Anti-ultraviolet absorption space irradiation-resistant glass and manufacturing process thereof

An anti-ultraviolet and radiation-resistant technology, used in glass manufacturing equipment, manufacturing tools, glass molding, etc. Effects of UV absorption properties, reduced R&D and production costs, excellent UV absorption resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

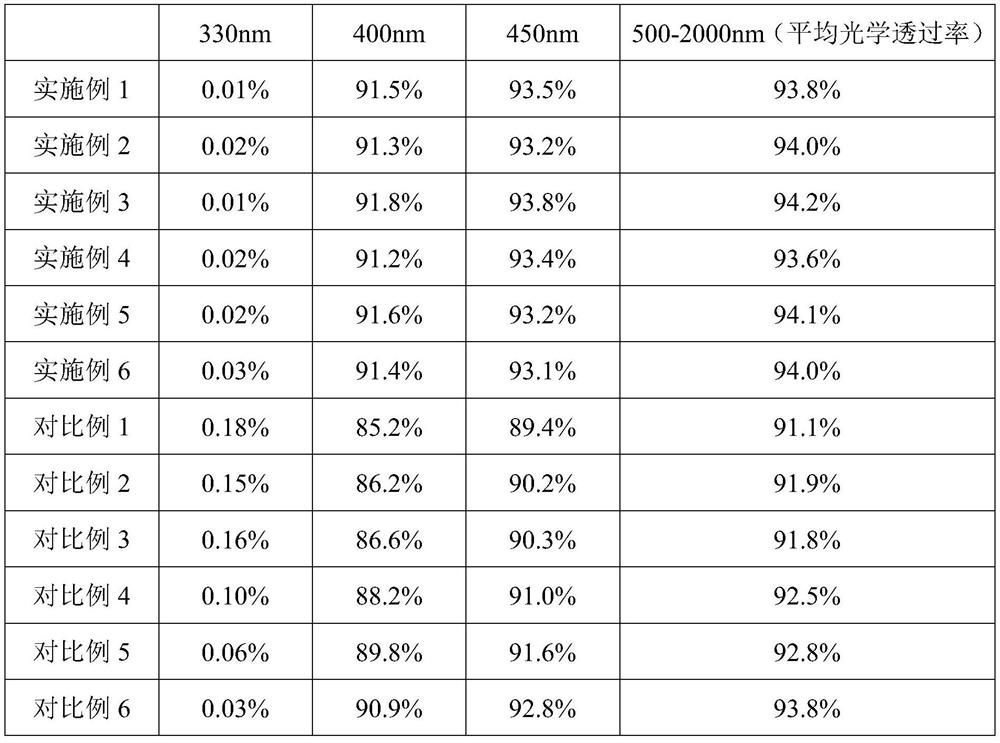

Examples

Embodiment 1

[0036] Anti-ultraviolet absorption space radiation-resistant glass, in parts by mass, the glass raw materials include 1.2 parts of ceria, 4.6 parts of neodymium oxide, 0.8 parts of lanthanum oxide, 3.5 parts of ytterbium oxide, 3.4 parts of sodium carbonate, and 4.7 parts of aluminum oxide , 72.2 parts of silica sand, 5.7 parts of strontium carbonate, 11.3 parts of barium carbonate, 0.3 parts of selenium dioxide, 2.5 parts of bismuth trioxide, 0.5 parts of tellurium dioxide, 10 parts of potassium nitrate, 1.2 parts of antimony trioxide, 1.6 parts of pyroantimony Sodium acid.

[0037] The preparation method of the anti-ultraviolet absorption space radiation-resistant glass comprises the following steps:

[0038] A. Prepare materials

[0039] Weigh each component according to the above raw material formula, mix evenly, and obtain the mixture for subsequent use;

[0040] B. Melting

[0041] Put the raw materials into a melting furnace at 200°C to heat up, and melt the raw mate...

Embodiment 2

[0049] Anti-ultraviolet absorption space radiation-resistant glass, in parts by mass, the glass raw materials include 5.9 parts of ceria, 0.5 parts of neodymium oxide, 3.2 parts of lanthanum oxide, 0.7 parts of ytterbium oxide, 12.3 parts of sodium carbonate, and 0.4 parts of aluminum oxide , 78.3 parts of silica sand, 10.7 parts of strontium carbonate, 4.6 parts of barium carbonate, 1.5 parts of selenium dioxide, 0.9 parts of bismuth trioxide, 1.6 parts of tellurium dioxide, 4.8 parts of potassium nitrate, 2.5 parts of antimony trioxide, 0.7 parts of pyroantimony Sodium acid.

[0050] The preparation method of the anti-ultraviolet absorption space radiation-resistant glass comprises the following steps:

[0051] A. Prepare materials

[0052] Weigh each component according to the above raw material formula, mix evenly, and obtain the mixture for subsequent use;

[0053] B. Melting

[0054] Put the raw materials into a melting furnace at 150°C to heat up, and melt the raw ma...

Embodiment 3

[0062] Anti-ultraviolet absorption space radiation-resistant glass, in parts by mass, the glass raw material includes 2 parts of ceria, 1 part of neodymium oxide, 2 parts of lanthanum oxide, 1 part of ytterbium oxide, 6 parts of sodium carbonate, and 3 parts of aluminum oxide , 75 parts of silica sand, 8 parts of strontium carbonate, 7 parts of barium carbonate, 1.2 parts of selenium dioxide, 1 part of bismuth trioxide, 1 part of tellurium dioxide, 5 parts of potassium nitrate, 2 parts of antimony trioxide, 1 part of pyroantimony Sodium acid.

[0063] The preparation method of the anti-ultraviolet absorption space radiation-resistant glass comprises the following steps:

[0064] A. Prepare materials

[0065] Weigh each component according to the above raw material formula, mix evenly, and obtain the mixture for subsequent use;

[0066] B. Melting

[0067] Put the raw materials into a melting furnace at 320°C to raise the temperature, melt the raw materials into molten glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com