Positive and negative photoresist technology combined microstrip line manufacturing method

A manufacturing method and technology of microstrip lines, which are applied in the manufacture of microstructure devices, metal material coating processes, processes for producing decorative surface effects, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

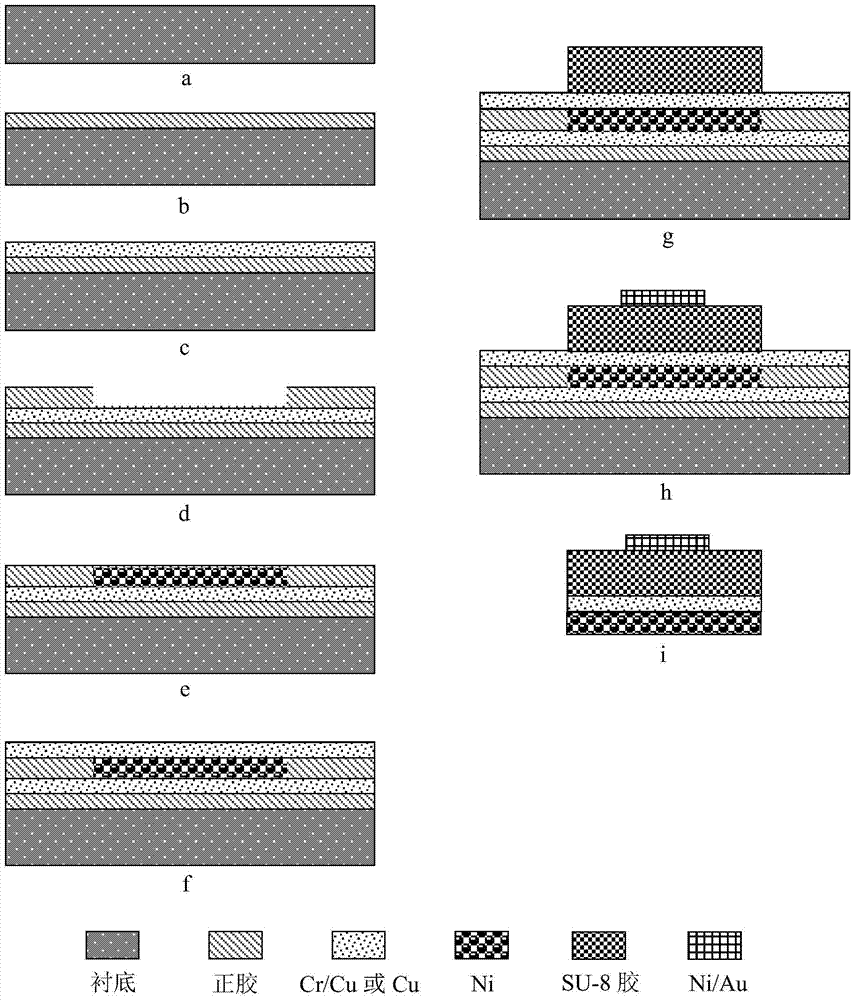

[0022] A microstrip line manufacturing method combining positive and negative glue technology, comprising the following steps:

[0023] (1) Put a certain size of glass or silicon wafer (such as 4 inches) 2 SO 4 +H 2 o 2 , deionized water in order to wash, dry, and then evaporate HMDS (a coupling agent) on the substrate.

[0024] (2) Coat AZ4620 positive photoresist on the treated substrate with a thickness of 5 μm by spin coating.

[0025] (3) Pre-baking the photoresist on a hot plate, the conditions are 65°C / 30min, 95°C / 60min, 120°C / 60min, and cool with the furnace.

[0026] (4) Deposit Cr / Cu seed layer with magnetron multi-target sputtering machine,

[0027] (5) Coating AZ4620 positive resist, 10 μm, on the Cr / Cu seed layer.

[0028] (6) Pre-bake the photoresist on a hot plate, the conditions are 65°C / 30min, 95°C / 60min, and cool with the furnace.

[0029] (7) SUSS MA6 UV lithography machine for exposure and development.

[0030] (8) Ni metal plating.

[0031] (9) ...

Embodiment 2

[0046] (1) Wash a glass or silicon wafer of a certain size (such as 4 inches) with H2SO4+H2O2 and deionized water in sequence, dry it, and then evaporate HMDS (a coupling agent) on the substrate.

[0047] (2) Coat the ARP positive photoresist on the processed substrate by spin coating, with a thickness of 10 μm.

[0048] (3) Pre-bake the photoresist with a program-controlled oven, the conditions are 65°C / 40min, 95°C / 90min, 120°C / 90min, and cool with the furnace.

[0049] (4) Deposit Cu seed layer with magnetron multi-target sputtering machine, thickness

[0050] (5) Coating AZ4620 positive resist, 10 μm, on the Cu seed layer.

[0051] (6) Pre-baking the photoresist with a program-controlled oven, the conditions are 65°C / 400min, 95°C / 90min, and cool with the furnace.

[0052] (7) SUSS MA6 UV lithography machine for exposure and development.

[0053] (8) Ni metal plating.

[0054] (9) After the electroplating is completed, the film is hardened, and the condition is 120°C / 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com