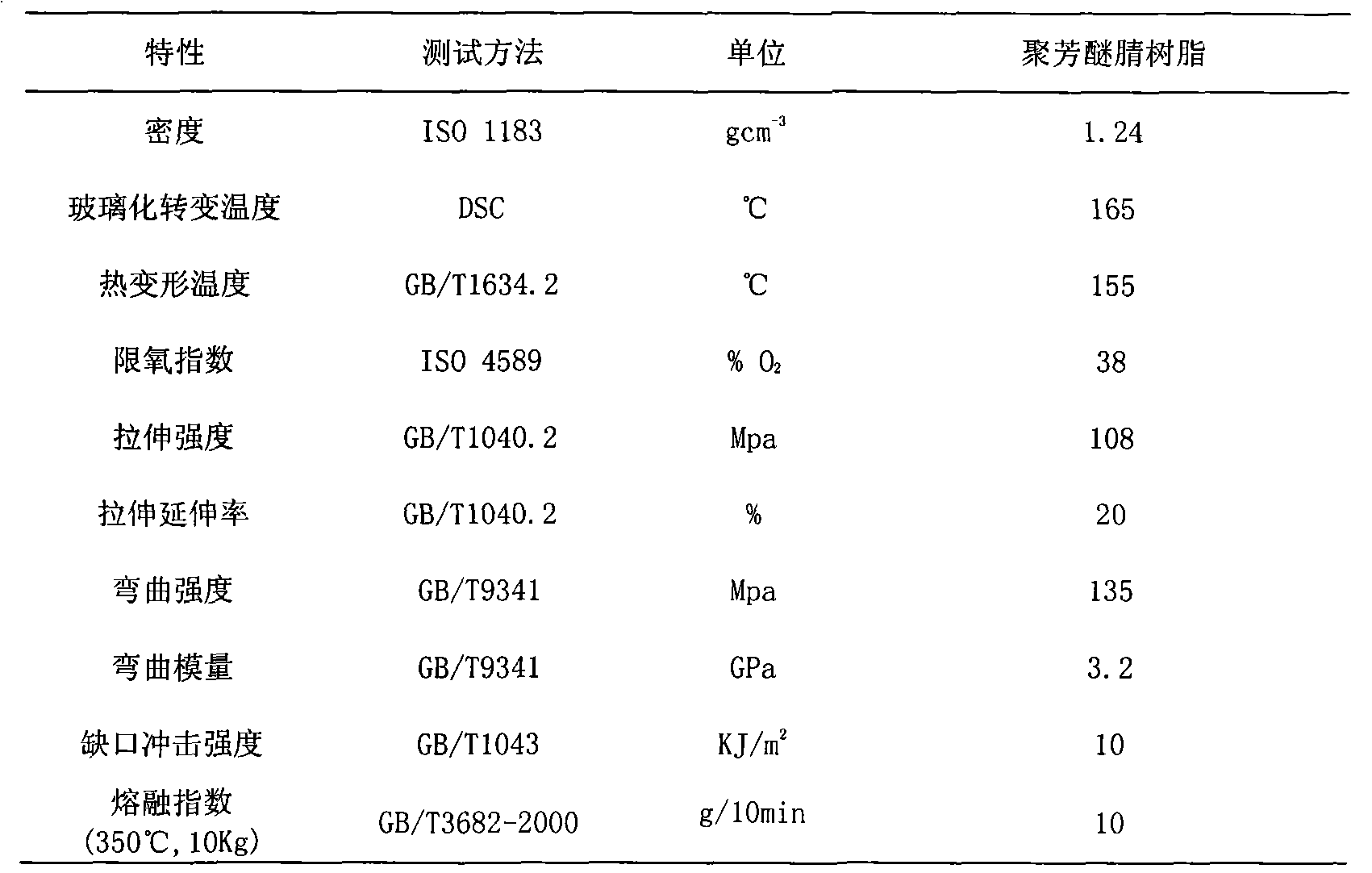

Embodiment 1

[0022] According to the following molar ratio: 2,6-dichlorobenzonitrile: hydroquinone: resorcinol: anhydrous potassium carbonate: N-methylpyrrolidone: toluene=1:0.9:0.1:1.2:6:1.3 Weigh the raw materials into the reactor, heat and stir to 140°C for dehydration reaction. During the dehydration reaction, the water produced by the reaction is separated by a reflux device and toluene is refluxed; after the dehydration reaction for 2 hours, the reaction system is heated to 200°C and atmospheric pressure When the polymerization reaction occurs until the phenomenon of polymer climbing rods occurs, the diluted solution of N-methylpyrrolidone solvent is injected into the reactor until the solution viscosity is less than 2000 centipoise. The diluted solution system is sprayed into the precipitation tank containing the precipitating agent in the manner of pressure spray, and then heated and stirred, fully refluxed, and separated by a centrifuge for solid-liquid separation, and the separated...

Embodiment 2

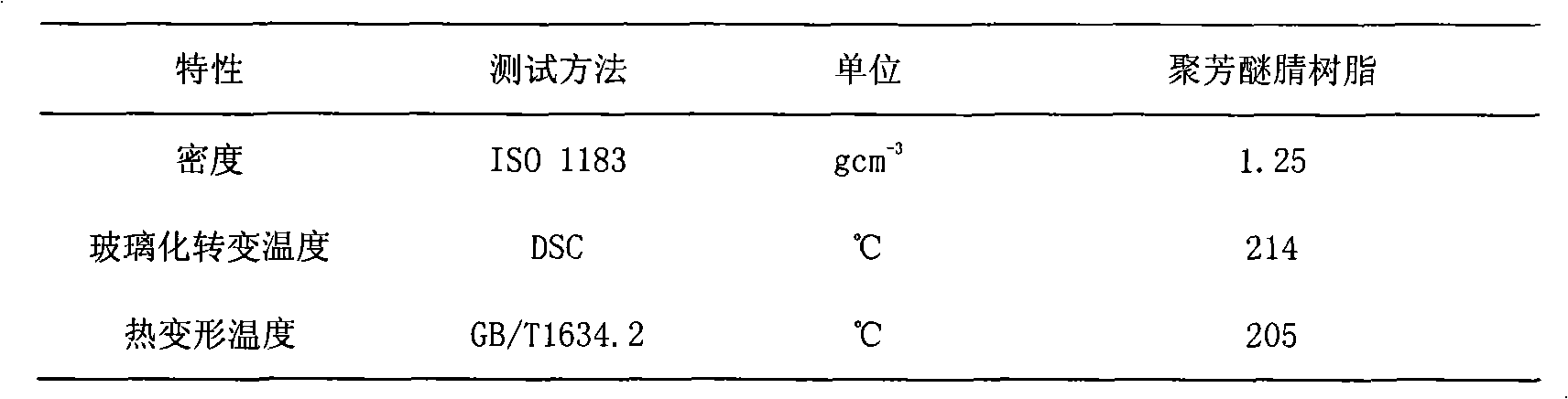

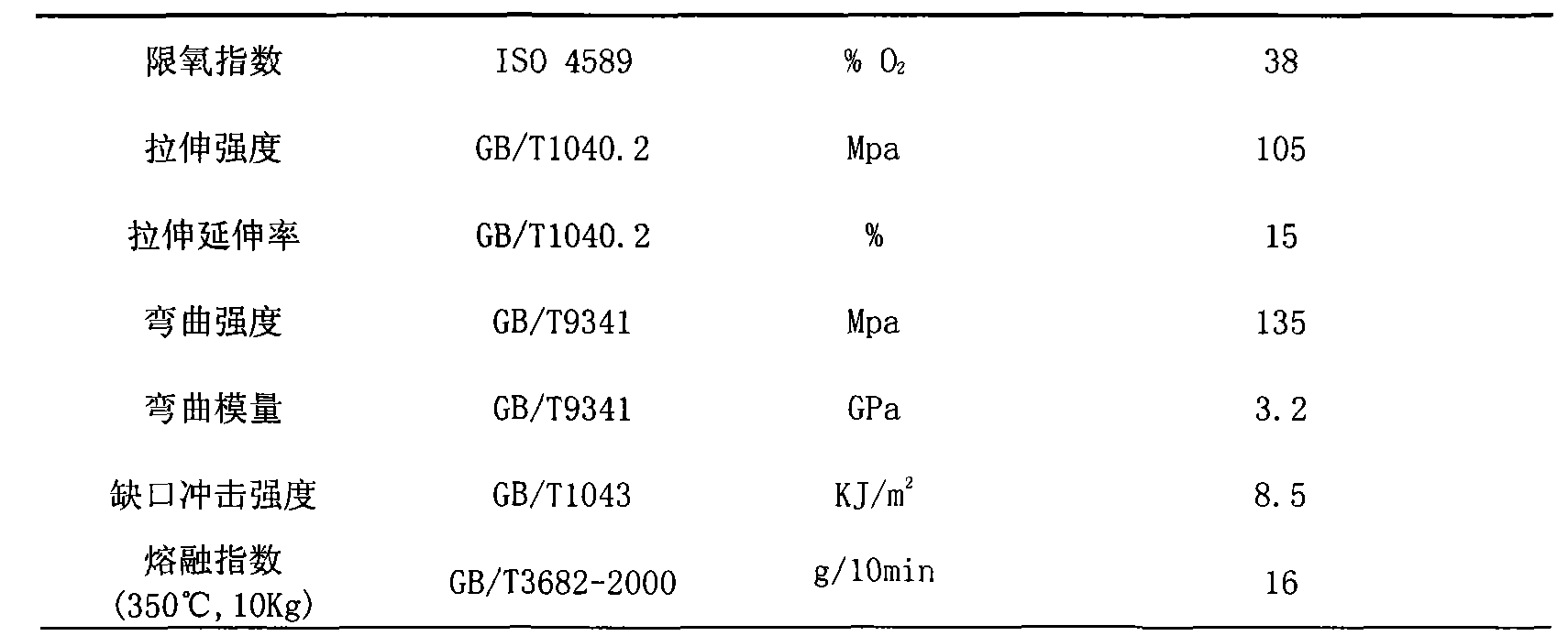

[0026] According to the following molar ratio: 2, 6-dichlorobenzonitrile: biphenol: anhydrous potassium carbonate: N-methylpyrrolidone: toluene = 1:1:1.3:7:1.4 weigh the raw materials into the reactor During the dehydration reaction, the water produced by the reaction is separated by a reflux device and the toluene is refluxed; after the dehydration reaction for 3 hours, the reaction system is heated to 200°C and polymerized under normal pressure until the polymer When the pole climbs, the diluted solution of N-methylpyrrolidone solvent is injected into the reactor until the solution viscosity is less than 2000 centipoise. The diluted solution system is sprayed into the precipitation tank containing the precipitating agent in the manner of pressure spray, and then heated and stirred, fully refluxed, and separated by a centrifuge for solid-liquid separation, and the separated liquid is transported to the rectification tower for rectification and recovery of the solvent In order ...

Embodiment 3

[0031] According to the following molar ratio: 2,6-dichlorobenzonitrile: bisphenol A: anhydrous potassium carbonate: N-methylpyrrolidone: toluene = 1:1:1.2:6:1.3 Weigh the raw materials into the reactor , Heating and stirring to 140°C for dehydration reaction. During the dehydration reaction, the water produced by the reaction is separated by a reflux device and toluene is refluxed; after the dehydration reaction for 3 hours, the reaction system is heated to 200°C and the polymerization reaction is carried out under normal pressure until polymer creep occurs. During the rod phenomenon, the N-methylpyrrolidone solvent diluted solution injected into the reaction kettle until the solution viscosity is less than 2000 centipoise. The diluted solution system is sprayed into the precipitation tank containing the precipitating agent in the manner of pressure spray, and then heated and stirred, fully refluxed, and separated by a centrifuge for solid-liquid separation, and the separated l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com