Integral method for reprocessing spent fuel

A back-end processing and spent fuel technology, applied in the direction of reactor fuel elements, extraction water/sewage treatment, radioactive purification, etc., can solve the problems of insufficient consideration of logistics and radionuclide rationality, and achieve radiation protection and good radiation According to the stability, the effect of simplifying the extraction and purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

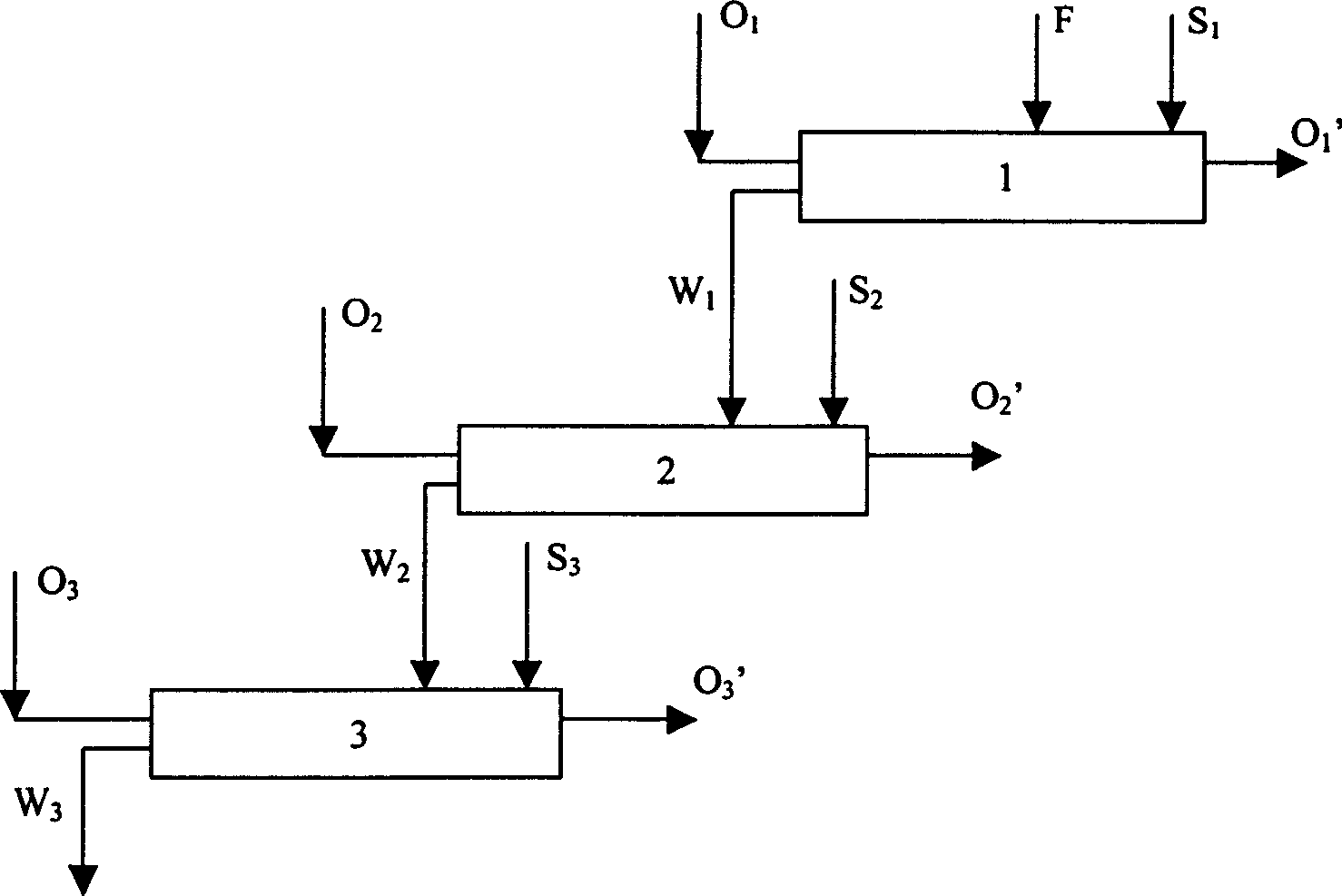

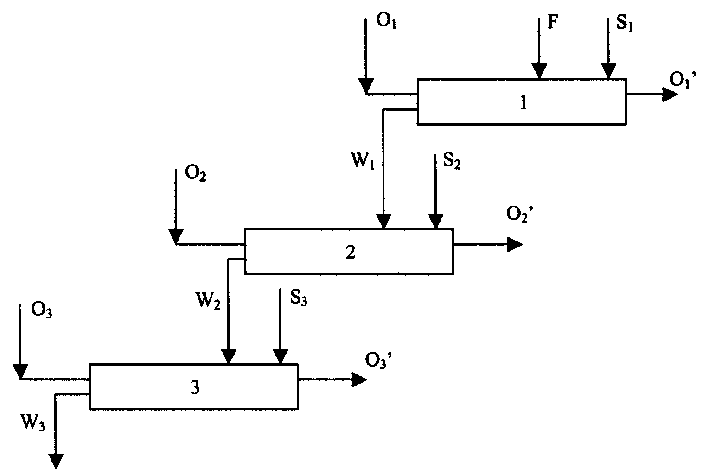

[0038] The extraction cascade test was carried out at 25°C, and the extraction was carried out according to the process described in the process flow. The specific data are as follows:

[0039] F: Spent fuel element solution containing 3.0 mol / L nitric acid

[0040] o 1 : 0.1mol / L isopropoxy calix[4]crown 6+0.1mol / L dicyclohexyl and 18crown 6-n-octanol solution

[0041] S 1 : 1.5mol / L nitric acid solution

[0042] o 2 : 0.2mol / L N, N, N', N'-tetra(2-ethylhexyl)-3-oxa-glutaramide-90% kerosene+10% n-octanol solution

[0043] S 2 : 1.5mol / L nitric acid solution

[0044] o 3 : 30% tributyl phosphate-kerosene solution

[0045] S 3 : 0.7mol / L nitric acid solution

[0046] Levels: 14 levels in the first section; 16 levels in the second section; 12 levels in the third section

[0047] Organic phase / aqueous phase flow ratios are: 1 / 3-3 / 1; 1 / 3-3 / 1; 2 / 1-5 / 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com