Folder for processing flat seam allowance of shoulder girdle

A nozzle and shoulder strap technology, applied in textiles and papermaking, cloth feeding mechanism, sewing equipment, etc., can solve the problems of not meeting the requirements of mass production, time-consuming and labor-intensive processing, and high technical level requirements, so as to reduce human operation errors , Simple and convenient to use, lower technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

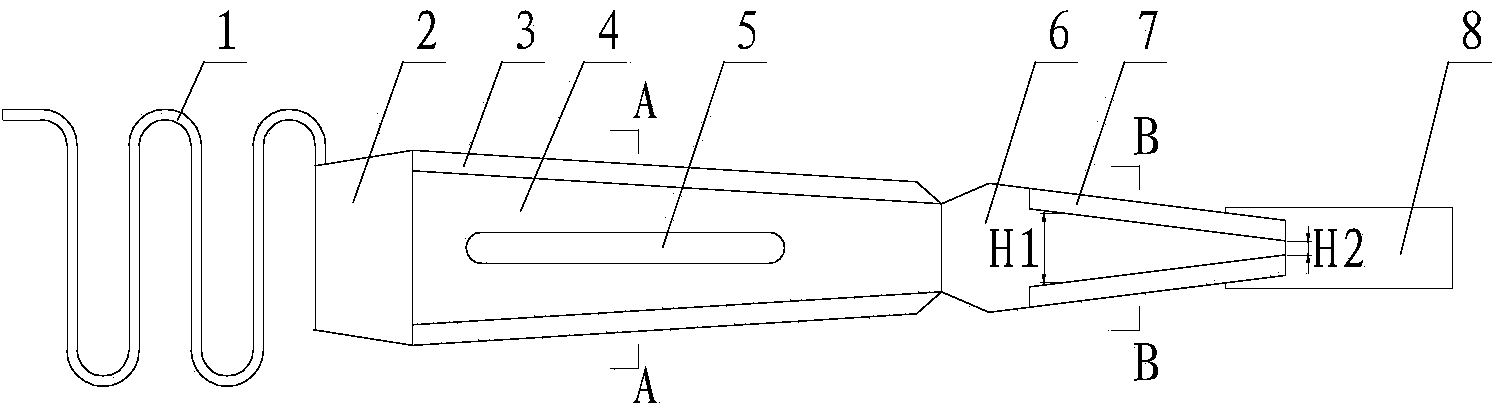

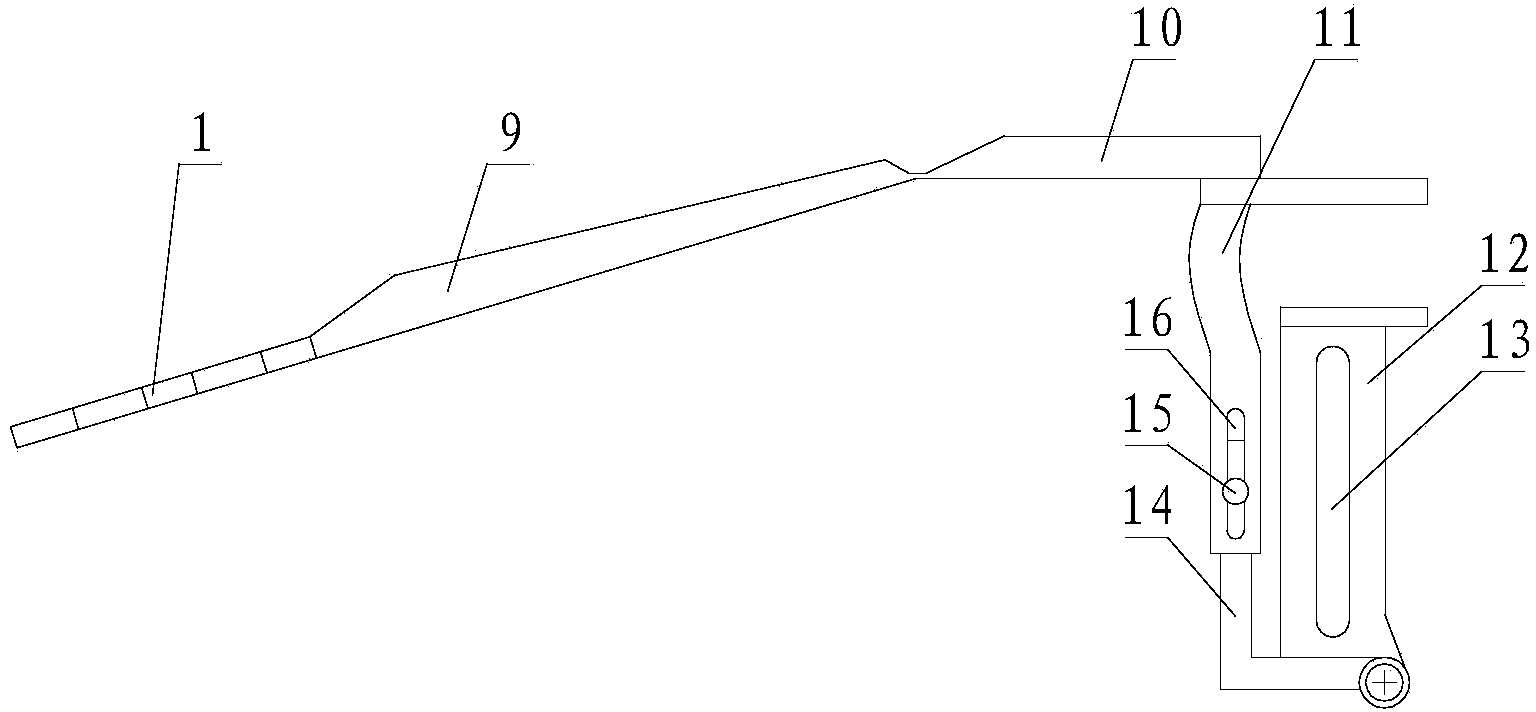

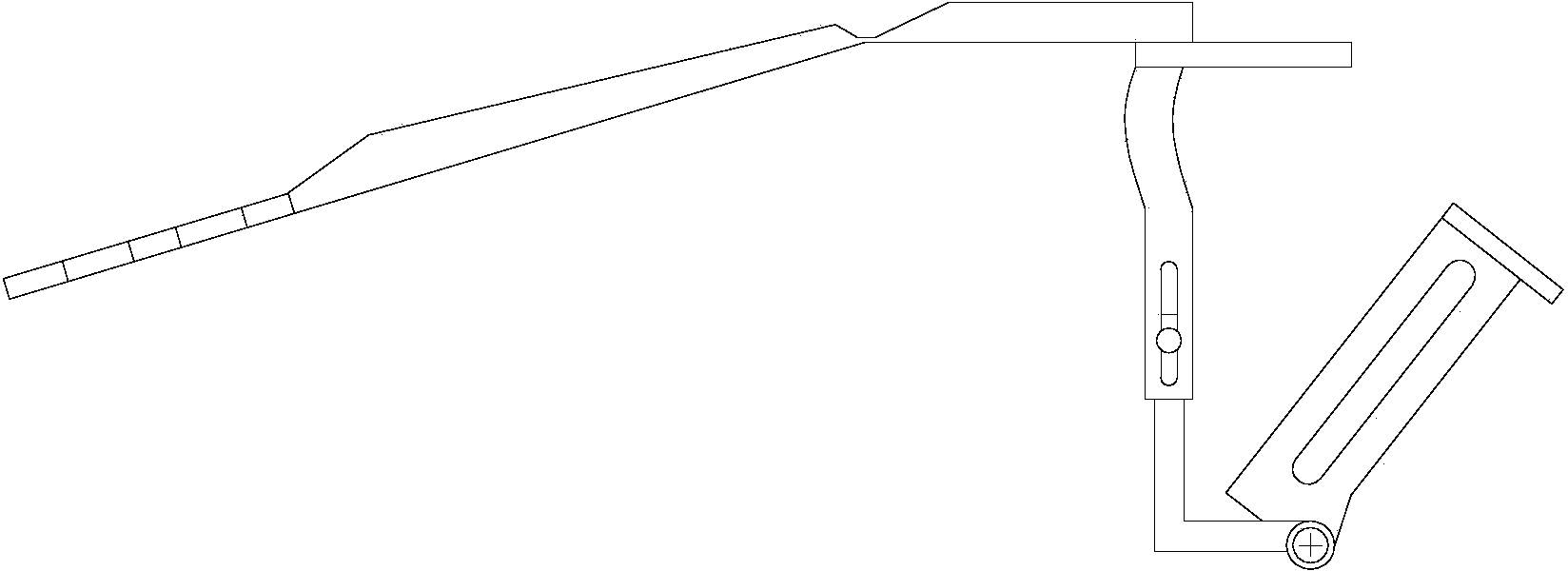

[0020] A mouthpiece for processing shoulder straps with a full mouth, comprising a fabric bending part 9, a fabric folding part 10 and a connecting piece 8, the fabric bending part is composed of a bottom plate 2 and an upper pressing plate 4, and the left and right outer edges of the bottom plate are folded inward to form a Arc edge 3, the upper pressing plate is arranged above the base plate, there is a gap between the upper pressing plate and the base plate, the gap is the distribution channel 17, the left and right sides of the upper pressing plate are respectively connected with two arc edges, and a long hole is formed on the upper pressing plate 5. The rear end (feed end) of the base plate is connected with an S-shaped guide frame 1; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com