Method and system for measuring geometric density of nuclear fuel pellet

A technology of density measurement and nuclear fuel, applied in specific gravity measurement, measurement device, analysis material, etc., can solve the problems of large human error of measurement personnel, scratched surface of the measured object, low measurement efficiency, etc., and achieves fast measurement speed and simple structure. Stable and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings.

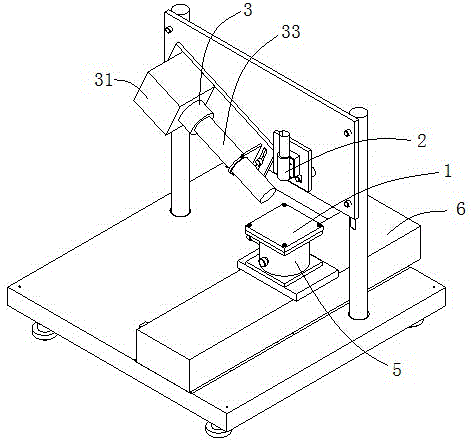

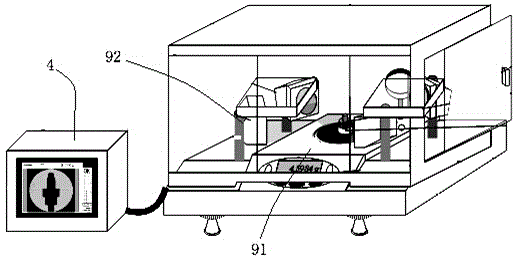

[0041] During specific implementation: if Figure 1~Figure 5 As shown, a nuclear fuel pellet geometric density measurement system includes a mass measurement module 91 and a diameter and height measurement module 92, and the diameter and height measurement module 92 includes at least one set of surface light sources and two-dimensional surface array CMOS sensor; the length of the surface light source and the two-dimensional area array CMOS sensor is greater than the diameter of the core block to be measured; the height of the surface light source and the two-dimensional area array CMOS sensor is greater than the height of the core block to be measured; The two-dimensional area array CMOS sensor is connected to a computer measurement and control device 4, and the computer measurement and control device 4 includes a data processing module and a display, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com