Water boiler solution nuclear reactor having inherent security

A safety and reactor technology, applied in the direction of nuclear reactors, uniform reactors, reactors, etc., can solve the problems of low production capacity and only reactor power, and achieve the effect of meeting market needs, considerable social benefits, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

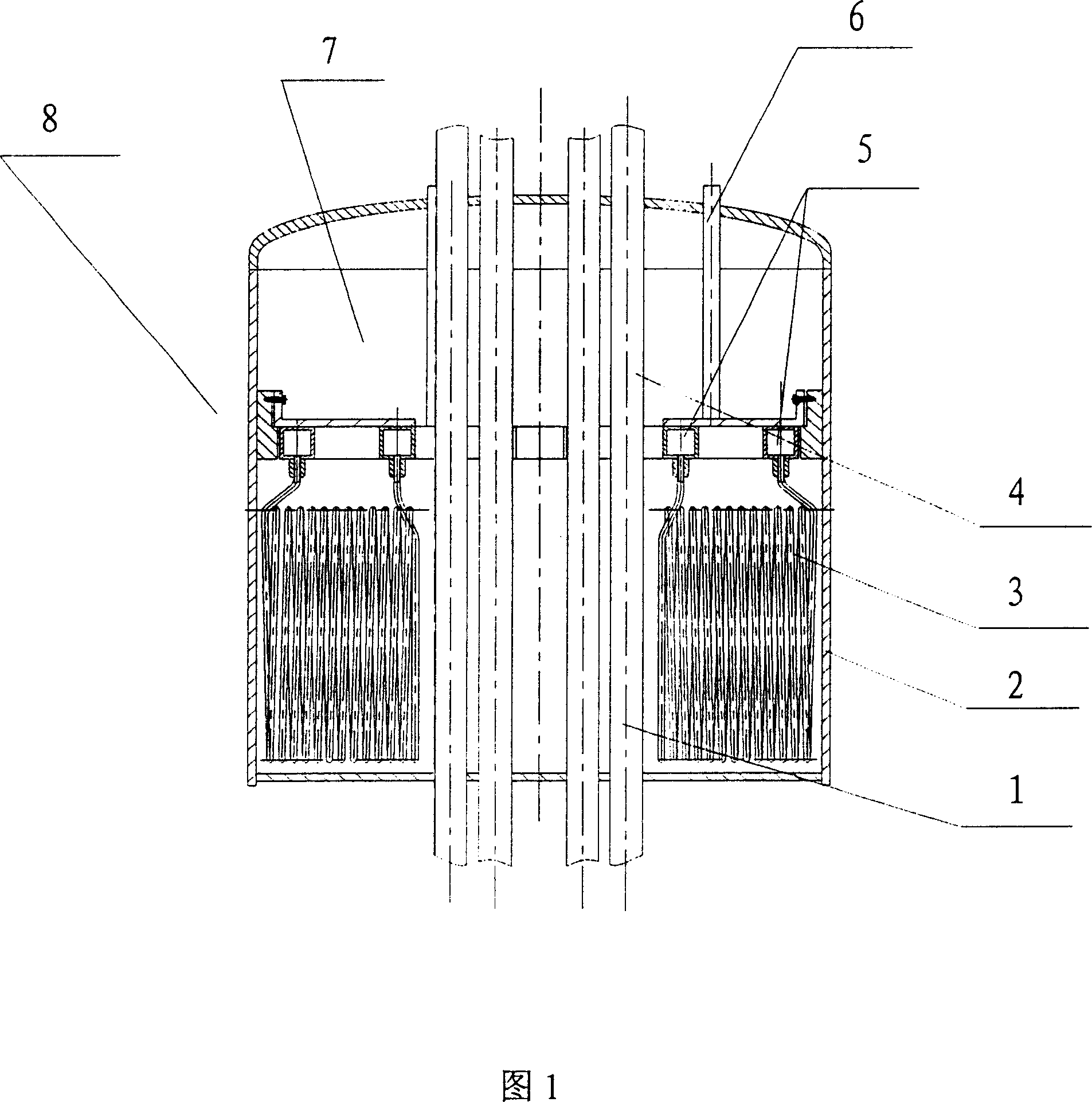

[0026] As shown in Figure 1, a flat-bottomed cylindrical core structure is adopted, and the core liquid does not contain combustible neutron poison Gd-155. Enriched uranium UO 2 (NO 3 ) 2 Solution or UO 2 SO 4 The solution is placed in the core vessel 2, the diameter (inner diameter) of the core is 70cm, the height of the core vessel is about 70cm, the height of the core solution is 25-32cm (varies with the concentration of uranium in the solution), and the core material liquid is divided into inner and outer areas radially 3-6 control rod conduits 4 are arranged in one inner area without cooling tubes, the control rod conduits 4 are sealed and welded with the upper cover and lower bottom of the core vessel 2, the inside of the control rod conduits 4 is cooling water, and the outside of the control rod conduits 4 is connected with the fuel solution For contact, the outer area of the core material liquid radial direction is arranged with a cooling pipe fuel inner area 3, ...

Embodiment 2

[0030] As shown in Figure 1, a flat-bottomed cylindrical core structure is adopted, and an appropriate combustible neutron poison Gd-155 (expressed as Gd(NO 3 ) 3 form).

[0031] The core structure is the same as that of embodiment 1, only at UO 2 (NO 3 ) 2 Gadolinium-155 was added. Core design calculation result K eff See Table 2 for the change with the concentration of uranium in the solution, K eff The maximum point corresponds to a uranium concentration of 52gU / L, the operating point of the reactor can be selected at 46gU / L, the corresponding solution volume is 122.3L, and the amount of Gd-155 is 9.13g. Uniform fuel consumption at full power operation at a concentration of 46gU / L, K eff See Table 3 for the change with fuel consumption.

[0032] Numbering

[0033] EFPD

Embodiment 3

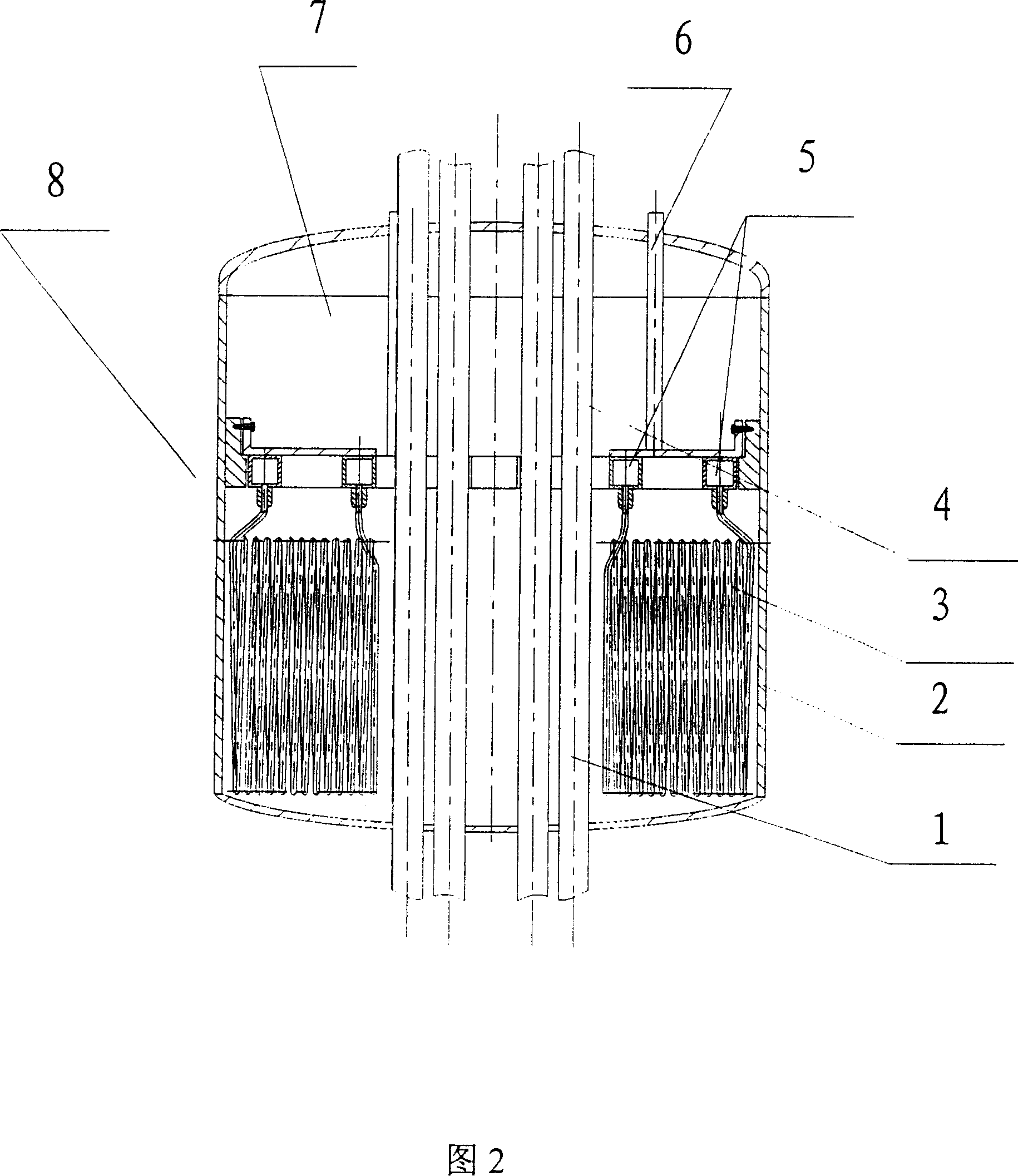

[0035] As shown in Figure 2, the cylindrical core structure with dish bottom does not contain combustible neutron poison Gd-155 in the core feed liquid.

[0036] The core structure is basically the same as in Example 1, except that the bottom of the core is changed from a flat bottom to a dish bottom. The bottom R of the dish is 630mm, the r is 63mm, the dish height is 142mm, and the dish volume is 33.70L. The height of the core solution is 21.4-30.5cm (varies with the concentration of uranium in the solution), the initial loading of uranium-235 is 3.00kg, and the enrichment degree of uranium-235 is 90%. Core design calculation result K eff See Table 4 for the change with the concentration of uranium in the solution, K eff The maximum point corresponds to a uranium concentration of 44gU / L, and the operating point of the stack can be selected at 36gU / L, corresponding to a solution volume of 95L. To achieve 100L, the core diameter must be increased.

[0037] Number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com