Pre-tensioning track slab pre-tensioning jack and its method of tensioning track slab prestressed threaded steel bar

A technology for threaded steel bars and track slabs, which is applied to tracks, track laying, track maintenance, etc., can solve the problems of low construction efficiency, large human body counter-impact, and high construction strength, and achieves improved construction efficiency, reduced human errors, and improved The effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but this is not a limitation of the present invention. The scope of protection of the present invention is subject to the contents recorded in the claims. protection scope of the present invention.

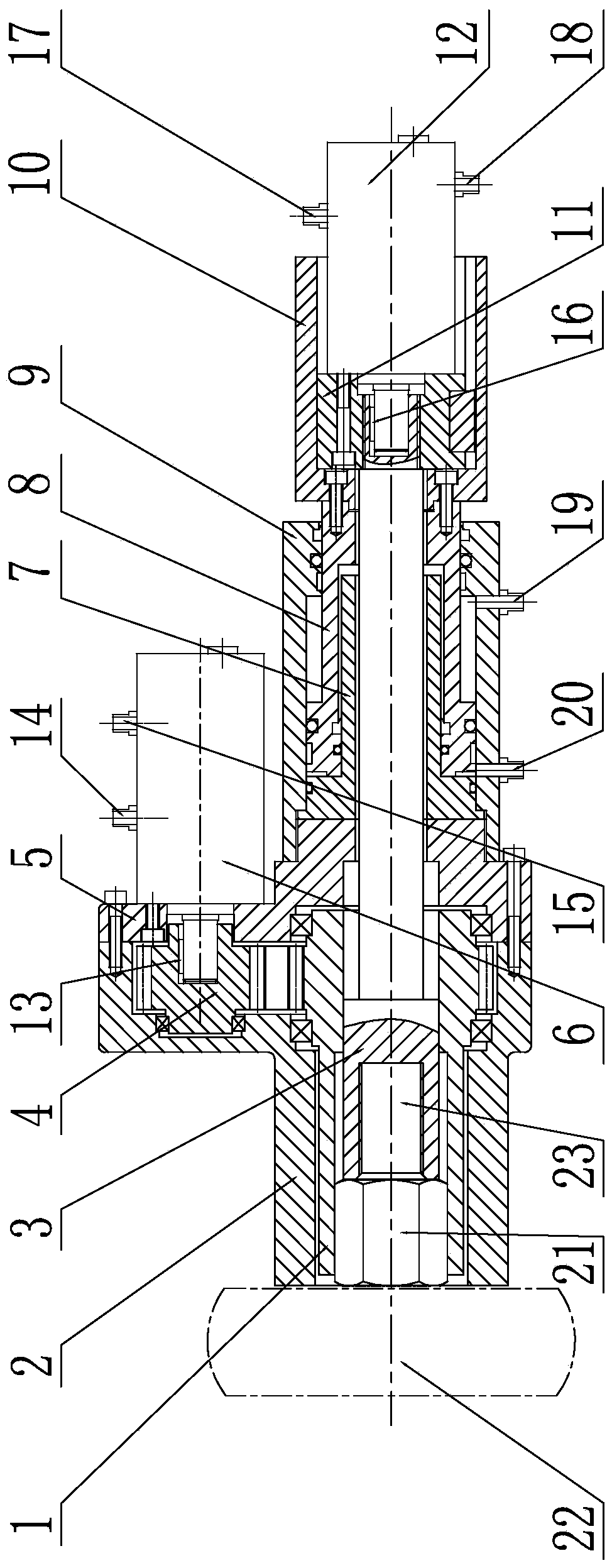

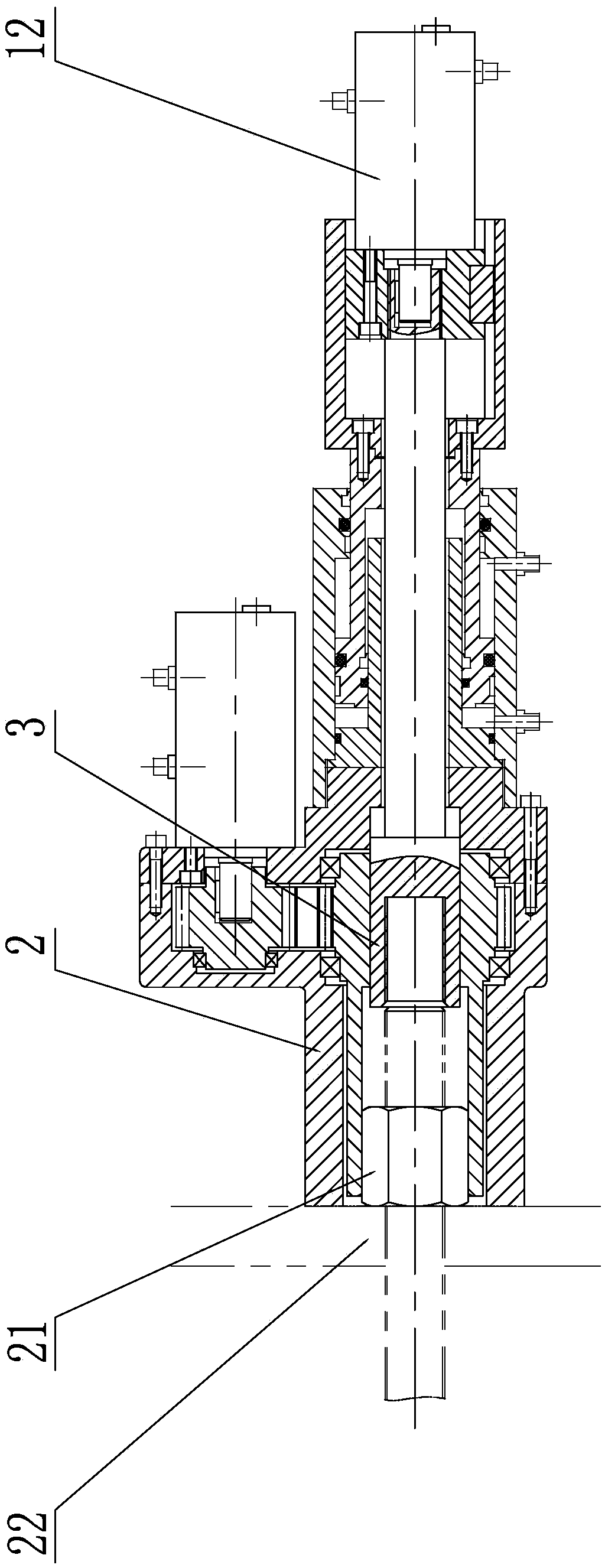

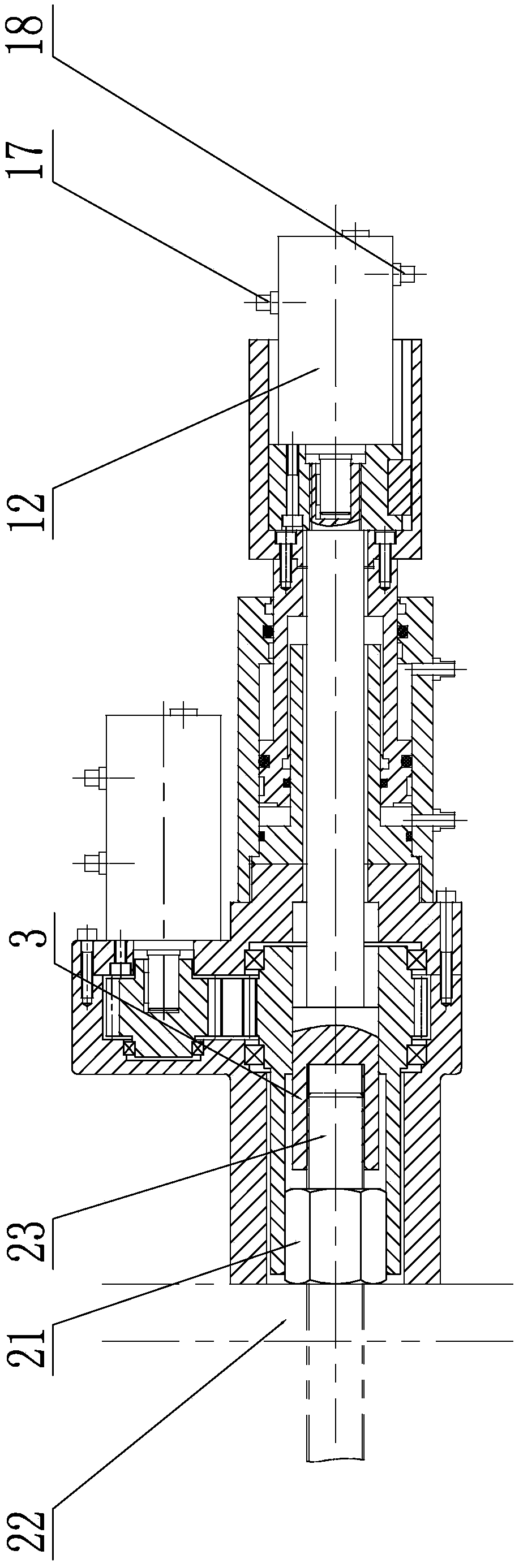

[0051] The overall technical structure of this embodiment is as shown in the figure. The pre-tensioned track slab pre-tensioning jack includes a piston 8 and an inner cylinder 7 that are set in the cylinder liner 9 and fit together. The cylinder liner 9 is connected to the oil pump through a pipeline; it also includes The following institutions:

[0052] A. Fixed nut rotation mechanism: It includes a box that is fitted on the surface of the cylinder liner 9 and the inner cylinder 7, and the first hydraulic motor 6 fixed on the box. The rotating output shaft of the first hydraulic motor 6 is connected to the pinion 4 and The inner hexagonal sleeve gear 1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com