Apparatus and method for directly preparing UO2 by molten salt electrolysis of U3O8

A molten salt electrolysis, UO2 technology, applied in the field of nuclear energy, can solve the problems of high fuel consumption, high radiation, high plutonium content, etc., and achieve the effects of reducing emissions, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

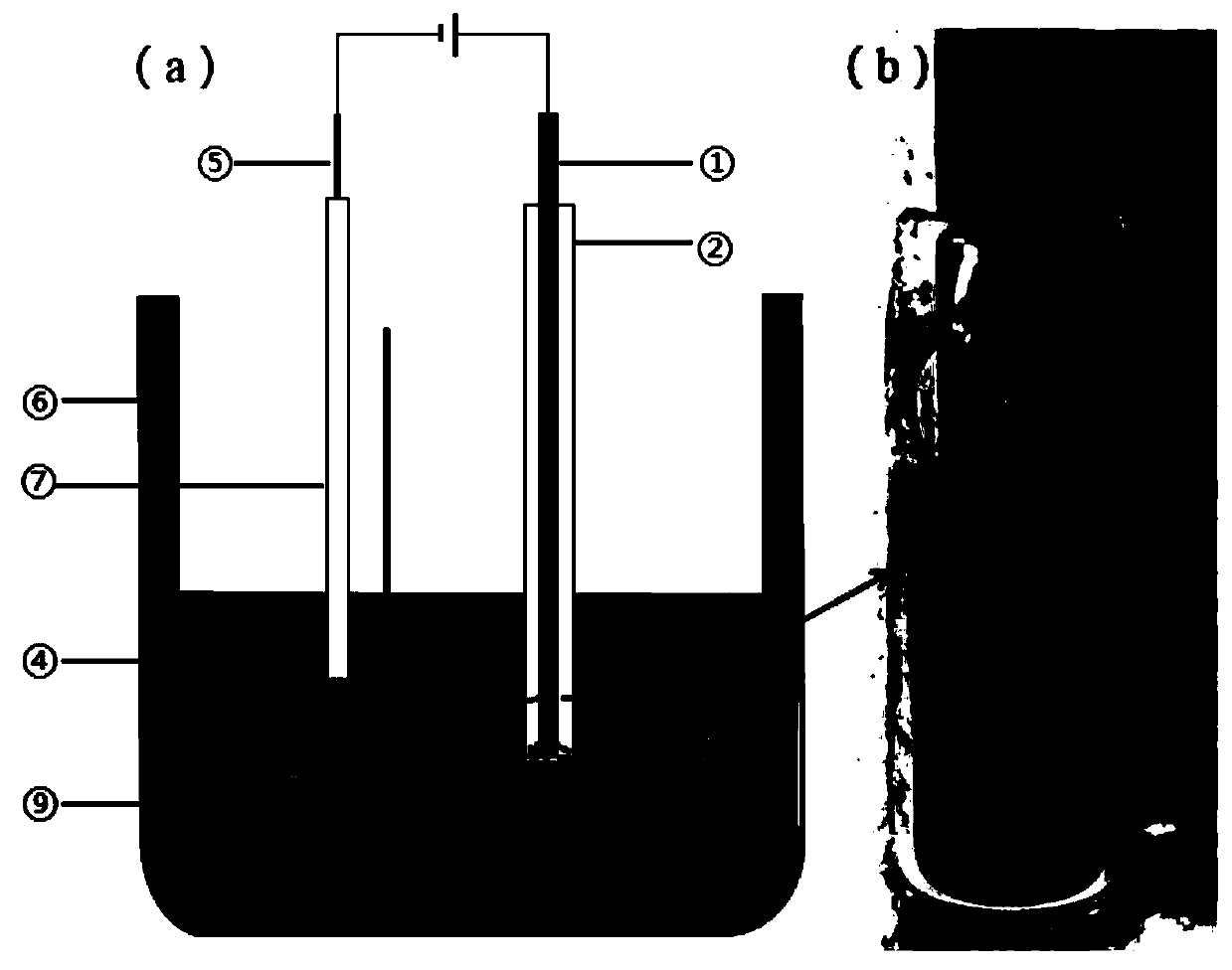

[0042] (1) Experimental device

[0043] The experimental device adopted in the embodiment is as figure 1 (a) and figure 1 As shown in (b), the 0.3gU 3 o 8 The powder is loaded in the anode glass sleeve (such as figure 1 (b) shown). The electrolyte used was LiCl-KCl eutectic molten salt, and the LiCl-KCl eutectic salt was dried in a vacuum muffle furnace at 200°C for 72 hours before use, in order to remove the moisture absorbed by the LiCl-KCl eutectic salt. The cathode used is Mo cathode, which is ground and polished with SiC sandpaper before use, then soaked in dilute hydrochloric acid for a few minutes, then cleaned with ethanol until it is shiny, and dried for later use. figure 1 (a) Electrolysis of U for chloride molten salt system 3 o 8 Preparation of UO 2 Device diagram, ①-graphite rod, ②-quartz glass tube with closed bottom and holes on both sides, ③-U 3 o 8 Powder, ④-chloride molten salt, ⑤-molybdenum sheet, ⑥-electrolytic cell crucible, ⑦-corundum sleeve, ⑧-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com