Uranium dioxide single crystal/nano-diamond composite fuel and preparation method thereof

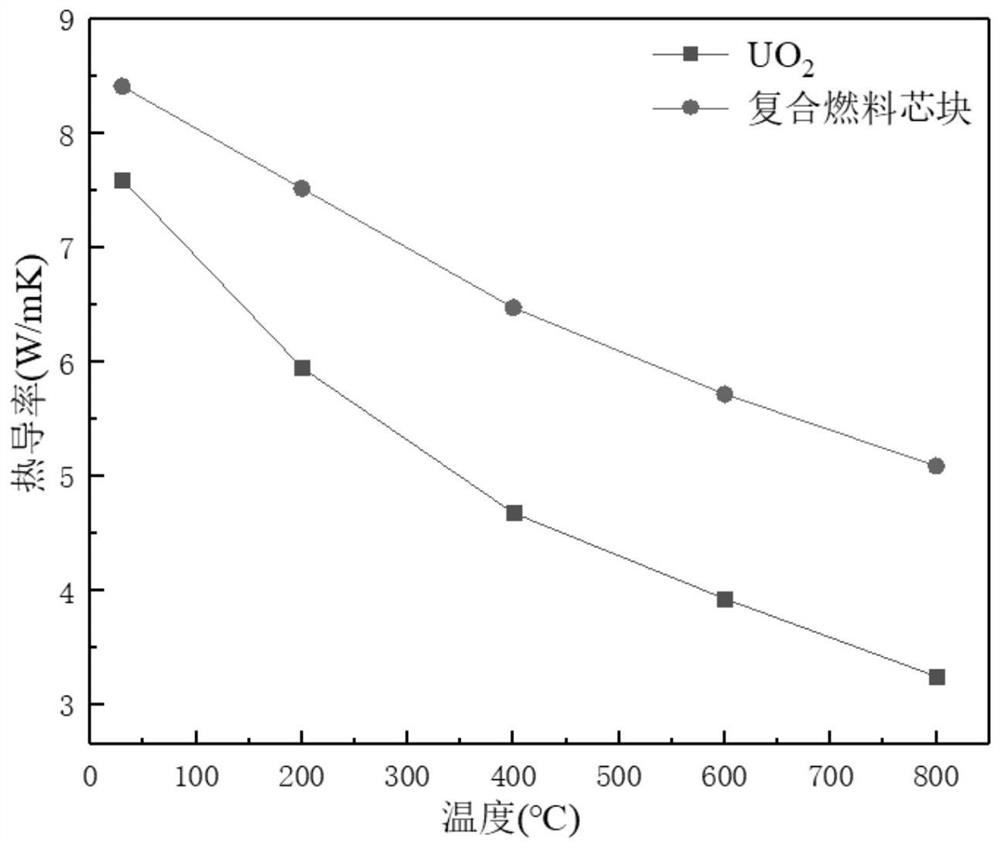

A technology of nano-diamond and nano-diamond powder, which is applied in the field of nuclear power, can solve the problems of low thermal conductivity and affect fuel safety, etc., and achieve the effects of improving thermal conductivity, improving safety, and improving economy and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

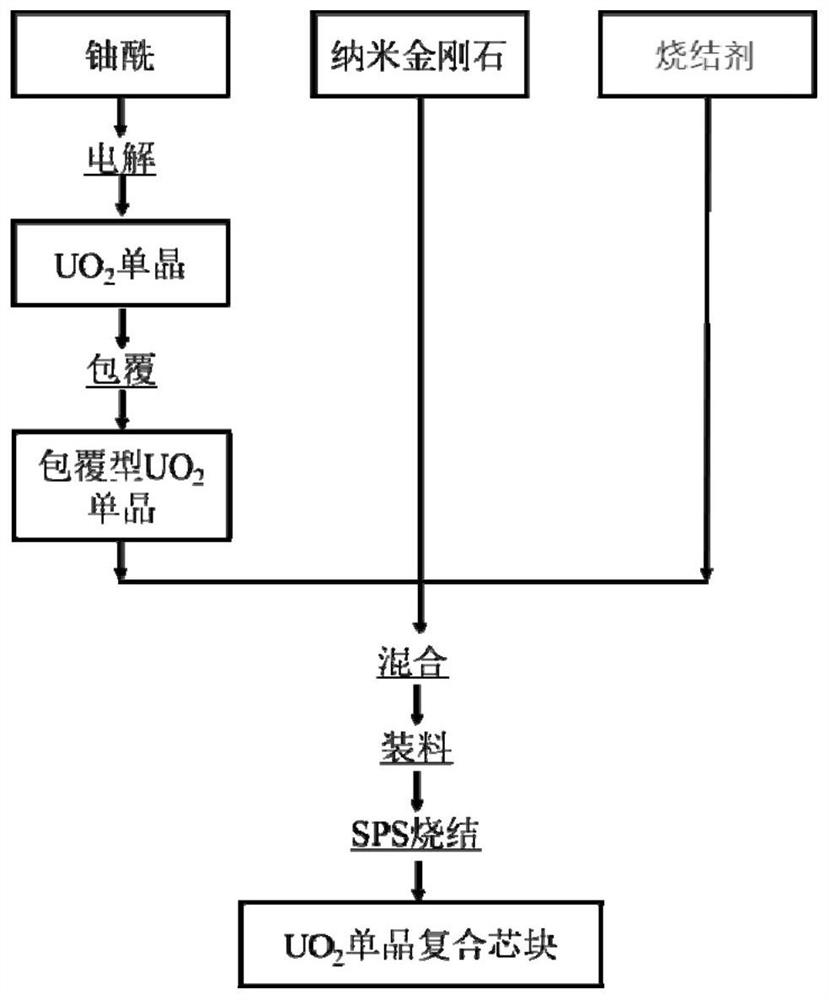

Method used

Image

Examples

Embodiment 1

[0025] 1) Using uranyl fluoride as raw material, UO with a particle size of 50-300 μm is prepared by electrolysis 2 Single crystals were distilled under reduced pressure, ultrasonically washed with deionized water, and dried naturally. At 1300°C, high-temperature annealing in Ar atmosphere, the heating and cooling rate is 20°C / min, and the temperature is kept for 2h.

[0026] 2) Take 100-300μm self-made UO in the sieve 2 Single crystal, acetylene supported by Ar in a CVD furnace at 1300 °C to obtain coated UO 2 For single crystal, the coating time is 1.2h, and the thickness of the coating layer is 20μm.

[0027] 3) The coated 6.88g UO 2 The single crystal, 0.55g of nano-diamond powder with a particle size of 40nm and 0.1%wt of acrylic wax were added into the polytetrafluoro tank, and stirred evenly for 1h.

[0028] 4) Spray boron nitride spray on the surface of the carbon felt, dry in a drying oven at 200°C for 30 minutes, place the pad on the inside and both ends of the m...

Embodiment 2

[0032] 1) Using uranyl chloride as the raw material, the method of electrolysis is used to prepare UO with a particle size of 200-800 μm 2Single crystal, washed three times with deionized water, and dried in a vacuum oven at 100°C.

[0033] 2) Ultrasonic cleaning with deionized water was used to remove impurities, drying at 100°C, high temperature annealing at 1750°C, the sintering atmosphere was Ar, the heating and cooling rate was 5°C / min, and the holding time was 8h.

[0034] 3) Sieve homemade UO with a thickness of 200-600 μm 2 Single crystal, acetylene was carried by argon in a CVD furnace, and coated at 1500°C for 0.8h to obtain coated UO 2 Single crystal, cladding layer thickness about 10μm.

[0035] 4) The coated 7.74g UO 2 The single crystal, 0.28g of nano-diamond powder with a particle size of 0.1-1 μm and 0.5%wt of acrylic wax were added into the polytetrafluoro tank, and stirred evenly for 2h. Single crystal UO 2 The particle volume content is 90%.

[0036] 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com