Laser protection film doped with dye

A protective film and dye technology, applied in the field of dye-doped laser protective film, can solve the problems of complex production process, inability to transform, limited protection angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Under the yellow light environment, take 15 parts by mass of achiral polymerizable monomer HCM008, 59 parts by mass of achiral polymerizable monomer HCM009, 14.36 parts by mass of achiral polymerizable monomer HCM020, and 8.83 parts by mass of left-handed The photoinitiator Irgacure-819 of sexual dopant S1011, 1.85 mass parts, the polymerization inhibitor Tinuvin 328 of 0.01 mass parts and the positive dichroic dye D1 of 1 mass part are placed in a brown bottle, add 4mL to the brown bottle After dichloromethane, stir at room temperature for 30min, then heat at 80°C for 3h, completely evaporate the dichloromethane to prepare mixture A; take 15 parts by mass of achiral polymerizable monomer HCM008, 59 parts by mass of non- Chiral polymerization monomer HCM009, 14.36 parts by mass of HCM020, 8.83 parts by mass of left-handed chiral dopant R1011, 1.85 parts by mass of photoinitiator Irgacure-819, 0.01 parts by mass of inhibitor Tinuvin 328 and 1 part by mass of Put the posi...

Embodiment 2

[0027]Under the yellow light environment, take 15 parts by mass of achiral polymerizable monomer HCM008, 59 parts by mass of achiral polymerizable monomer HCM009, 14.36 parts by mass of achiral polymerizable monomer HCM020, and 8.83 parts by mass of left-handed The photoinitiator Irgacure-819 of sexual dopant S1011, 1.85 mass parts, the polymerization inhibitor Tinuvin 328 of 0.01 mass parts and the positive dichroic dye D1 of 1 mass part are placed in brown bottle, and described positive dichroism The neutral dye is the same as in Example 1. After adding 4mL of dichloromethane to the brown bottle, stir at room temperature for 30min, then heat at 80°C for 3h, and completely evaporate the dichloromethane to make mixture A; take 15 parts by mass of Achiral polymerizable monomer HCM008, 59 parts by mass of achiral polymerizable monomer HCM009, 14.36 parts by mass of HCM020, 8.83 parts by mass of left-handed chiral dopant R1011, 1.85 parts by mass of photoinitiator Irgacure-819, T...

Embodiment 3

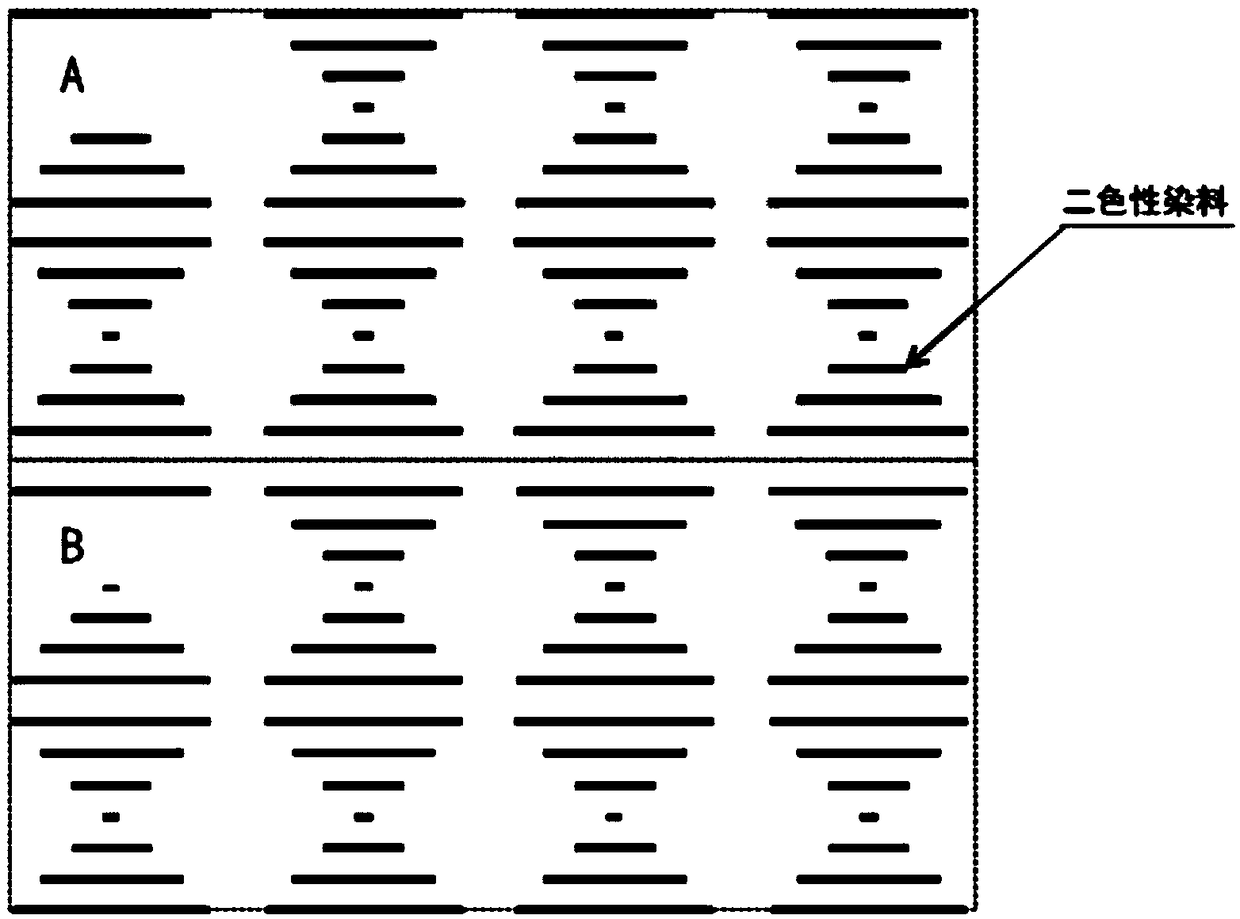

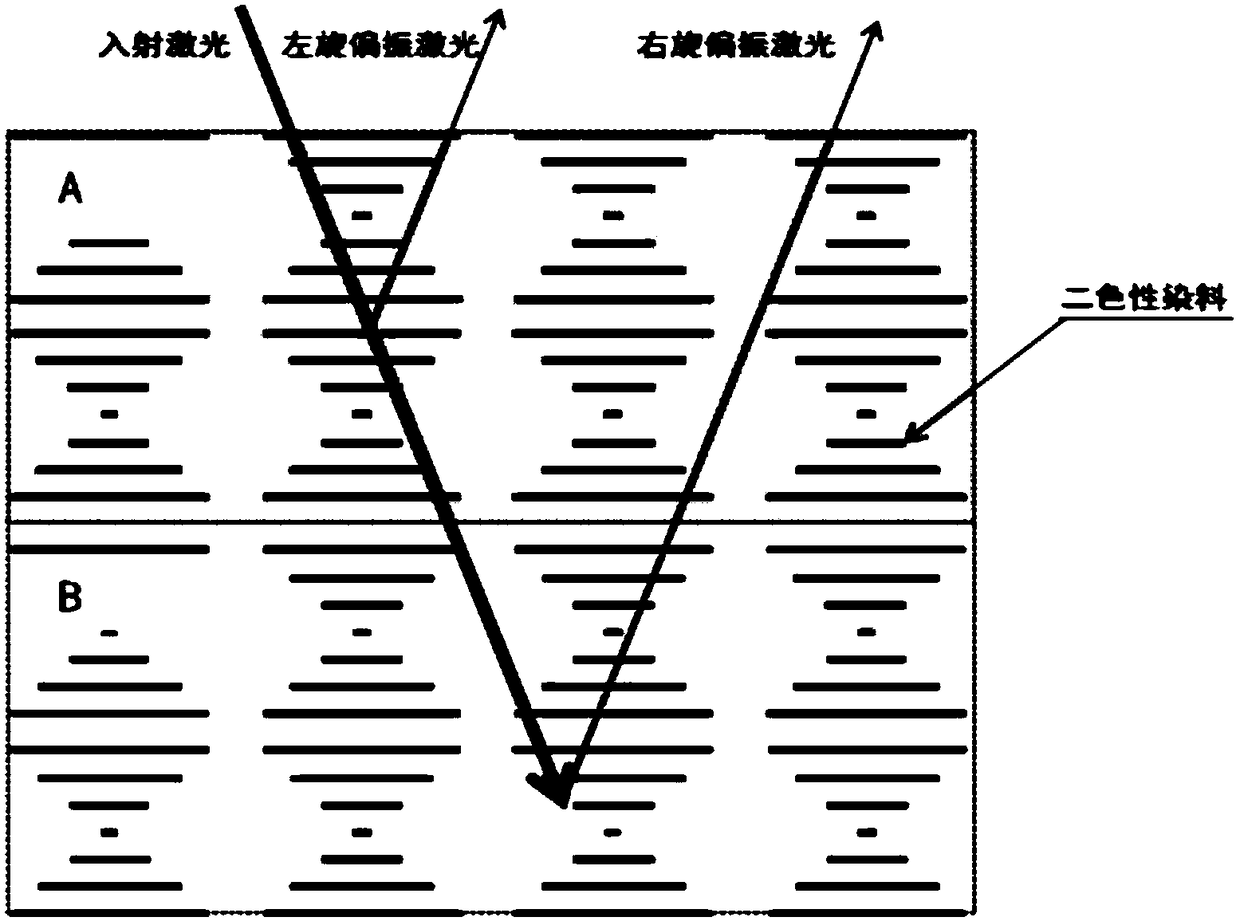

[0030] This embodiment provides a dye-doped laser protection film, comprising a polymer layer A and a polymer layer B arranged in sequence, the polymer layer A is formed by curing a mixture A under an ultraviolet light source, and the mixture A includes 15 Mass parts of achiral polymerizable monomer HCM008, 59 mass parts of achiral polymerizable monomer HCM009, 14.36 mass parts of achiral polymerizable monomer HCM020, 8.83 mass parts of left-handed chiral dopant S1011, 1.85 mass parts Parts of photoinitiator Irgacure-819, 0.01 mass part of polymerization inhibitor Tinuvin 328 and 1 mass part of positive dichroic dye D1, wherein polymerization monomer, left-handed chiral dopant, photoinitiator and polymerization inhibitor Polymer one is formed by polymerization under ultraviolet light, and the molecules of the polymer one are arranged in a left-handed helical structure, and at the same time, the molecular arrangement of the dye molecules is the same as that of the polymer one; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com