Automatic cooling and automatic cone shearing device for turned optical fiber preformed bars

An optical fiber preform and automatic cooling technology, which is applied in manufacturing tools, glass manufacturing equipment, etc., can solve problems such as blockage, improve work efficiency and reduce human error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

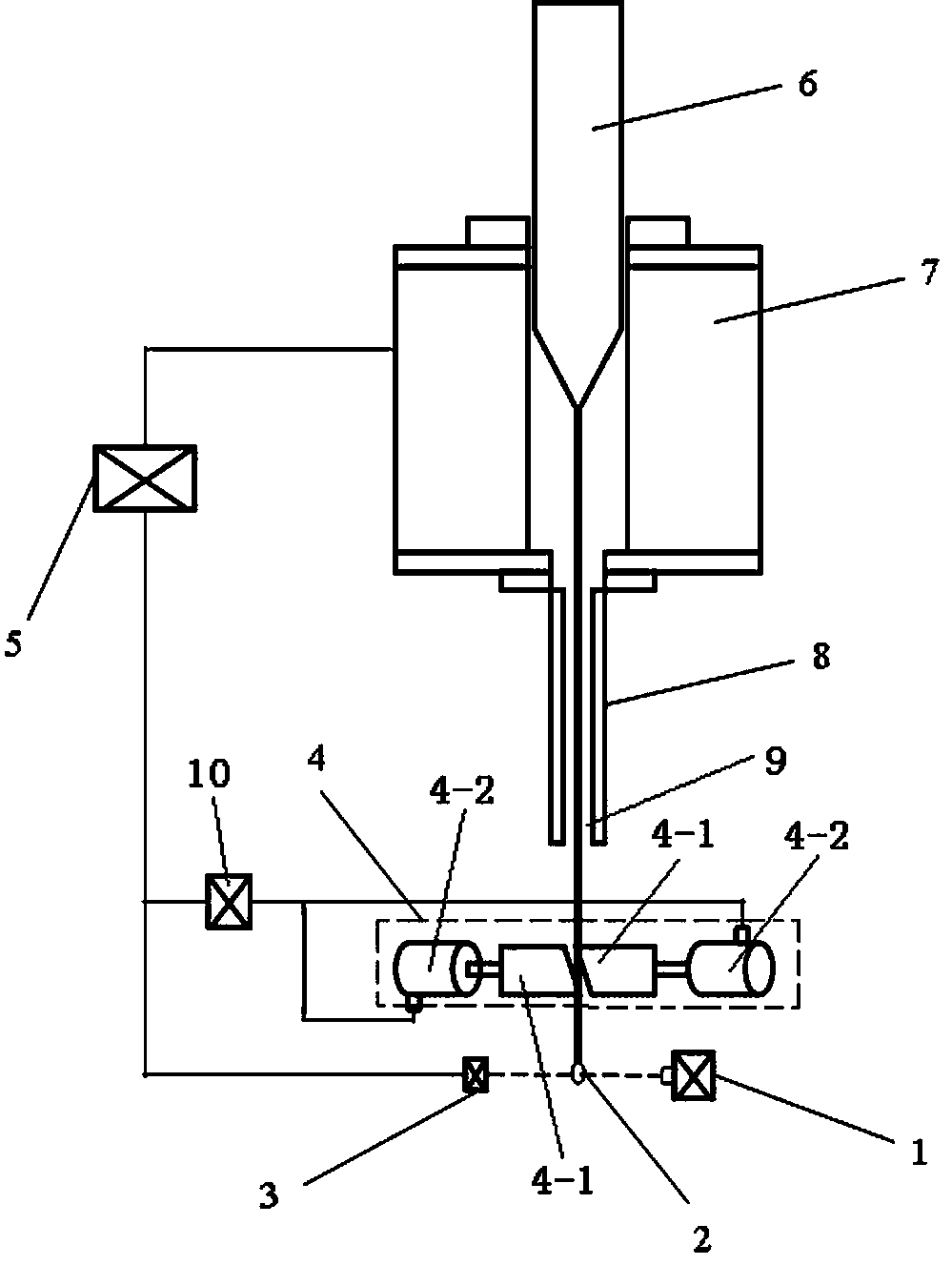

[0016] as attached figure 1 As shown, an optical fiber preform automatic cooling and automatic shear cone device includes an automatic shear head device 4, a signal transmitter 1, a signal receiver 3, and a programmable controller PLC 5 for a drawing furnace. The automatic cutting head device 4 is installed on both sides of the fiber channel under the annealing tube 8 of the fiber drawing furnace, and the signal transmitter 1 and the signal receiver 3 are respectively installed on both sides of the fiber channel under the automatic cutting head device. The programmable controller PLC 5 is respectively connected to the power supply of the automatic cutting head device 4 and the wire drawing furnace 7 through control lines, and the programmable controller PLC 5 is connected to the signal receiver 3 through a signal transmission line. After the signal receiver 3 detects the falling of the material head, the signal receiver 3 feeds back a signal to the programmable controller PLC5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com