Solar spectrum total reflection type antistatic thermal control coating and preparation method thereof

A thermal control coating, solar spectrum technology, applied in reflective/signal coatings, coatings, conductive coatings, etc., can solve the problems of large surface potential difference, poor space environment irradiation stability, low solar heat flow reflectivity, etc. The effect of low, excellent radiation stability in space environment, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

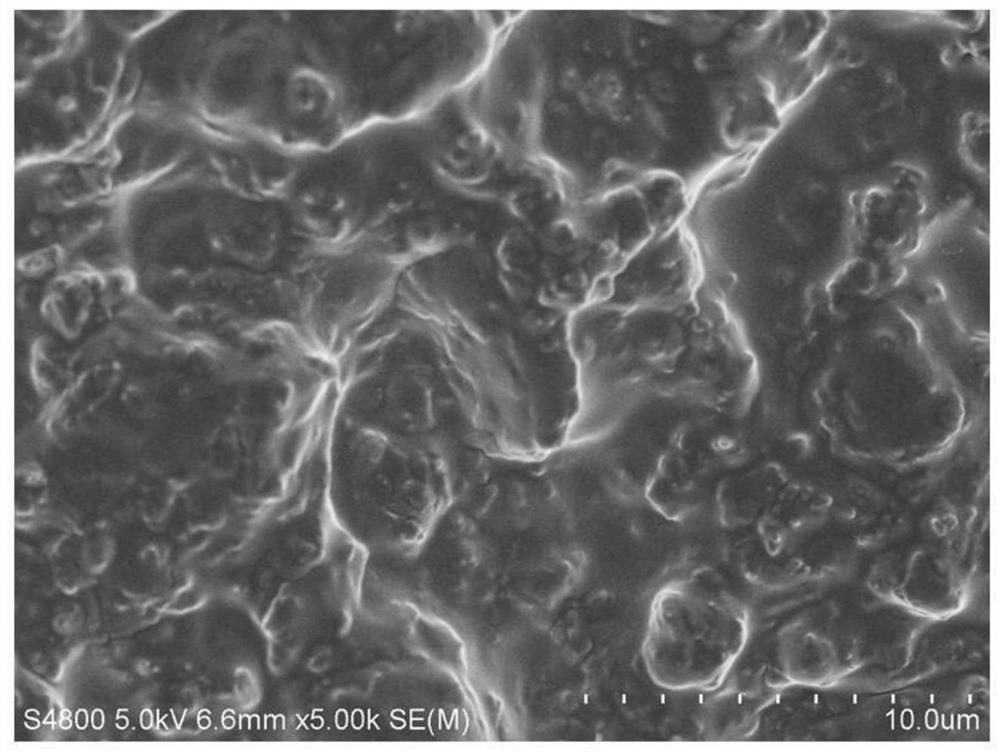

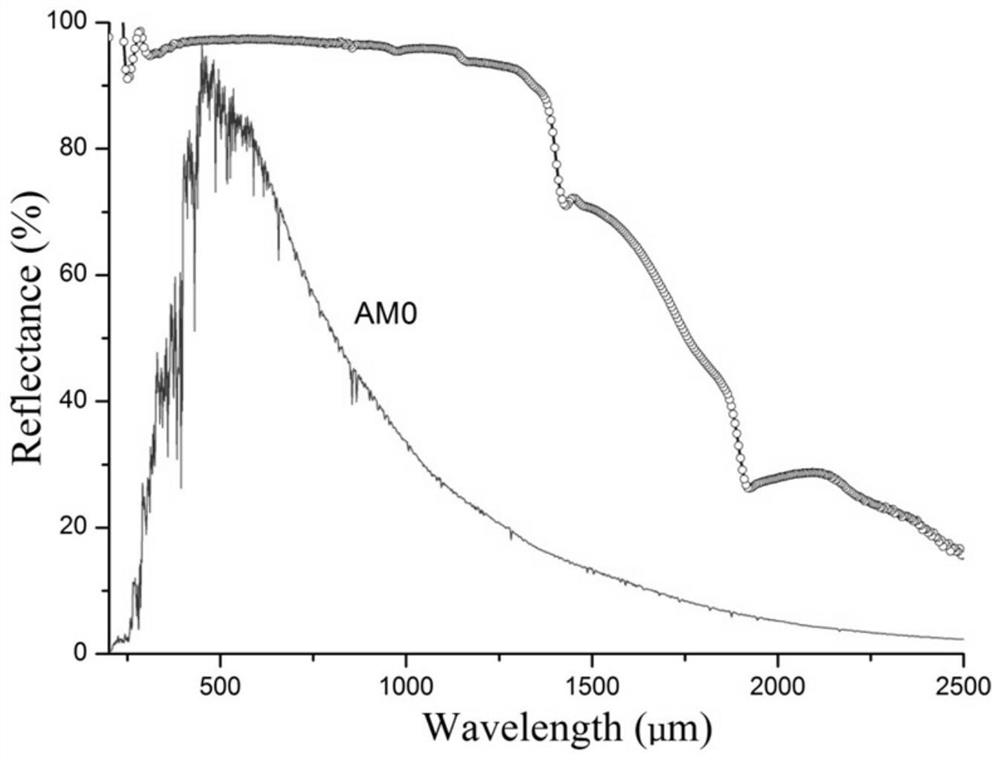

Image

Examples

Embodiment 1

[0027] (1) In terms of mass percentage, weigh 40% ultra-wide bandgap Ga 2 o 3 Powder pigment, the particle size distribution of the pigment is controlled at 100~800nm by ball milling; the Ga 2 o 3 Powder pigments are of analytical purity and above.

[0028] (2) Weigh 40% potassium silicate binder and add 10% distilled water to dilute. The preparation method of potassium silicate binder is as follows: add analytically pure potassium hydroxide and silicon micropowder powder in a molar ratio of 3, add 5% distilled water to mix and disperse, put them in a hydrothermal reaction kettle and stand at 180°C for 100 hours to prepare.

[0029] (3) Evenly pour the gallium oxide powder pigment ground and dried in step (1) into the potassium silicate binder solution, add 5% distilled water to stir and disperse, control the speed at 1000r / min, and stir for 4 hours;

[0030] (4) Weigh 5% of functional additives and add them to the solution described in step (3) and fully disperse and mi...

Embodiment 2

[0033] (1) In terms of mass percentage, weigh 30% of ultra-wide bandgap Ga 2 o 3 Powder pigment, the particle size distribution of the pigment is controlled at 100~800nm by ball milling; the Ga 2 o 3Powder pigments are of analytical purity and above.

[0034] (2) Weigh 50% lithium water glass binder and add 8% distilled water to dilute. Lithium water glass binder is prepared by mixing and dispersing analytically pure lithium hydroxide and silicon micropowder powder with 4% distilled water at a molar ratio of 2.5, putting them in a hydrothermal reactor and standing at 180°C for 100 hours.

[0035] (3) Evenly pour the gallium oxide powder pigment ground and dried in step (1) into the lithium water glass binder solution, add 4% distilled water to stir and disperse, the speed is controlled at 1000r / min, and the stirring time is 4h;

[0036] (4) Weigh 8% of functional additives and add them to the solution described in step (3) and fully disperse and mix. The auxiliary agent...

Embodiment 3

[0039] (1) In terms of mass percentage, weigh 50% ultra-wide bandgap MgO powder pigment, and control the particle size distribution of the pigment to 100-800nm by ball milling; the MgO powder pigment is of analytical purity or above.

[0040] (2) Weigh 40% potassium silicate binder and add 2% distilled water to dilute. Potassium silicate binder is prepared by mixing and dispersing analytically pure potassium hydroxide and silicon micropowder powder with 2% distilled water at a molar ratio of 4, putting them in a hydrothermal reactor and standing at 180°C for 100 hours.

[0041] (3) Pour the ground and dried MgO powder pigment in step (1) evenly into the potassium silicate binder solution, add 3% distilled water to stir and disperse, control the speed at 800r / min, and stir for 4 hours;

[0042] (4) Weigh 5% of functional additives and add them to the solution described in step (3) and fully disperse and mix. The auxiliary agent is 2% aluminum phosphate and 3% calcium fluorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com