Flat plate type nuclear fuel component

A technology for nuclear fuel assembly and nuclear fuel, which is applied to fuel elements, fuel element assembly, nuclear engineering, etc., can solve problems such as uneven distribution of nuclear fuel cores, accidents, and nuclear fuel element damage, and achieve reasonable distribution, high coolant flow rate, The effect of high heat flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments.

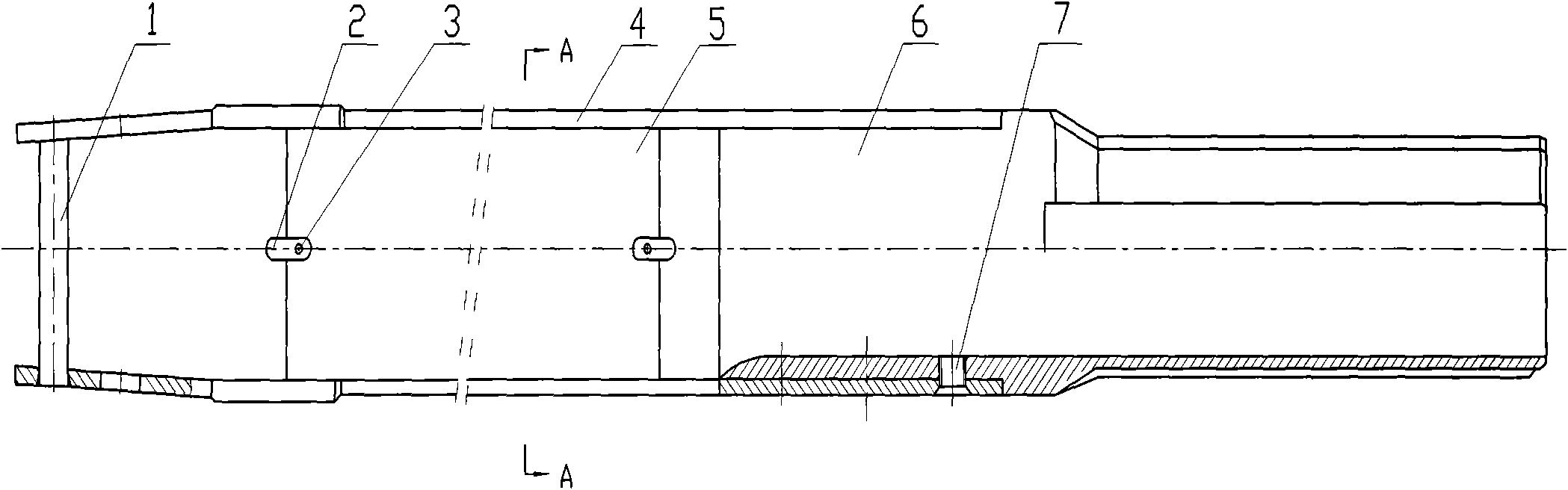

[0025] This embodiment discloses a flat-plate nuclear fuel assembly used in China Advanced Research Reactor (CARR).

[0026] The flat-plate nuclear fuel assembly is located in the center of the reactor active area and placed on the cone surface of the square hole of the grid plate of the reactor core. The plug of the nuclear fuel assembly is inserted into the rectangular hole of the core grid plate, and the conical surface of the plug rests on the conical surface of the grid plate. The upper part of the nuclear fuel assembly relies on the protrusion of the side plate to maintain the radial clearance fit between the standard nuclear fuel assembly and surrounding assemblies and other core components.

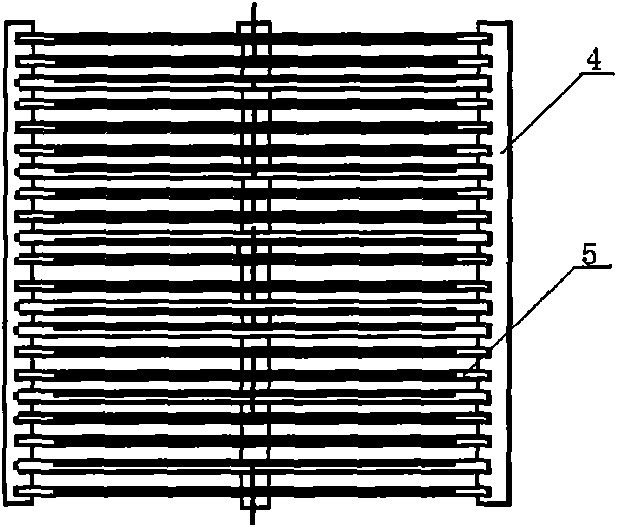

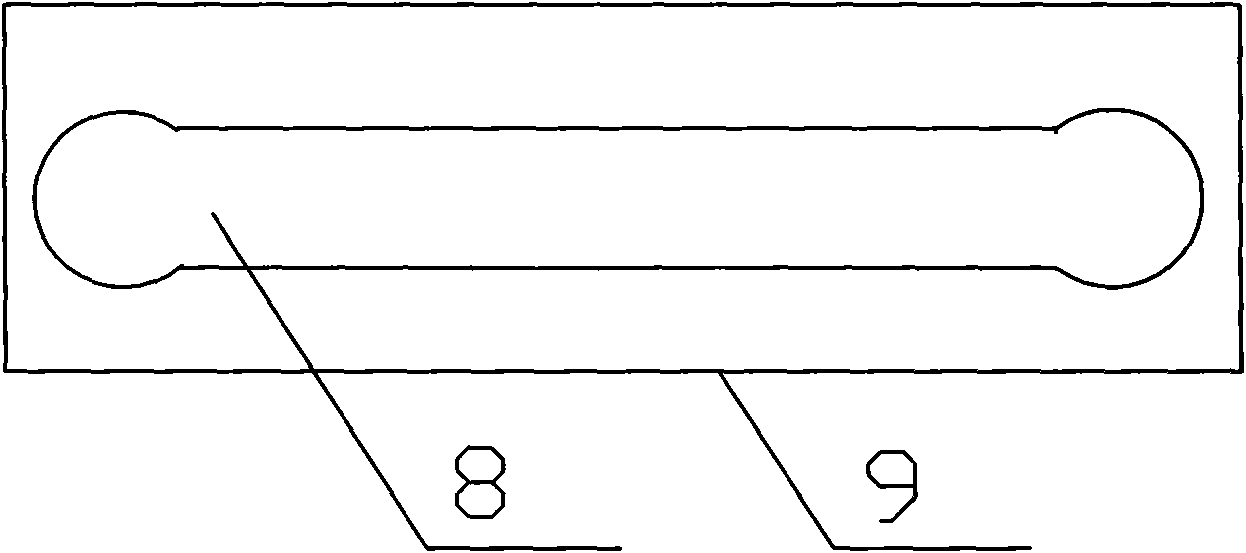

[0027] The flat nuclear fuel assembly includes a side plate 4 , a nuclear fuel plate 5 , and a rectangular plug 6 . The upper half of the nuclear fuel assembly is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com