Patents

Literature

156 results about "Nuclear fuel cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The nuclear fuel cycle, also called nuclear fuel chain, is the progression of nuclear fuel through a series of differing stages. It consists of steps in the front end, which are the preparation of the fuel, steps in the service period in which the fuel is used during reactor operation, and steps in the back end, which are necessary to safely manage, contain, and either reprocess or dispose of spent nuclear fuel. If spent fuel is not reprocessed, the fuel cycle is referred to as an open fuel cycle (or a once-through fuel cycle); if the spent fuel is reprocessed, it is referred to as a closed fuel cycle.

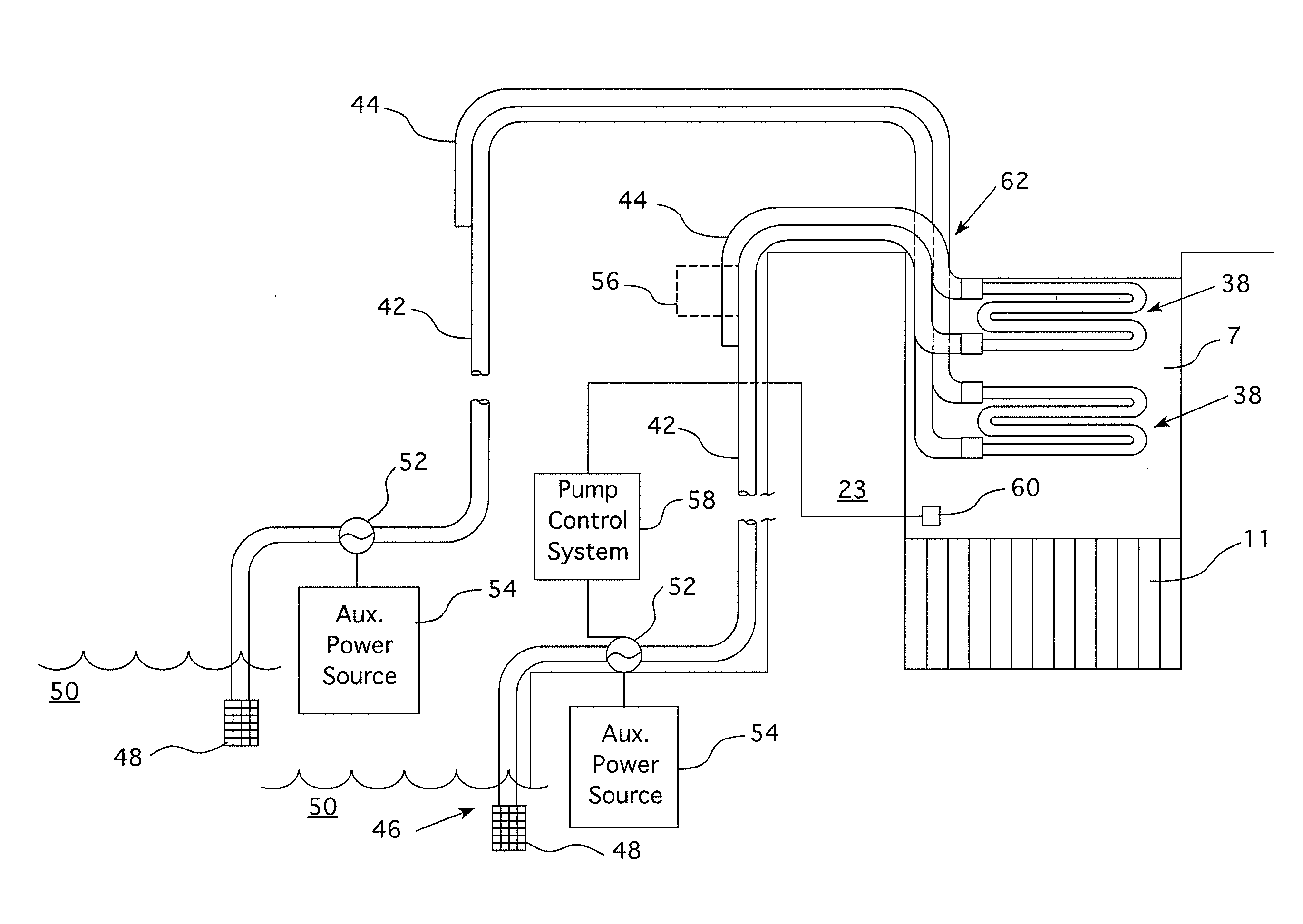

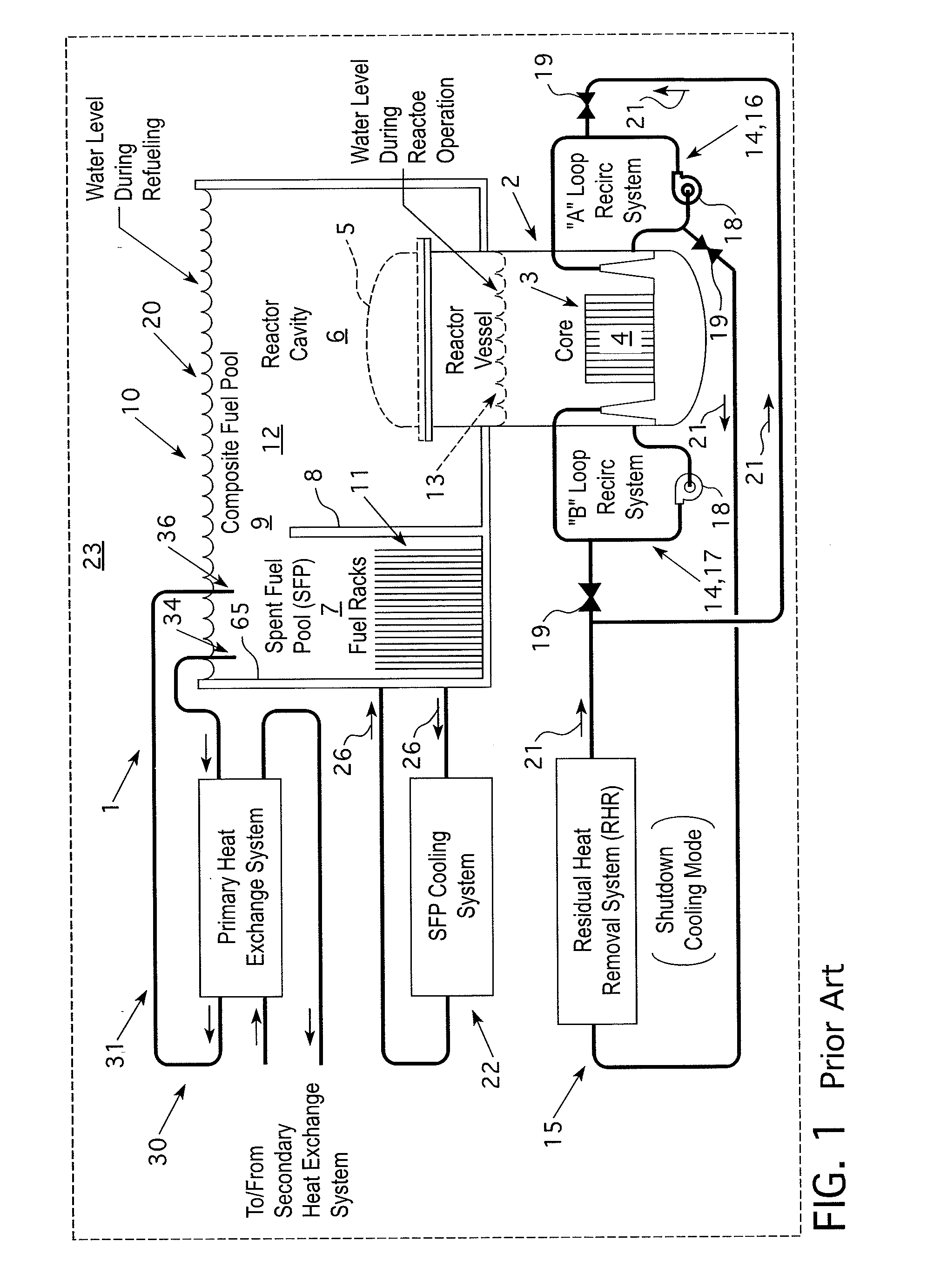

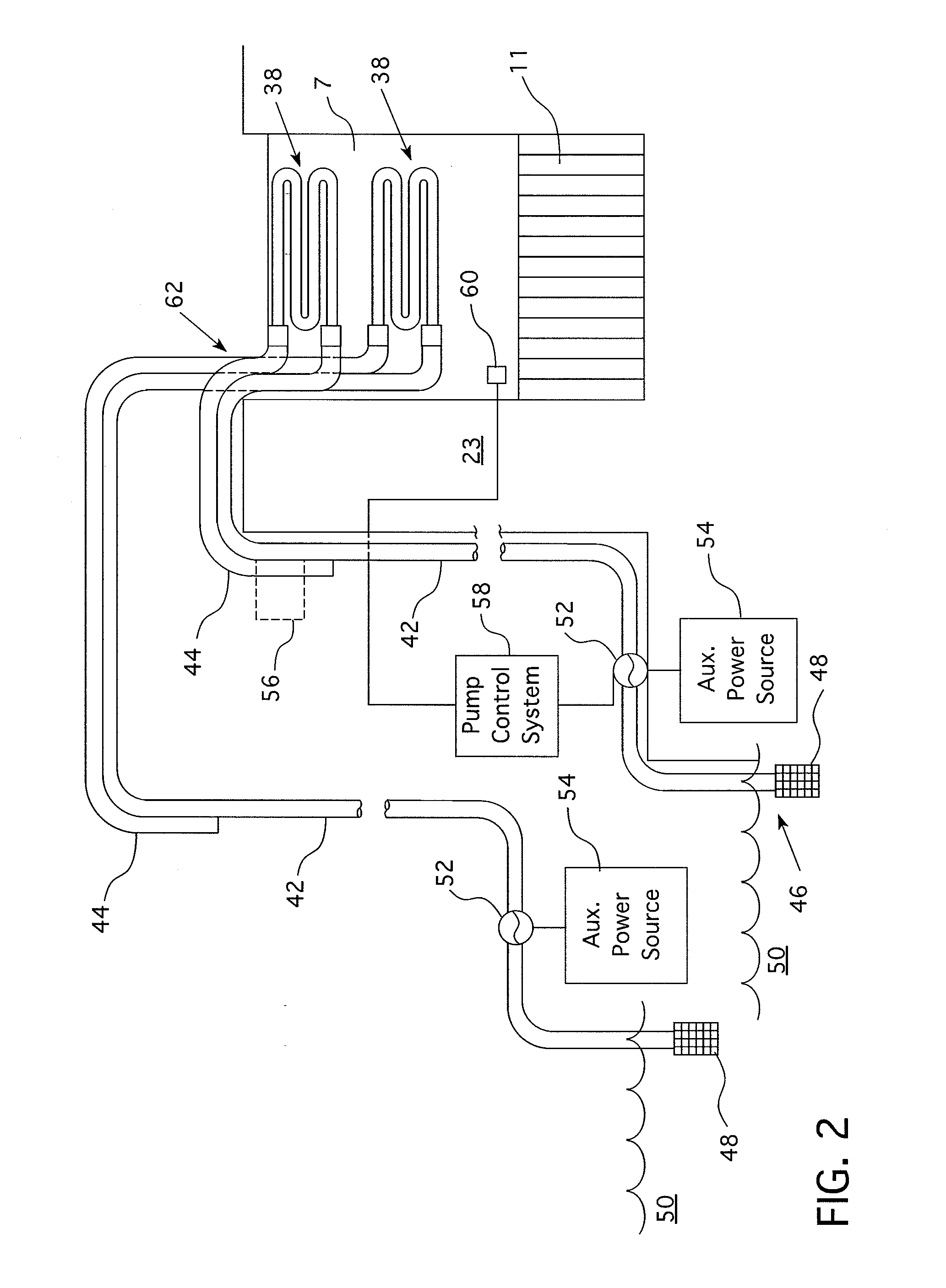

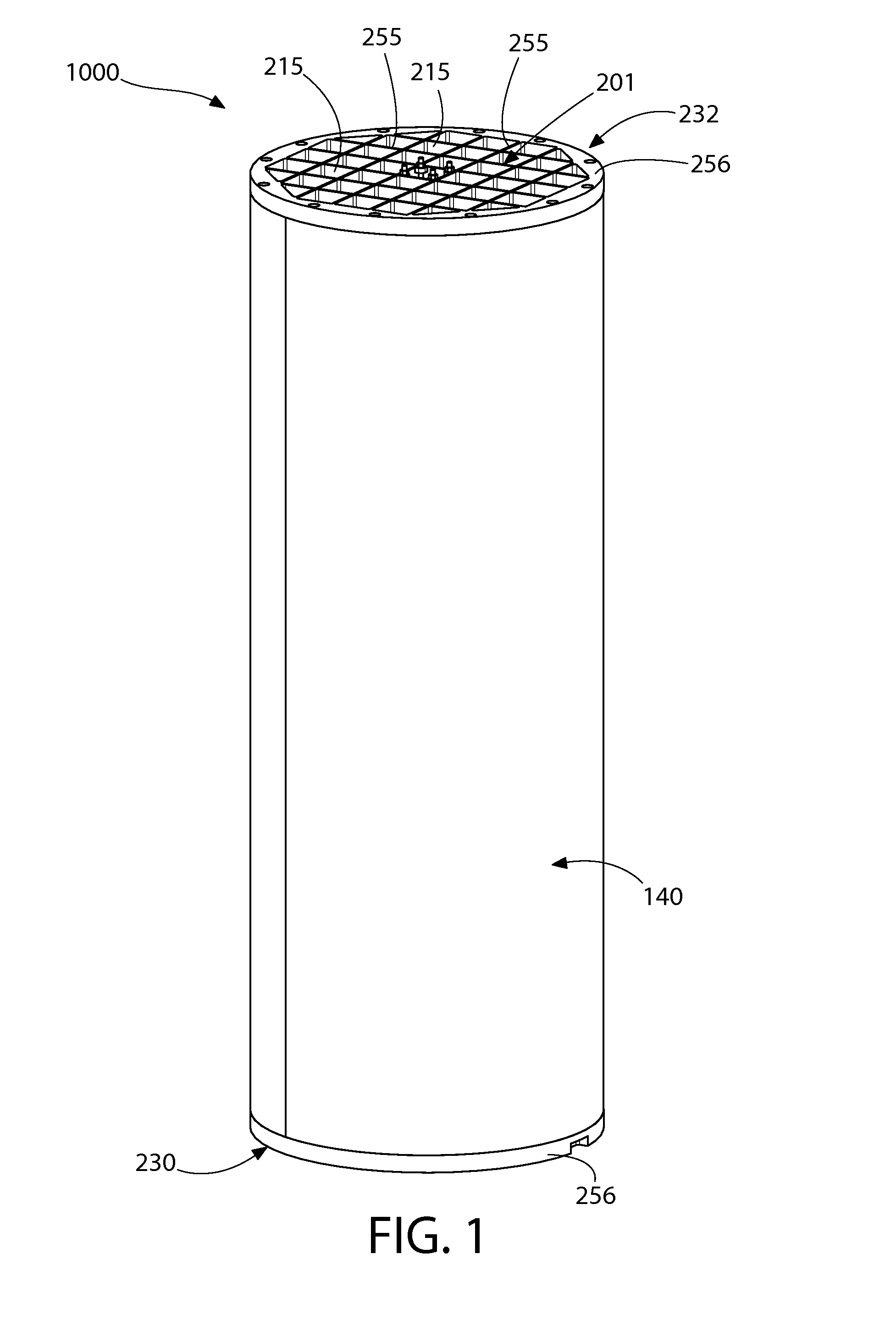

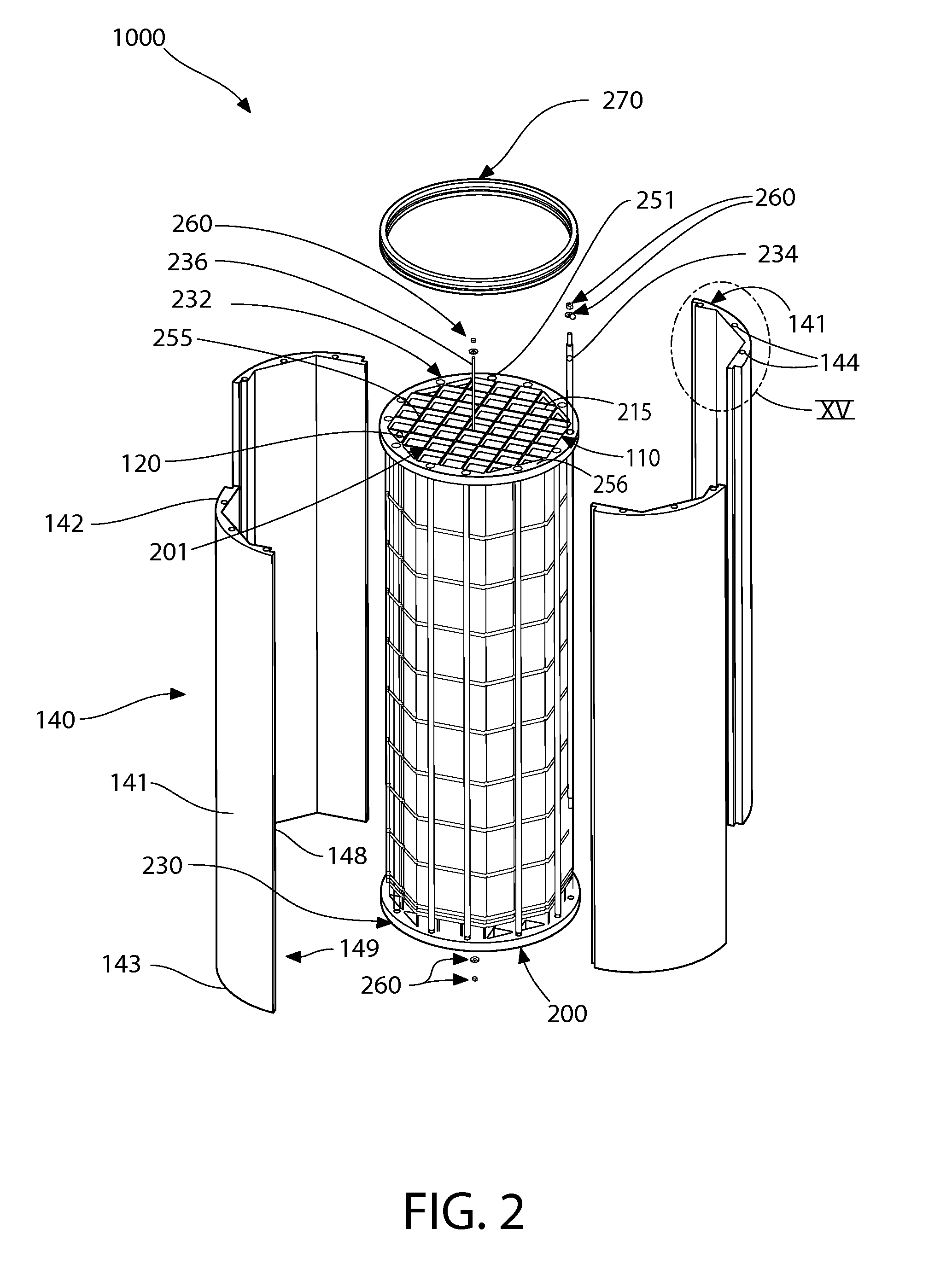

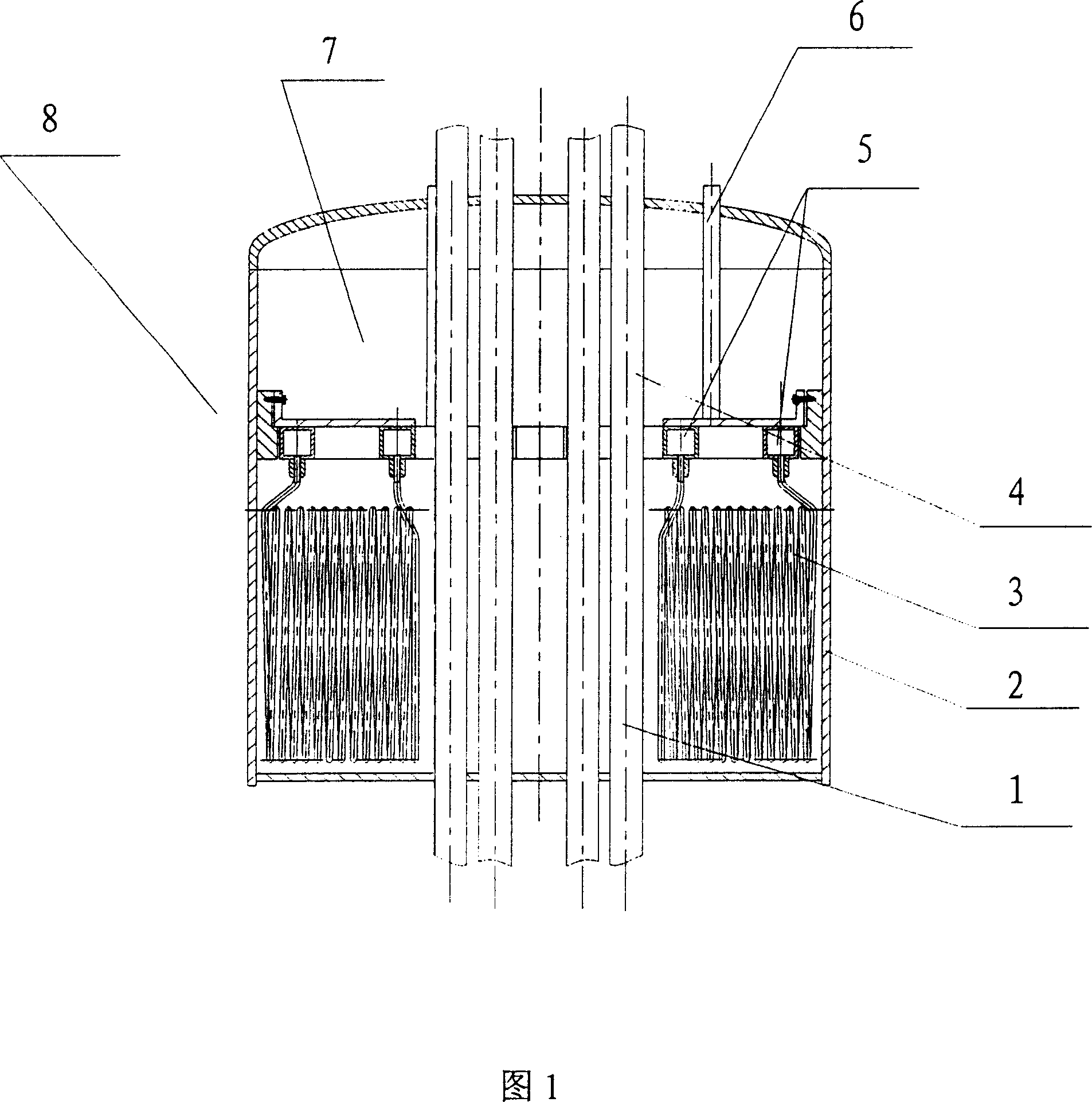

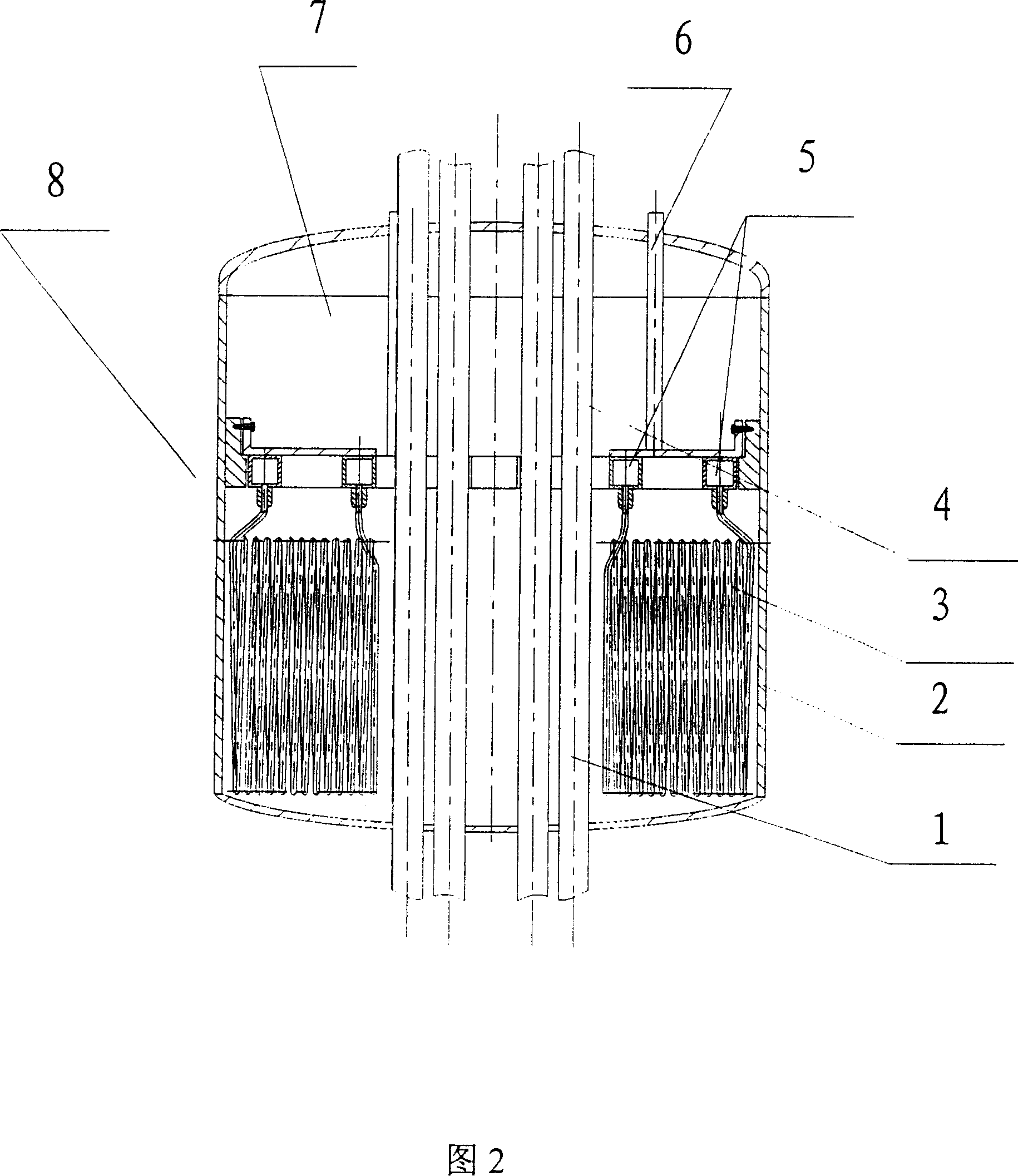

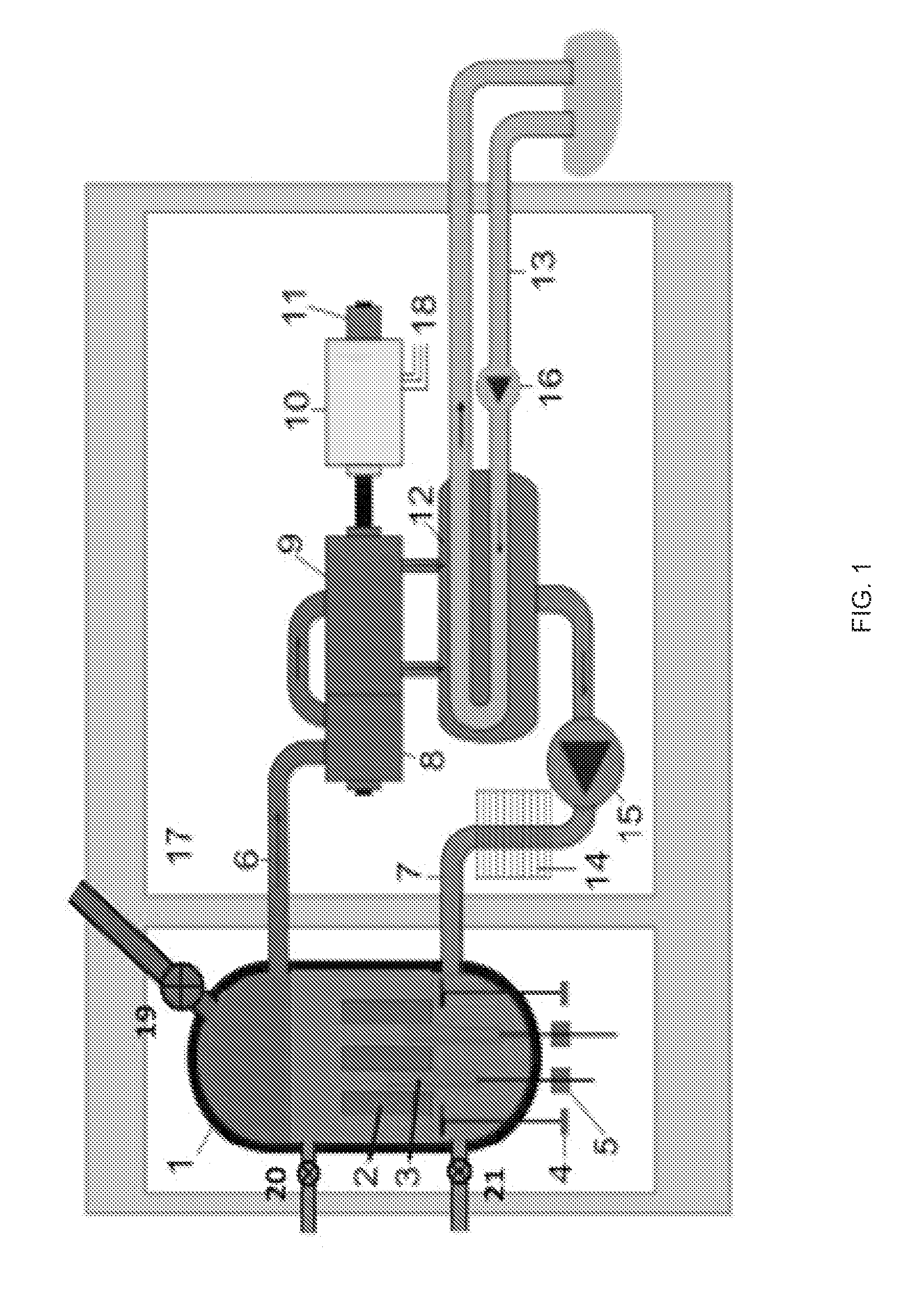

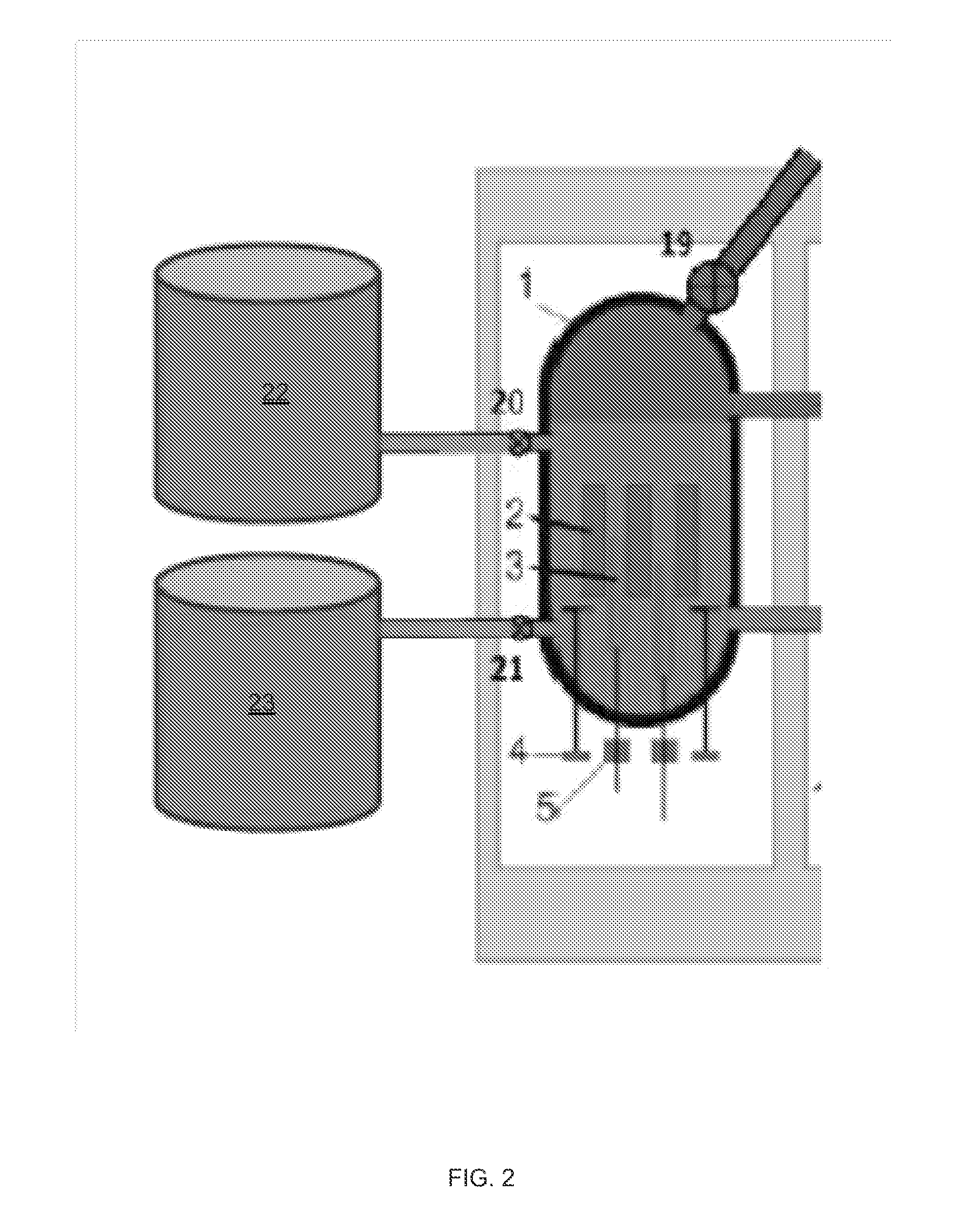

Self-contained emergency spent nuclear fuel pool cooling system

ActiveUS20120250813A1Nuclear energy generationEmergency protection arrangementsSTI OutpatientCooling fluid

An auxiliary system for cooling a spent nuclear fuel pool through a submersible heat exchanger to be located within the pool. In each train or installation, a single loop or series of loops of cooling fluid (e.g., sea water or service water) is circulated. The system is modular, readily and easily installed during an emergency and can be self operating with its own power source. Multiple trains may be used in parallel in order to accomplish the required degree of spent fuel pool cooling required.

Owner:WESTINGHOUSE ELECTRIC CORP

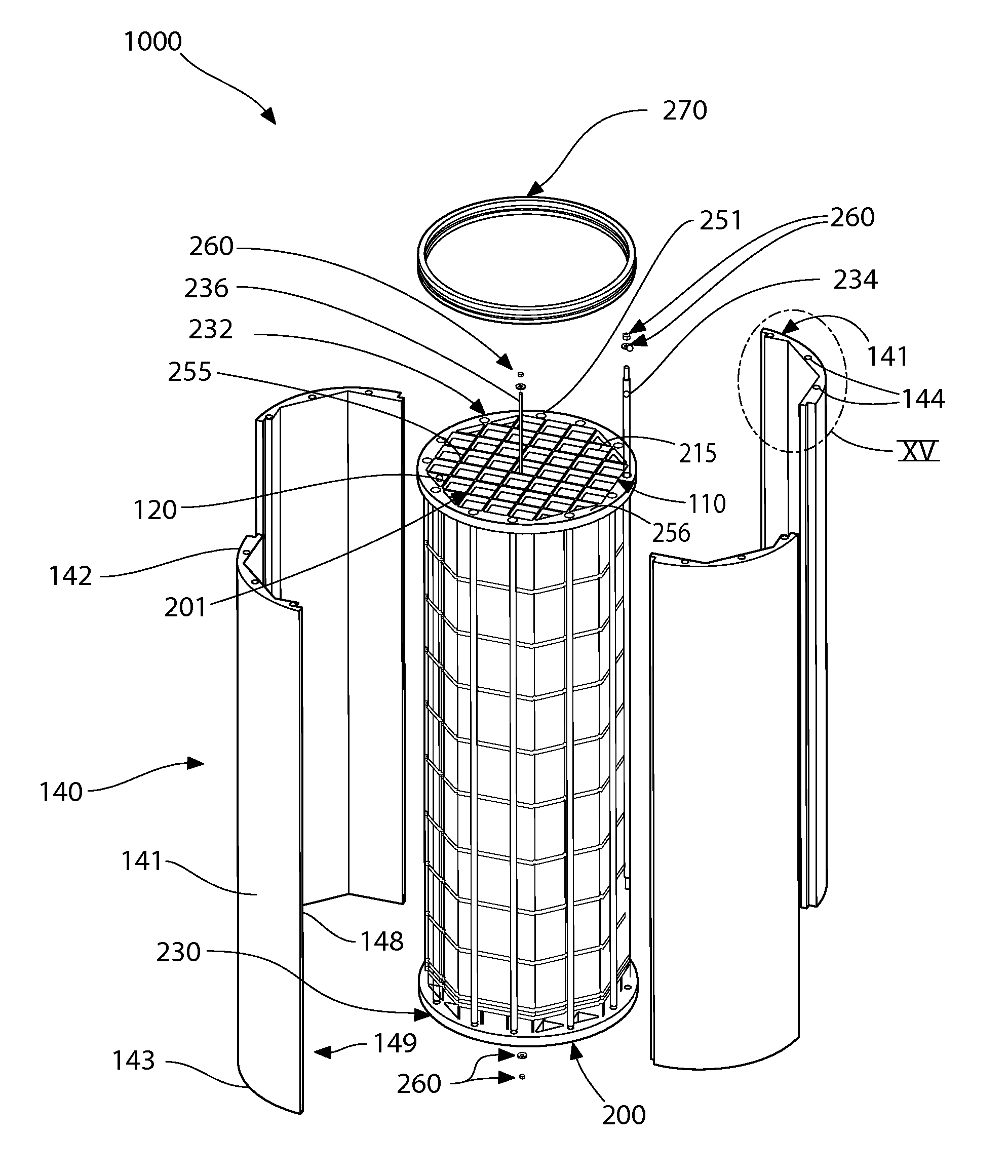

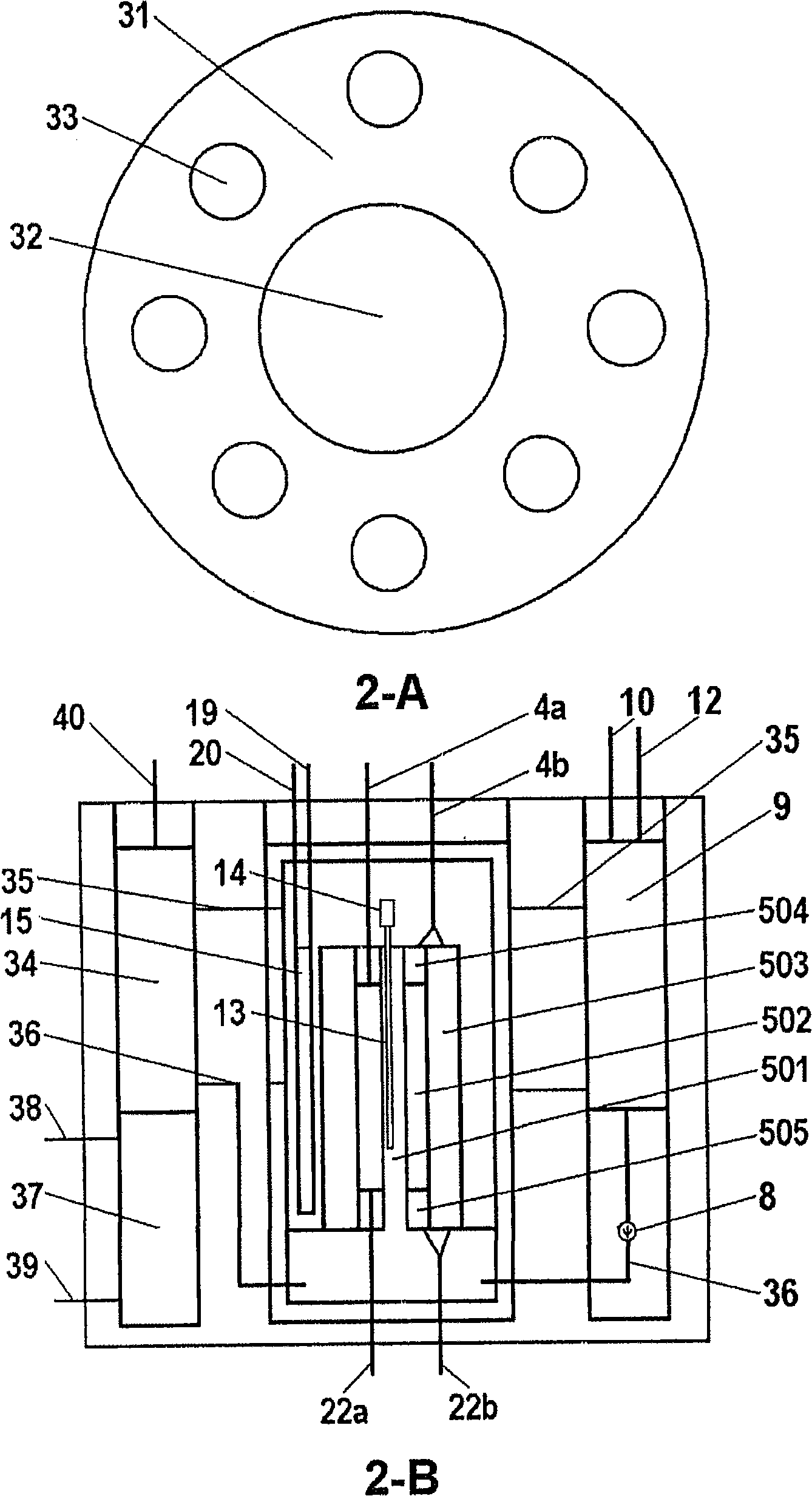

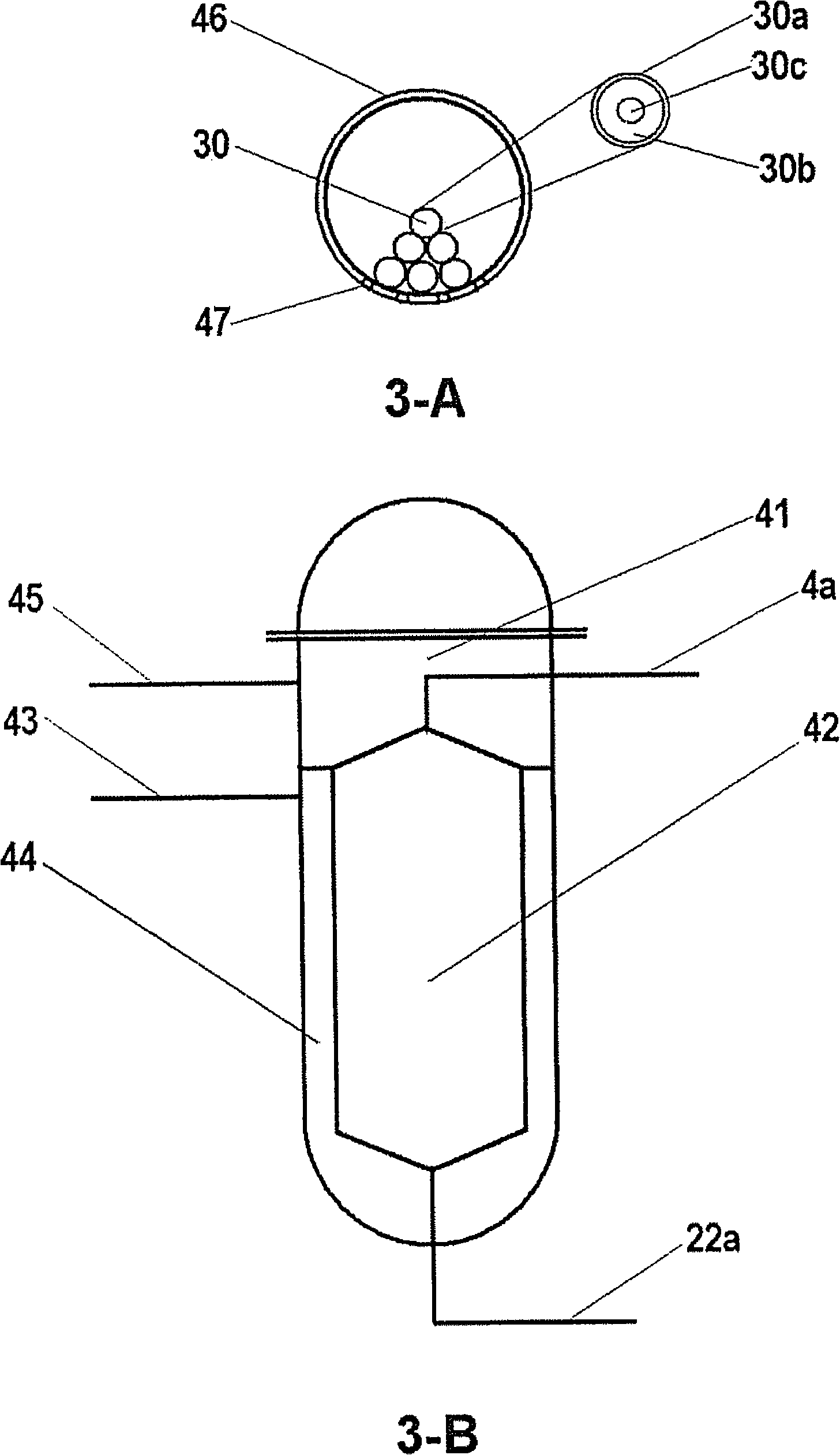

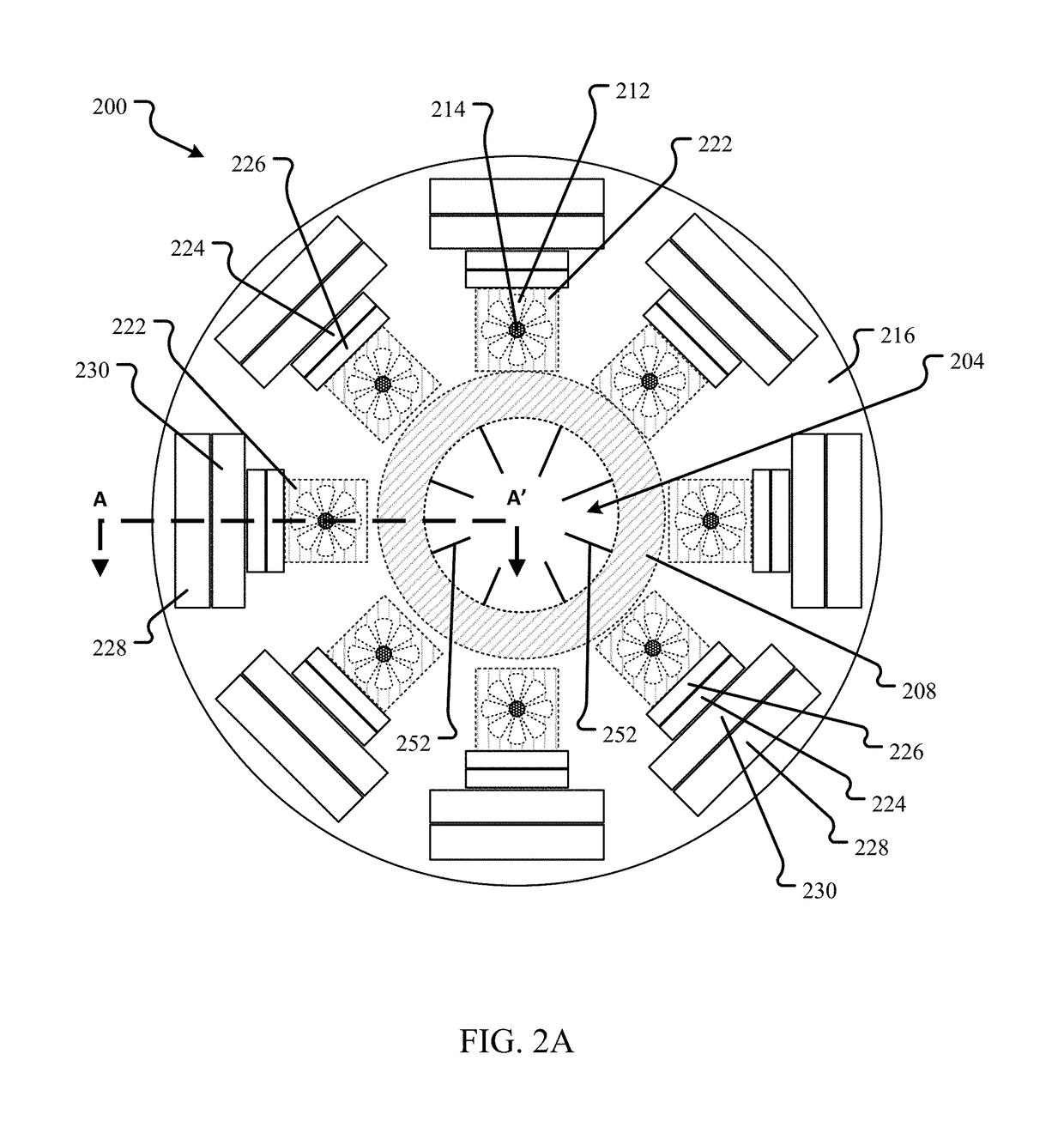

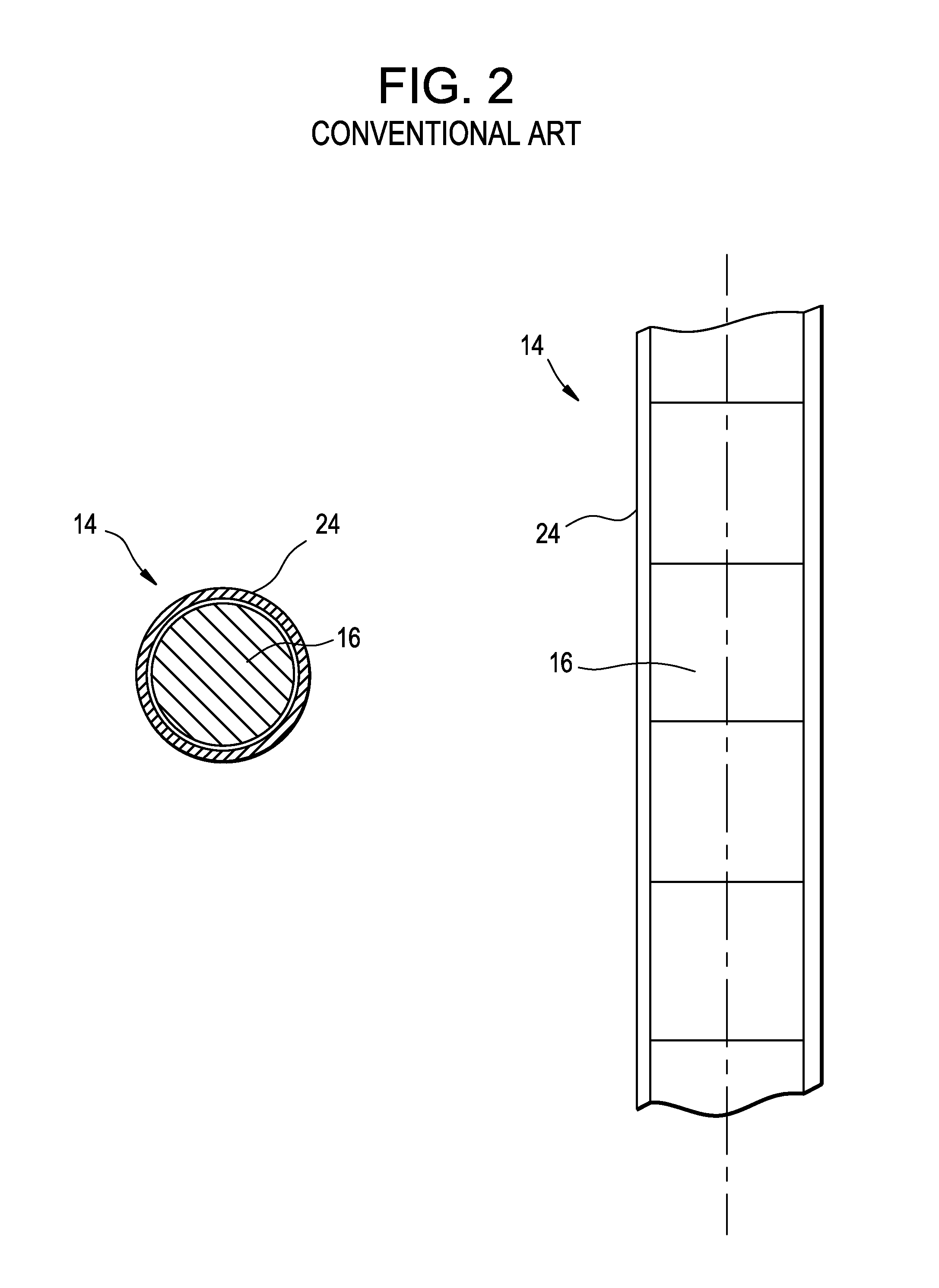

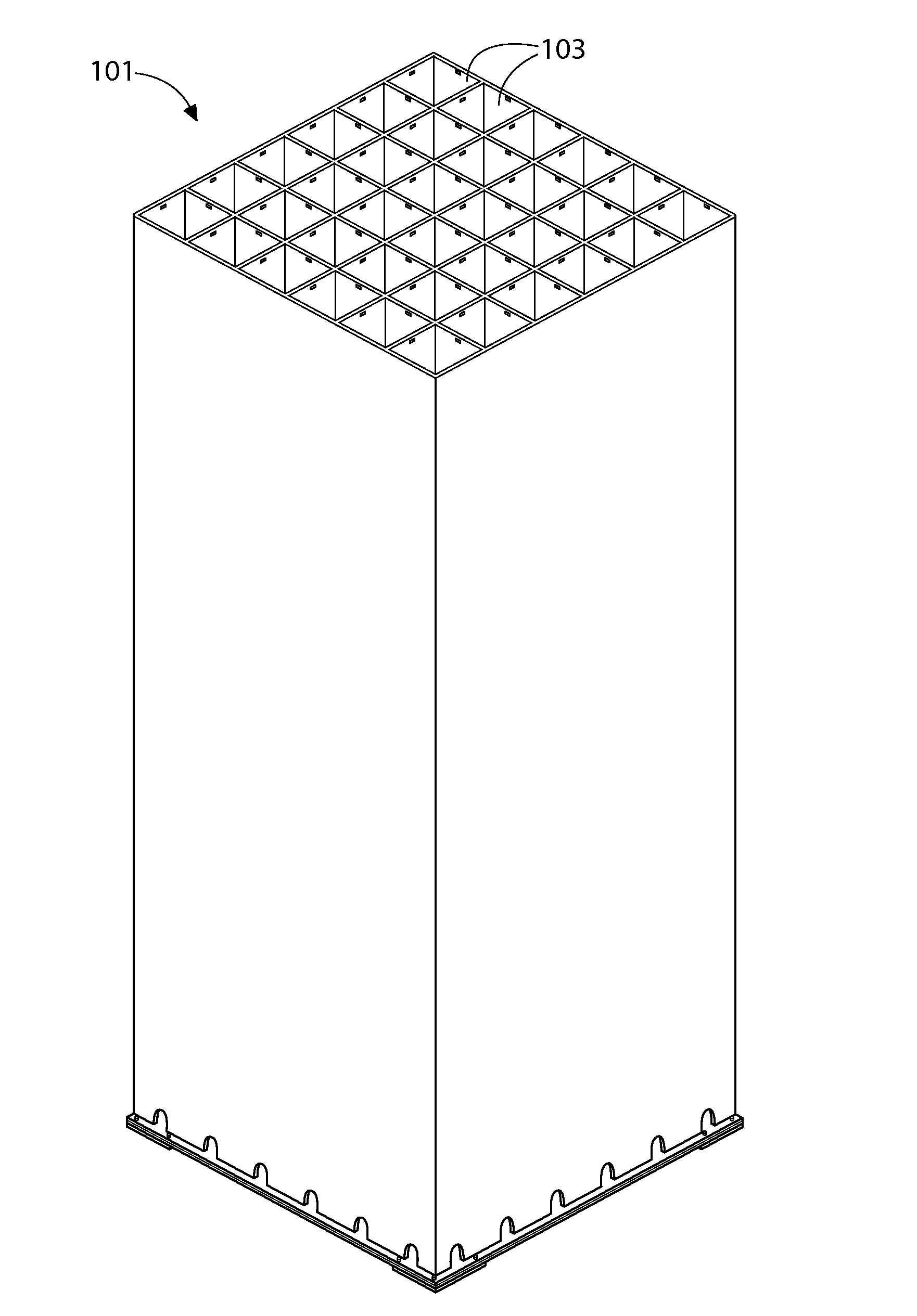

Nuclear fuel core, nuclear fuel cartridge, and methods of fueling and/or defueling a nuclear reactor

ActiveUS20150170766A1Improve cycle lifeExtended service lifeNuclear energy generationFuel element assembliesNuclear reactor coreNuclear reactor

A portable nuclear fuel cartridge comprising a unitary support structure and a plurality of nuclear fuel assemblies that collectively form a nuclear fuel core. The nuclear fuel core is integrated into the unitary support structure to collectively form a self-supporting assemblage than can be lifted as a single unit. In another aspect, the invention is a method of fueling and / or defueling a nuclear reactor utilizing a nuclear fuel cartridge that is loaded and / or unloaded from the nuclear reactor as a single unit. In another aspect, a nuclear reactor core is provided that comprises a nuclear fuel core comprising; a plurality of first nuclear fuel assemblies, each of the plurality of first nuclear fuel assemblies having a first transverse cross-sectional configuration; and a plurality of second nuclear fuel assemblies, each of the plurality of second nuclear fuel assemblies having a second transverse cross-sectional configuration that is different than the first transverse cross-sectional configuration.

Owner:SMR INVENTEC

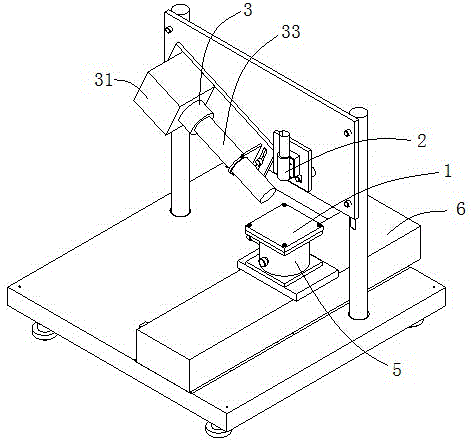

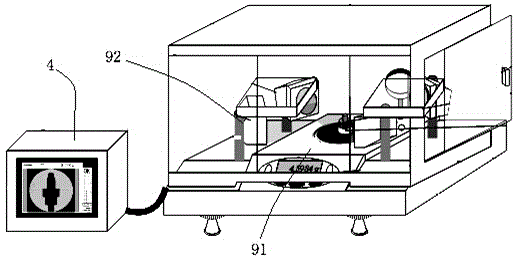

Method and system for measuring geometric density of nuclear fuel pellet

InactiveCN105571983AReduce the impact of human errorFast measurementUsing optical meansSpecific gravity measurementRepeatabilityMeasurement precision

The invention discloses a method and system for measuring the geometric density of a nuclear fuel pellet. The method comprises the following steps that the mass of the pellet to be detected is firstly obtained through a balance, then the boundary dimension of the pellet to be detected is measured, the volume of the pellet to be detected is calculated according to the boundary dimension of the pellet to be detected, and then the volume is divided by the mass to obtain the density of the pellet to be detected. According to the step of measuring the boundary dimension of the pellet to be detected, the diameter and height of the pellet to be detected are further measured. The method has the advantages of being high in measurement precision, high in measurement speed and the like. The system has the advantages of being simple and stable in structure, convenient to operate, high in disturbance resisting capacity, easy to maintain, accurate in locating, high in detecting precision, good in repeatability, wide in application range, beneficial for improving the measurement precision and the like.

Owner:CHONGQING UNIV +1

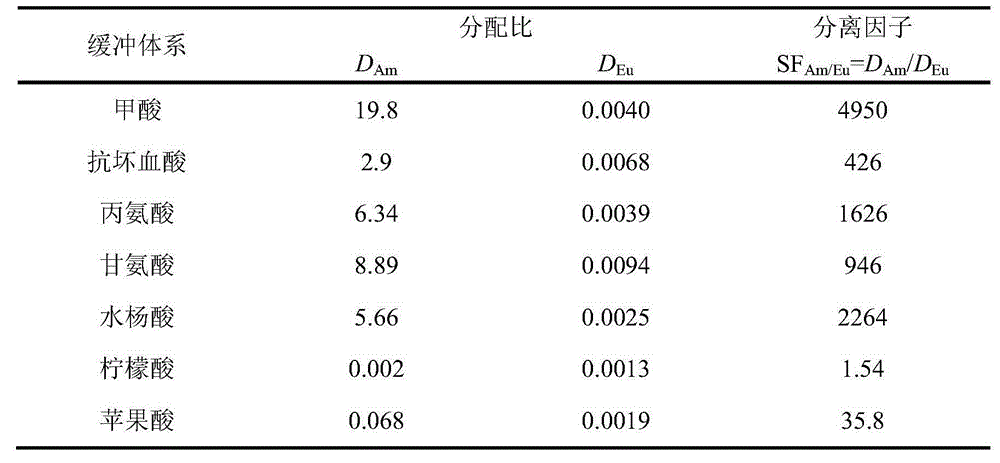

Method for extracting and separating trivalent lanthanum and trivalent actinium ion

ActiveCN104894372AMaintain efficient extraction and separation performanceImprove stabilityProcess efficiency improvementPh regulationActinium

The invention relates to a method for extracting and separating trivalent lanthanum and trivalent actinium ions and belongs to the technical field of nuclear fuel circulation and waste liquid treatment. The method uses bis(2,4,4-trimethylpentyl) dithiophosphinic acid as an extracting agent, uses long-chain alkane as a thinning agent and uses a weak acid buffer system to effectively stabilize the pH value of the water phase of an extraction system, pH regulation does not need to be performed to the system during extraction, trivalent actinium elements can be high-selectively extracted and separated out from the water phase, and most of trivalent lanthanum elements are remained in the water phase. The method for extracting and separating trivalent lanthanum and trivalent actinium ions has the advantages that the extraction and separation performance of trivalent lanthanum and trivalent actinium ions is high and stable and the prospect of application in the field of advanced nuclear circulation is better.

Owner:TSINGHUA UNIV +1

Method and device for fast breeding and converting nuclear fuel

InactiveCN101315815ALow costMeet needsFuel elementsNuclear energy generationInherent safetyNuclear power

The invention discloses a method and a device for fast multiplicating and transforming nuclear fuel with high inherent security and low cost, and the method and the device adopt 'moving solid nuclear fuel' which can flow and is similar to fluid, can be applied in a fast neutron reactor, and produce more nuclear fuel with less fissile fuel initial installation quantity and lower cost in a shorter time, thus satisfying the nuclear fuel demand at the current world nuclear power big development stage. The method and the device for fast multiplicating and transforming nuclear fuel are real nuclear reactors with inherent security, and can thoroughly eliminate the serious accident of massive radioactive release caused by element melting of the nuclear fuel which still possibly occurs in the current nuclear power station.

Owner:吕应中

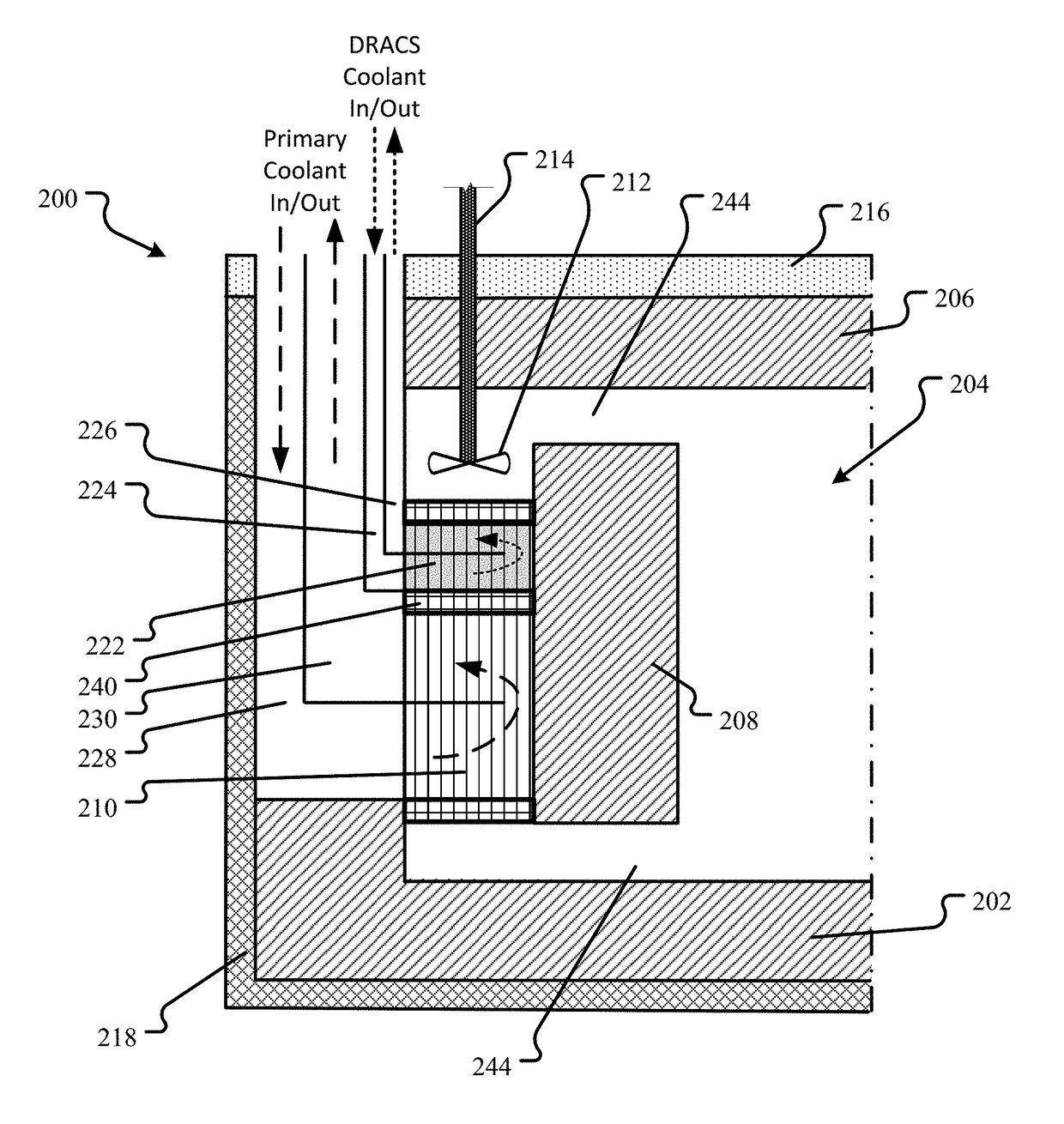

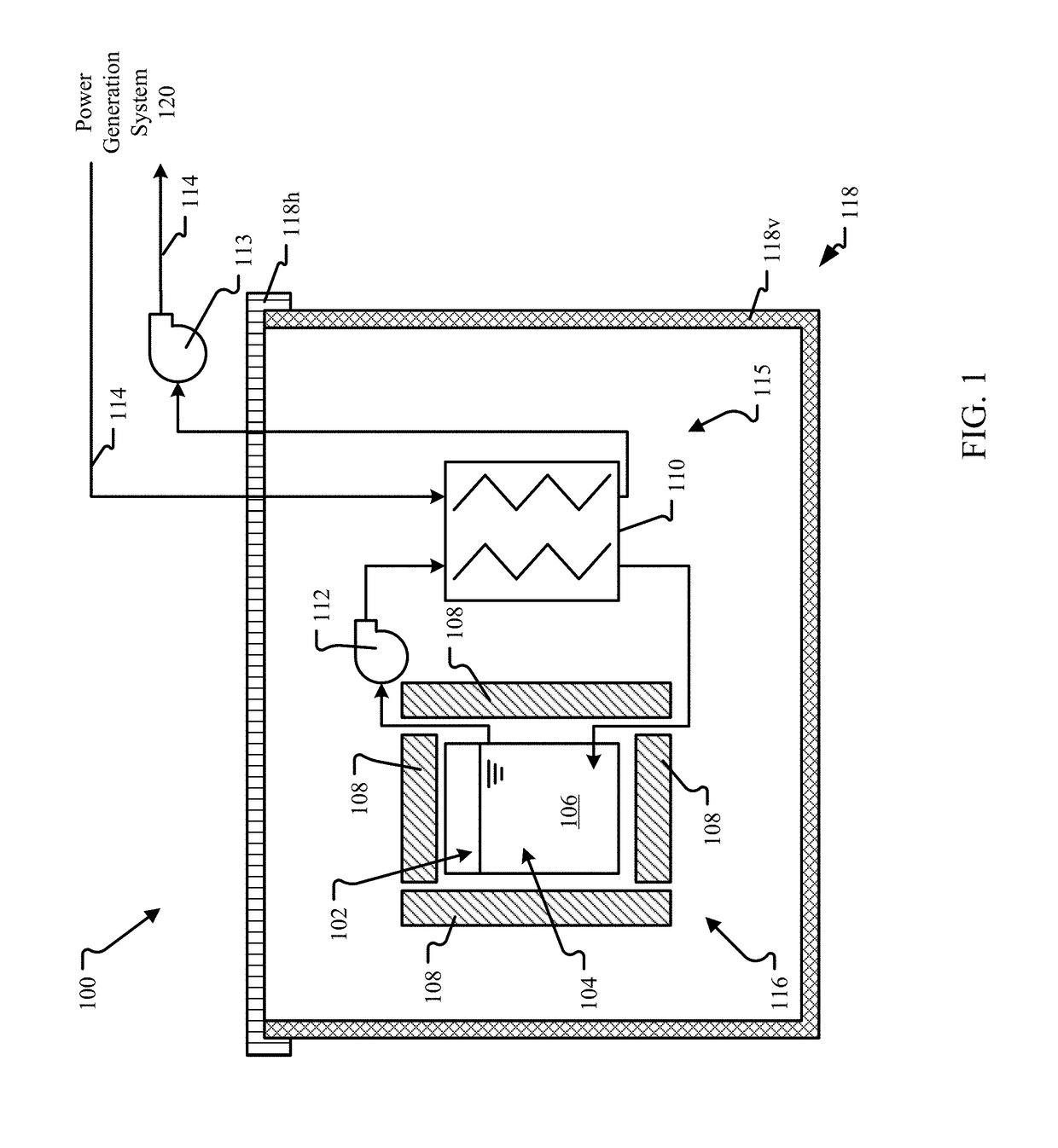

Thermal management of molten fuel nuclear reactors

ActiveUS20180137944A1Improve power densitySave on fuel costsNuclear energy generationFast fission reactorsNuclear reactorOperating temperature

This disclosure describes various configurations and components of a molten fuel fast or thermal nuclear reactor for managing the operating temperature in the reactor core. The disclosure includes various configurations of direct reactor auxiliary cooling system (DRACS) heat exchangers and primary heat exchangers as well as descriptions of improved flow paths for nuclear fuel, primary coolant and DRACS coolant through the reactor components.

Owner:TERRAPOWER

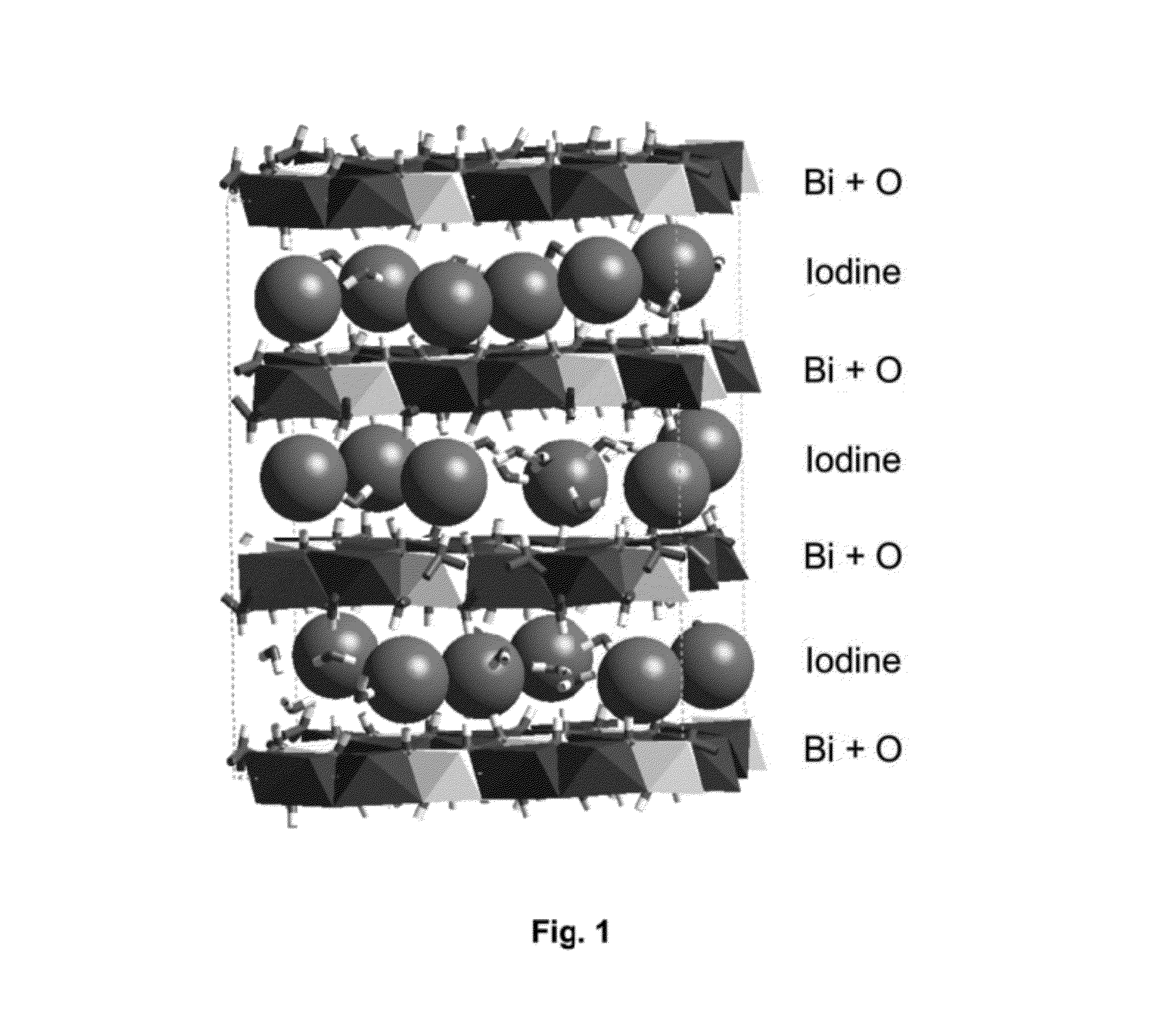

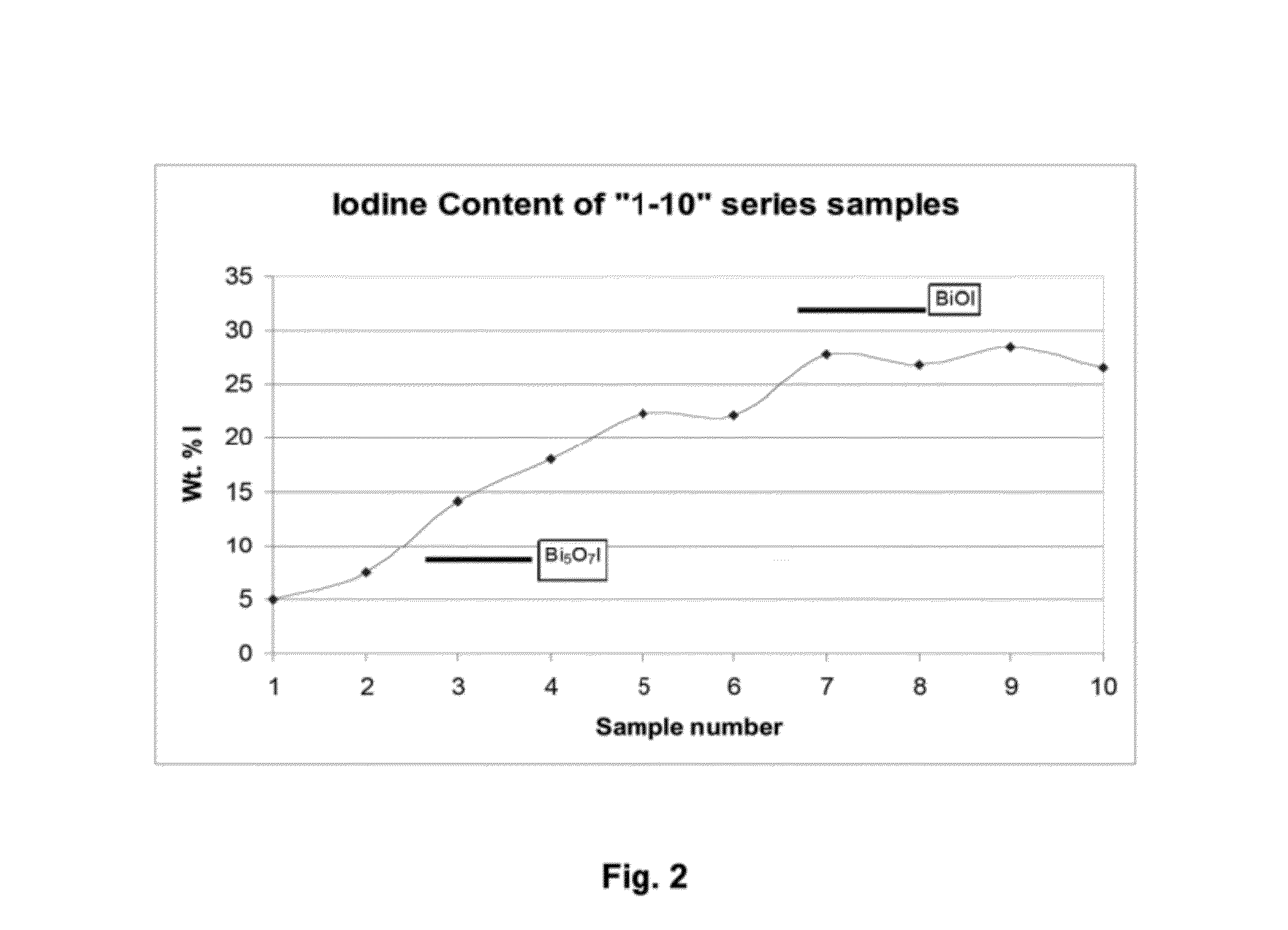

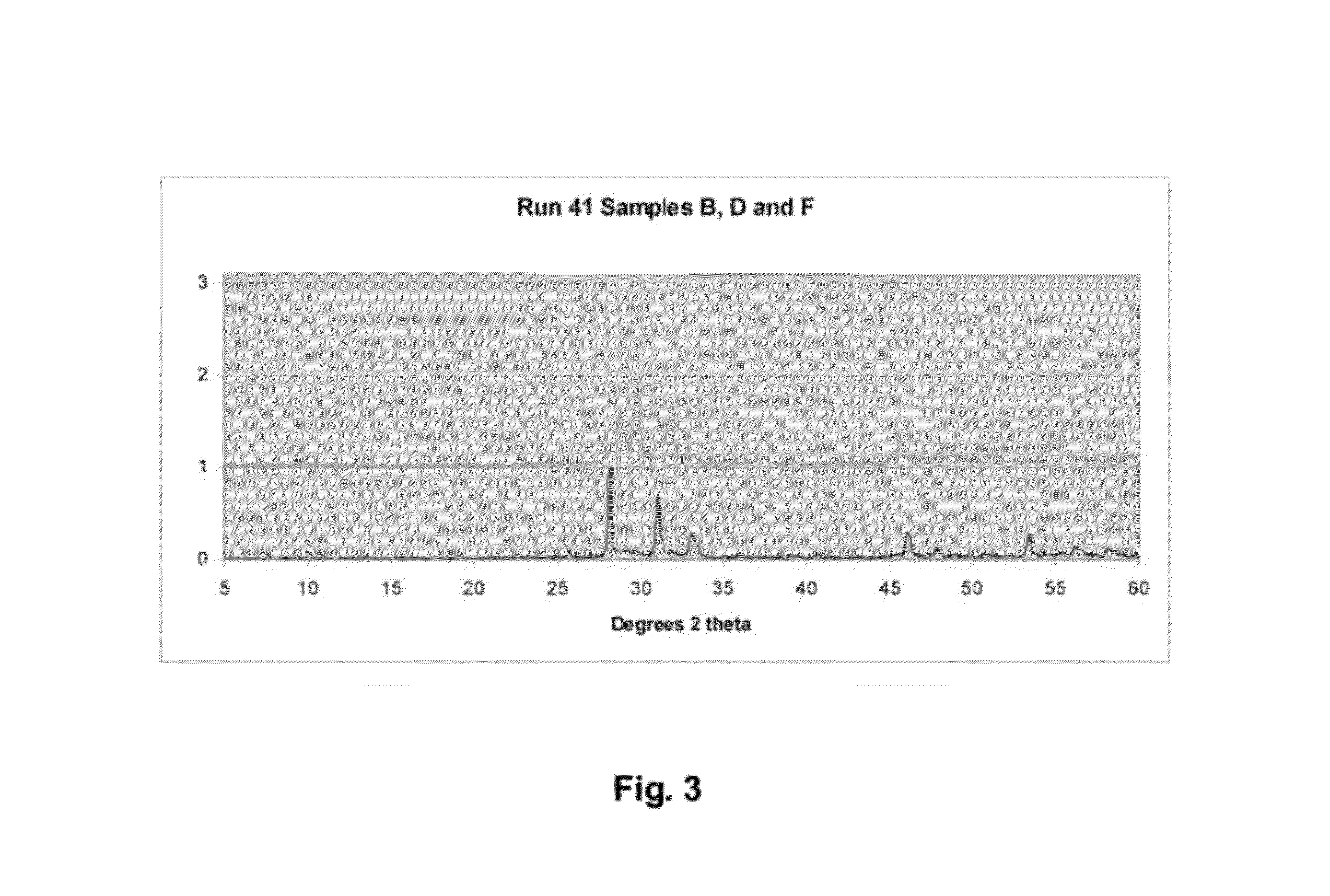

Mixed-layered bismuth-oxygen-iodine materials for capture and waste disposal of radioactive iodine

ActiveUS8383021B1Transuranic element compoundsSolid waste disposalSolubilityWaste Isolation Pilot Plant

Materials and methods of synthesizing mixed-layered bismuth oxy-iodine materials, which can be synthesized in the presence of aqueous radioactive iodine species found in caustic solutions (e.g. NaOH or KOH). This technology provides a one-step process for both iodine sequestration and storage from nuclear fuel cycles. It results in materials that will be durable for repository conditions much like those found in Waste Isolation Pilot Plant (WIPP) and estimated for Yucca Mountain (YMP). By controlled reactant concentrations, optimized compositions of these mixed-layered bismuth oxy-iodine inorganic materials are produced that have both a high iodine weight percentage and a low solubility in groundwater environments.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

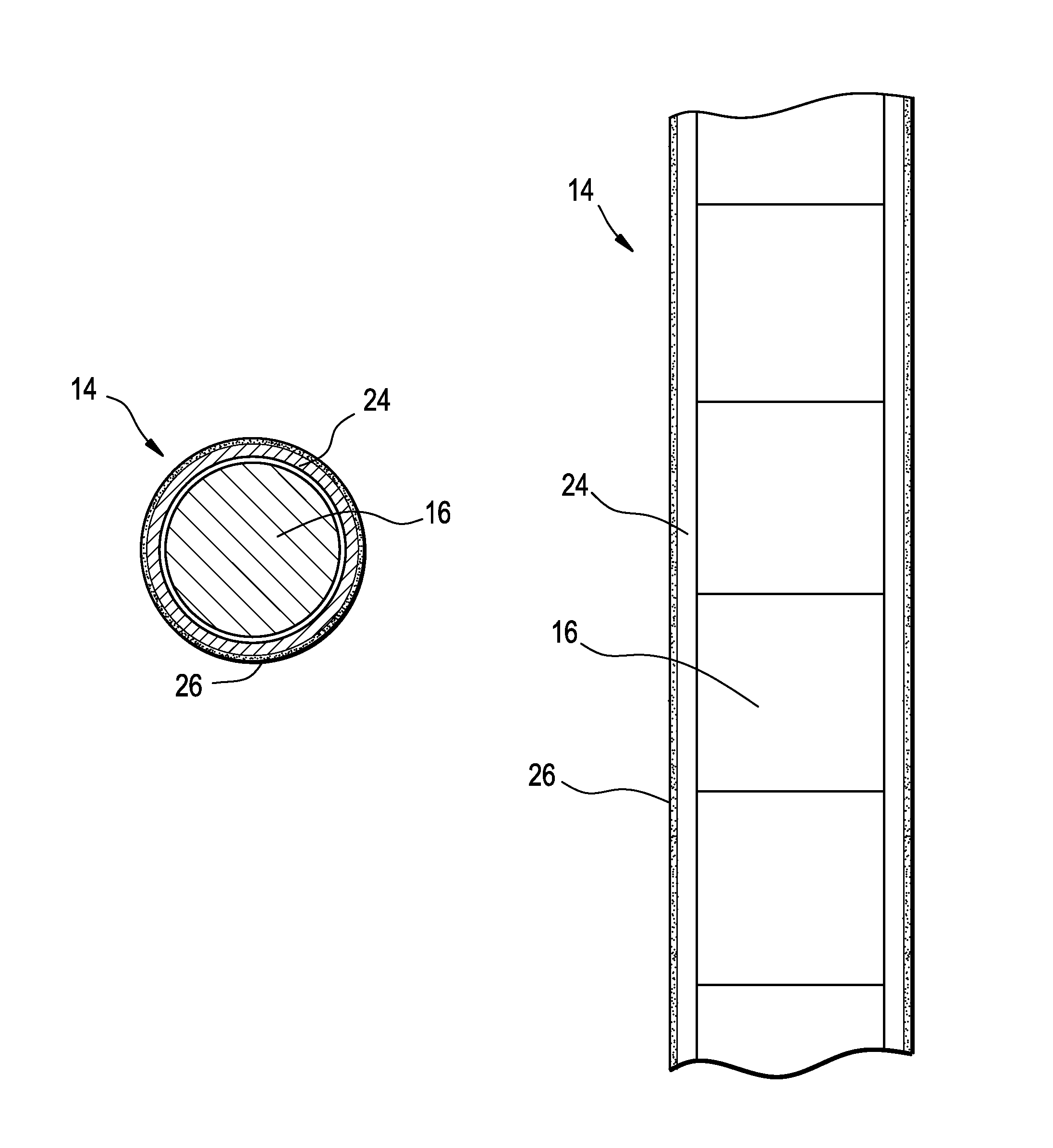

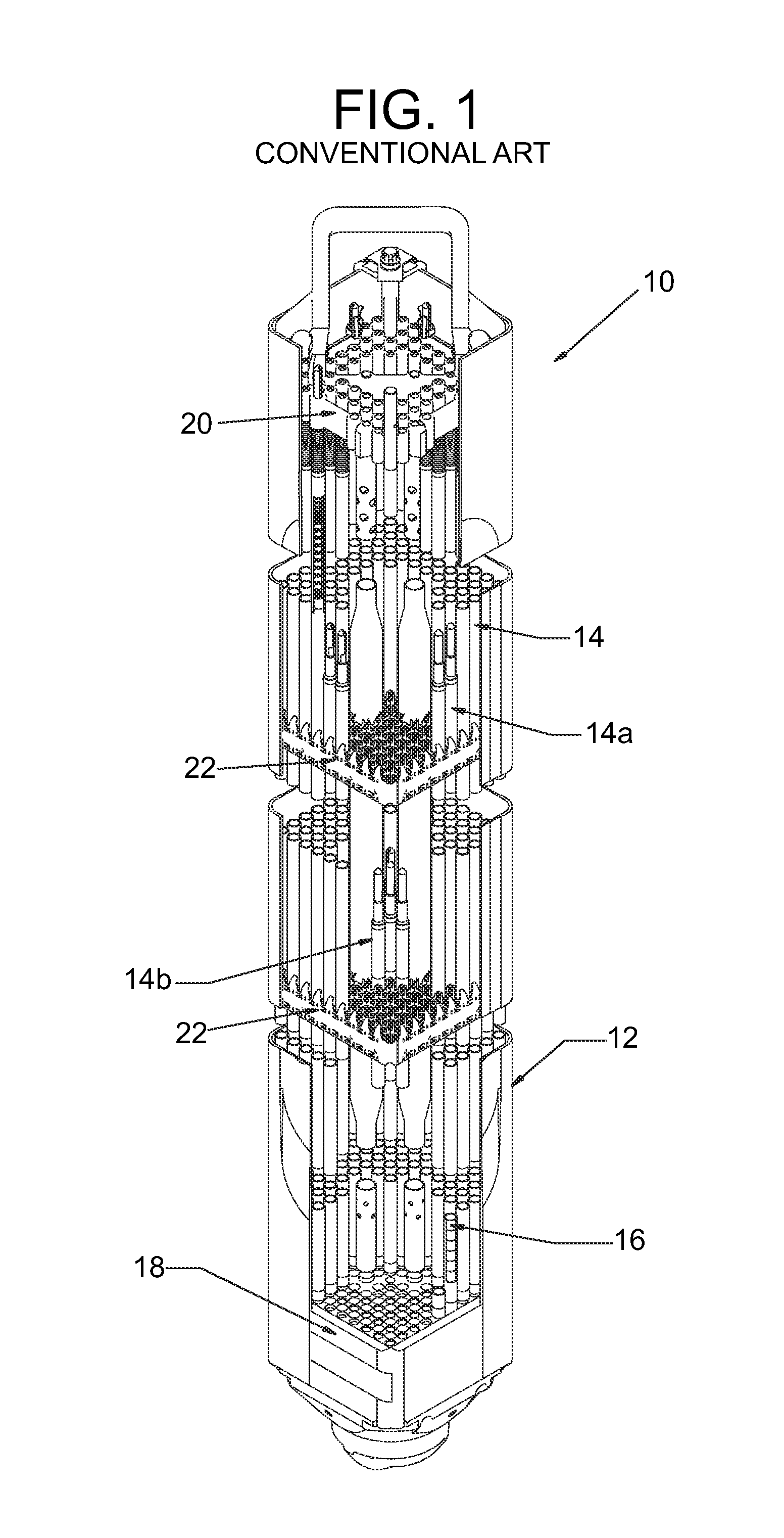

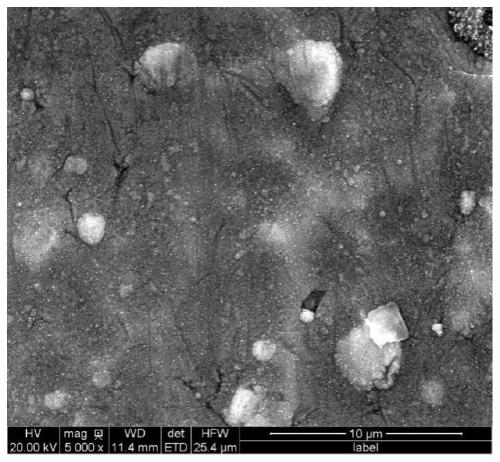

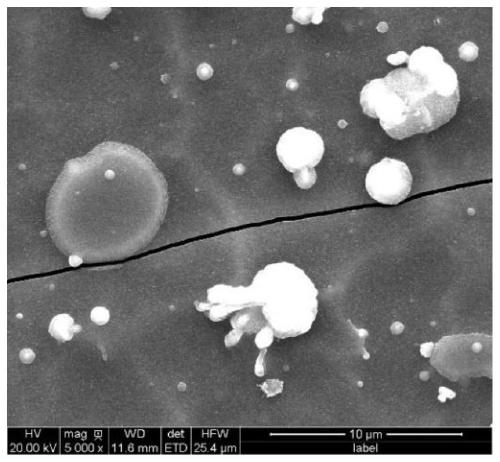

Method and apparatus for a fret resistant fuel rod for a light water reactor (LWR) nuclear fuel bundle

A method and apparatus for a fret resistant fuel rod for a Boiling Water Reactor (BWR) nuclear fuel bundle. An applied material entrained with fret resistant particles is melted or otherwise fused to a melted, thin layer of the fuel rod cladding. The applied material is made of a material that is chemically compatible with the fuel rod cladding, allowing the fret resistant particles to be captured in the thin layer of re-solidified cladding material to produce an effective and resilient fret resistant layer on an outer layer of the cladding.

Owner:GLOBAL NUCLEAR FUEL -- AMERICAS

Nuclear fuel, a fuel element, a fuel assembly and a method of manufacturing a nuclear fuel

The invention refers to a nuclear fuel, a fuel element, a fuel assembly and a method of manufacturing a nuclear fuel. The nuclear fuel is adapted for use in a water cooled nuclear reactor, including light water reactors LWR, such as Boiling Water Reactors BWR and Pressure Water Reactors PWR. The nuclear fuel comprises an uranium-containing compound consisting of UN. The uranium content of the uranium-containing compound comprises less than 10% by weight of the isotope 235U. The nuclear fuel comprises an additive substantially consisting of at least one element, in elementary form or as a compound, selected from the group consisting of Zr, Mo, Si, Al, Nb and U.

Owner:WESTINGHOUSE ELECTRIC SWEDEN

Water boiler solution nuclear reactor having inherent security

ActiveCN1992095AIncrease production capacityMeet market needsNuclear energy generationHomogenous reactorsNuclear reactorNuclear fuel cycle

The invention discloses a water-boiler solution-type reactor with fixed security, the concentrated UO2(NO3)2 solution or UO2SO4 solution is as the nuclear fuel, the flat in-core structure is adopted, the ratio of in-core solution height to in-core diameter is 0.3-0.8, when the ratio of volume to power is maintained at 2.0-2.5kW / L, the volume of the in-core solution can achieve 50-200L, the power of heap is bigger than 100kW.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

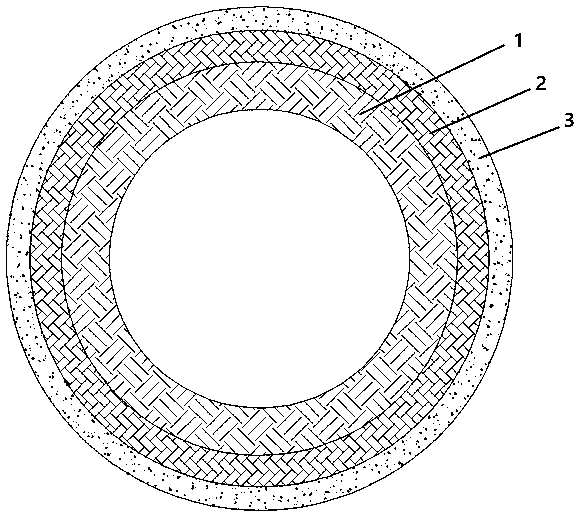

Nuclear fuel cladding pipe and preparation method thereof

ActiveCN107686364AHigh strengthTake off easilyOptical rangefindersNuclear energy generationFiber bundleGas phase

The invention discloses a nuclear fuel cladding pipe and a preparation method thereof. A pipe wall of the nuclear fuel cladding pipe sequentially comprises a first fiber-reinforced ceramic matrix composite layer, a second fiber-reinforced ceramic matrix composite layer and a ceramic layer from inside to outside, wherein the first fiber-reinforced ceramic matrix composite layer is composed of a first fiber prefabricated body and a first ceramic matrix filled into hole gaps of the first fiber prefabricated body, the second fiber-reinforced ceramic matrix composite layer is composed of a second fiber prefabricated body and a second ceramic matrix filled into hole gaps of the second fiber prefabricated body, and the first fiber prefabricated body is formed by winding fiber cloth which is soaked in a resin adhesive into a pipe and curing-carbonizing the pipe, the second fiber prefabricated body is formed by weaving a plurality of fiber bundles which are soaked in the resin adhesive, windingthe fiber bundles on the periphery of the fiber cloth wound pipe and curing-carbonizing the fiber bundles, and the ceramic layer is prepared by a chemical vapor deposition method. The forming methodcan form thin and long fiber-reinforced ceramic matrix composite tubular members in batch; furthermore, the length is not limited, a technology has strong practicability, and an equipment requirementis low.

Owner:NAT UNIV OF DEFENSE TECH

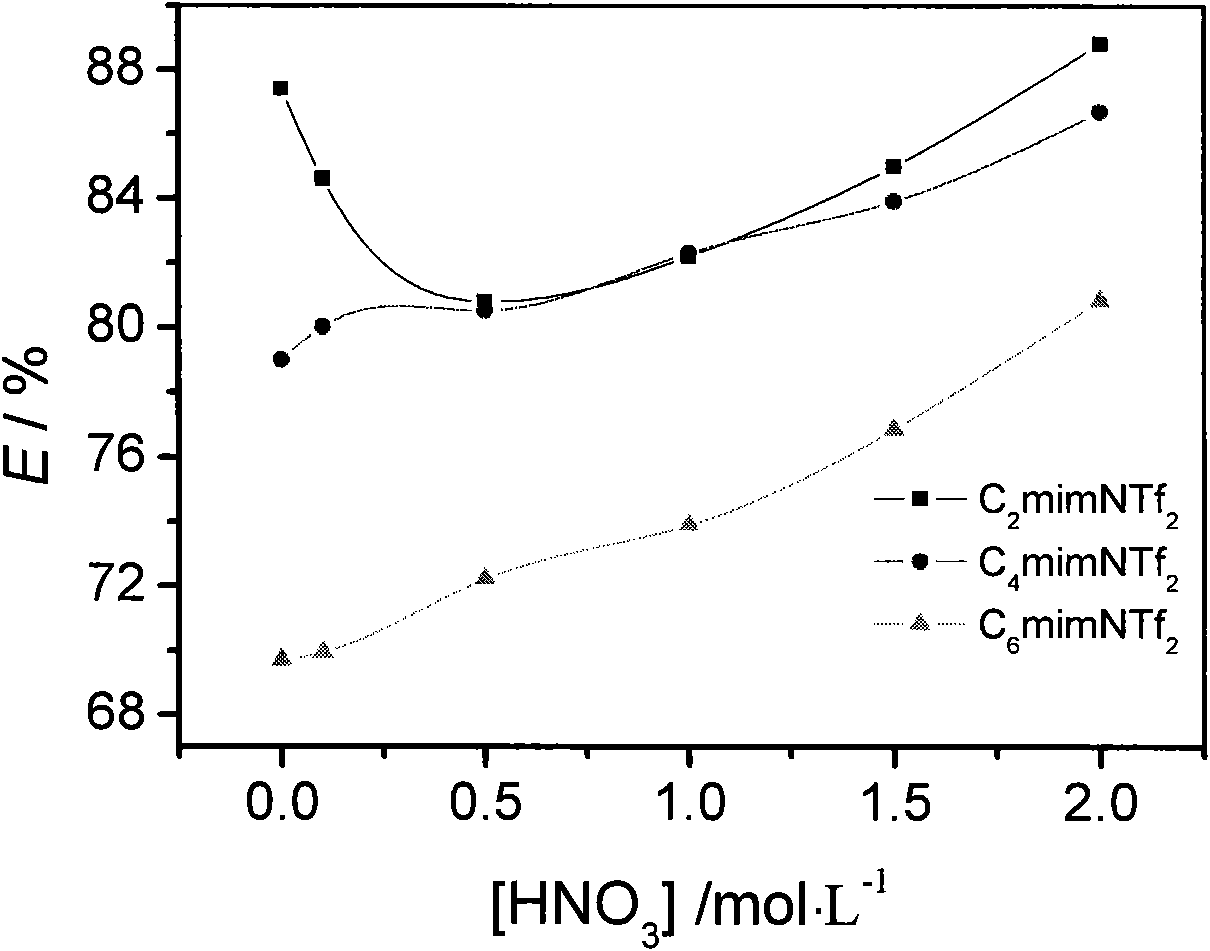

Method for extracting and separating uranyl ions from aqueous phase

InactiveCN101638722AEfficient extraction performanceEasy extractionProcess efficiency improvementDiluentUranyl

The invention discloses a method for extracting and separating uranyl ions from an aqueous phase. In the method, hydrophobic ion liquid serves as a diluting agent and octyl phenyl group-N, N-diisobutylamine formacyl methylphosphineoxide serves as an extracting agent so as to extract uranyl ions from an aqueous solution containing the uranyl ions. The method can be used for efficiently extracting the cesium ions from the aqueous phase, and the extracting distribution ratio can reach more than 10<3> at most. The method has a wide applicable range to different aqueous phase acidity conditions, and can be used for extracting the cesium ions from neutral conditions to 3MHNO3; ion liquid serves as a diluting agent, and phenomena which are disadvantageous to technology such as emulsification in the process of extracting the cesium ions do not exist. Ion liquid almost has no volatility, thus the system is environmental-friendly. To sum up, the method of the invention has favorable applicationprospect in the field of nuclear fuel recycling.

Owner:PEKING UNIV

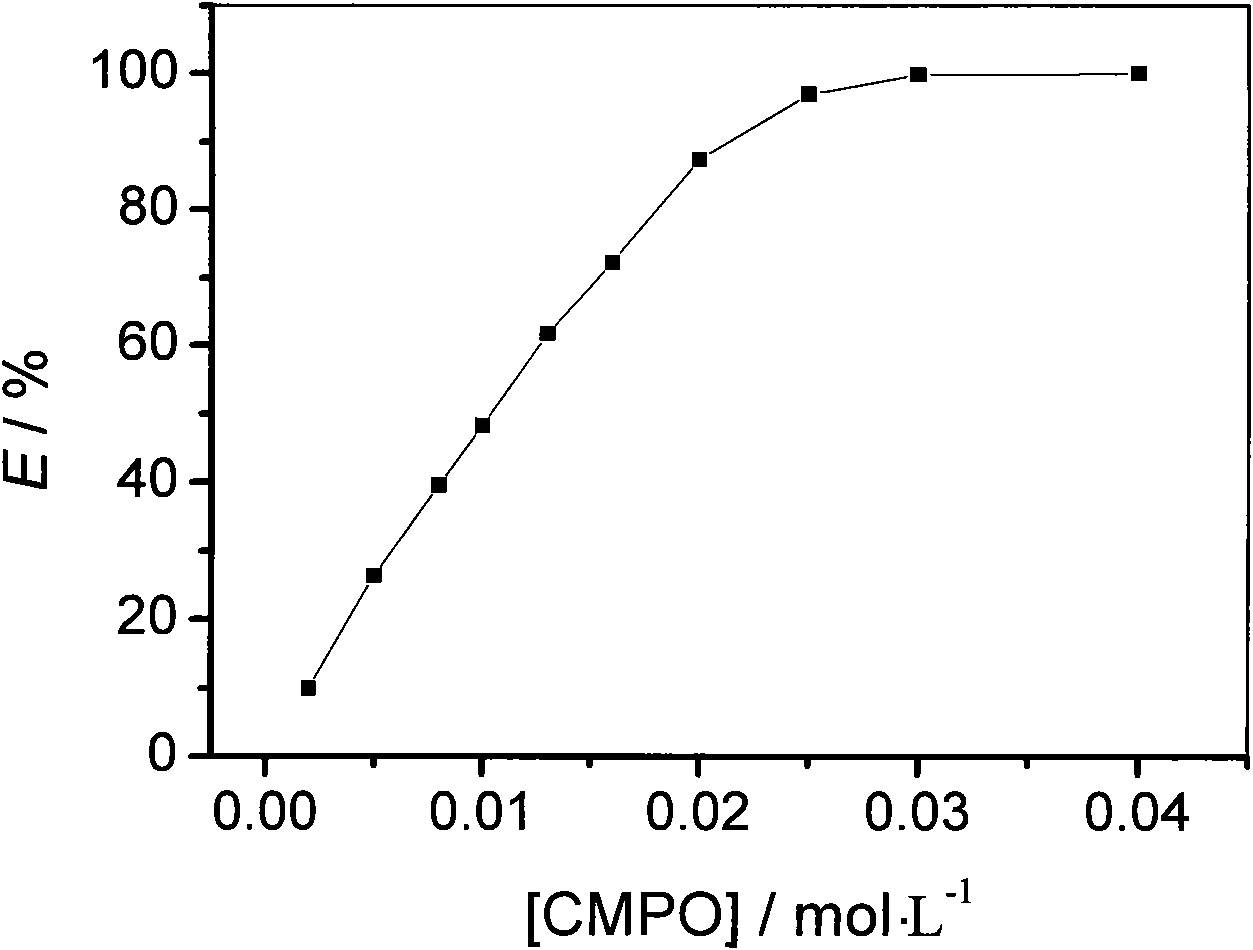

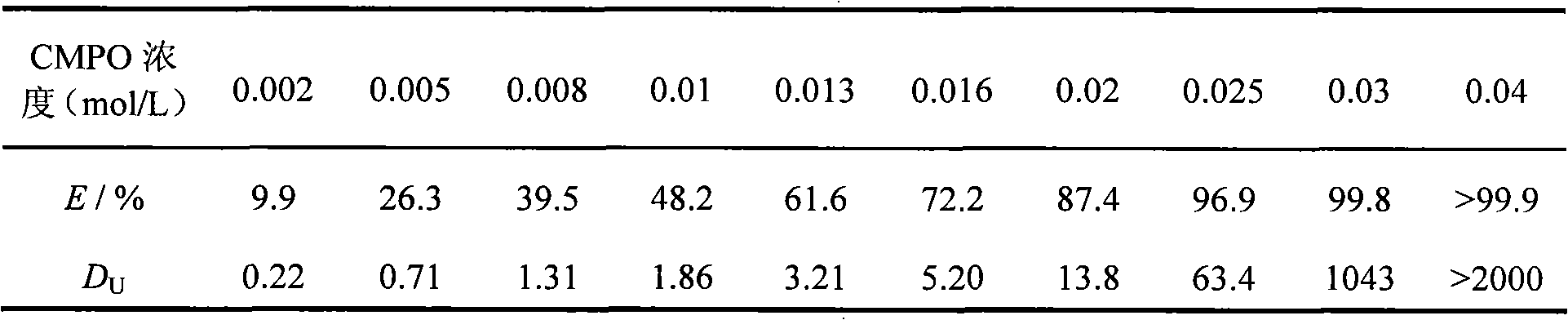

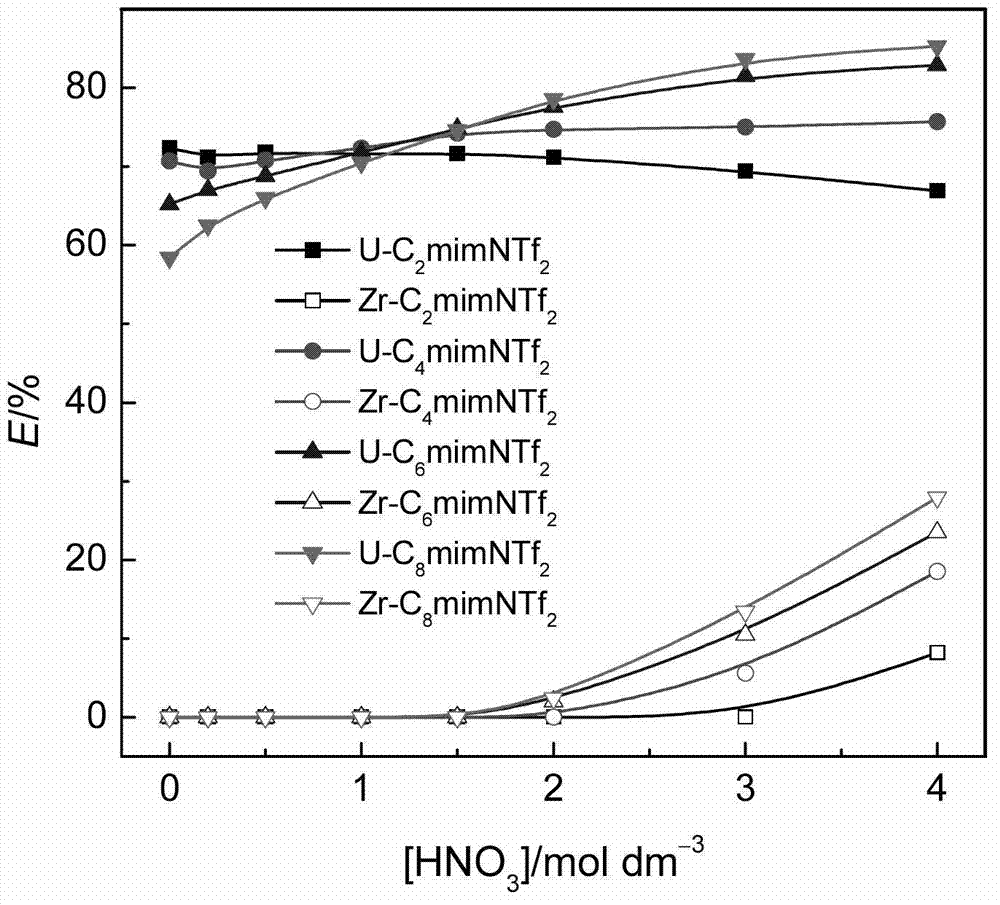

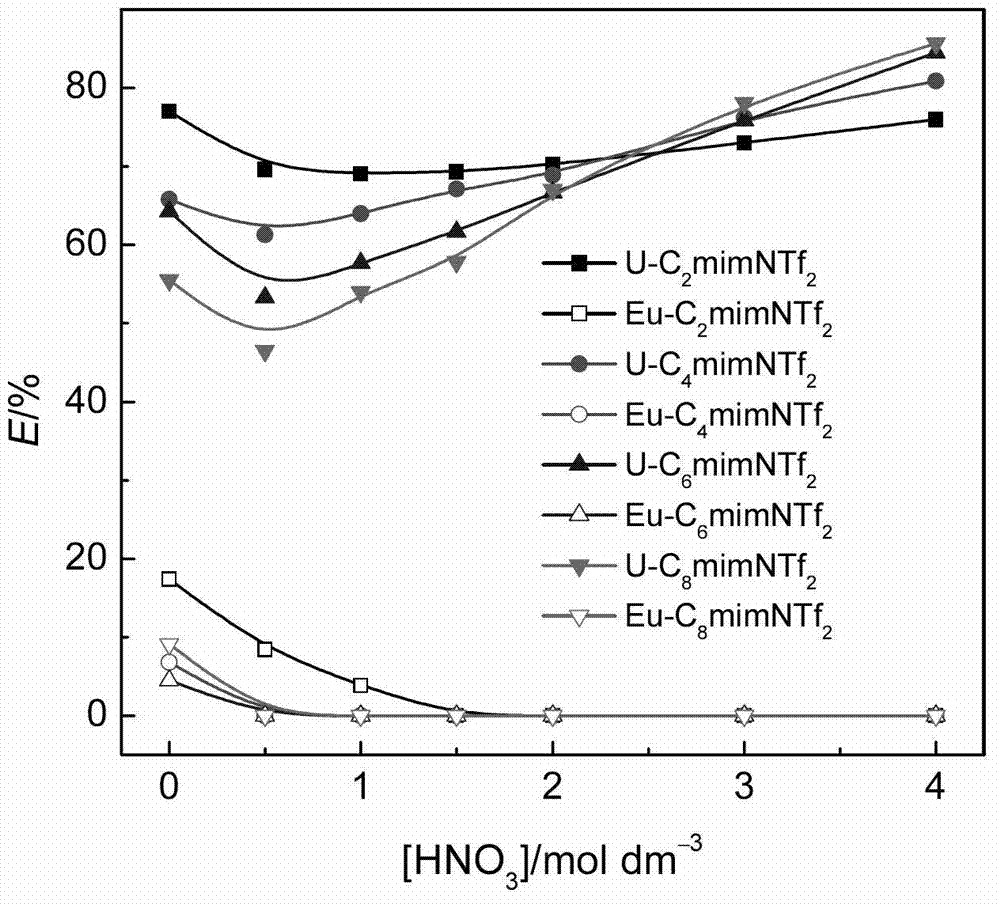

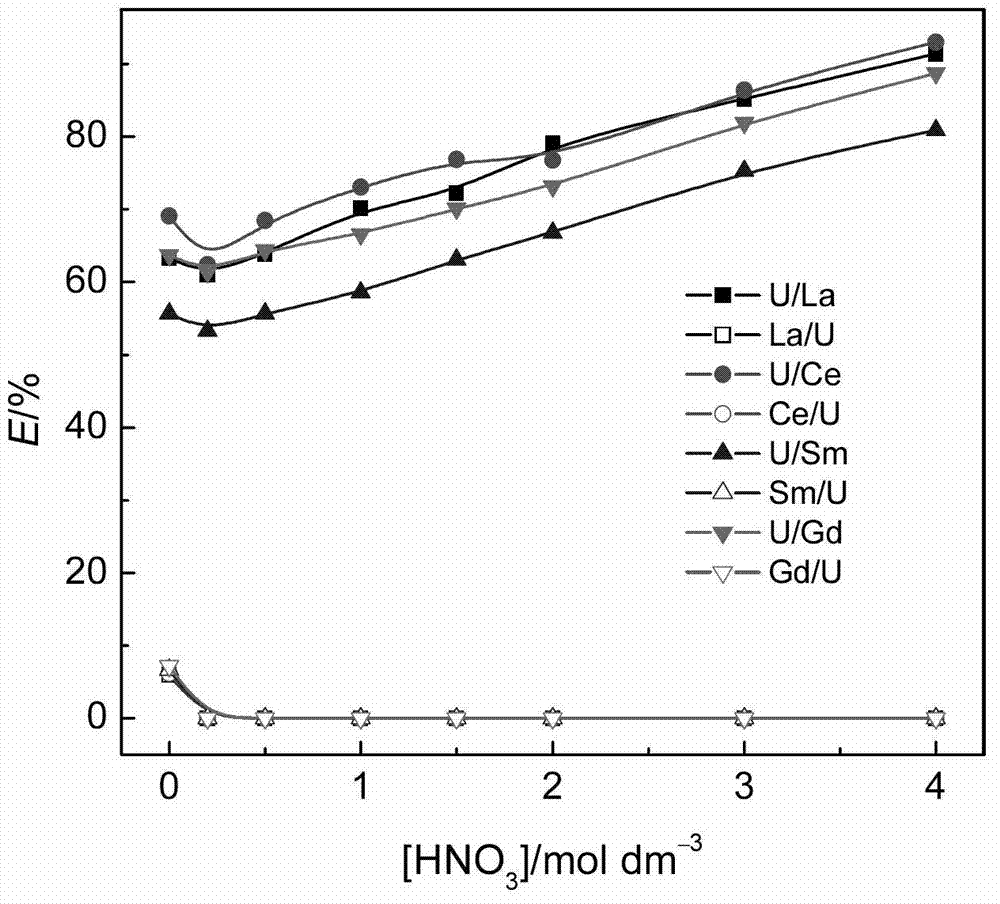

Method for extracting and separating uranyl ions from water phase containing zirconium ions and lanthanide ions

InactiveCN102776373AGreat selective extraction performanceEasy to separateProcess efficiency improvementLanthanideUranyl

The invention discloses a method for extracting and separating uranyl ions from a water phase containing zirconium ions and lanthanide ions. The method taking a hydrophobic ionic liquid as a diluent and taking octyl (phenyl)-N, N-diisobutyl carbonoyl methyl-phosphine oxide (CMPO) as an extracting agent comprises the following steps of: extracting and separating out the uranyl ions efficiently from the water phase containing the zirconium ion and / or the lanthanide ions, wherein the zirconium ions and the lanthanide ions are not extracted or are low in extracted ratio. The method is suitable for a large water phase acid degree range, and the uranyl ions can be selectively extracted from the moderate condition to 4mol / L of HNO3. The ion liquid nearly has volatility, and the using process is environment-friendly. The method provided by the invention has wide application prospect in the field of nuclear fuel cycle.

Owner:PEKING UNIV

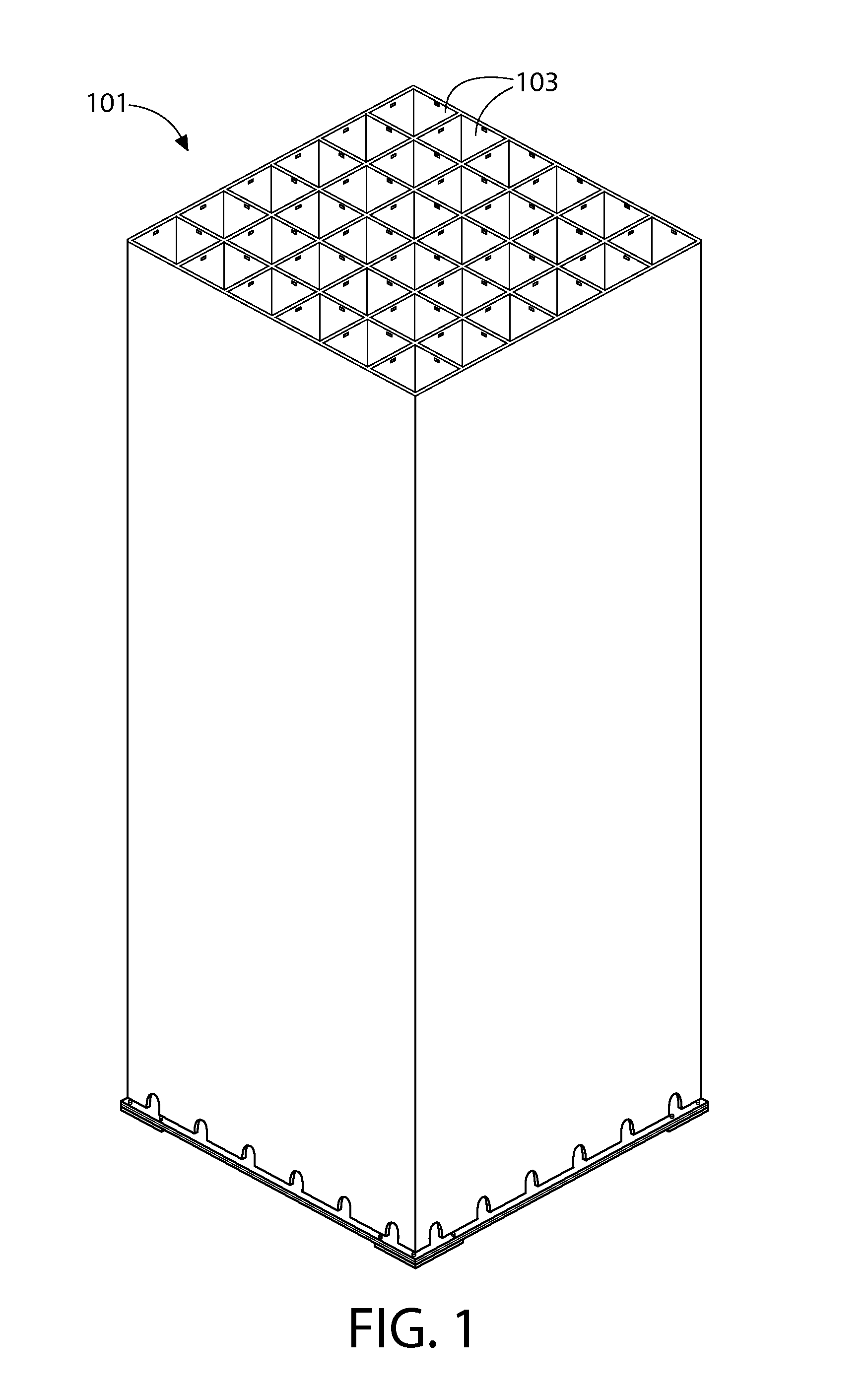

Snap-in insert for reactivity control in spent nuclear fuel pools and casks

A neutron absorbing apparatus, for insertion into a fuel cell storage system, includes a corner spine, a first all and a second wall, each wall being affixed to the corner spine to form a chevron shape. Each wall includes an absorption sheet affixed to the corner spine, each absorption sheet being formed of a metal matrix composite having neutron absorbing particulate reinforcement, and a guide sheet affixed to and covering a fractional upper portion of the absorption sheet and extending over a top of the absorption sheet. The absorption sheet extends along the corner spine a greater length than the guide sheet.

Owner:HOLTEC INT

Emergency and back-up cooling of nuclear fuel and reactors

InactiveUS20140105348A1Increase powerPower plant safety arrangementNuclear energy generationNitrogenNuclear reaction

An embodiment uses liquid nitrogen, the densest and highly transportable form of nitrogen, and the cold nitrogen gas it produces when released from its container, for emergency cooling of fuel rods and nuclear reaction chambers.

Owner:LIN HENDEL CATHERINE

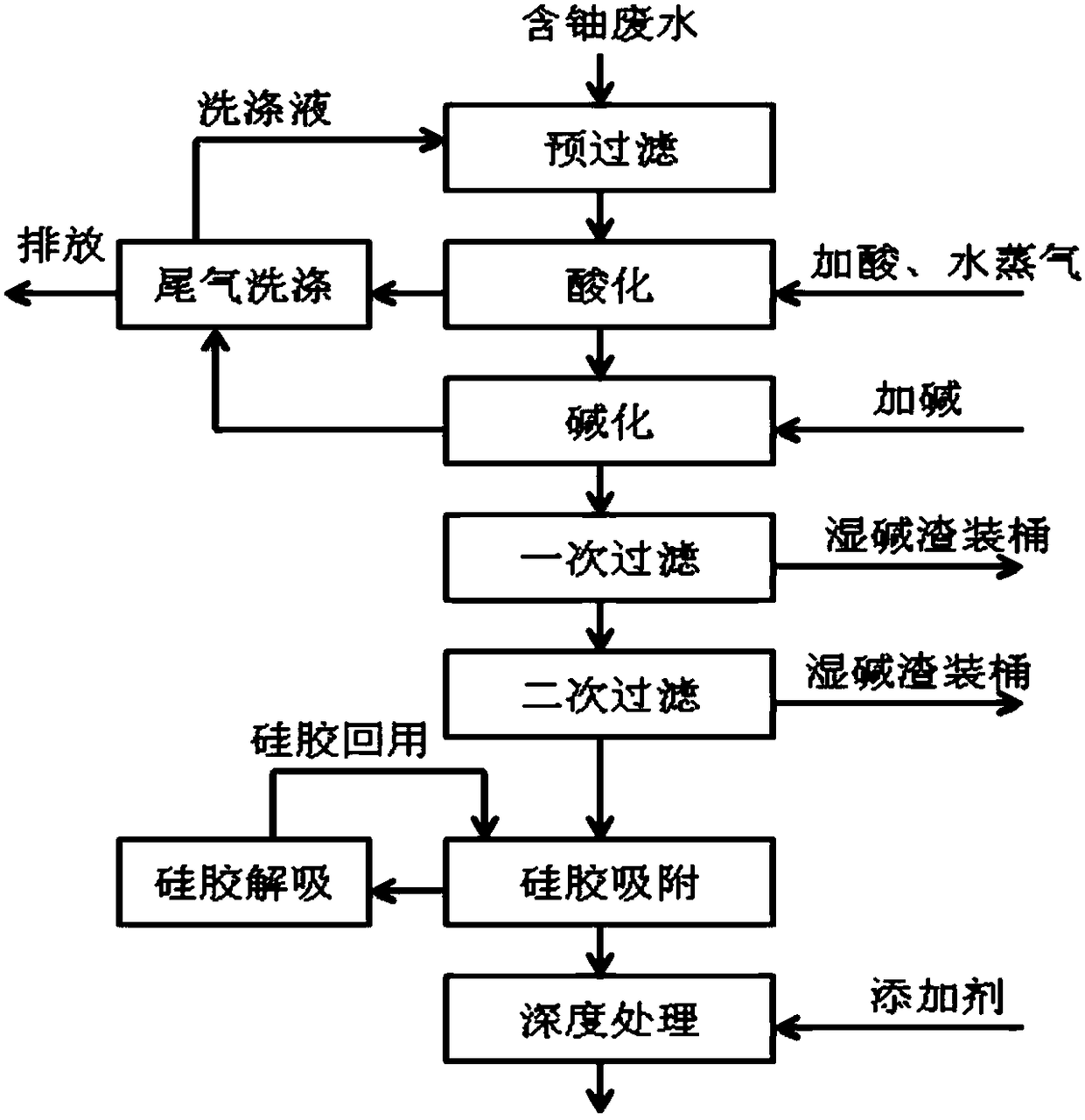

Uranium-containing wastewater treatment method

ActiveCN108257706AAvoid affecting adsorptionAvoid pollutionRadioactive decontaminationParticulatesDesorption

The invention belongs to nuclear fuel circulation technologies, and specifically discloses a uranium-containing wastewater treatment method. The treatment method is characterized in that firstly uranium-containing wastewater is subjected to pre-filtration, and followed by acidification treatment and alkalization treatment; and after being filtered again, the wastewater is subjected to silica gel adsorption uranium removing, after the wastewater reaches standards, deep treatment is performed, and if the wastewater does not reach the standards, deep treatment is performed after silica gel desorption. According to the treatment method, particulate matters in the wastewater are removed through pre-filtration firstly, thereby avoiding high temperature acidification making the uranium concentration of the wastewater increased to bring critical safety problems; with the help of the high temperature acidification, acid gases are driven off, and organic matters are destroyed, thereby avoiding affecting the adsorption of the silica gel on uranium; after the acidification, ammonia water, sodium hydroxide or the like is added to precipitate most of the uranium in the wastewater, thereby reducing the uranium concentration in the wastewater, and the precipitated wastewater is subjected to two stage filtration to make most of uranium-containing particles intercepted, thereby avoiding the uranium-containing particles polluting the silica gel, and improving the service life and the adsorption effect of the silica gel.

Owner:CNNC JIANZHONG NUCLEAR FUEL

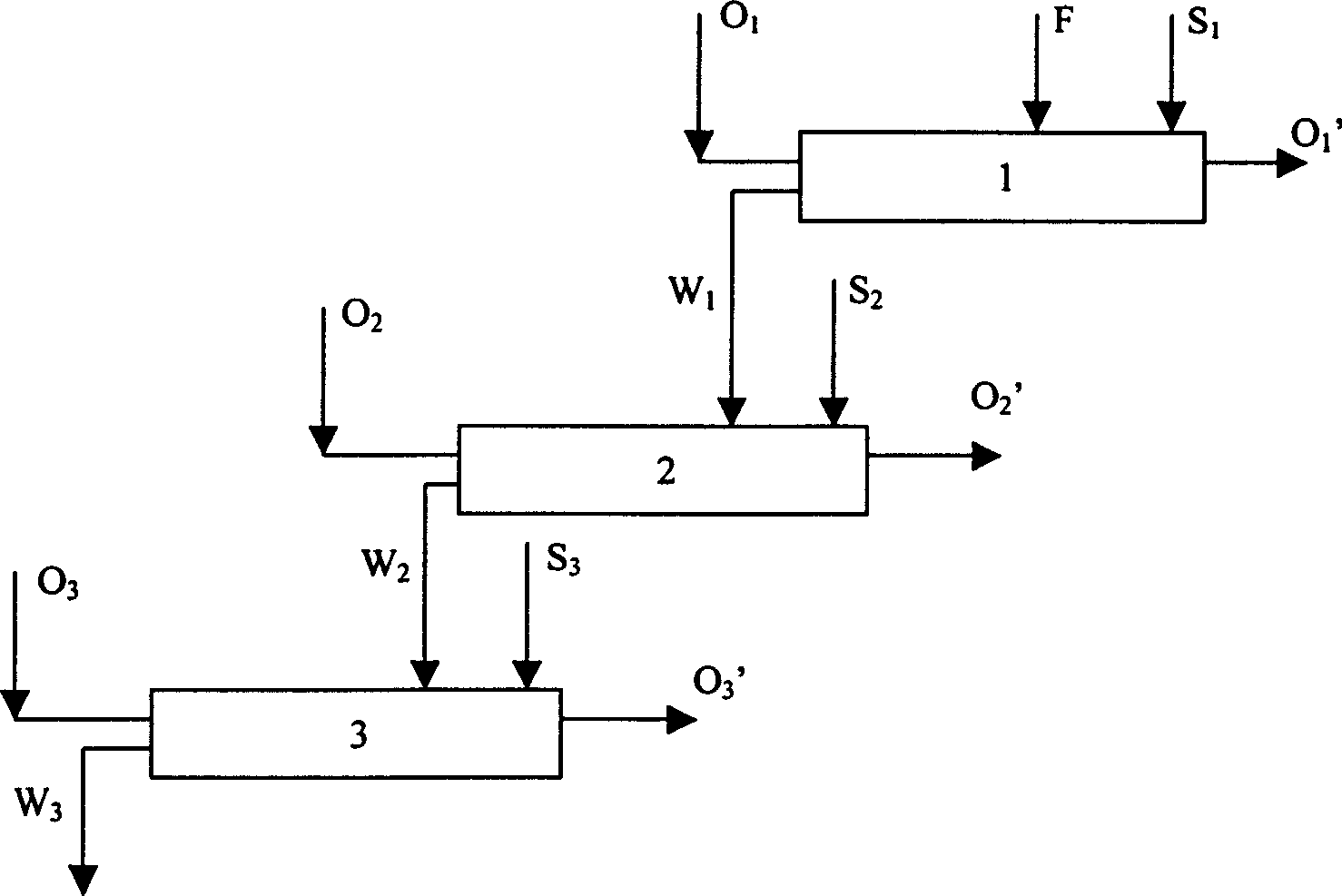

Integral method for reprocessing spent fuel

InactiveCN1448959AImprove radiation stabilityDoes not visibly decomposeNuclear energy generationRecycling and recovery technologiesNuclear reactorKerosene

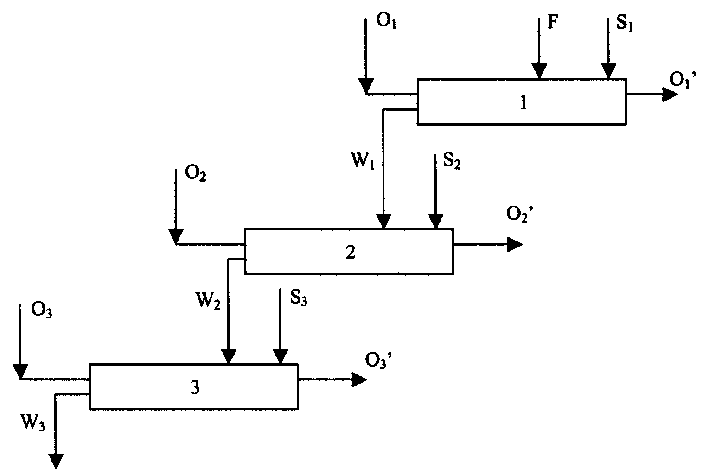

The integrated exhausted fuel post-treatment method belongs to the field of circularly utilizing nuclear fuel. The method is to use three kinds of extracting systems, including O1 phase, O2 phase and O3 phase, to treat the exhausted fuel solution from nuclear reactor via sectional multi-stage countercurrent extraction and washing. Sr and Cs in the solution is first extracted to the organic O1 phase; Np, Pu, Am, Cm and other transuranic elements are then extracted to organic O2 phase; U is extracted to organic O3 phase; these three kinds of organic phase are backextracted to obtain three kinds of water solution of Sr+Cs, transuranic elements and U separately; and these three kinds of water solution are further treated. The said process can treating exhausted fuel and high-radioactive waste liquid integrally.

Owner:TSINGHUA UNIV

Fuel spacer for a nuclear fuel bundle

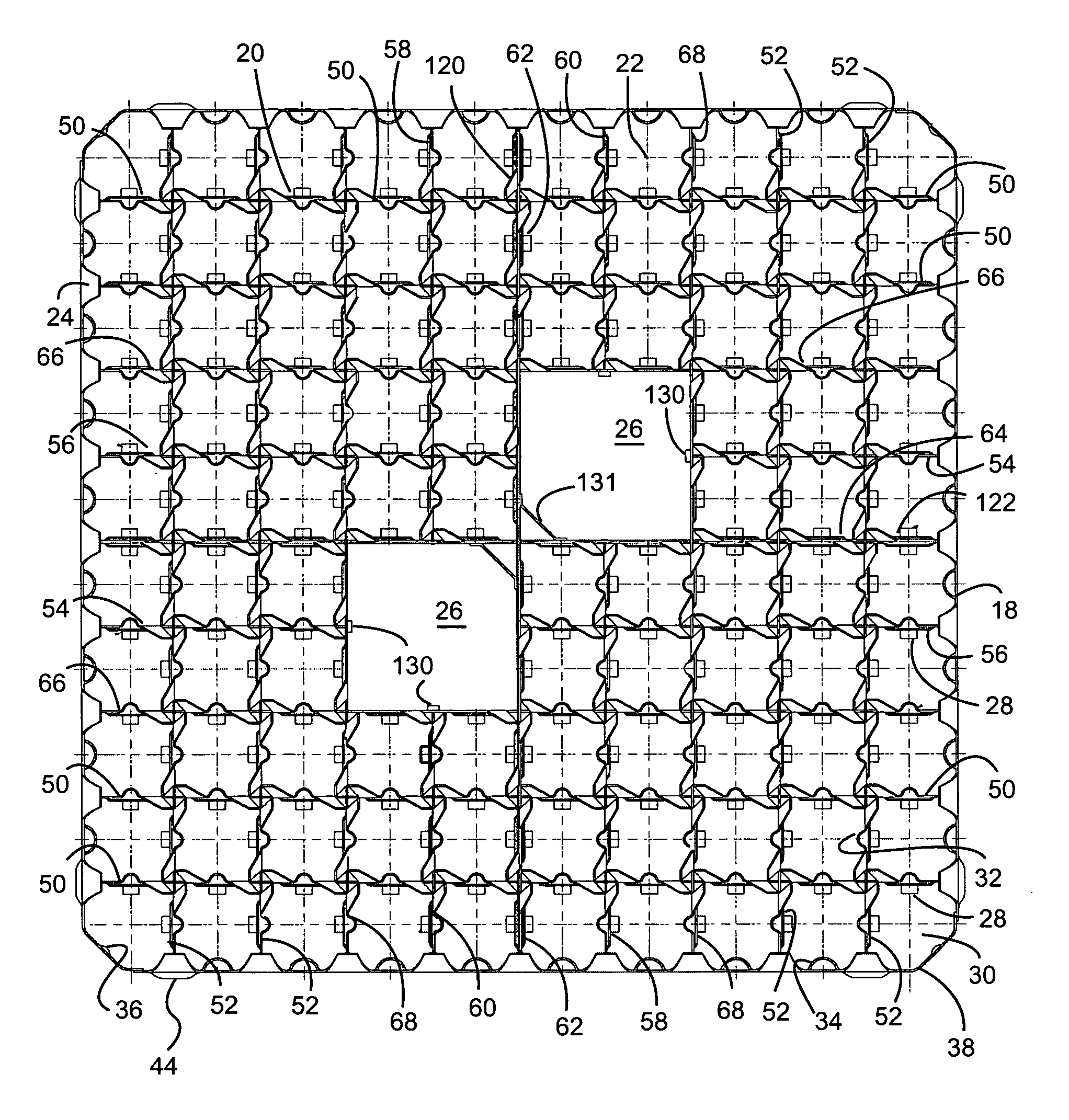

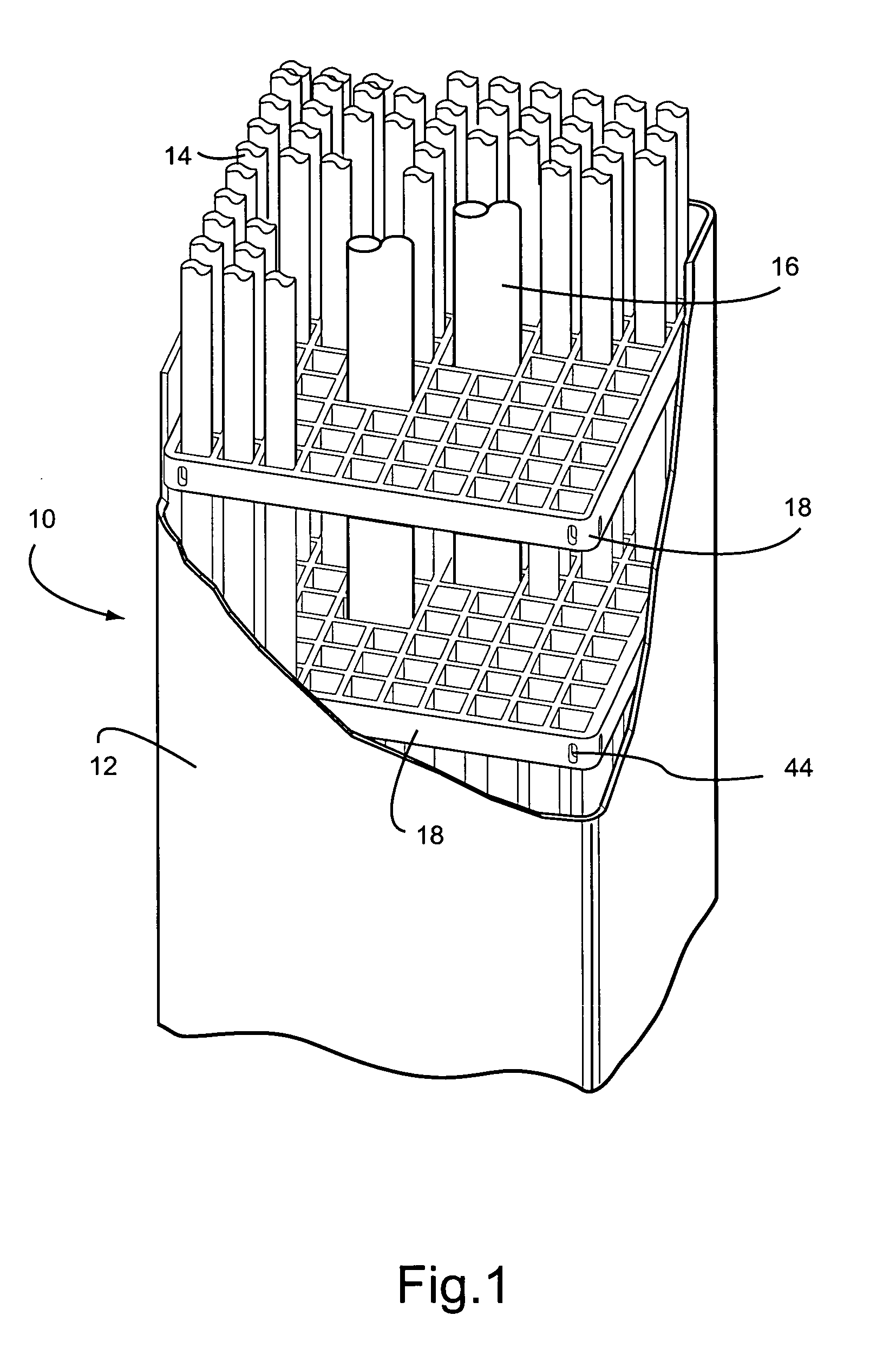

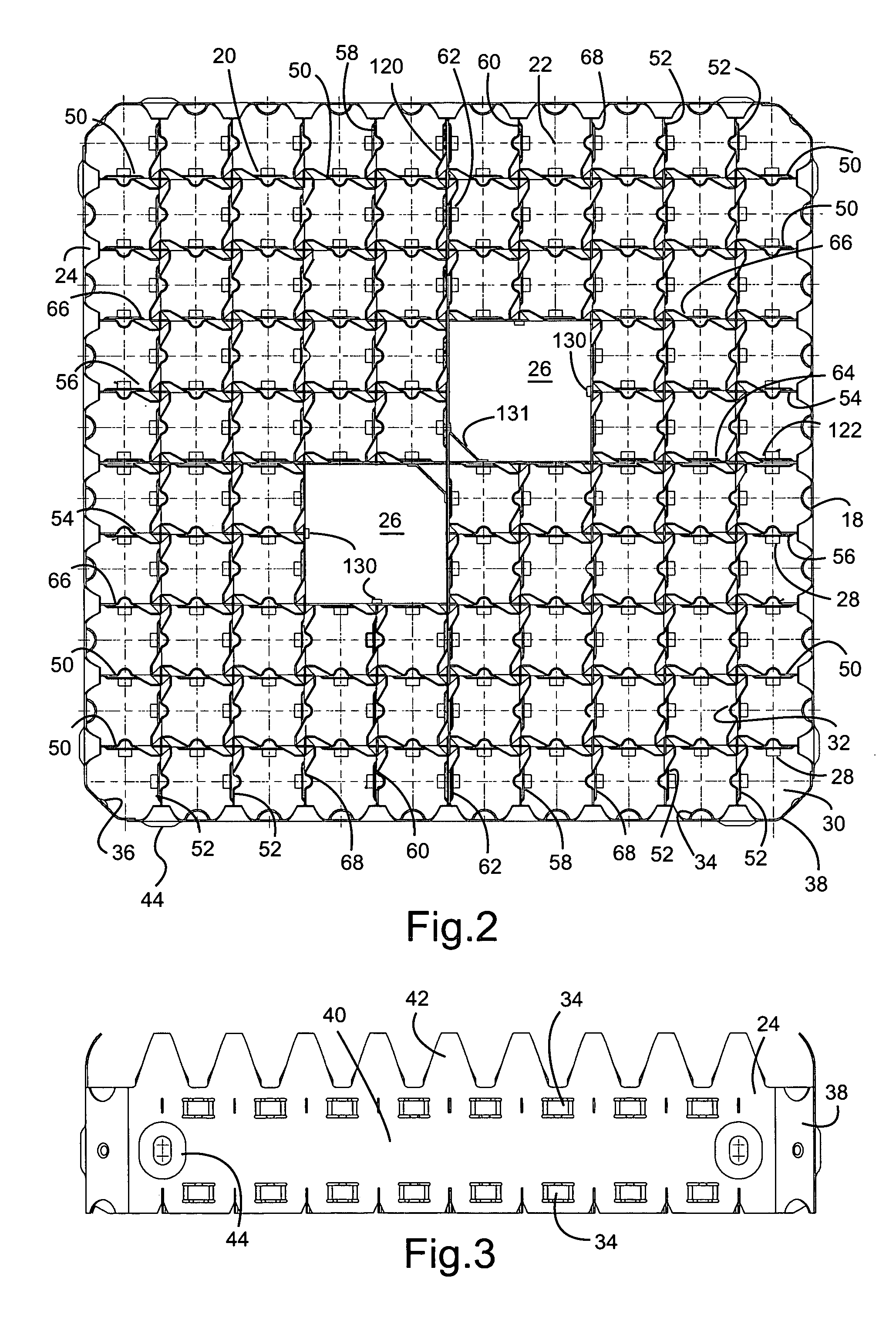

InactiveUS20070030943A1Minimize parts countEasy to assembleNuclear energy generationFuel element assembliesFuel cellsDiagonal

A spacer for a nuclear fuel assembly includes dividers orthogonally interdigitated relative to one another defining fuel and water rod cells. The dividers defining fuel rod cells have openings carrying an integrally formed spring which projects into the fuel cell to bear the fuel rod in the cell against an opposite stop carried by an opposing divider. The dividers are arranged in a 10x10 array with diagonally opposing quadrants being mirror images of one another. The dividers are surrounded by a peripheral band with integrally formed stops projecting into the peripheral cells enclosing the spacer.

Owner:GLOBAL NUCLEAR FUEL -- AMERICAS +1

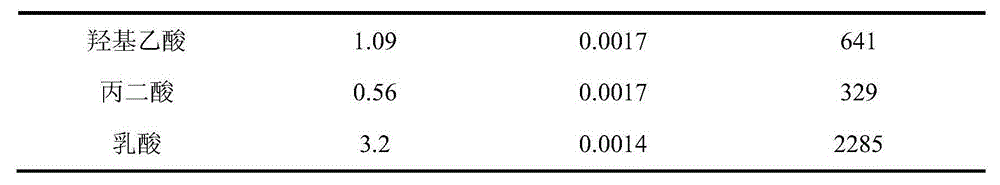

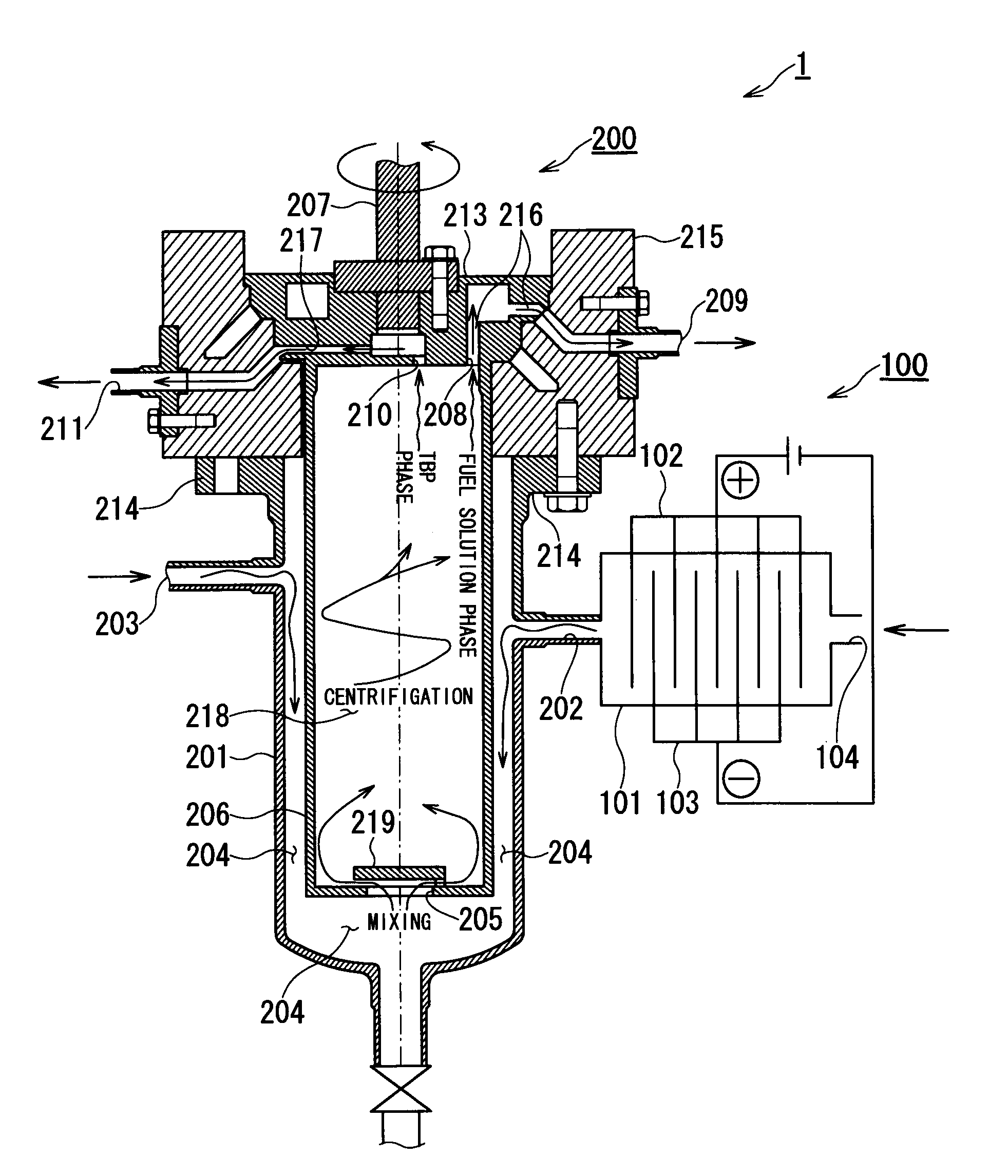

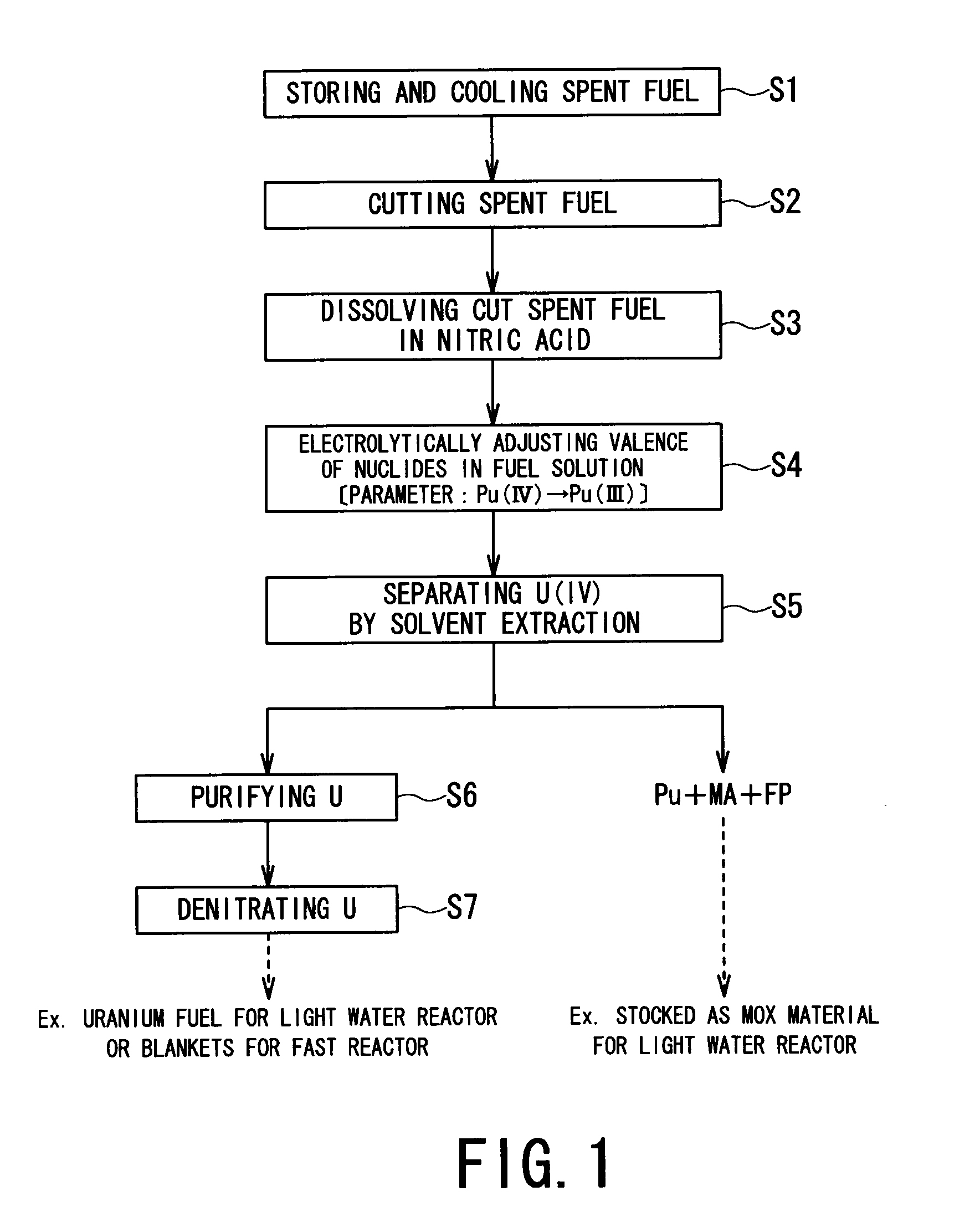

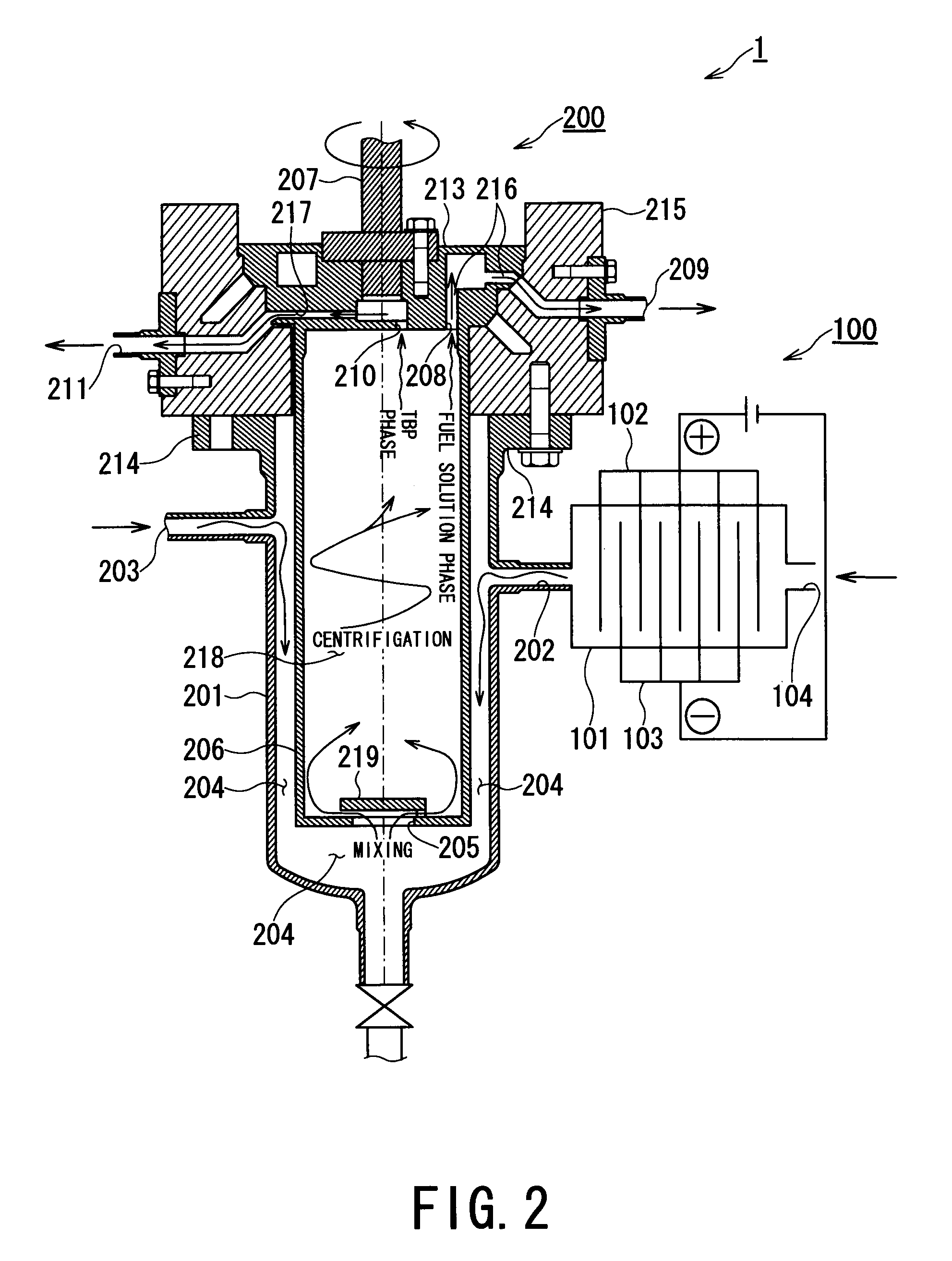

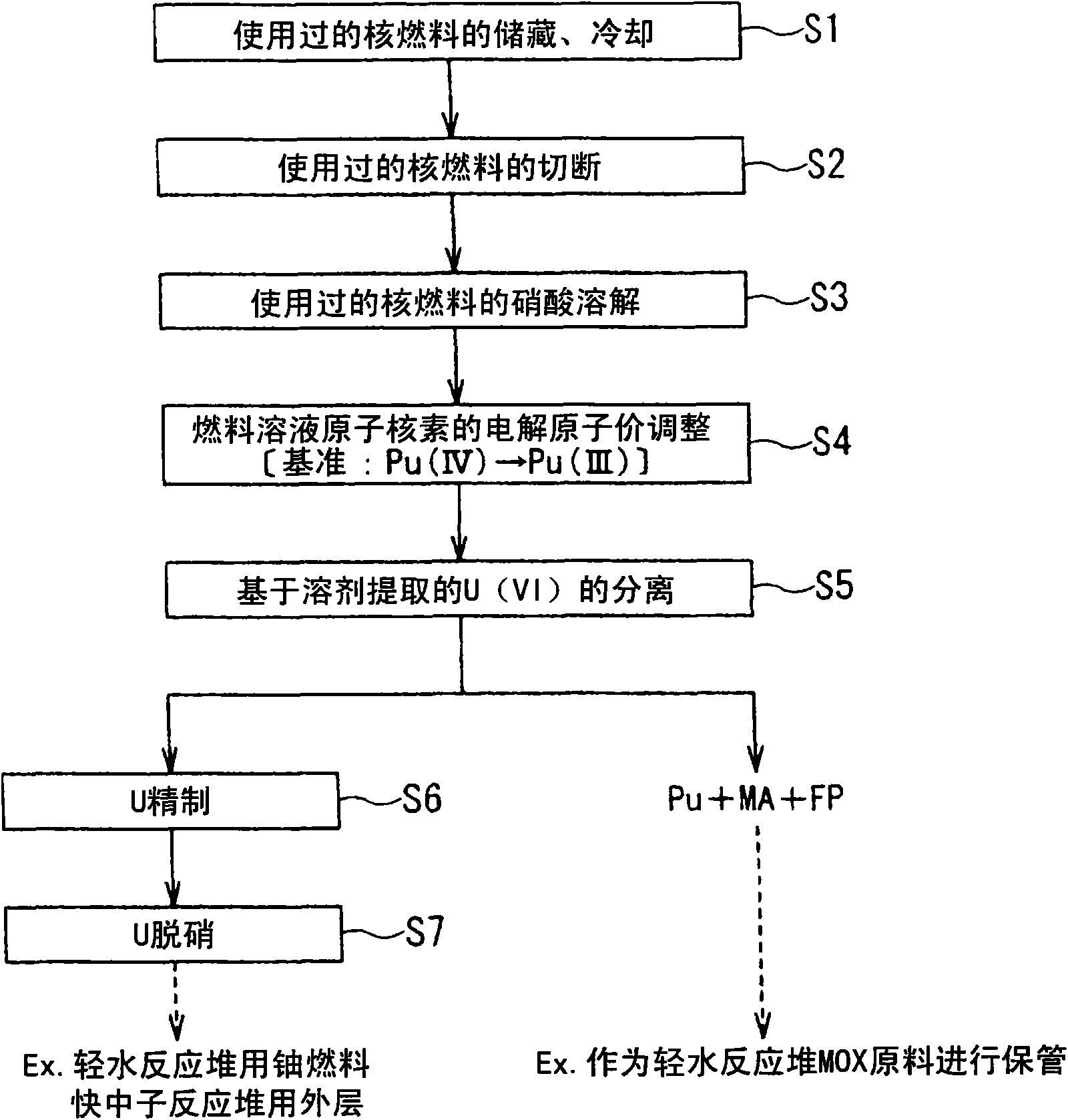

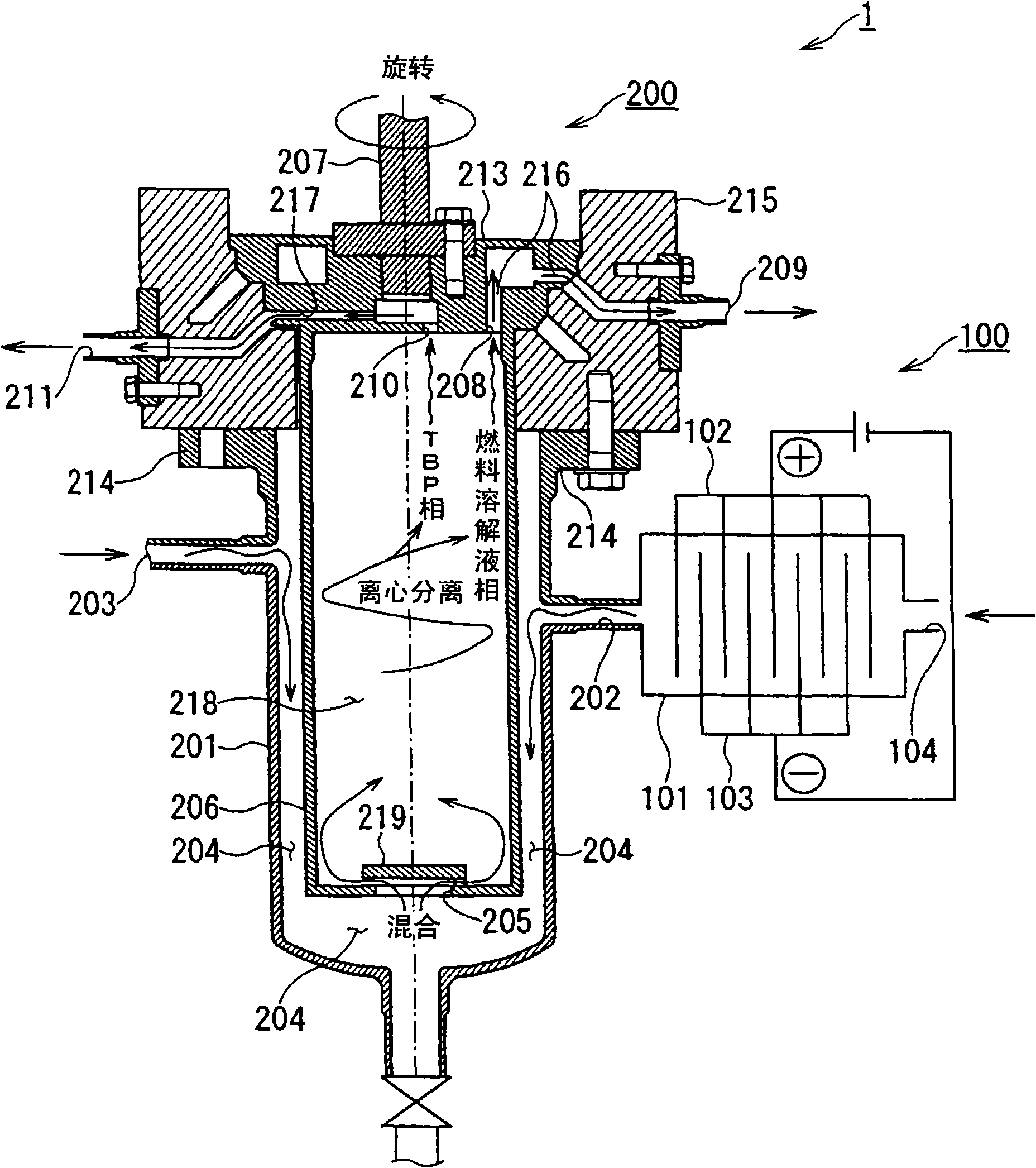

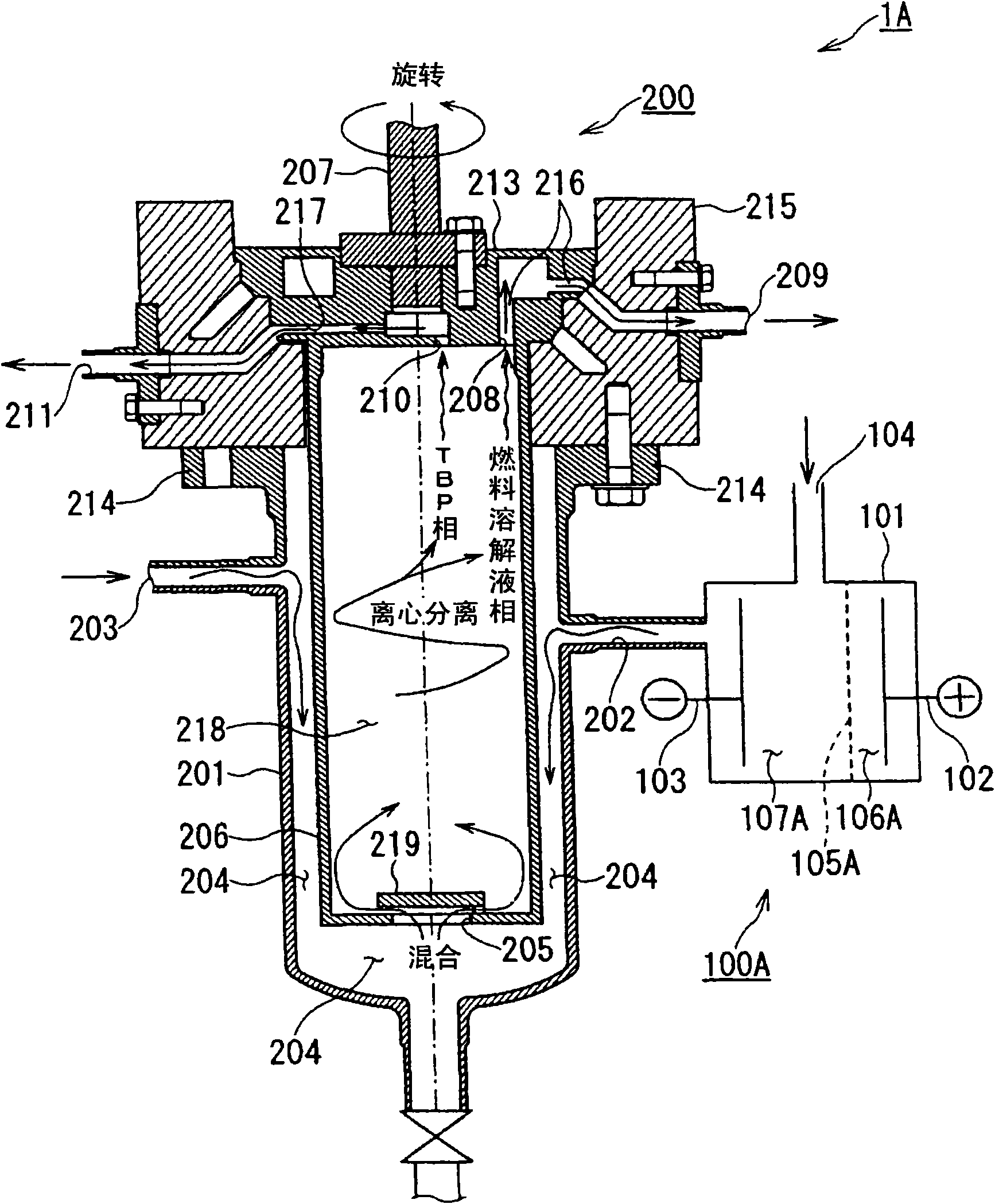

Method for reprocessing spent nuclear fuel and centrifugal extractor therefor

ActiveUS20100038249A1Isolation difficultRecovery difficultPhotography auxillary processesElectrolysis componentsElectrolysisEngineering

A spent nuclear fuel is reprocessed by dissolving a spent nuclear fuel in an aqueous nitric acid solution and separating and recovering nuclides contained in the resulting fuel solution by solvent extraction. A spent nuclear fuel reprocessing method includes: an electrolytic valence adjustment step in which nuclides contained in the fuel solution is electrolytically reduced without removing fission products or minor actinides until valence of plutonium is at a level at which solvent extraction efficiency is low by using the valence of plutonium contained in the fuel solution as a parameter; and a nuclide separation step in which, by using an extraction solvent which extracts uranium contained in the fuel solution, uranium is distributed from the fuel solution subjected to the electrolytic valence adjustment step to the extraction solvent.

Owner:KK TOSHIBA

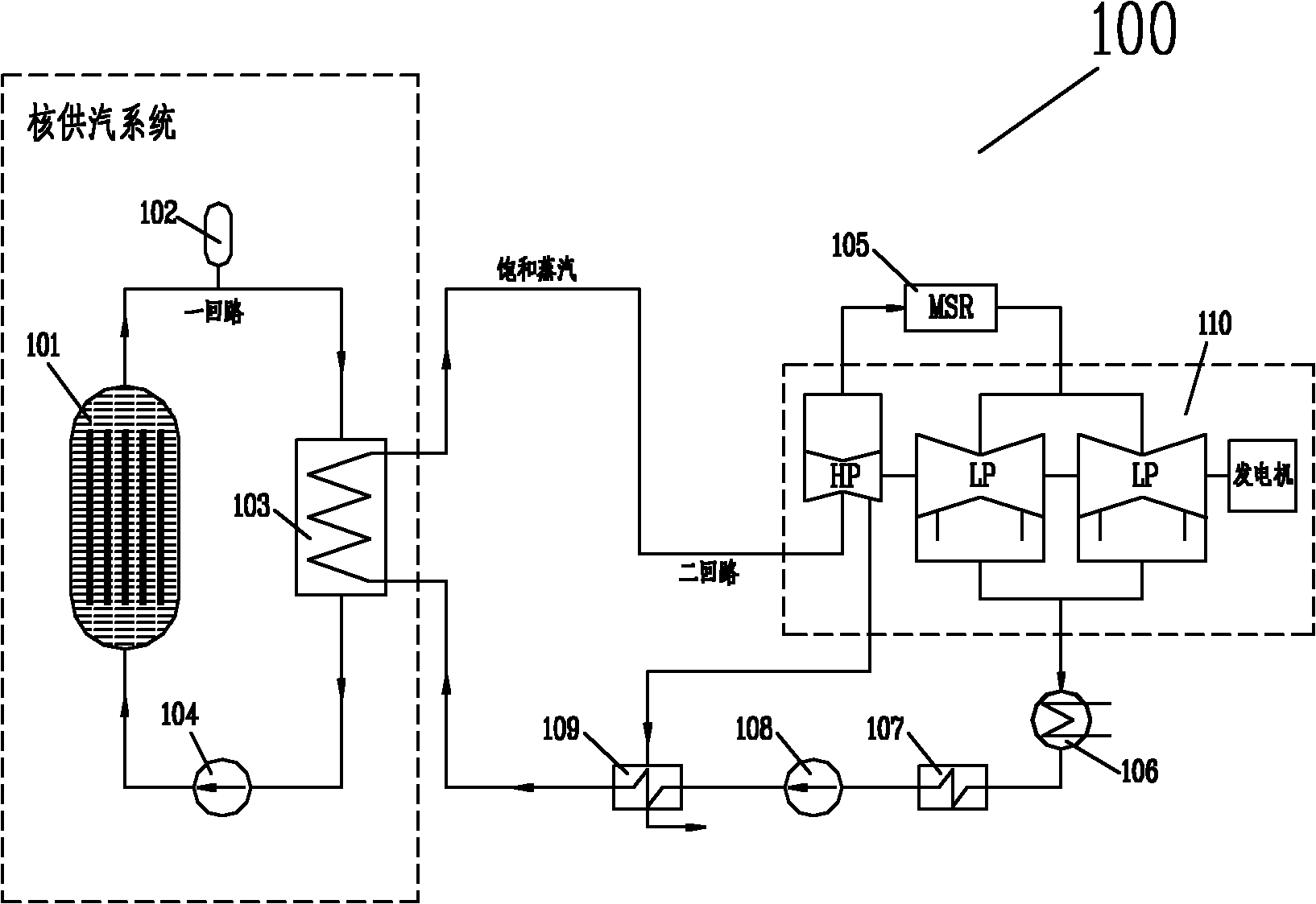

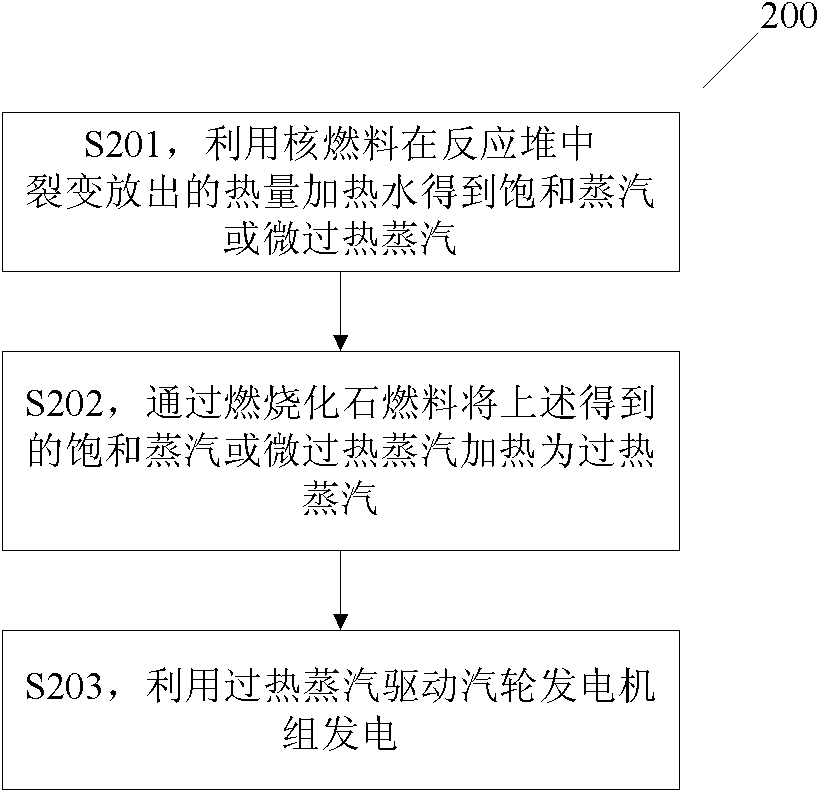

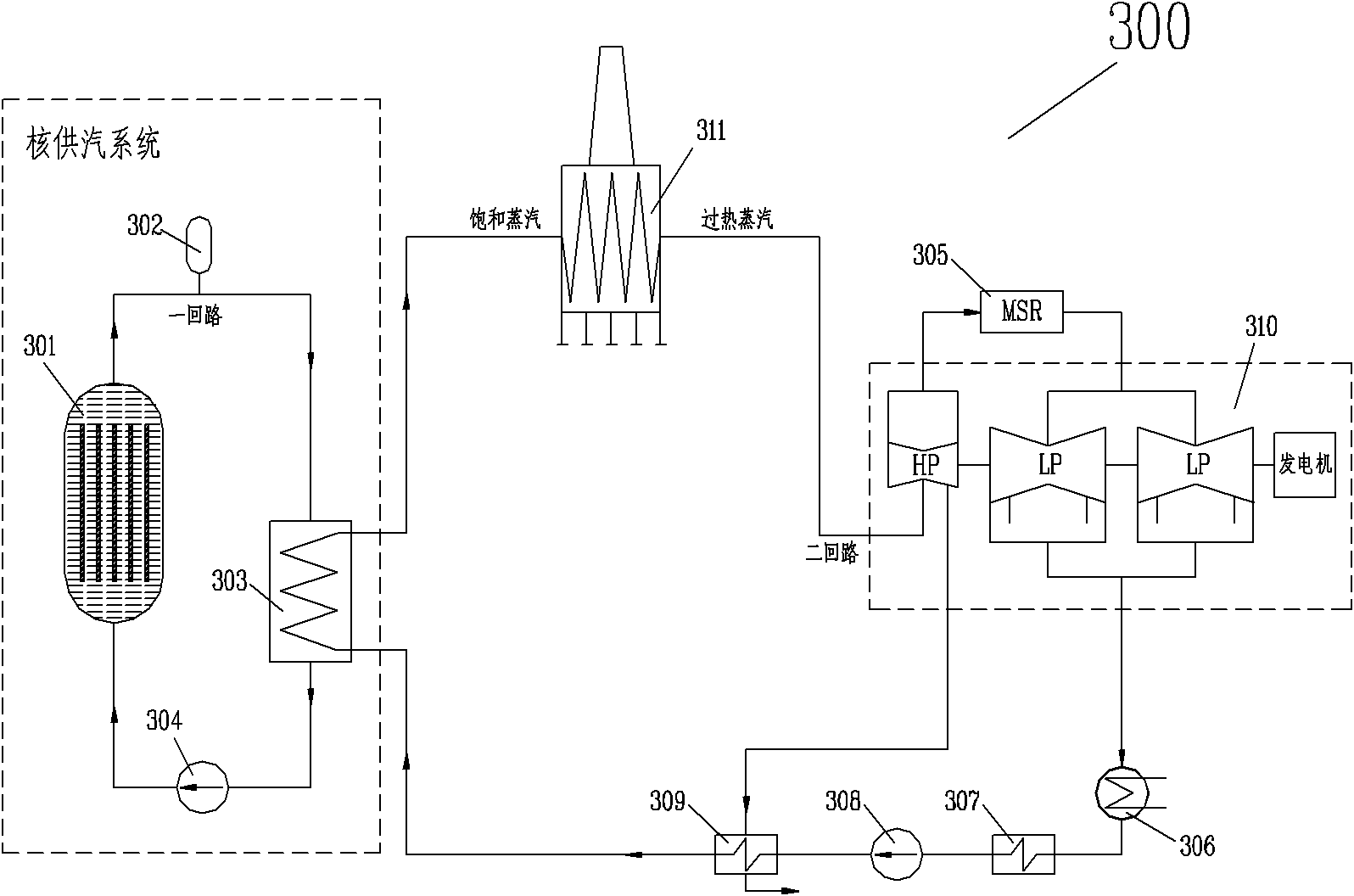

Method and system for generating power jointly by nuclear fuel and fossil fuel

InactiveCN102174904AReduce volumeImprove thermal efficiencyNuclear energy generationSteam superheatersHigh energySuperheater

The invention relates to a method and a system for generating power jointly by nuclear fuel and fossil fuel.The method comprises the following steps: using heat released by the fission of nuclear fuel in a reactor to heat water to obtain saturated vapour or slightly superheated steam; heating the saturated vapour or slightly superheated steam into superheated steam by burning fossil fuel; using the superheated steam to drive a steam turbine generator unit to generate power. The system comprises a nuclear steam supply system which uses the heat released by the fission of the nuclear fuel in the reactor to heat water to obtain the saturated vapour or slightly superheated steam, at least one steam superheater, a steam superheating device which is used for heating the saturated vapour or slightly superheated steam into superheated steam by burning the fossil fuel, and a steam turbine generator unit which generate power by using the superheated steam. In the invention, the steam superheater for burning the fossil fuel is integrated in a nuclear fuel power generation system, so that the system has the advantages of high energy utilization ratio, low power generation cost and the like.

Owner:上海宁松热能环境工程有限公司

Method for cycle using multi-stack combined nuclear fuel

ActiveCN101206930AIncrease profitLow costNuclear energy generationNuclear power plant controlFuel reprocessingPressurized water reactor

The invention relates to a nuclear power technology, in particular to a multi-reactor combined nuclear fuel cycle utilization method which is applied to the management design of first core fuel for a nuclear plant. A plurality of reactors with fuel elements which can be interchanged are combined to operate the cycle utilization of nuclear fuel, parts of fuel elements are used in a plurality of reactors in sequence. The invention has the advantages that the utilization ratio of the fuel for the newly-built the nuclear power station at the earlier stage can be improved to the level during the equilibrium cycle at the later stage, and the fuel purchasing cost and the post treatment cost of the fuel are saved; the long cycle refueling of a refueling shutdown reactor type can be realized in the first core. The method also can be used for the optimization of the management design of the reactor core fuel among operating reactors, thereby improving the fuel utilization ratio. The method of the invention is suitable for both the refueling shutdown reactor type and a continuous refueling reactor type and suitable for a pressurized water reactor, a boiling water reactor, a heavy water reactor and a high temperature gas cooled reactor.

Owner:CHINA NUCLEAR POWER DESIGN COMPANY

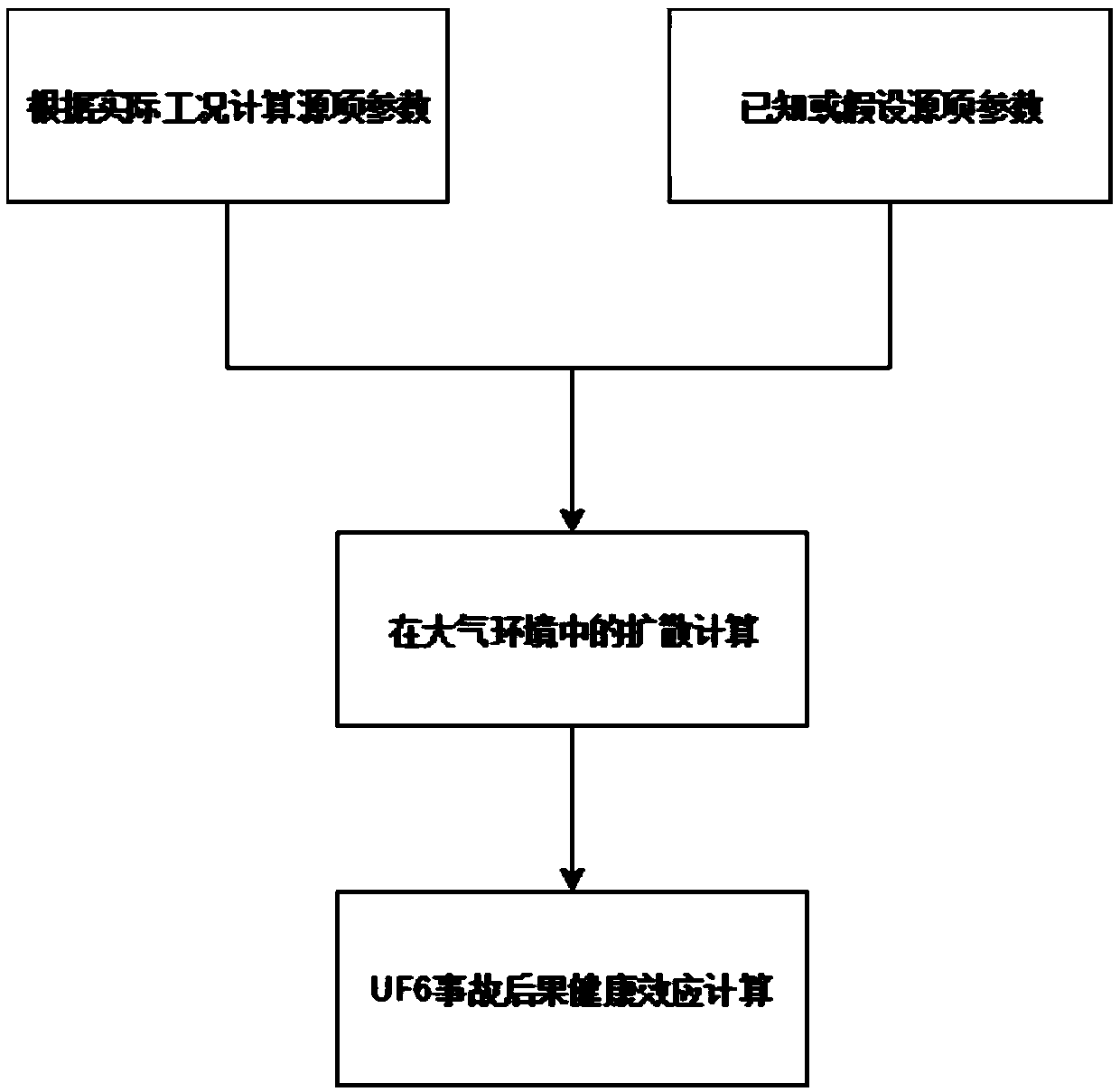

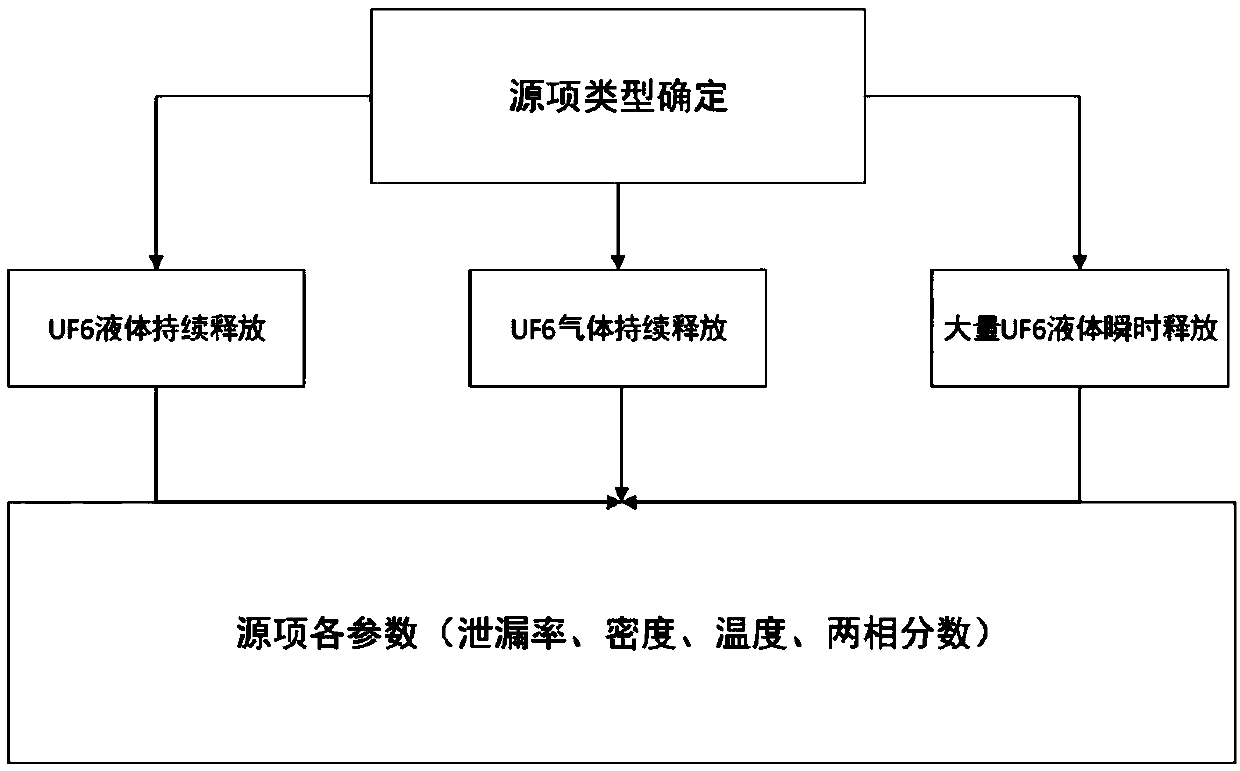

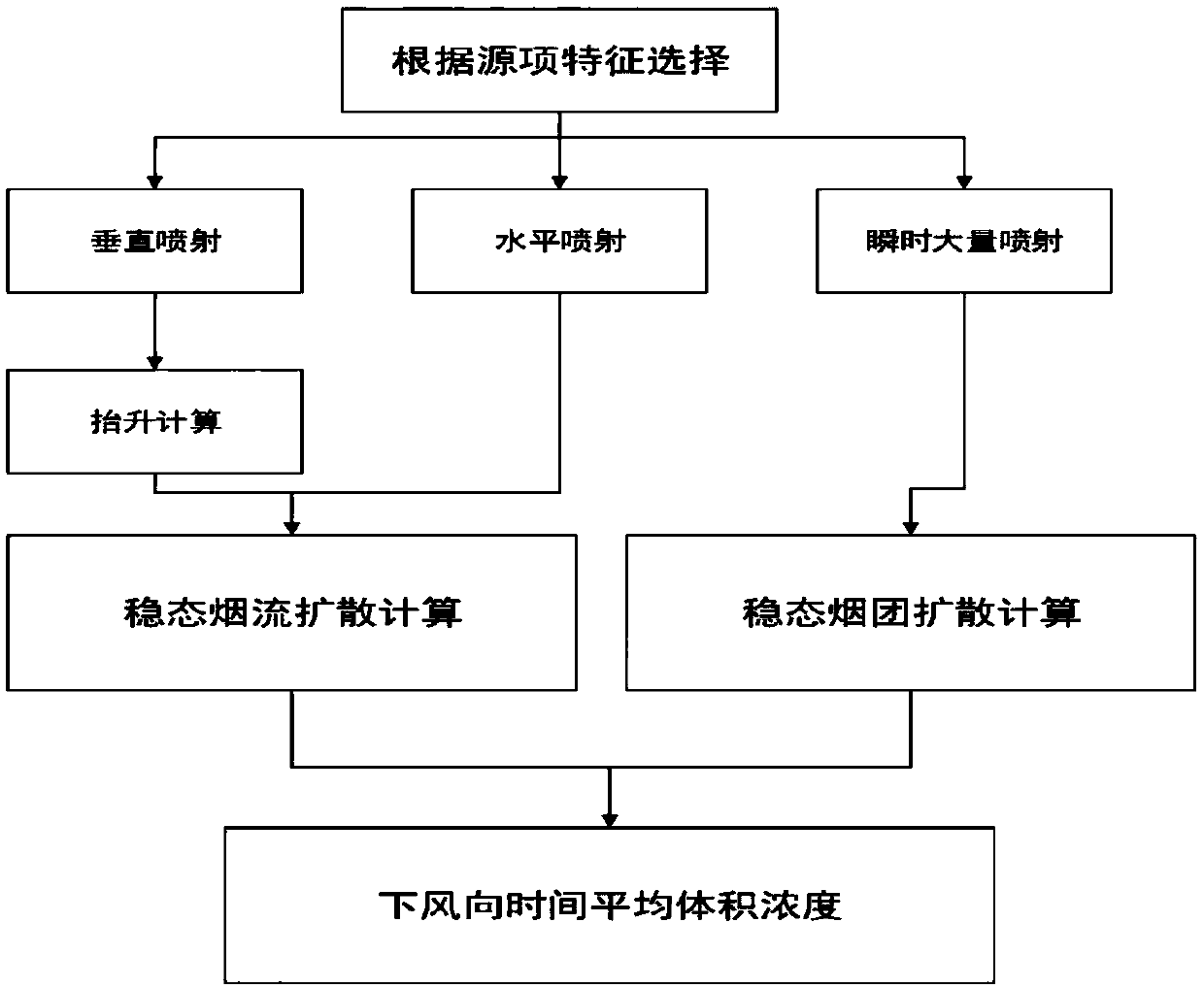

Nuclear fuel circulation facility UF6 accident leakage consequence evaluation and calculation method

ActiveCN110390444AEstimate calculation is simple and fastCalculation results are sure and reliableResourcesDiffusionSimulation

The invention belongs to the technical field of nuclear safety evaluation, and relates to a nuclear fuel circulation facility UF6 accident leakage consequence evaluation and calculation method. The evaluation calculation method sequentially comprises the following steps: (1) determining source item parameters: calculating the source item parameters according to actual working conditions, or knowing or assuming the source item parameters; (2) carrying out diffusion calculation in the atmospheric environment under different accident scenes according to the source item parameters determined in the step (1); and (3) calculating the UF6 accident consequence health effect. By utilizing the evaluation calculation method, the accident leakage consequence evaluation calculation exclusive to UF6 canbe simply and quickly carried out, and the calculation result is more definite and reliable.

Owner:CHINA INST FOR RADIATION PROTECTION

Flat plate type nuclear fuel component

InactiveCN102063944AReasonable distributionThe core body contains high uranium densityOptical rangefindersFuel elementsHeat flowHigh density

The invention belongs to the technical field of nuclear fuel and particularly relates to a flat plate type nuclear fuel component. The nuclear fuel component comprises side plates, a nuclear fuel plate and a rectangular plug, wherein the nuclear fuel plate is prepared by the related method of the invention; the nuclear fuel plate is fixed on the side plates arranged on the two sides, the lower end of the nuclear fuel plate is provided with a positioning comb; the rectangular plug is inserted in a rectangular structure on the lower end of the nuclear fuel component and fixedly connected with the positioning comb which is arranged on the lower end; the nuclear fuel plate contains a jacket and nuclear fuel chips which are covered in the jacket; the thickness of the edge of each nuclear fuel chip is no more than the thickness of the middle; and the jacket is made of aluminum 6061. In the nuclear fuel plate provided by the invention, the nuclear fuel chips are distributed evenly, thus the safety risk can be reduced. The flat plate type nuclear fuel component formed by the nuclear fuel plate also has the advantages of high uranium density of the chips, high density of heat flow and high flow rate of coolant.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

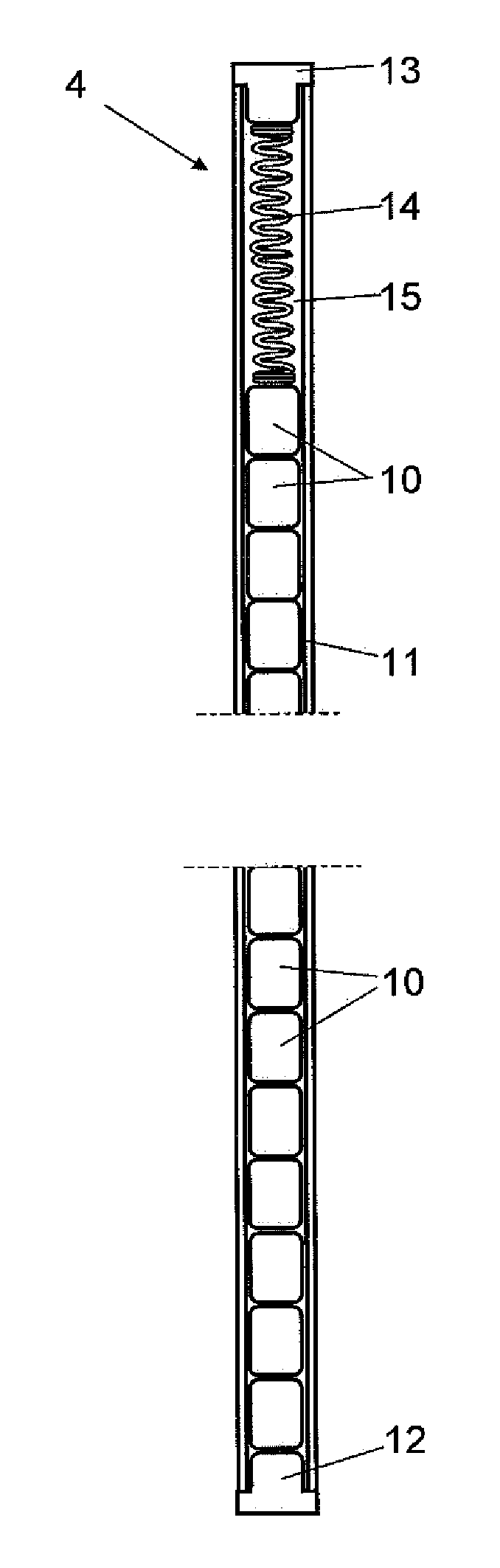

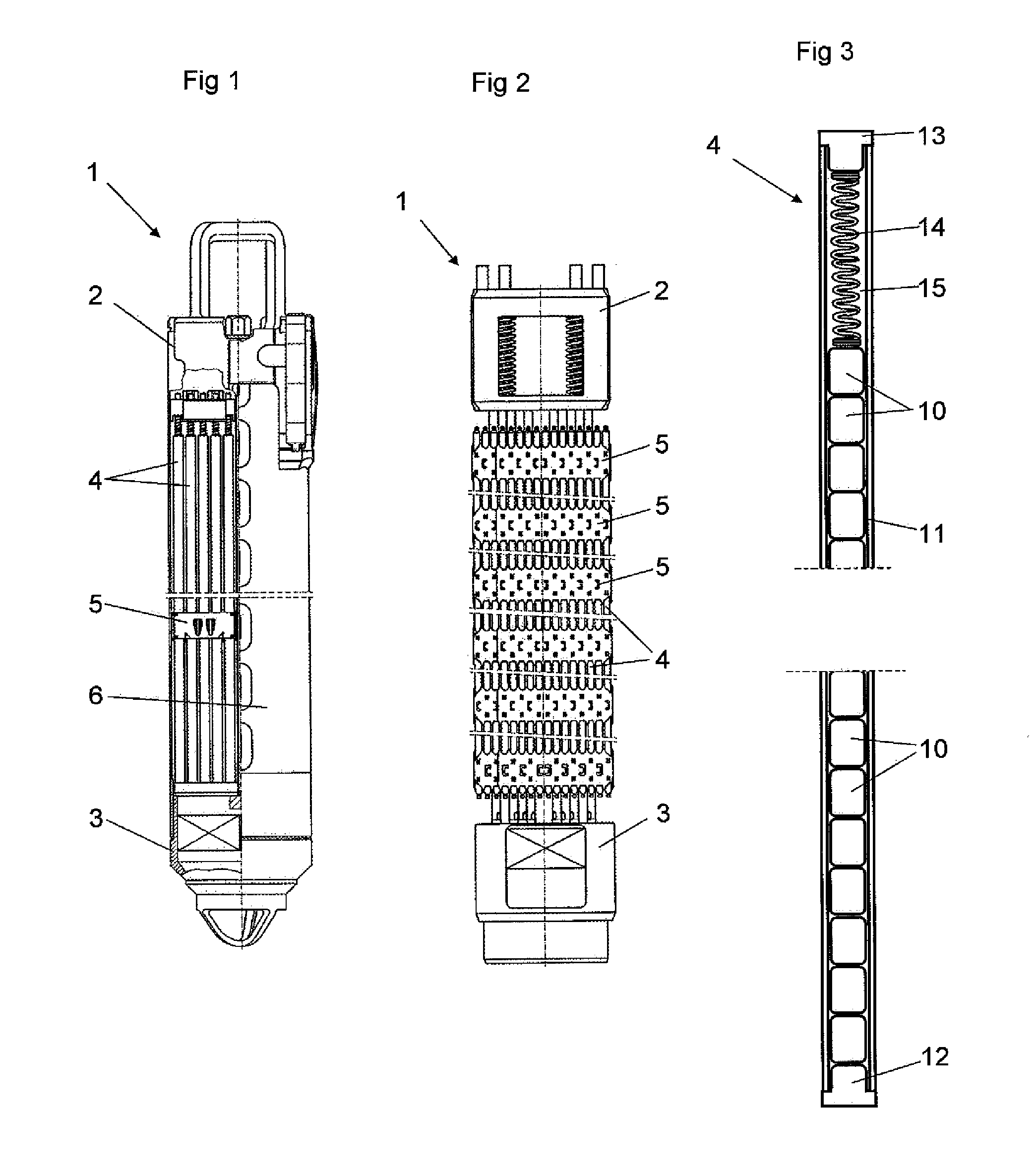

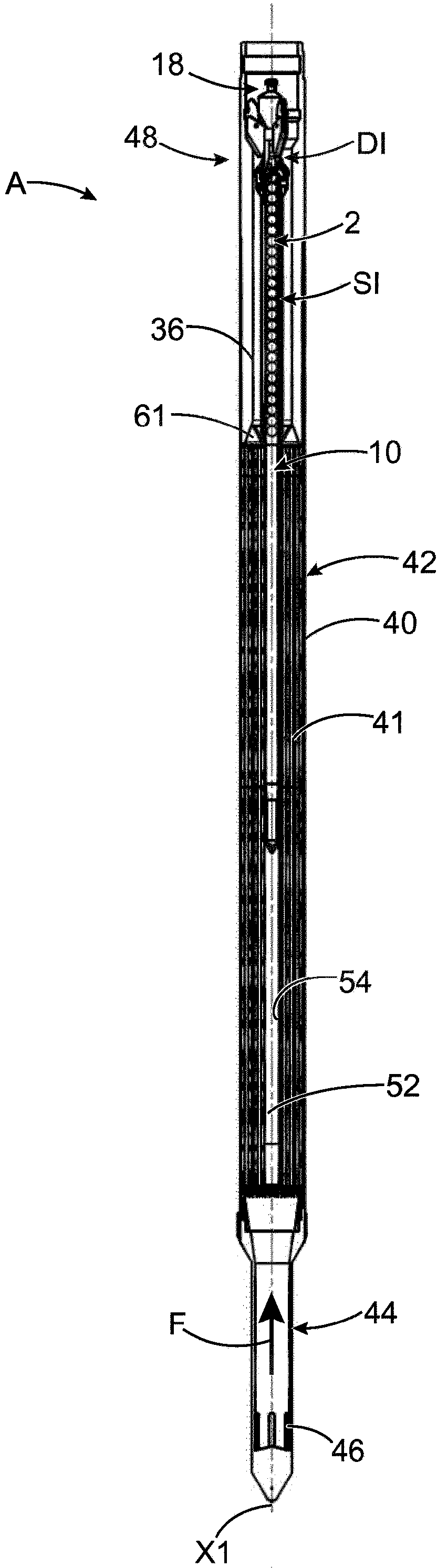

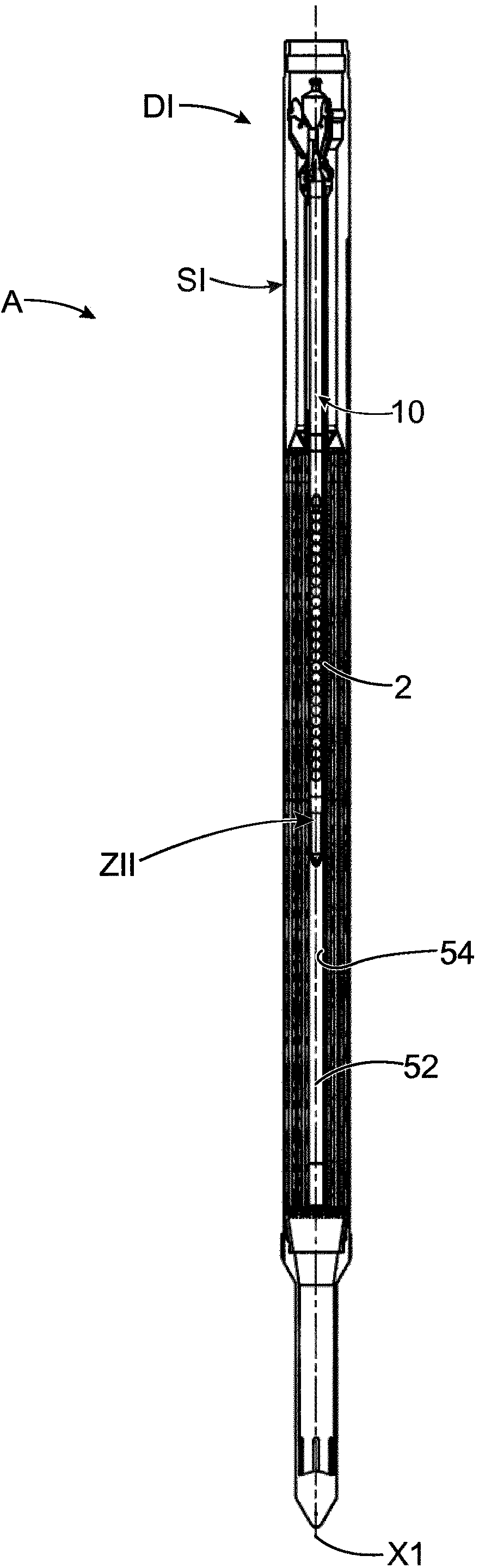

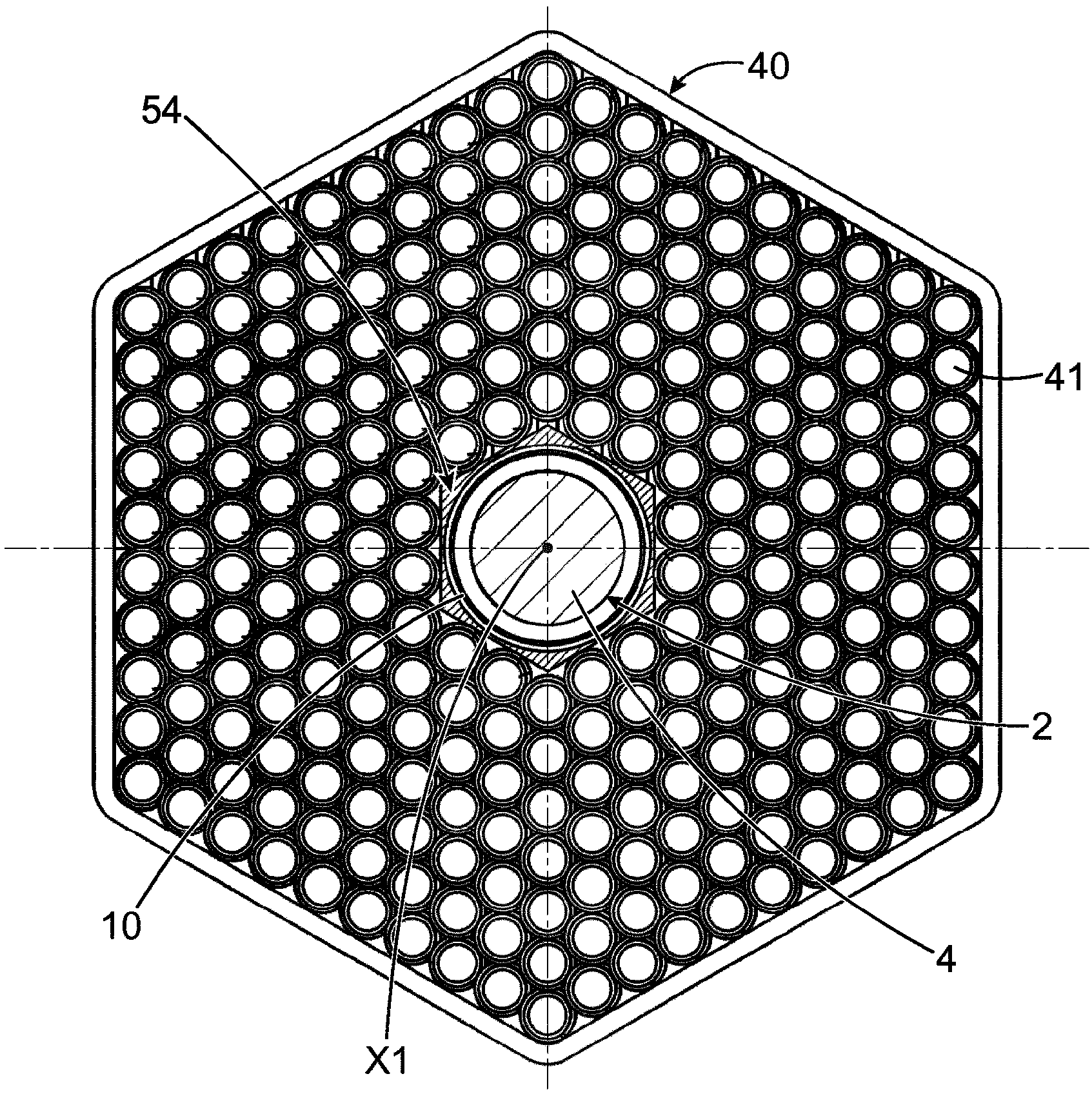

Assembly for anuclear reactor, comprising nuclear fuel and system for triggering and inserting at least one neutron absorber and/or mitigator element

A carrier assembly for a nuclear reactor is disclosed. The carrier assembly comprises: a housing (40); a fissile area located in the bottom portion of the housing (40); a free volume located in the top portion of the housing (40); a free space (52) in the fissile area, extending along the longitudinal axis over the height of the fissile area from the end thereof located in the top portion; a sheath (54) bordering the free space (52); and a triggering and insertion system (SI). The triggering and insertion system comprises a capsule (10) having a longitudinal axis, an absorber and / or mitigator member (2) suspended in the capsule, and a triggering and insertion device (DI) designed to release the absorber member in the event of an accidental situation occurring in relation to the assembly. The capsule (10) is inserted into the sheath (54), while the triggering and insertion system is removably mounted in the carrier assembly.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +2

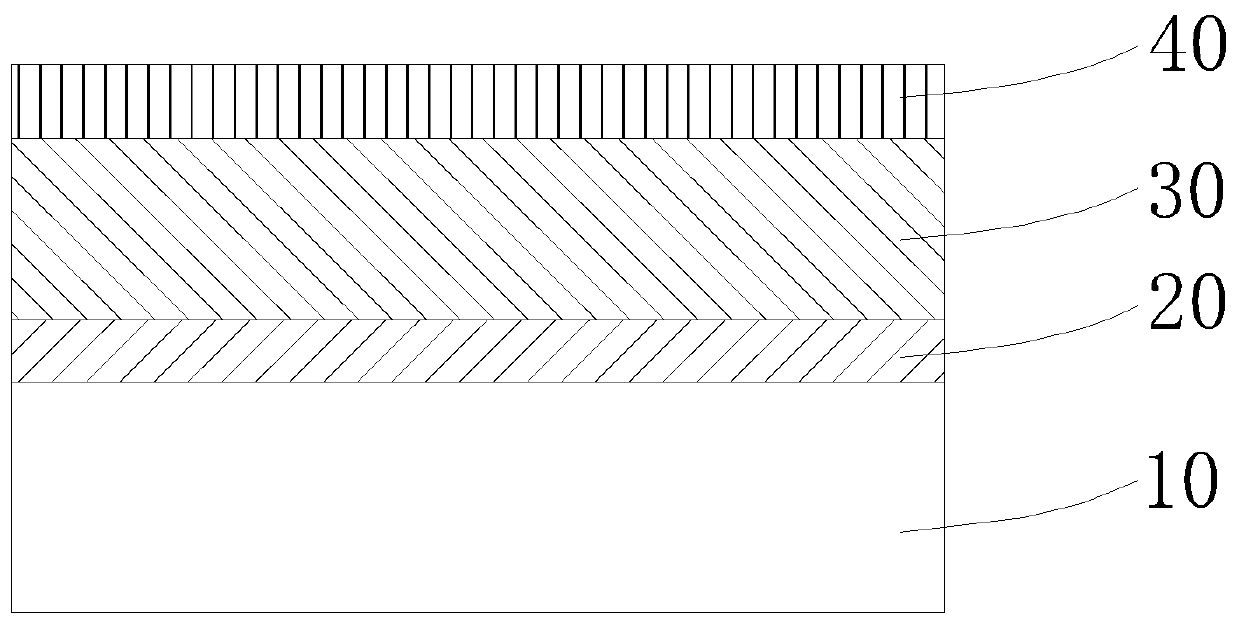

Nuclear fuel cladding and preparation method thereof and nuclear fuel assembly

ActiveCN109868475AGood resistance to water vapor oxidationImprove fault tolerance performanceOptical rangefindersNuclear energy generationWater vaporOxidation resistant

The invention relates to a nuclear fuel cladding and a preparation method thereof and a nuclear fuel assembly. The nuclear fuel cladding includes a zirconium alloy substrate and a coating arranged onthe surface of the zirconium alloy substrate, and the coating includes a transition layer for laminating to the surface of the zirconium alloy substrate, and an MAX phase layer and a sealing layer which are successively arranged on the surface of the transition layer in a stacked mode, wherein the sealing layer is a hard coating. The nuclear fuel cladding has the good vapor oxidation resistant performance, and thus the accident fault freedom of the nuclear fuel cladding is effectively improved. When the nuclear fuel cladding is used for the nuclear fuel assembly, the safety can be effectivelyimproved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing initial molten salt system in molten salt electrolysis dry after-treatment process

ActiveCN104562089AReduce operating proceduresReduce volume and disposal costsProduction lineAfter treatment

The invention belongs to the technical field of nuclear fuel cycle dry after-treatment and discloses a method for preparing an initial molten salt system in a molten salt electrolysis dry after-treatment process. The method comprises the following steps: introducing chlorination gases into LiCl-KCl eutectic molten salt and spent fuel positioned in an electrolytic cell so as to introduce uranium ion into the molten salt, thereby obtaining the initial molten salt system needed by molten salt electrolysis dry after-treatment. The method has the advantages that the chlorination rate of the chlorination gases is high, the uranium ion can be introduced into the electrolytic cell in situ, and an extra uranium chloride production line does not need to be established.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for reprocessing spent nuclear fuel and centrifugal extractor therefor

InactiveCN101650980AEnhanced inhibitory effectLiquid separation by electricityNuclear energy generationEngineeringSolvent

The invention provides a method for reprocessing a spent nuclear fuel which can reprocess highly purified uranium without arranged with a step of separating Pu from solely from a spent nuclear fuel, and solely separated reprocessing of the reprocessed Pu is more difficult and has an excellent repression effect to nuclear proliferation. In a method for reprocessing a spent nuclear fuel by dissolving a spent nuclear fuel in an aqueous nitric acid solution and separating and recovering nuclides contained in the resulting fuel solution by solvent extraction comprising an electrolytic valence adjustment step by using the valence of plutonium contained in the fuel solution as a parameter until the valence of plutonium becomes 3 in which nuclides contained in the fuel solution is electrolyticallyreduced without removing fission products or minor actinides; a nuclide separation step in which, by using an extraction solvent which extracts uranium contained in the fuel solution, uranium is distributed from the fuel solution subjected to the electrolytic valence adjustment step to the extraction solvent.

Owner:KK TOSHIBA

Preparation method for uranium molybdenum alloy powder

ActiveCN102240812AEliminate the effects of preparationShorten the production cycleNuclear energy generationReactor fuel susbtancesNuclear technologyDistilled water

The invention provides a preparation method for uranium molybdenum alloy powder, and the method is used for preparing the uranium molybdenum alloy powder meeting the demand on a certain particle size and belongs to the field of nuclear technique application. The preparation method provided by the invention mainly comprises the following steps of: cleaning and activating before activating the uranium molybdenum alloy. By cleaning the uranium molybdenum alloy with aqua regia, distilled water, absolute ether, absolute ethyl alcohol, and the like, an oxide layer on the surface of the uranium molybdenum alloy can be efficiently removed, thereby achieving the clean surface of the uranium molybdenum alloy before absorbing hydrogen. Parameters of an activating process are efficiently controlled, thereby accurately controlling the particle size of the uranium molybdenum alloy powder. The preparation method for the uranium molybdenum alloy powder provided by the invention has the characteristics of less working procedures, simple process, small investment, and the like, and is suitable for being applied to the field of nuclear fuel cycle.

Owner:SICHUAN INST OF MATERIALS & TECH

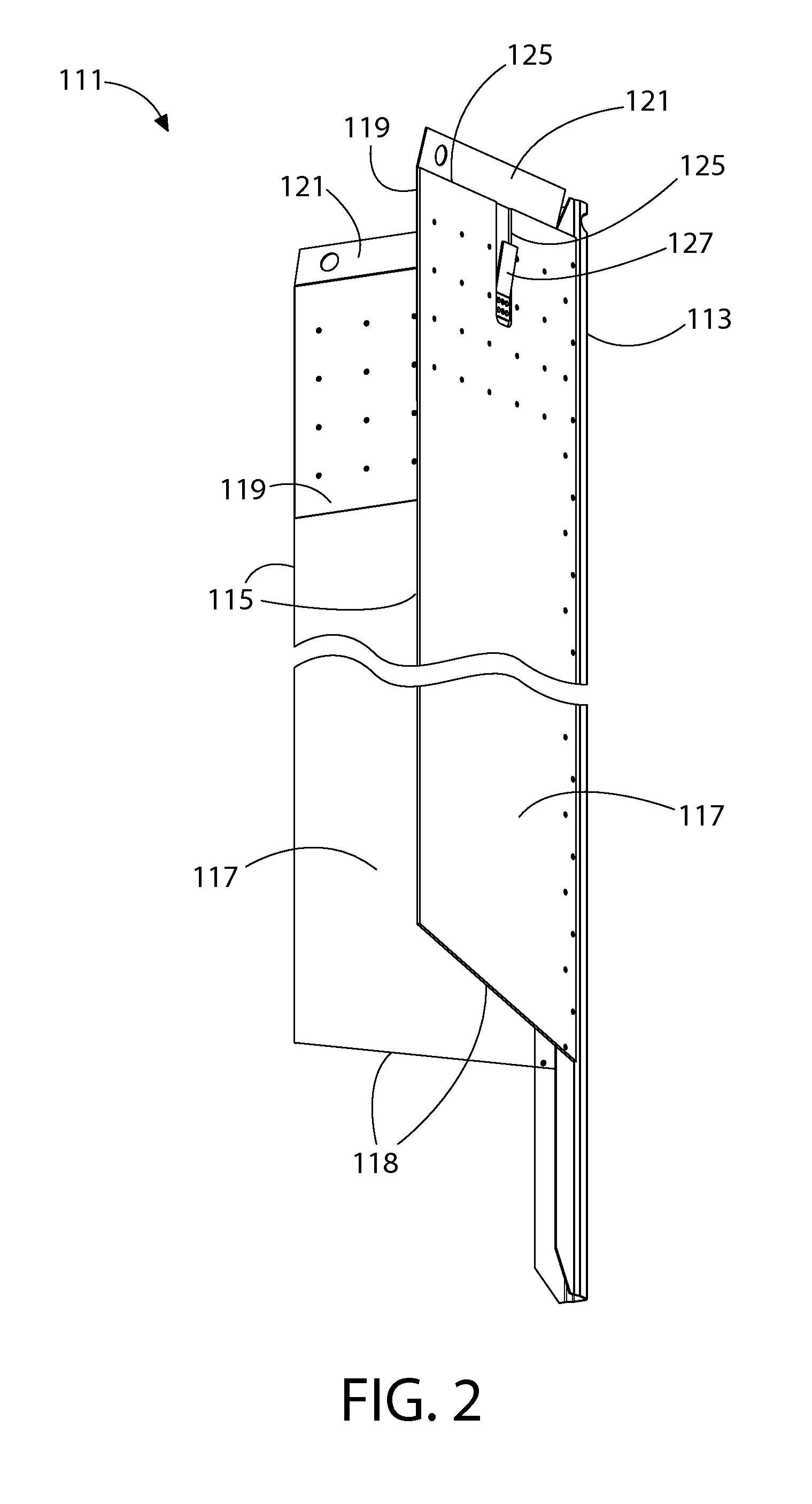

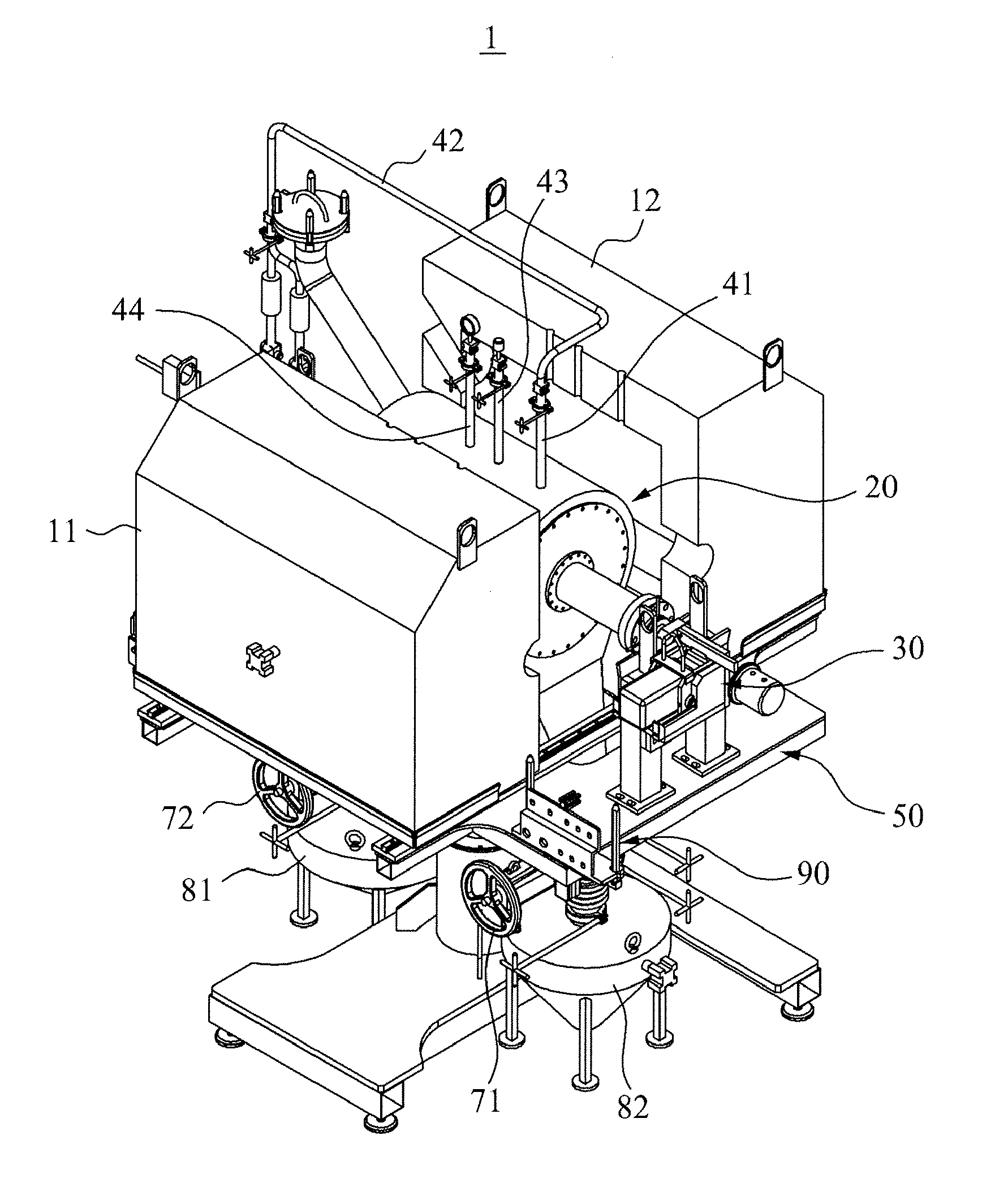

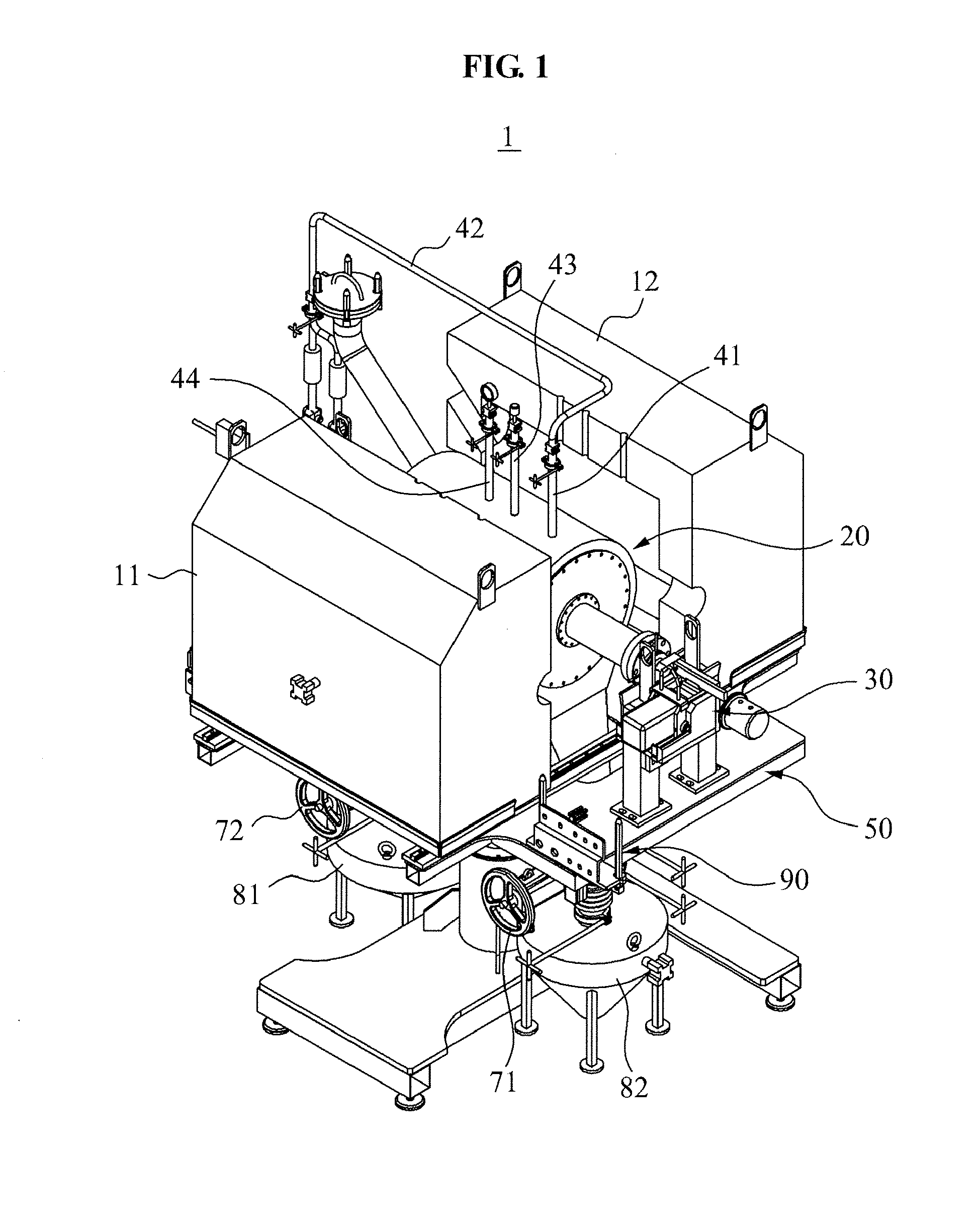

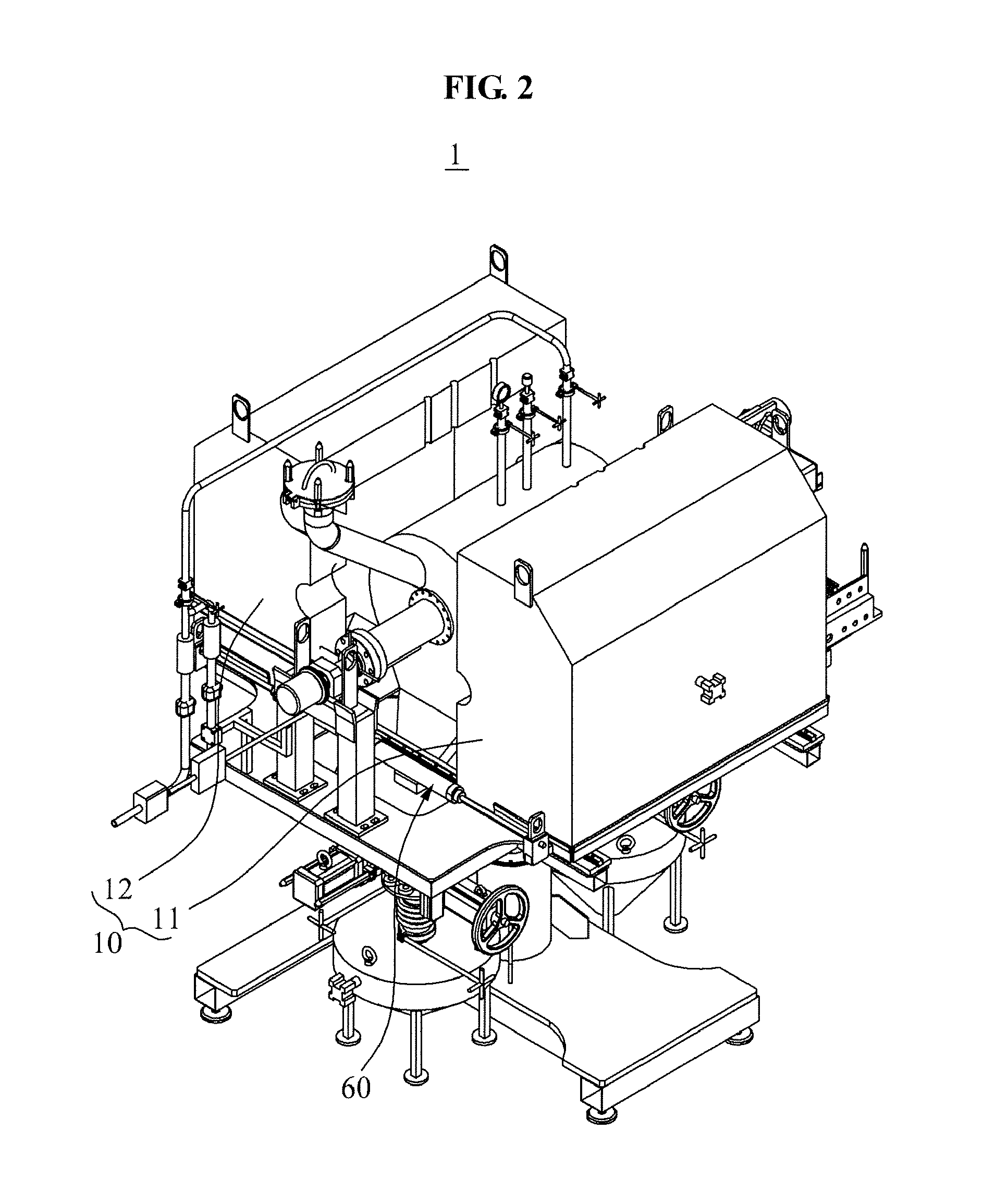

Prefabricated vol-oxidizer for spent nuclear fuel for convenient operation and maintenance

ActiveUS20120051978A1Easy maintenancePromote repairNuclear energy generationRecycling and recovery technologiesNuclear fuel cycleNuclear fuel

A vol-oxidizer for spent nuclear fuel is provided. The vol-oxidizer includes a reactor module in which the spent nuclear fuel is put and oxidized; a heating module to heat the reactor module to a high temperature; a utility module to control an inner state of the reactor module, being connected with the reactor module; a support module to support the heating module and the reactor module; a drive module to supply a driving force for transferring the spent nuclear fuel within the reactor module; a valve module to control discharge of the spent nuclear fuel being oxidized in the reactor module; and a collecting container module to collect the spent nuclear fuel being oxidized and discharged from the reactor module. The respective modules are assembled and disassembled with respect to one another.

Owner:KOREA ATOMIC ENERGY RES INST +1

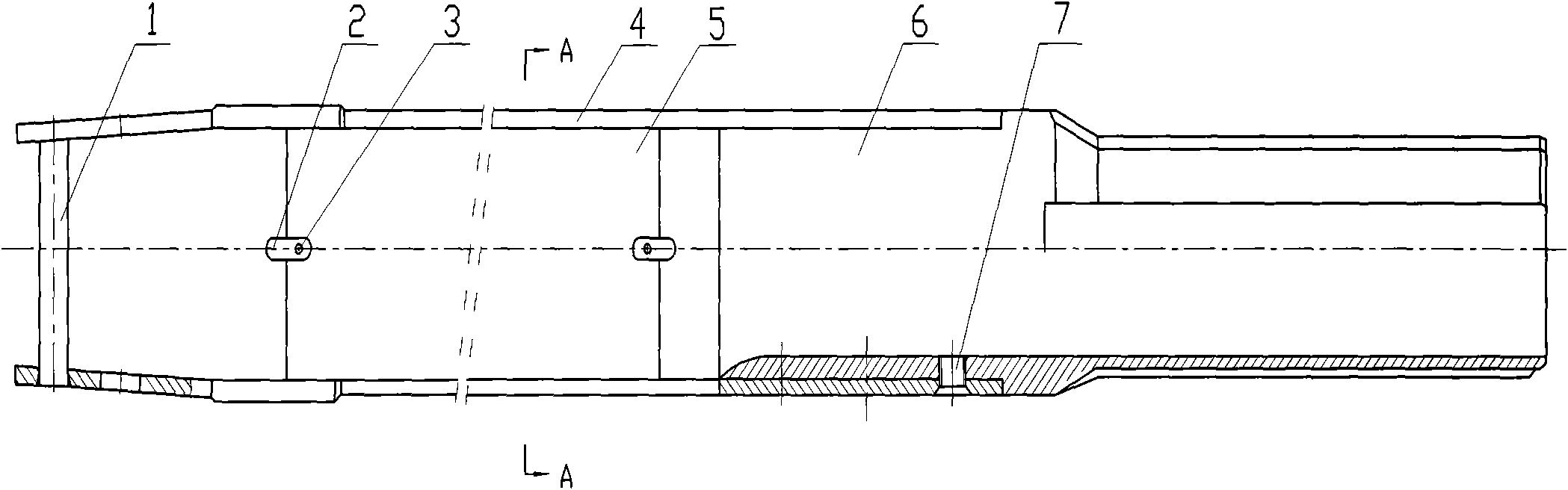

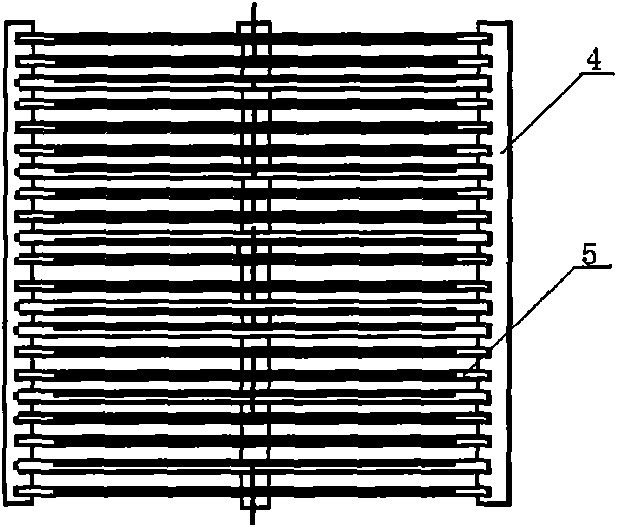

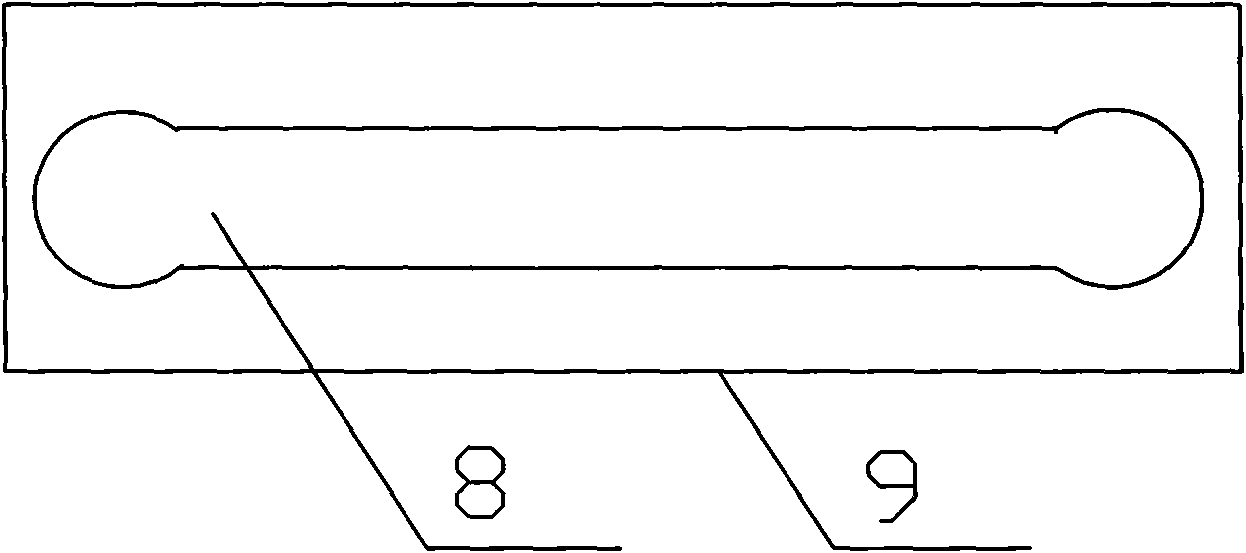

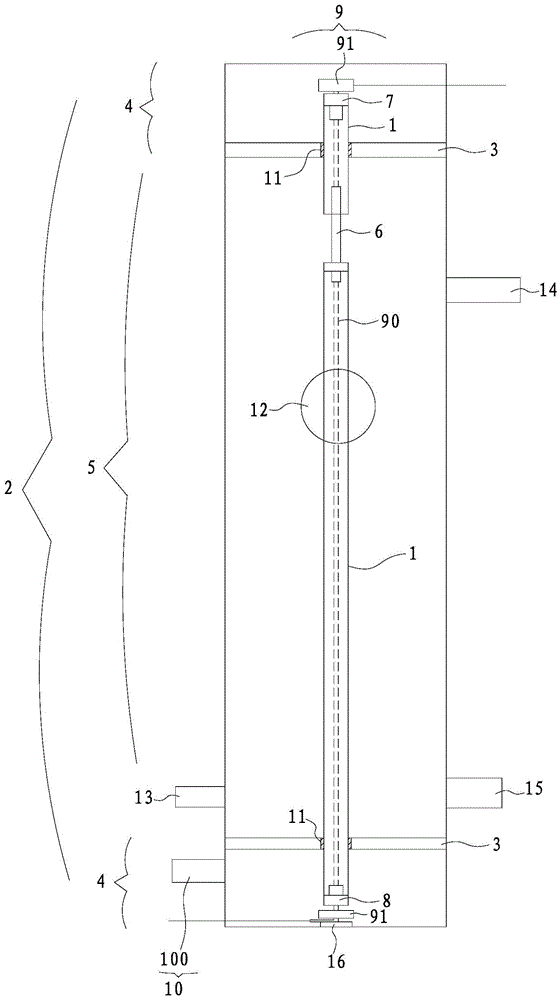

Experimental device for assessing performance of nuclear fuel cladding pipe under simulated LOCA working condition

ActiveCN105575446AEvaluate performanceSolve the problem of expansion and bendingNuclear energy generationNuclear monitoringFree expansionQuenching

The invention relates to an experimental device for assessing performance of a nuclear fuel cladding pipe under the simulated LOCA working condition. The experimental device comprises a mold cavity, an upper seal head, a lower seal head and a heating device; the mold cavity comprises vacuum cavities and a quenching cavity which are formed through dividing of sealing parts, the nuclear fuel cladding pipe at least comprises two sections, every two sections are connected with each other through a connecting part in a sealing mode, the two ends of each connecting part can be slidably arranged in the nuclear fuel cladding pipe, and an experimental pipe can freely telescope after being subjected to heating expansion; the heating device comprises a heating body, and the heating body is insulated from the inner wall of the nuclear fuel cladding pipe through the upper seal head, the lower seal head and the connecting parts. According to the experimental device, the fuel cladding pipe can freely expand and telescope in the pipe heating process, the expansion bending phenomenon in the nuclear fuel cladding pipe heating process can be prevented from occurring due to the fact that every two adjacent nuclear fuel cladding pipe sections are movably arranged in a sealed mode through one connecting part, and therefore the performance of the nuclear fuel cladding pipe can be accurately assessed.

Owner:SUZHOU NUCLEAR POWER RES INST +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com