Patents

Literature

98 results about "High iodine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The most reliable sources of natural iodine are sea vegetables and seafood. Other common sources are typically high in iodine because they were grown in iodine-rich soil, fed fish in their diet (i.e., chickens and eggs), or fortified (grains).

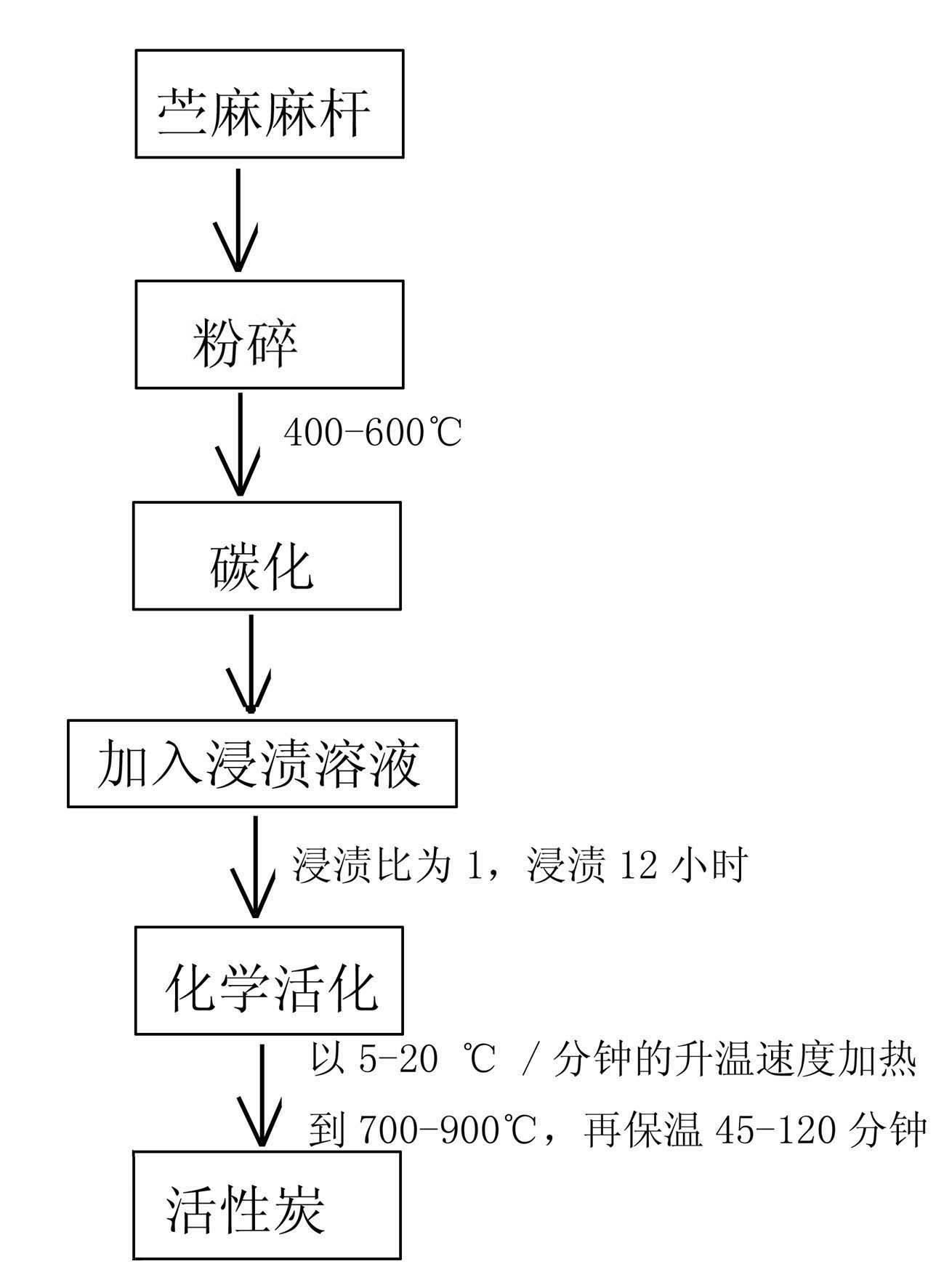

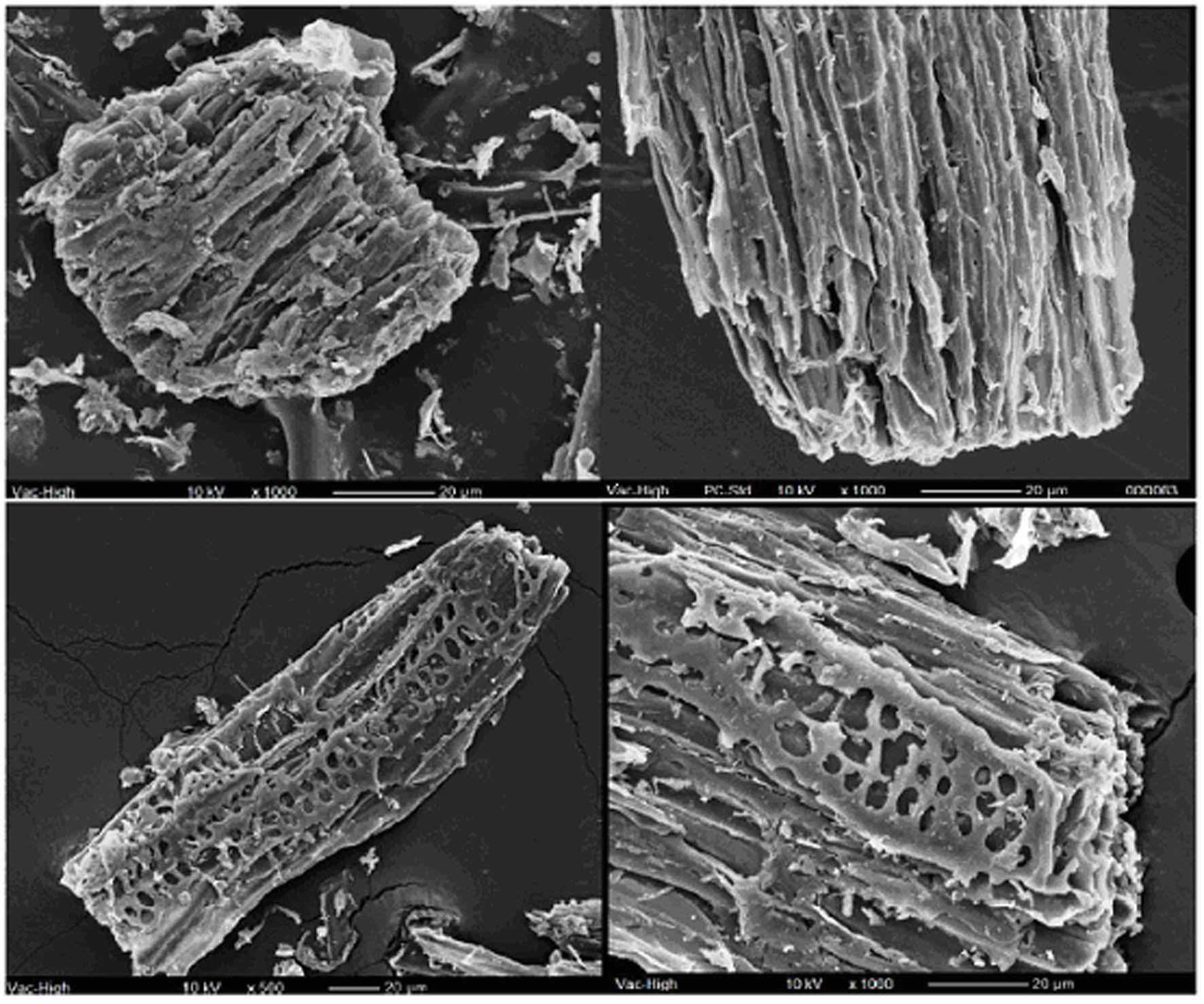

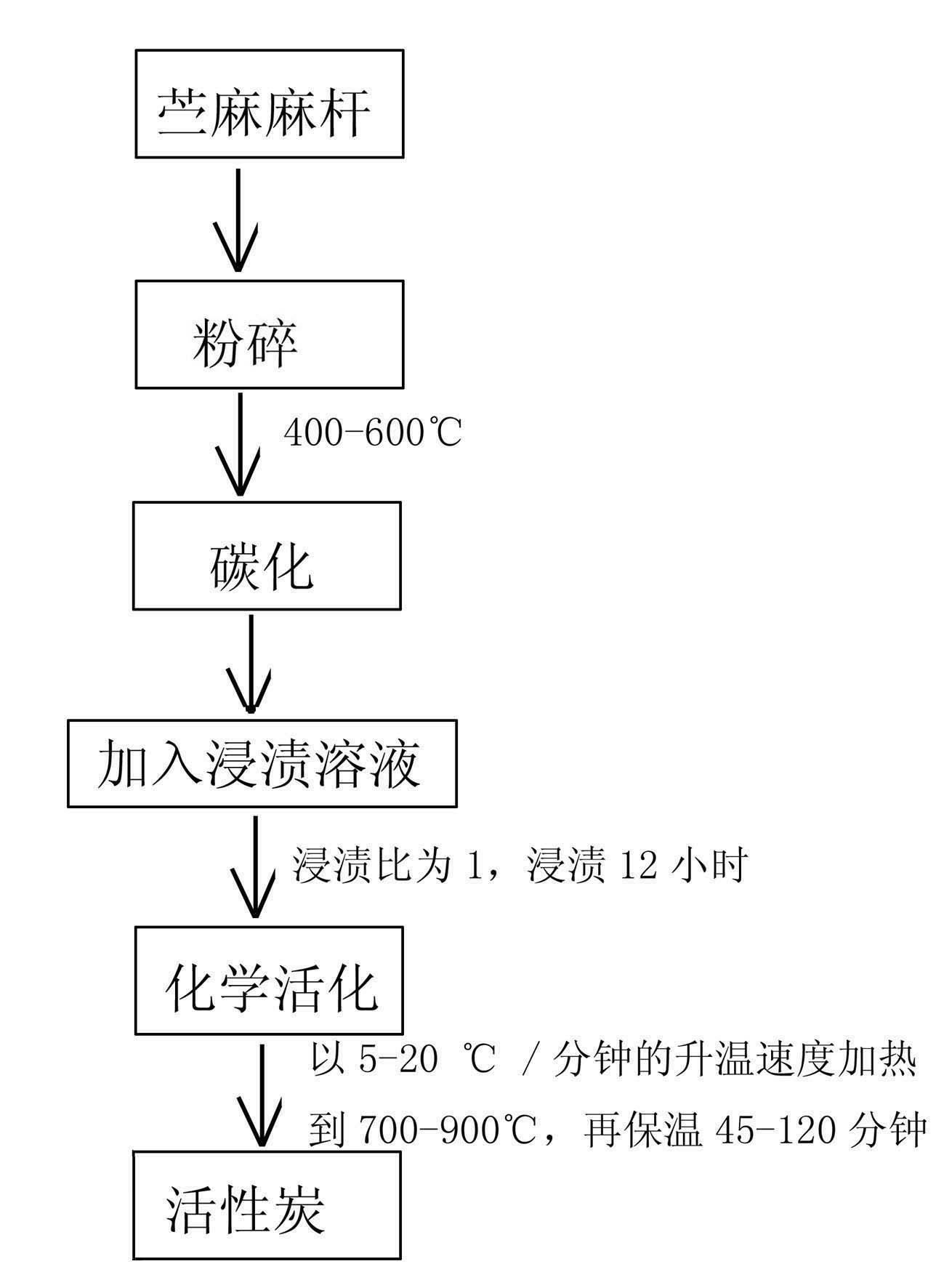

Method for preparing active carbon from ramie stalks

The invention relates to a method for preparing active carbon from ramie stalks. The method is simple, economical and environmentally-friendly, and the obtained active carbon has well-developed mesopores, high iodine adsorption value and high methylene blue adsorption value. The method comprises the following specific steps of: (1) smashing ramie stalks into particles of between 50 meshes and 200 meshes, carbonizing at the temperature of between 400 DEG C and 600 DEG C for 60-120 minutes, cooling to room temperature and extracting the particles out to obtain primary carbon; (2) putting the primary carbon into a soaking solution with the concentration of between 30 percent by mass and 70 percent by mass for soaking in the soaking ratio of between 1 and 4 for 12 hours, and dehydrating by using a centrifuge to obtain ramie stalk carbonized particles; and (3) putting the carbonized particles into a tubular carbonization furnace, heating to 700-900 DEG C at the temperature raising speed of between 5 DEG C per minute and 30 DEG C per minute, preserving heat for 45-120 minutes, cooling to room temperature, extracting the carbonized particles out, neutralizing with acid or alkali, cleaning with pure water until the pH value is between 6.5 and 7, and drying to obtain active carbon taking the ramie stalks as a raw material.

Owner:WUHAN TEXTILE UNIV

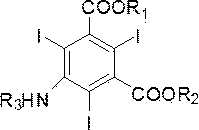

Method for recycling iodine from production waste liquid of X-CT series contrast agents

A method for recycling iodine from production waste liquid of X-CT series contrast agents comprises the following steps: firstly, converting iodine in iodinated organic compounds in organic waste liquid into inorganic iodide; secondly, concentrating, oxidizing the concentrated liquid by using a complex oxidizing agent, oxidizing the iodide anions into elementary iodine, and separating out elementary iodine by filtering; finally, extracting the residual elementary iodine from the filtrate by using an organic solvent so as to completely recycle the low-concentration elementary iodine. The iodine recycling method is applicable to treatment of iodine-containing waste liquid with diverse existing forms of iodine and high iodine content, thus solving the environment pollution problem caused by discharge of the iodine-containing waste liquid in the production process of the X-CT series iodine contrast agents and achieving the recycling of the iodine.

Owner:SICHUAN UNIV

External preparation for skin

InactiveUS20100021405A1Good formulation stabilityEffective penetrationCosmetic preparationsBiocideHigh concentrationPreparing skin

The present invention provides an external preparation for skin comprising a phospholipid having an iodine value of 80 to 110, ethanol in an amount of 55 to 83 wt % and water in an amount of 15 to 43 wt %, which is improved in it's preparation stability by suppressing an increase in an acid value of phospholipid. The present invention also provides an external preparation for skin which is improved in percutaneous absorption of medically effective ingredient(s). The present invention provides further a method for suppressing an increase in an acid value of phospholipid by comprising phospholipid having high iodine value and high concentration of ethanol and water, as well as a method for improving percutaneous absorption of medically effective ingredient(s) in external preparation for skin.

Owner:ROHTO PHARM CO LTD

Low-grade bauxite positive floatation collecting agent and preparing method thereof

InactiveCN107185723ALarge amount of solutionSolving Foam Delivery DifficultiesFlotationResource utilizationFatty acid

The invention relates to a low-grade bauxite positive floatation collecting agent. The collecting agent comprises, by weight, 5-25 parts of gutter oil treating fluid, 65-85 parts of high-iodine fatty acid, 5-8 parts of sodium hydroxide, 0.5-1 part of an MOA emulgator in a mixed preparation manner; and the gutter oil treating fluid is prepared from gutter oil, methyl alcohol or ethyl alcohol, hydroxylammonium chloride and an alkaline solution according to the weight ratio being 5:1:2:1. According to the low-grade bauxite positive floatation collecting agent, the gutter oil is made profitable; pretreatment modification is carried out on the gutter oil, the gutter oil and other agents are compounded to obtain the novel collecting agent, a series of problems such as large agent using amount, difficult foam transportation, poor beneficiation and separation indexes and high cost are solved to a large extent, efficient resource utilization, energy saving, emission reduction, cost reduction and efficiency increasing are facilitated, and the low-grade bauxite positive floatation collecting agent is of great significance in improving comprehensive competitive power of bauxite dressing plants.

Owner:平顶山市华兴浮选工程技术服务有限公司

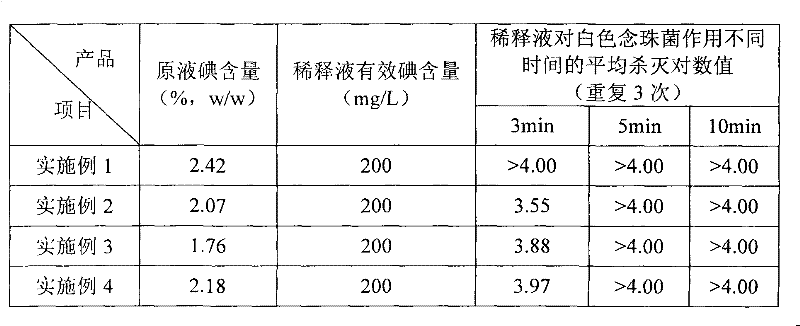

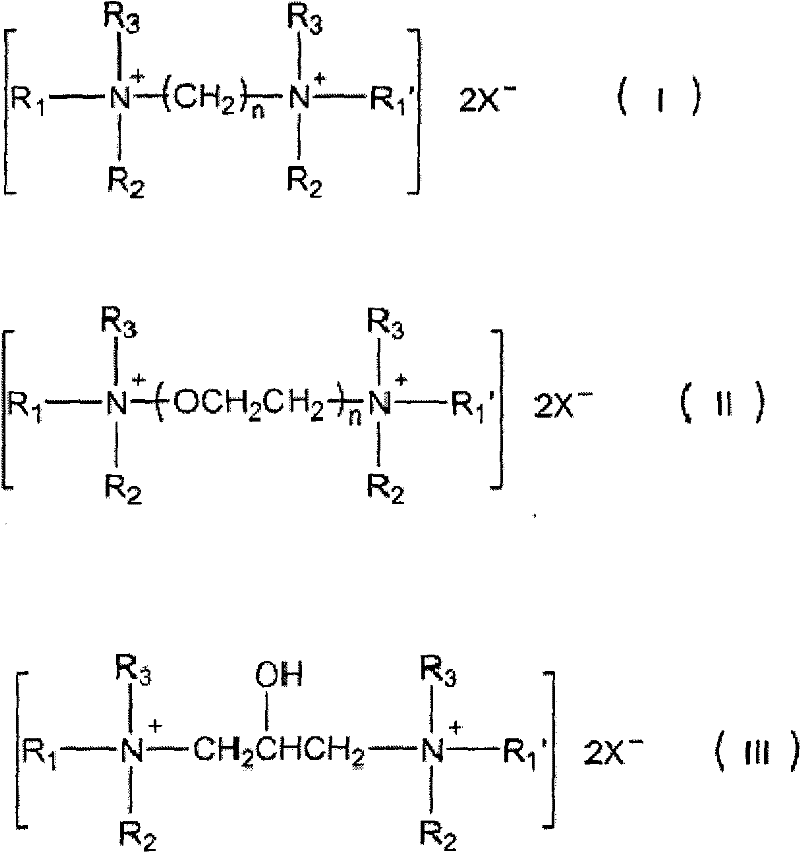

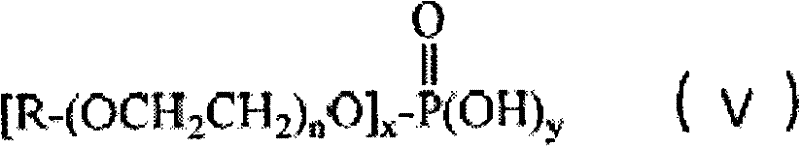

High-iodine controlled-release type sanitizer

The invention relates to a high-iodine controlled-release type sanitizer. A preparation method comprises the following steps of: reacting iodine with a complexing agent to obtain stable complex iodine; and coating the complex iodine by using micelle microcapsules formed by gemini quaternary ammonium salt to form a sterilization system which has double stable and controlled release effects on the iodine. The high-iodine controlled-release type sanitizer mainly comprises the following components: 5 to 20 percent of gemini quaternary ammonium salt, 1.6 to 8.0 percent of iodine, 10 to 30 percent of complexing agent, 2 to 16 percent of pH regulator and 30 to 80 percent of solvent. The prepared sanitizer has the advantages of high efficiency, stability, safety, no pollution, and perfect combination of quick sterilization and lasting sterilization, and can be widely applied to places required to be sterilized such as environments, water, epidemic areas, pet hospitals, poultry farming, animal husbandry, aquaculture farms and the like.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

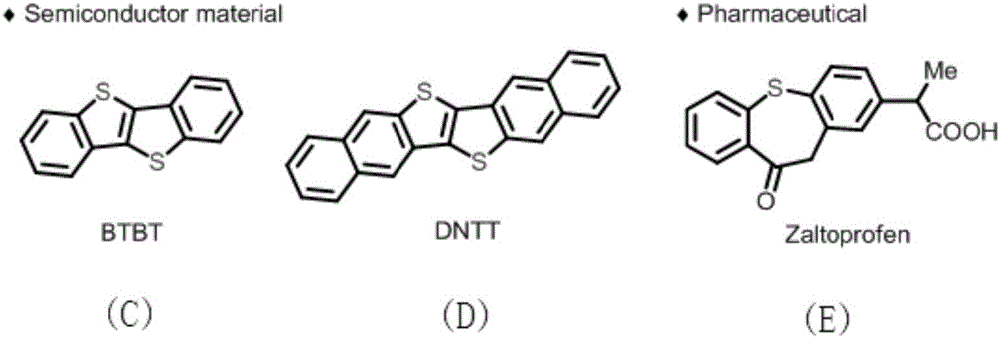

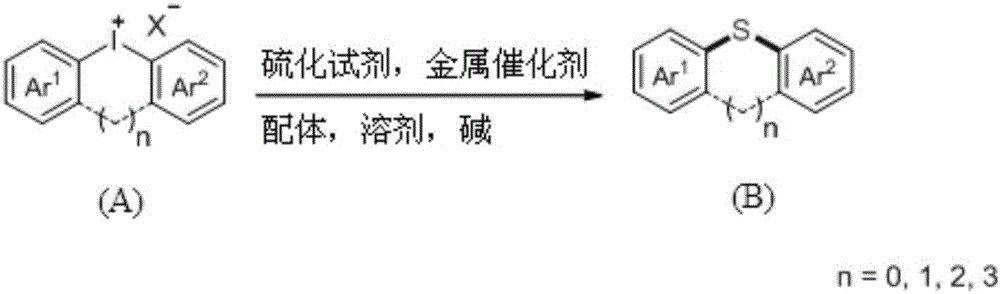

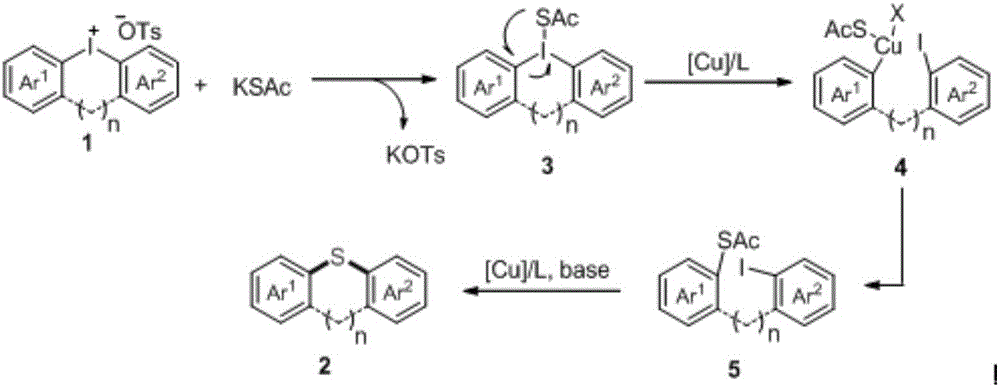

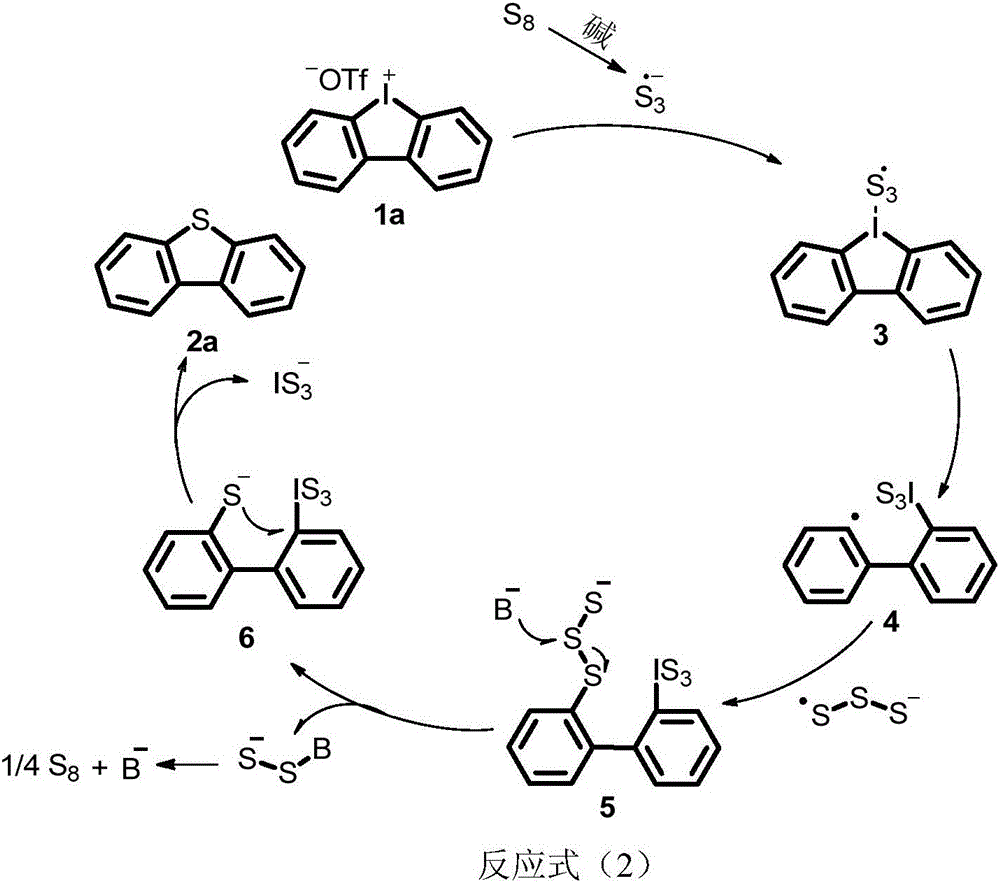

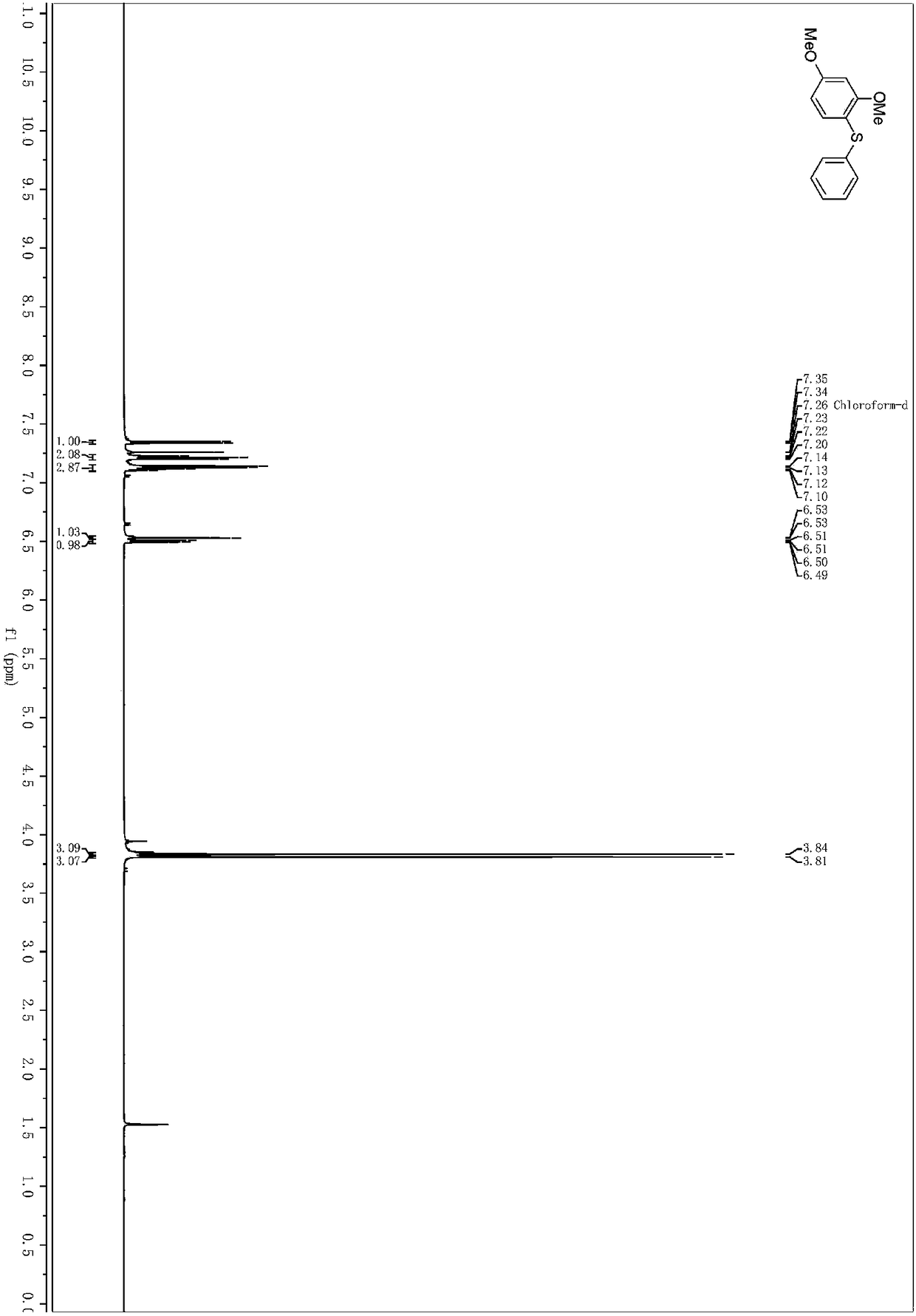

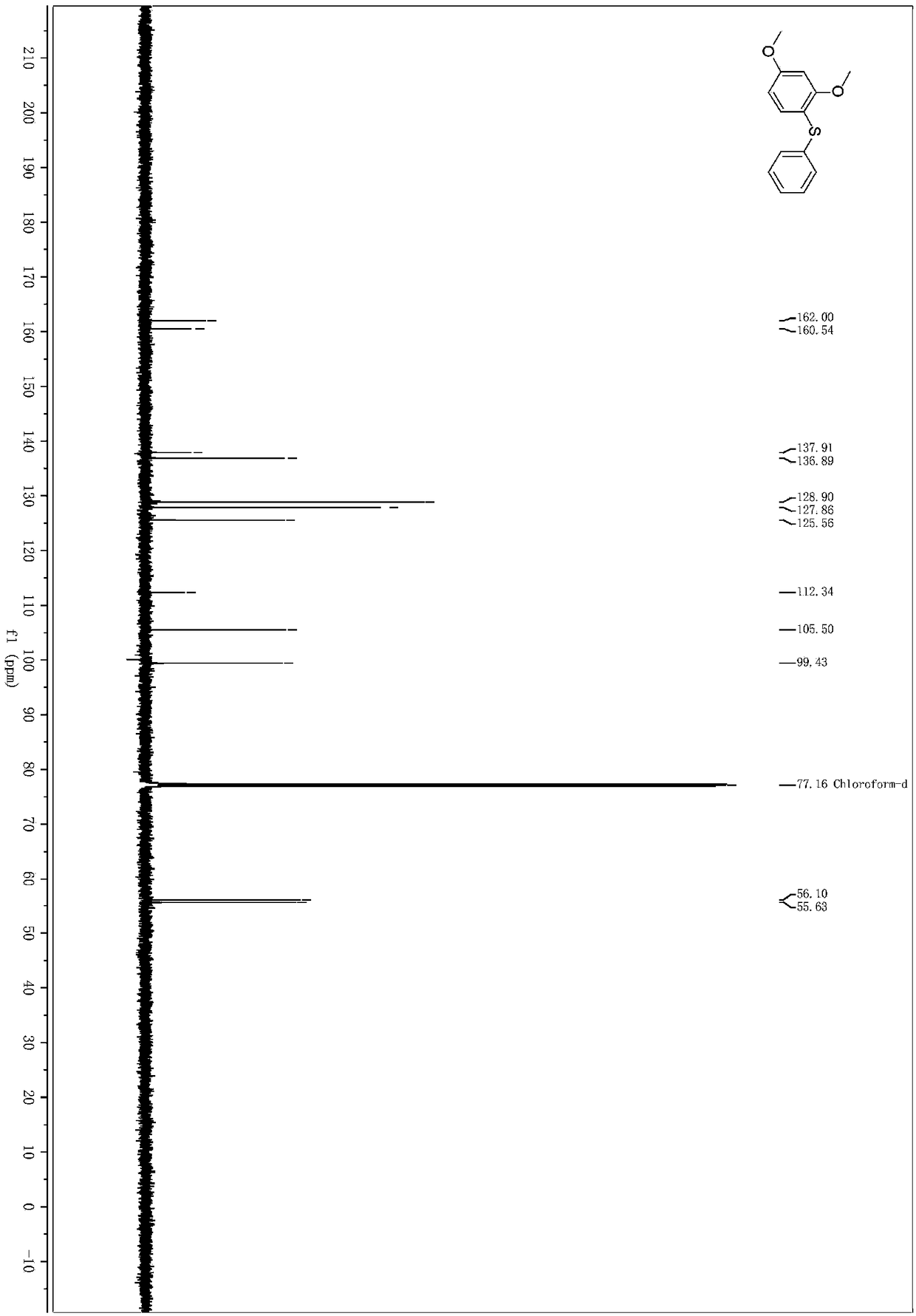

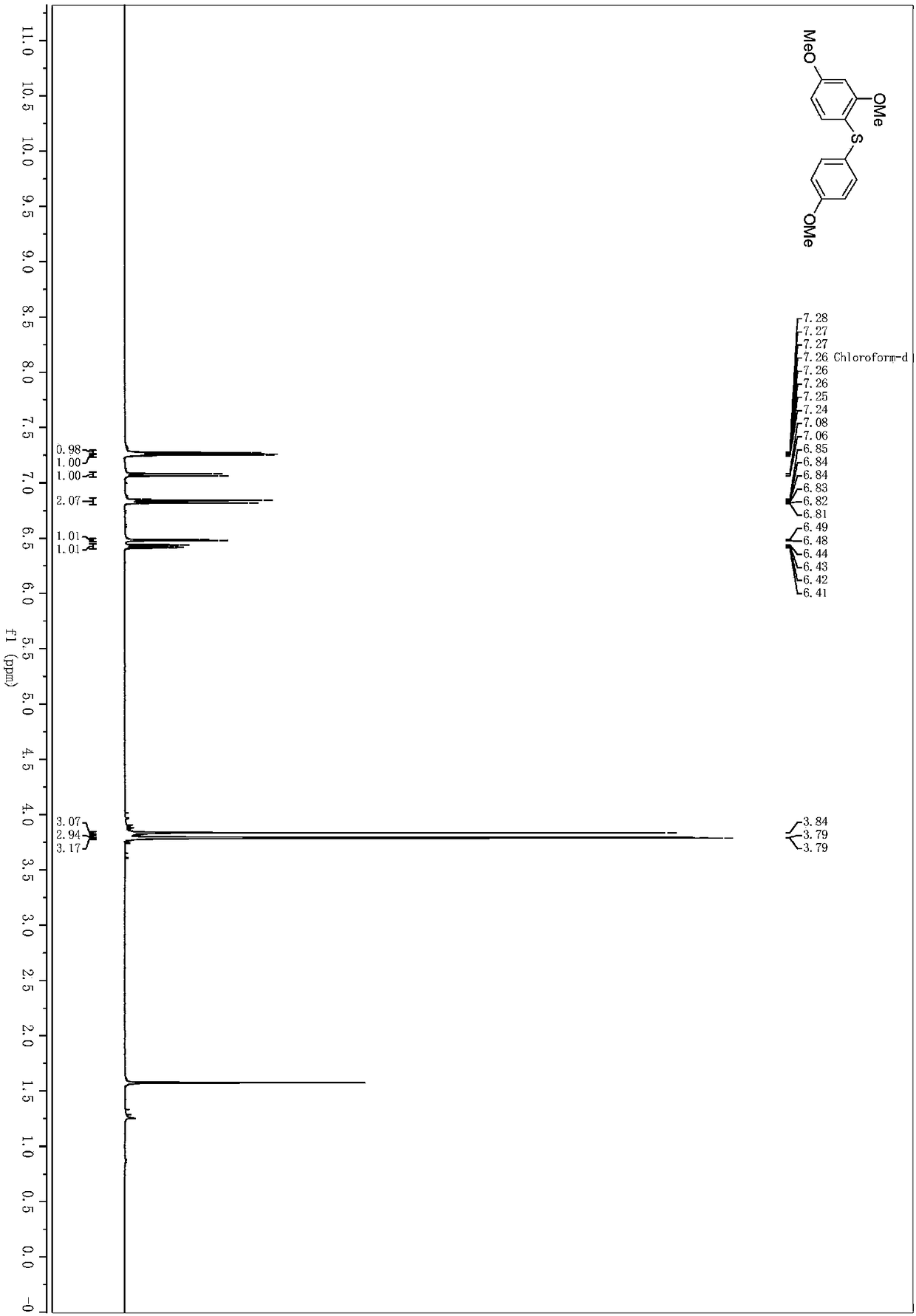

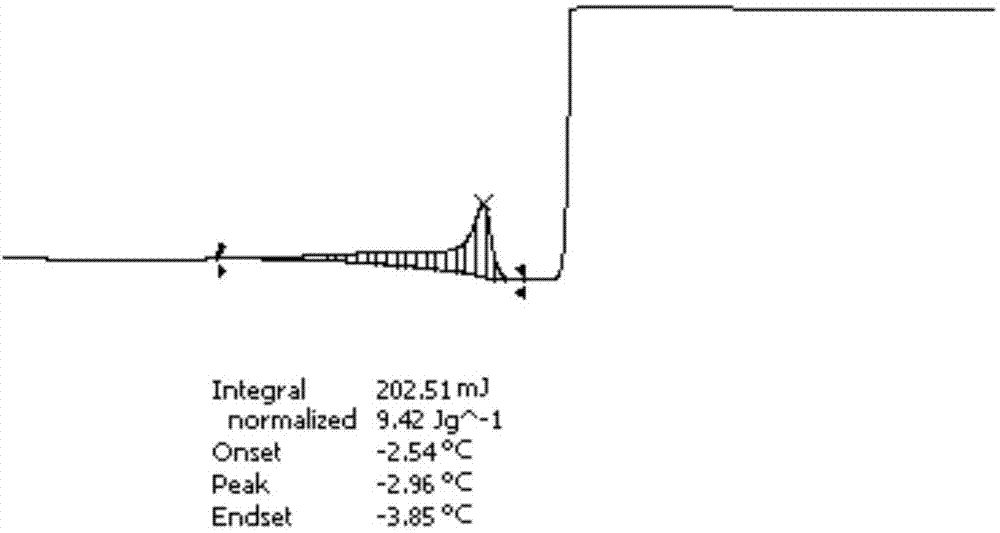

Diaryl thioether compound, and synthetic method and application thereof

The invention discloses a diaryl thioether compound, and a synthetic method and an application thereof. Various diaryl thioether compounds can be obtained through a reaction of a reaction raw material high iodine salt in dimethyl sulfoxide at 60-100DEG C under the action of an odorless sulfuration reagent, an alkali, a metal catalyst and a ligand for 3-12h. Sulfur is introduced in the later stage, so poisoning of sulfur to the metal catalyst and incompatibility of an oxidant in the early stage reaction are avoided; the above inorganic sulfur source is nontoxic and odorless; and two aryl groups in the high iodine salt are fully used, so the atom economy of the method is fully shown. The diaryl thioether compound prepared through the method can be further used to synthesize a photoelectric material BTBT and an anti-inflammatory drug zaltoprofen.

Owner:EAST CHINA NORMAL UNIV

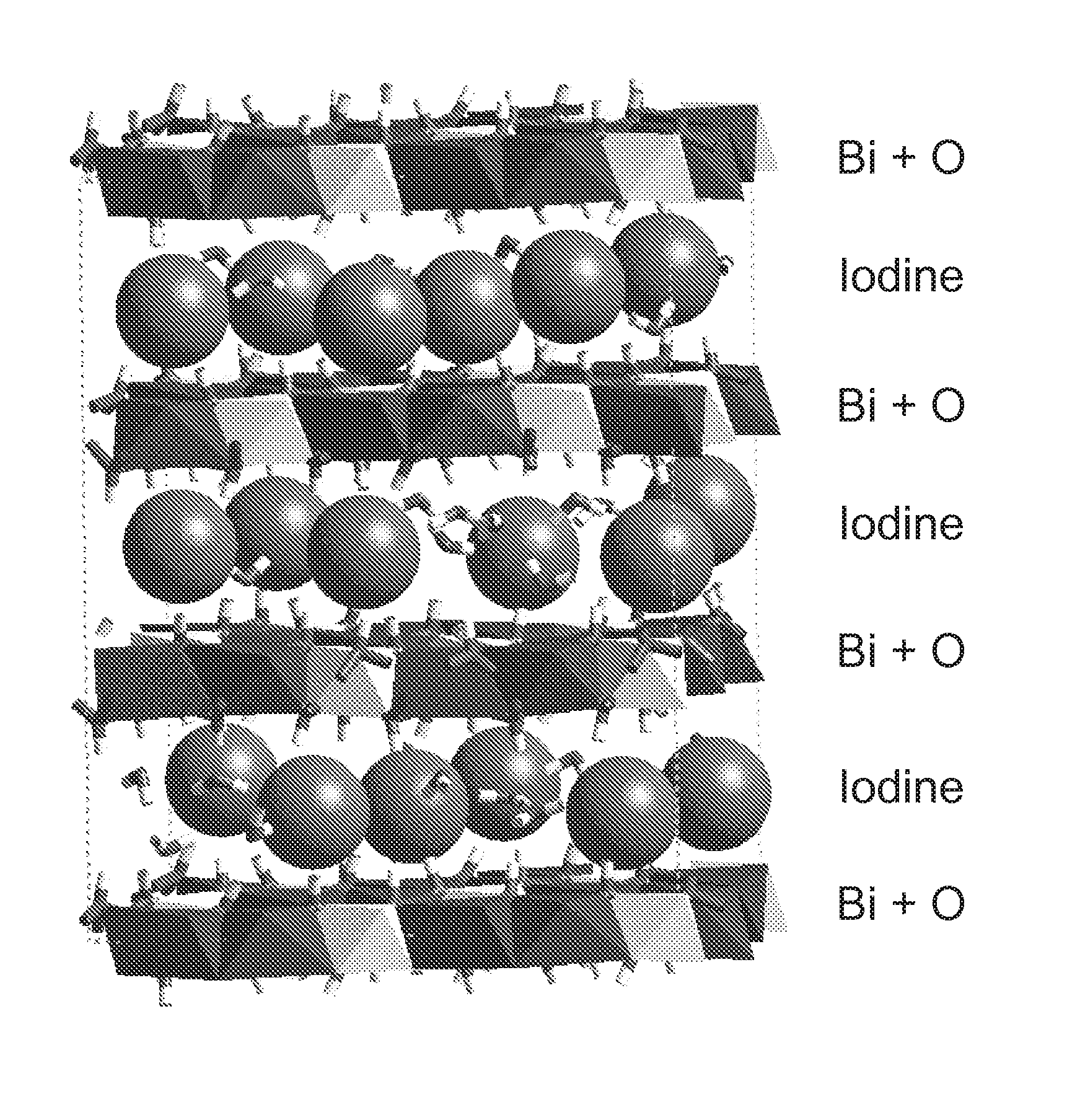

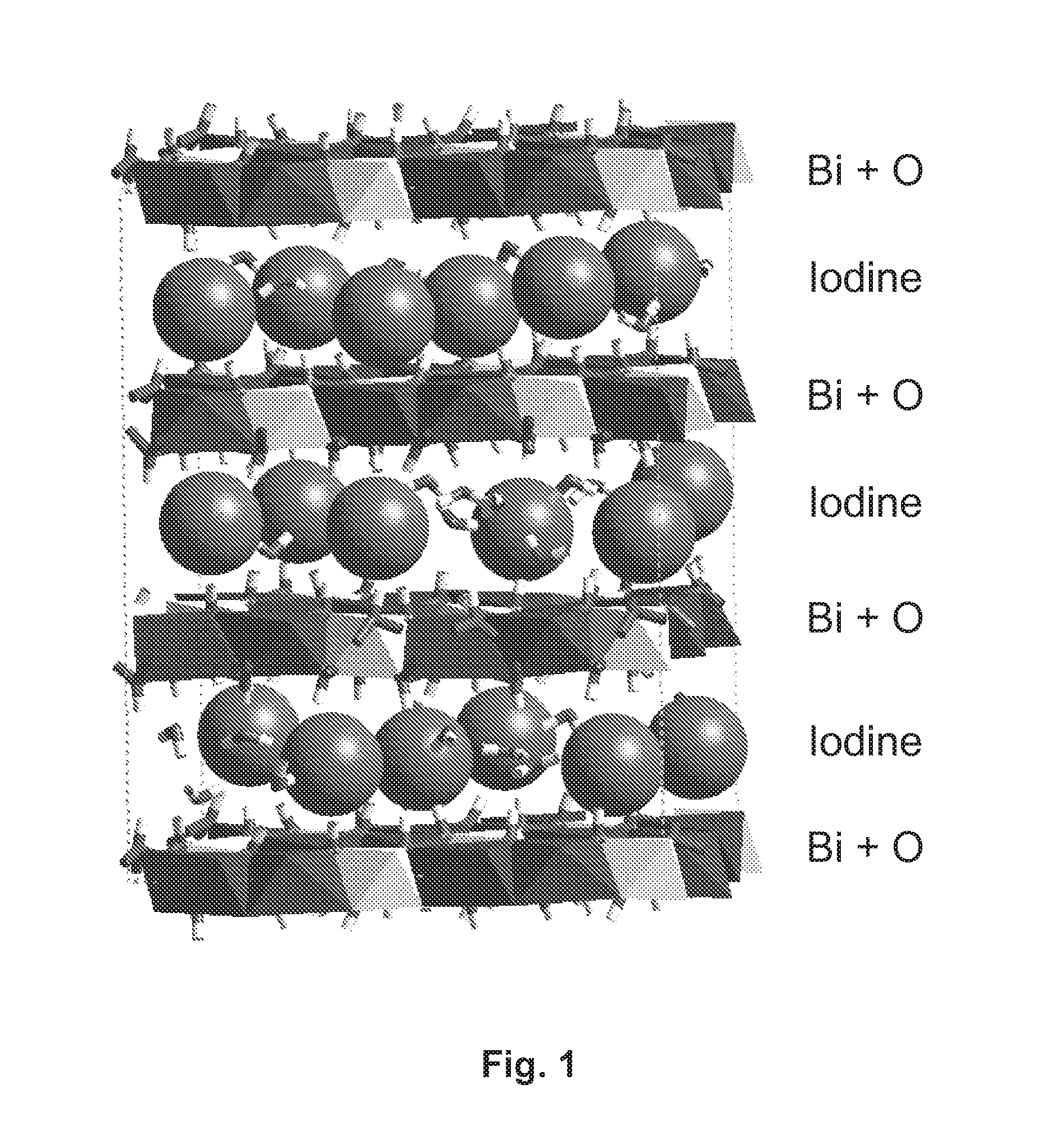

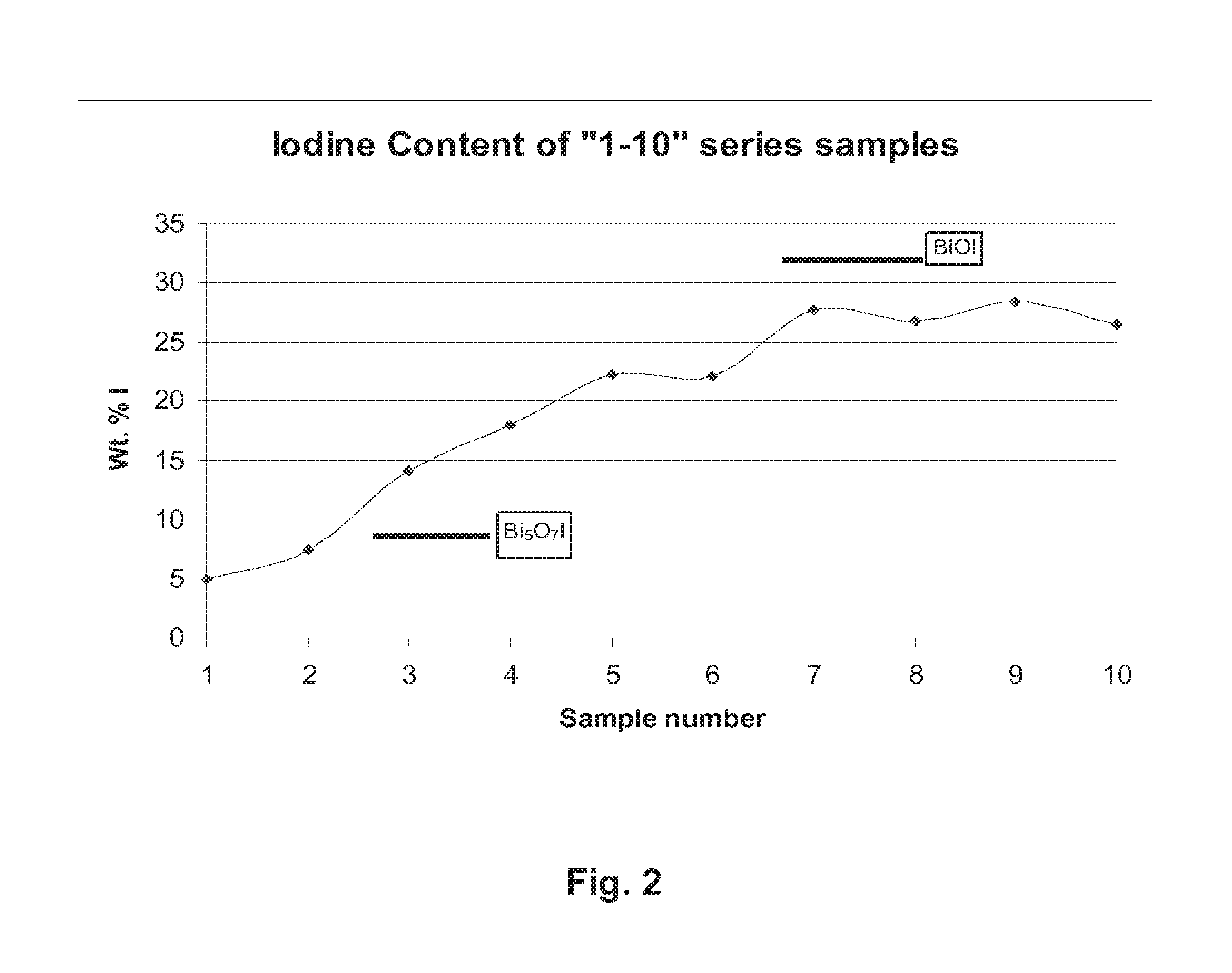

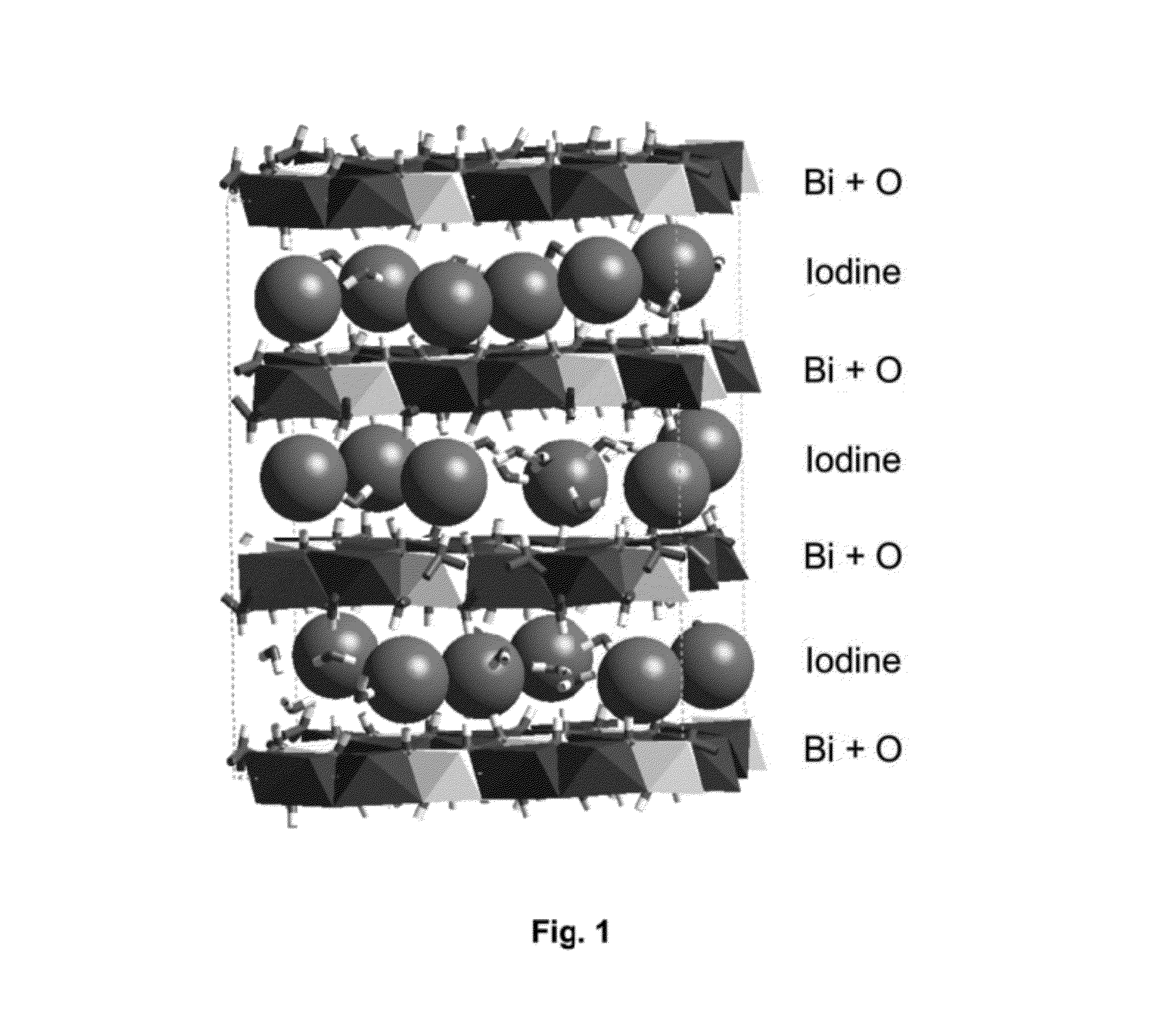

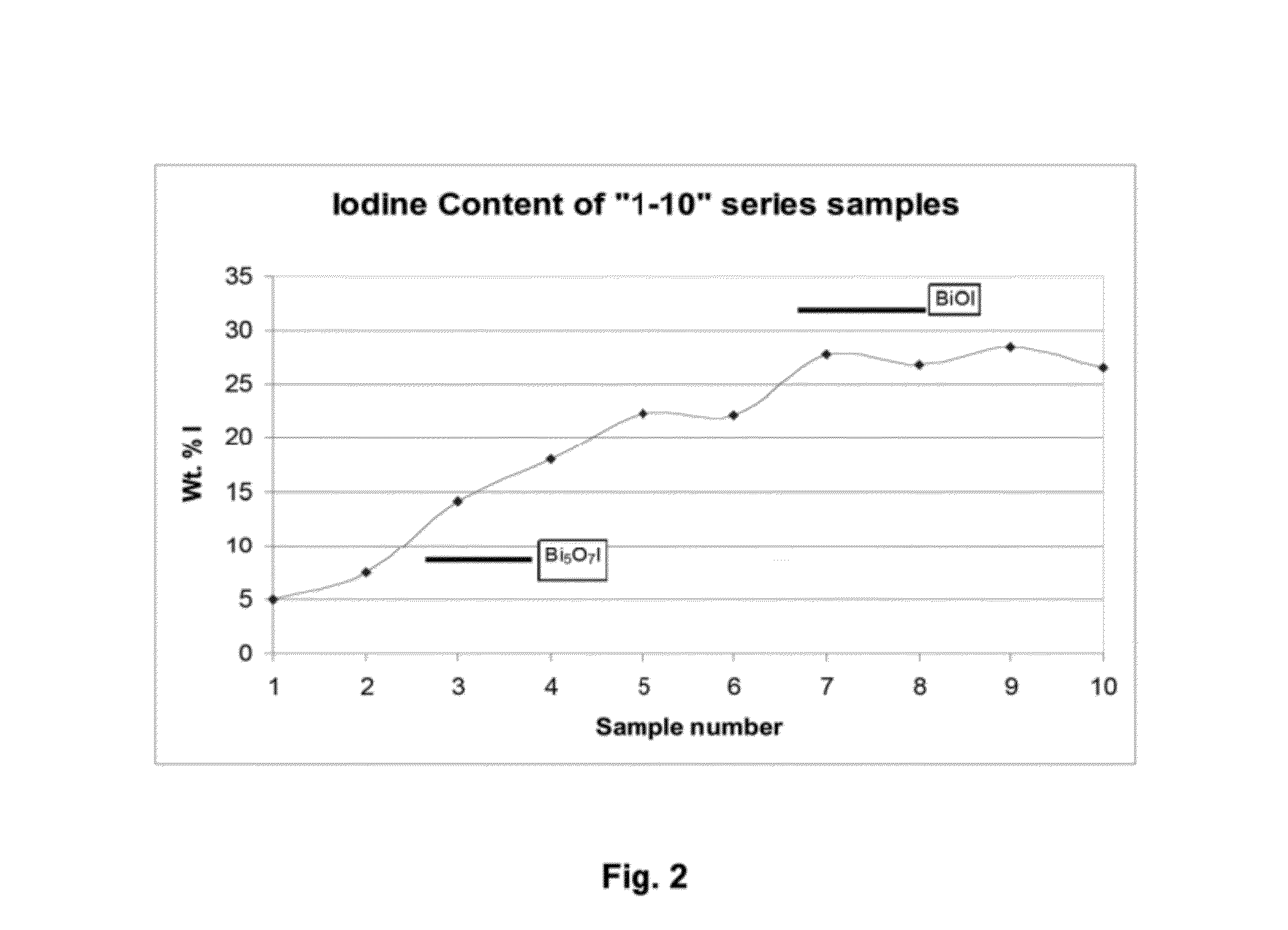

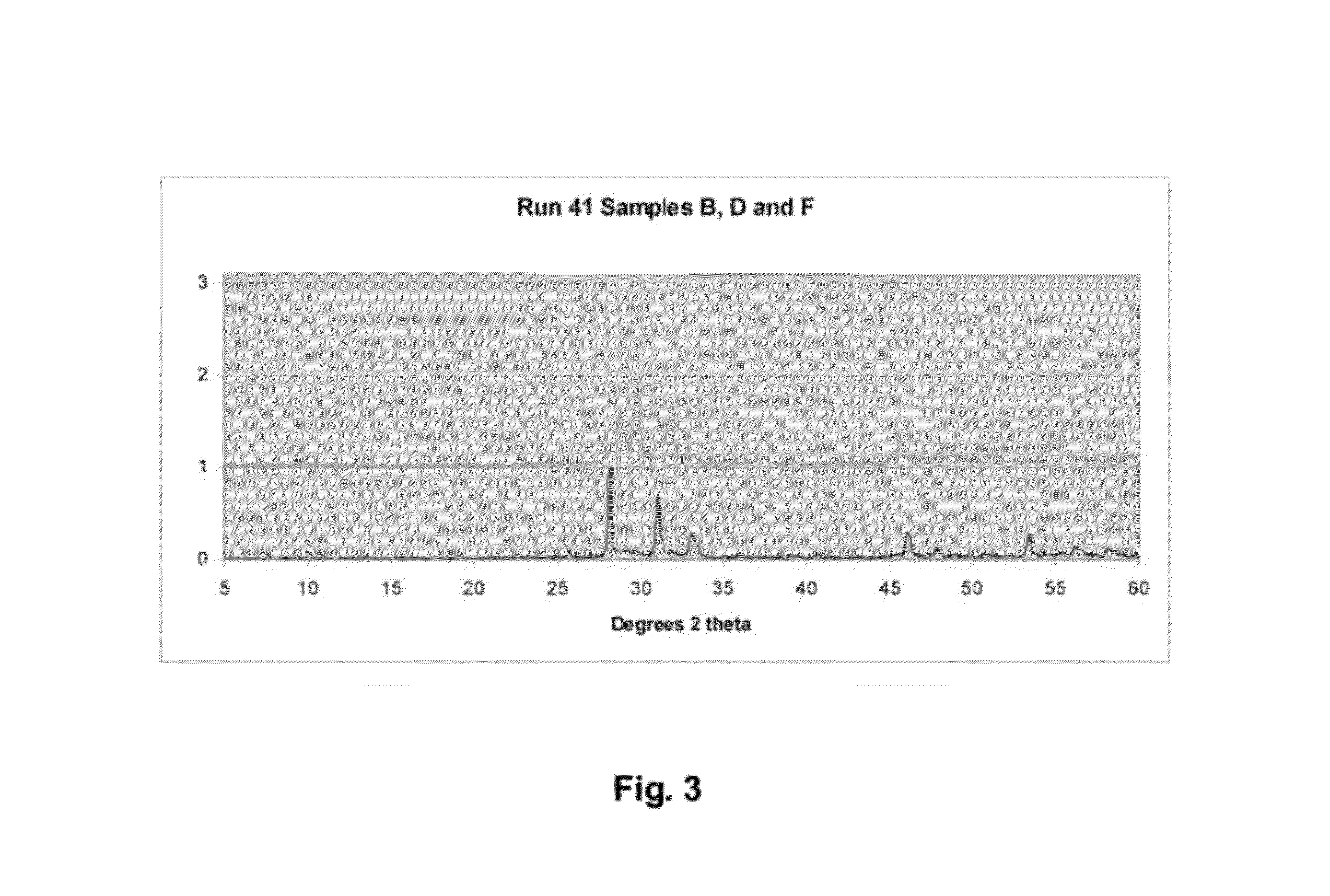

Mixed-layered bismuth-oxygen-iodine materials for capture and waste disposal of radioactive iodine

ActiveUS8383021B1Transuranic element compoundsSolid waste disposalSolubilityWaste Isolation Pilot Plant

Materials and methods of synthesizing mixed-layered bismuth oxy-iodine materials, which can be synthesized in the presence of aqueous radioactive iodine species found in caustic solutions (e.g. NaOH or KOH). This technology provides a one-step process for both iodine sequestration and storage from nuclear fuel cycles. It results in materials that will be durable for repository conditions much like those found in Waste Isolation Pilot Plant (WIPP) and estimated for Yucca Mountain (YMP). By controlled reactant concentrations, optimized compositions of these mixed-layered bismuth oxy-iodine inorganic materials are produced that have both a high iodine weight percentage and a low solubility in groundwater environments.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Method for recovering iodine in production waste liquid of X-CT series contrast media

ActiveCN101554994AAvoid wastingSolve pollutionIodineMultistage water/sewage treatmentLiquid wasteFiltration

The invention relates to a method for recovering iodine in production waste liquid of X-CT series contrast media. The method comprises the following steps: stewing and refluxing the waste liquid first to recover most of dissociated elementary substance iodine, reducing most of high hypervalent iodine into elementary substance iodine for precipitation; conducting filtration and separation, oxidizing the filtrate to oxidize most of iodine negative ions into elementary substance iodine for precipitation, conducting filtration and separation; and finally conducting active carbon absorption and sublimation and crystallization on filtrate to recover the low-concentration dissociated elementary substance iodine completely. The method for recovering iodine is suitable for treating the iodine-containing waste liquid that has strong acidity, high iodine content and multiple existing forms of iodine, and not only solves the problem that the discharge of iodine-containing waste liquid pollutes environment in the production process of X-CT series contrast media, but also realizes the recovery of iodine as well as the cyclic utilization of production waste liquid.

Owner:山西新天源药业有限公司

Compound feed for producing health-care eggs with high iodine and low cholesterol

The invention relates to a compound feed for producing health-care eggs with high iodine and low cholesterol. The compound feed is characterized by comprising the following components in percentage by weight in a formula: 63.65 percent of corn, 19.52 percent of soybean meal, 2 percent of fish meal, 4 percent of algae powder, 8.15 percent of stone powder, 1.62 percent of calcium hydrogen phosphate, 0.06 percent of methionine and 1 percent of premixed feed. A production method for the algae powder comprises the following steps of: cleaning algae by using seawater to remove sand and impurity, naturally airing or drying the algae, and crushing the algae into 30 to 40 meshes by a crusher. The compound feed broadens the utilization path of the natural wild algae powder, changes waste into valuable and reduces the production cost by using the algae powder taking enteromorpha as a main body and conventional feed raw materials. The compound feed does not contain antibiotic and other medicinal feed additives, can obviously improve the egg laying performance of chickens and the feed utilization rate, and also can produce the health-care eggs with main characteristics of high iodine and low cholesterol.

Owner:QINGDAO AGRI UNIV

Cultivation method for comprehensively preventing peanut disease and pest injury and continuous cropping obstacles

InactiveCN104813874AThe cultivation method is simpleSave manpower and material resourcesPlant protectionHigh resistanceContinuous cropping

The invention discloses a cultivation method for comprehensively preventing peanut disease and pest injury and continuous cropping obstacles, and belongs to the technical field of peanut high-yield high-efficiency cultivation. The cultivation method mainly includes the cultivation steps: selecting high-resistance varieties; applying organic manure, carbon-based special slow-released fertilizers for peanuts and agricultural microbiological bactericides; dressing seeds by 50% of ethylicin, 40% of rogor emulsifying oil, 50% of phoxim and 0.4% of ammonium molybdate; spraying 50% of thiophanate methyl turbid liquid, 75% of chlorothalonil, 3.6% of acetic acid and high iodine, 10% of quizalofop-p-ethyl cream, 10.8% of high-efficiency haloxyfop-methyl cream and 70% of Seoul cream after seeding and earthing. By the method, peanut disease and pest injury and the continuous cropping obstacles can be prevented once in the cultivation process of the peanuts, the cultivation method is simple, manpower and material resources are saved, and economic and social benefits are remarkable.

Owner:JILIN ACAD OF AGRI SCI

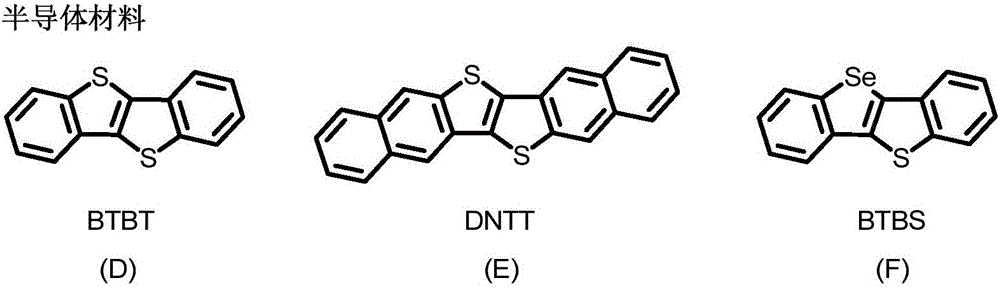

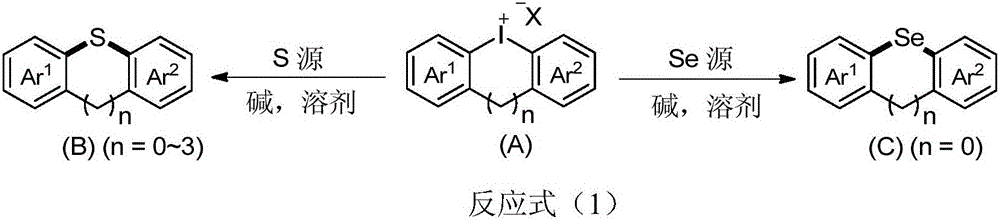

Diaryl ring fused sulfides and diaryl ring fused selenides, and synthesis method and application thereof

ActiveCN106397397AWide applicabilityRaw materials are cheap and easy to getOrganic chemistryLuminescent compositionsSynthesis methodsSulfide

The invention discloses a synthesis method of diaryl ring fused sulfides represented by formula (B) and diaryl ring fused selenides represented by formula (C). The method is characterized in that a reaction of a reaction raw material high-iodine salt is carried out in dimethyl sulfoxide under the action of an inorganic sulfuration reagent or selenylation reagent and an alkali at 60-100 DEG C to obtain the diaryl ring fused sulfides and the diaryl ring fused selenides. Sulfur or selenium is introduced in the later stage in the presence of a nonmetal catalyst, so poisoning of sulfur to a metal catalyst in the early stage reaction is avoided; the above inorganic sulfur source is nontoxic and odorless; and two aryl groups in the high-iodine salt are fully used, so the atom economy and the greenness of the method are fully shown. The diaryl ring fused sulfides and the diaryl ring fused selenides prepared through the method can be applied to synthesize photoelectric materials BTBT and BTBS.

Owner:EAST CHINA NORMAL UNIV

Radiation-proof plant fermentation beverage and manufacturing method

The invention discloses a radiation-proof plant fermentation beverage and a manufacturing method applied in the technical field of food. The formula of the beverage consists of algae, grape skin and seeds, concentrated black tea juice, blueberry, edible alcohol, high fructose syrup, xylitol, honey and water. The manufacturing method produces the beverage with radiation-proof function and special application by extracting the algae, the grape skin and seeds, the concentrated black tea juice and the blueberry juice through alcohol and implementing acetic acid fermentation. The manufacturing method comprises the following steps of: soaking and cleaning the algae by using warm water to remove impurities such as sand and the like and salt, and preparing algae size for later use; mixing the grape skin and seeds, the concentrated black tea juice and the blueberry juice in the algae size, adding the edible alcohol, and performing normal temperature extraction; inoculating acetic acid bacteria to the regulated solution, and performing deodorization, curing and precipitation treatment; and filtering the fermented solution, adding a proper amount of the high fructose syrup, the xylitol, the honey and the water to prepare the radiation-proof plant fermentation beverage, and filling the beverage. The beverage has very high iodine supplementing efficiency and safety, is rich in proanthocyanidin and tea polyphenol, is easily absorbed by the human body, and can relieve the social problem caused by nuclear radiation after being frequently drunk.

Owner:沈阳麦金利食品制造有限公司

Kelp dumplings and its making method

The kelp dumplings are made with stuffing comprising kelp as basic material, pork, peanut oil, turnip, bean curd, Chinese chive or other vegetable as supplementary material, and seasonings mixed together and wrapper to coat the stuffing. Its making process includes shredding kelp, slicing pork into paste, shredding turnip, cutting bean curd into dices, cutting Chinese chive or other vegetable, mixing while adding salt, gourmet, pungent and scenting material, etc. to obtain stuffing, wrapping and other steps. It has high iodine content, bright color and delicious taste.

Owner:纪仁忠

Non-ionic N-vinyl butyrate lactam iodine, high-stability non-ionic N-vinyl butyrate lactam iodine and relevant overspeed preparation method

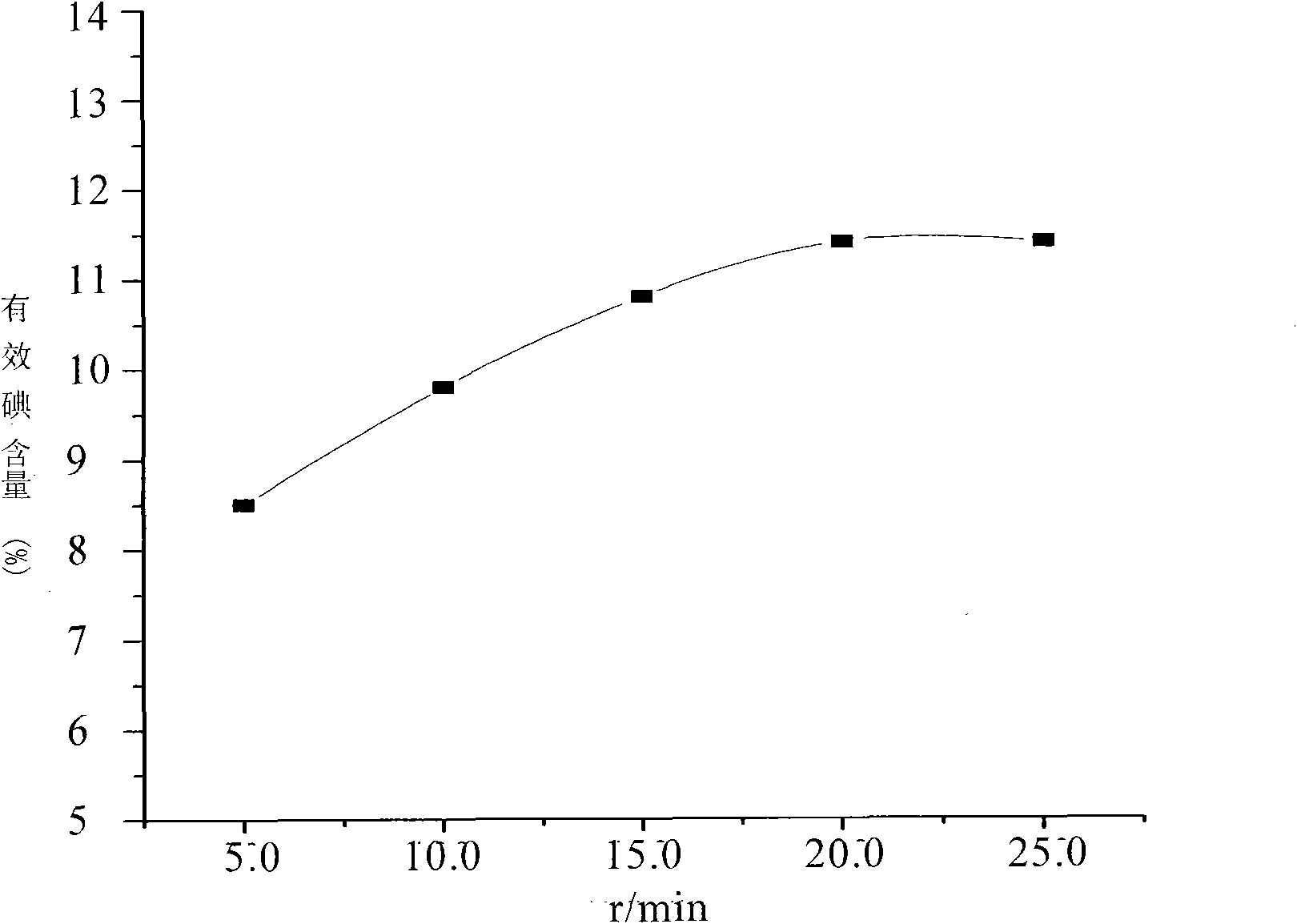

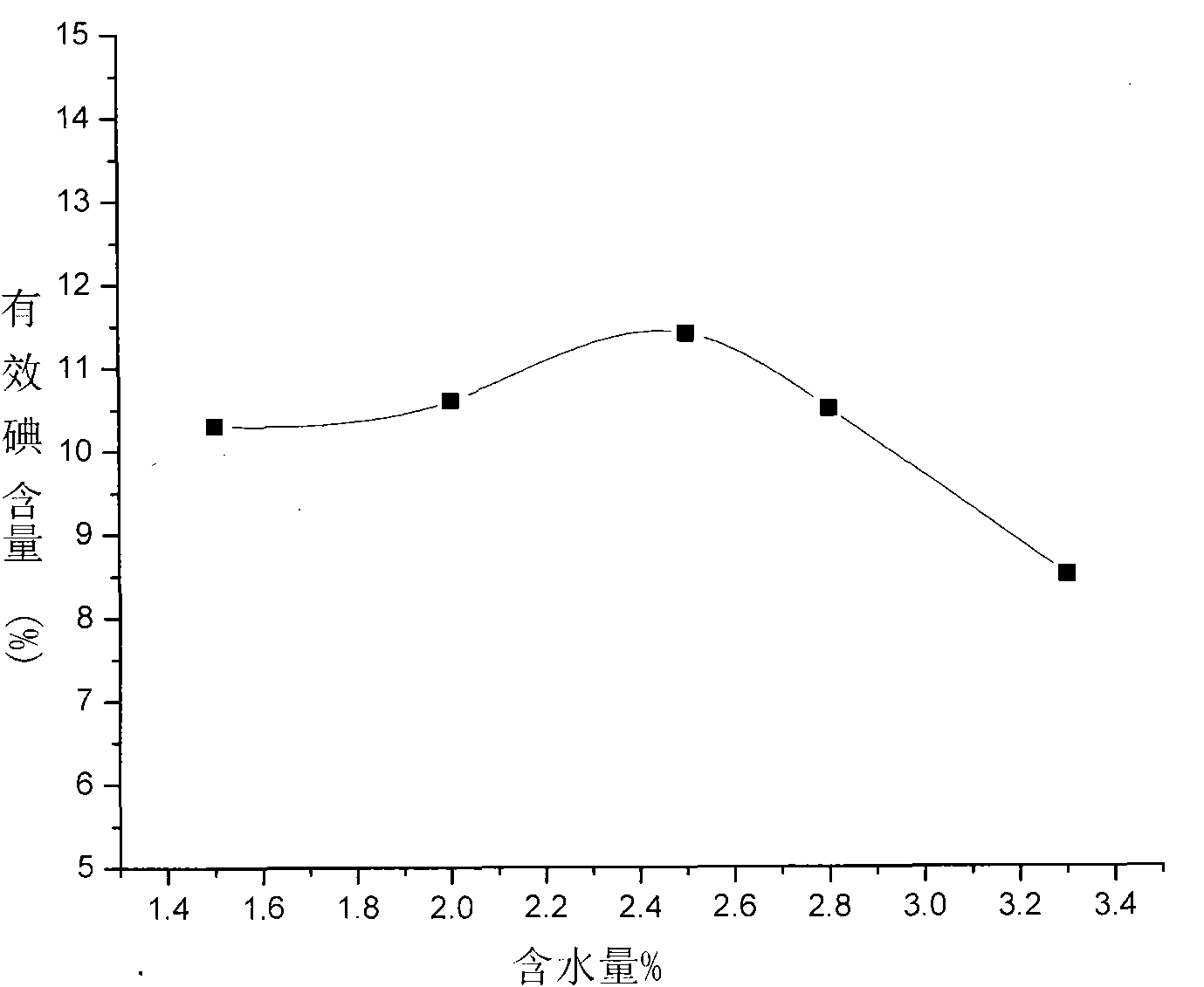

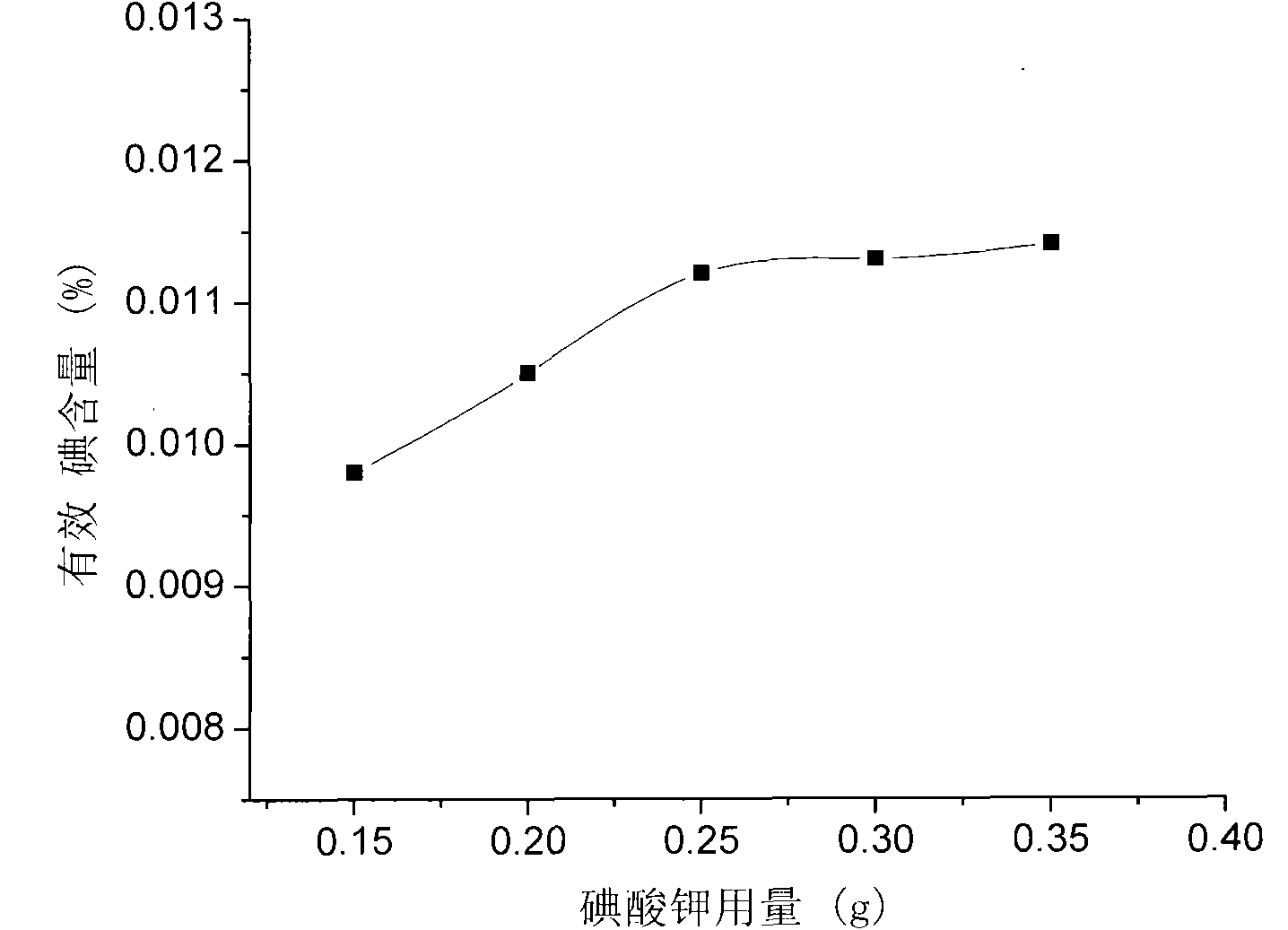

The invention provides a preparation method of non-ionic N-vinyl butyrate lactam iodine. The non-ionic N-vinyl butyrate lactam iodine is prepared by stirring homopolymerized N-vinyl butyrate lactam and iodine for 20 to 25 minutes at the temperature of 60 to 70 DEG C and the speed of 200 to 250r / min, wherein the viscosity-average molecular weight of the homopolymerized N-vinyl butyrate lactam is 40000 to 45000, and the PD value is smaller than 5.5; and the water content is 2.0 to 3.0 percent. The invention also provides non-ionic N-vinyl butyrate lactam iodine prepared in such a way, a method for preparing high-stability non-ionic N-vinyl butyrate lactam iodine in such a way and the relevant high-stability non-ionic N-vinyl butyrate lactam iodine. The non-ionic N-vinyl butyrate lactam iodine has high iodine content, simple, convenient and quick preparation and low cost, and the high-stability non-ionic N-vinyl butyrate lactam iodine has high stability and convenient use, meets the highest requirements of the relevant dispensatories of USP, ISP, BP, EP, CP and the like completely and is suitable for large-scale popularization and application.

Owner:宇昂科技有限公司

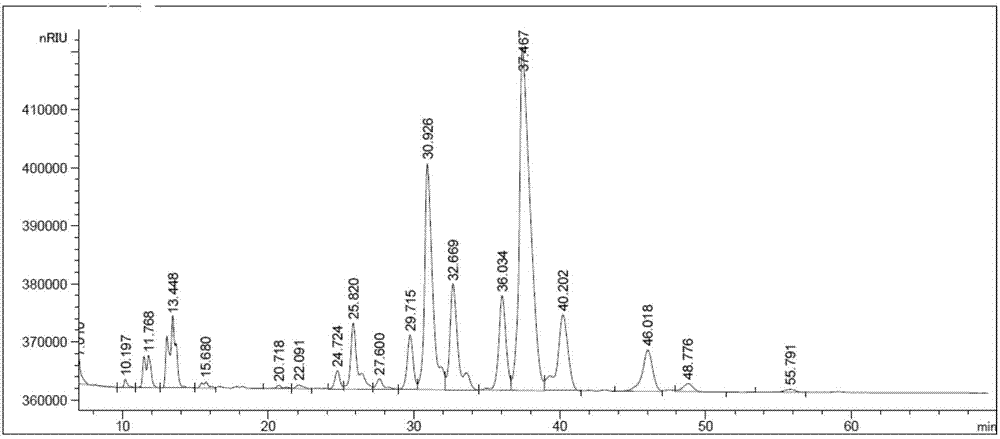

Preparation method and products of water phase thioether compound

InactiveCN108341760AEliminate problems such as residueImprove affordabilitySulfide preparationSolventBottle

The invention discloses a preparation method and products of a water phase thioether compound. The preparation method comprises following steps: ferric trichloride or zinc chloride are introduced intoa 4mL reaction bottle, an aryl compound and a water phase system containing 2wt.% surfactant TPGS-750-M are added at the same time, diallyl sulfide is added, stirring is carried out at a rotating speed of 500 to 1000rpm, 1min later, high iodine compound PIFA is added gradually, an obtained mixture is heated, and is stirred for 24 to 36h, ethyl acetate is adopted for extraction, rotary evaporationcondensation is carried out, and then silica gel column chromatography separation is adopted so as to obtain a product. The preparation method is capable of generating new C-S bonds from the simple aryl compound and the diallyl sulfide compound, low-toxicity high iodine salt reagent is adopted for catalysis, no metal catalyst or organic solvent system is needed, metal and solvent residue problemsare solved, operation is simple, yield is high, purity is 98% or higher, conditions are mild, substance range is wide, and the irritating odor of conventional thioether compound synthesis raw materials (thiophenol and mercaptan) is avoided.

Owner:NANJING FORESTRY UNIV

Zinc supplementing edible salt

InactiveCN106616846APromote absorptionImprove absorption rateFood ingredient as flavour affecting agentNatural extract food ingredientsBlood vesselAmino acid

The invention mainly relates to the field of food processing, and discloses zinc supplementing edible salt. The zinc supplementing edible salt is prepared from the following raw materials in parts by weight: iodine-free table salt, peanuts, eggs, Angel saccharomyces cerevisiae, acetic acid bacteria, complex enzymes, papain, zinc sulfate and a purslane herb extract. The zinc supplementing edible salt provided by the invention is balanced in nutrients and rich in amino acids, vitamins and organic zinc, and can protect heart and cerebral vessels, promote growth and development, enhance immunity and delay senescence; the used main raw material is the iodine-free table salt, so that the iodine content in finished products is reduced, and the production of high-iodine symptoms is avoided; and the zinc supplementing edible salt is convenient to eat, the sale volume of the zinc supplementing edible salt is increased by 11.6%, the economic benefits are increased by 10.2%, and the zinc absorptivity of the zinc supplementing edible salt disclosed by the invention is increased by 35.6% compared with that of zinc supplementing edible salt sold in the market.

Owner:ANHUI WEIXIAN FOOD

Method for preparing low-temperature-resistant palm oil with high iodine value

The invention relates to a method for preparing low-temperature-resistant palm oil with high iodine value. The method comprises the following steps: (1) heating palm oil with iodine value higher than 60 at a temperature of 60-80 DEG C while stirring to completely dissolve the palm oil, then, cooling to minus 10 to 0 DEG C, and maintaining the temperature; heating up to 3-6 DEG C and maintaining the temperature; cooling to 4-8 DEG C and maintaining the temperature; and (2) transferring the palm oil obtained in the step (1) into separation equipment, centrifugally separating the palm oil at minus 15 to minus 5 DEG C until the grease is divided into a solid phase and a liquid phase, and extracting the liquid phase to obtain a palm oil product. The method for preparing low-temperature-resistant palm oil with high iodine value provided by the invention can be used for obtaining low-temperature-resistant palm oil product with iodine value higher than 75. Since such novel substances as a crystallization inhibitor, a crystallization solvent and the like are not introduced into the method provided by the invention, the separation efficiency and the separation effect are improved and the operation time of the process is greatly shortened; and no wastewater is generated in the process, the safety is good, the energy consumption in the process is low and the quality of the final product is good, so that the application prospect is wide.

Owner:TIANJIN UNIV

Iodine reducing laminar material and method for processing iodine-enrichment water

InactiveCN1768960AIodine reduction effect is goodInorganic anion exchangersWater/sewage treatment by ion-exchangeMaterials scienceSodium hydroxide

Owner:BEIJING UNIV OF CHEM TECH

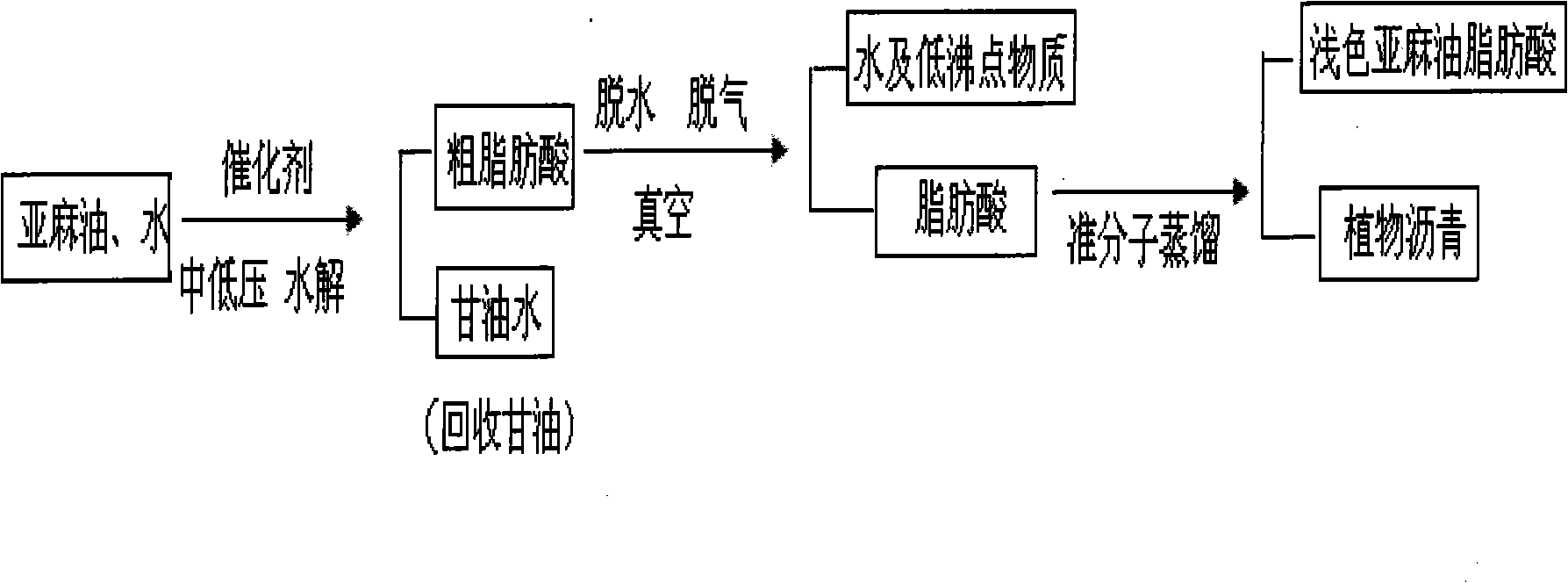

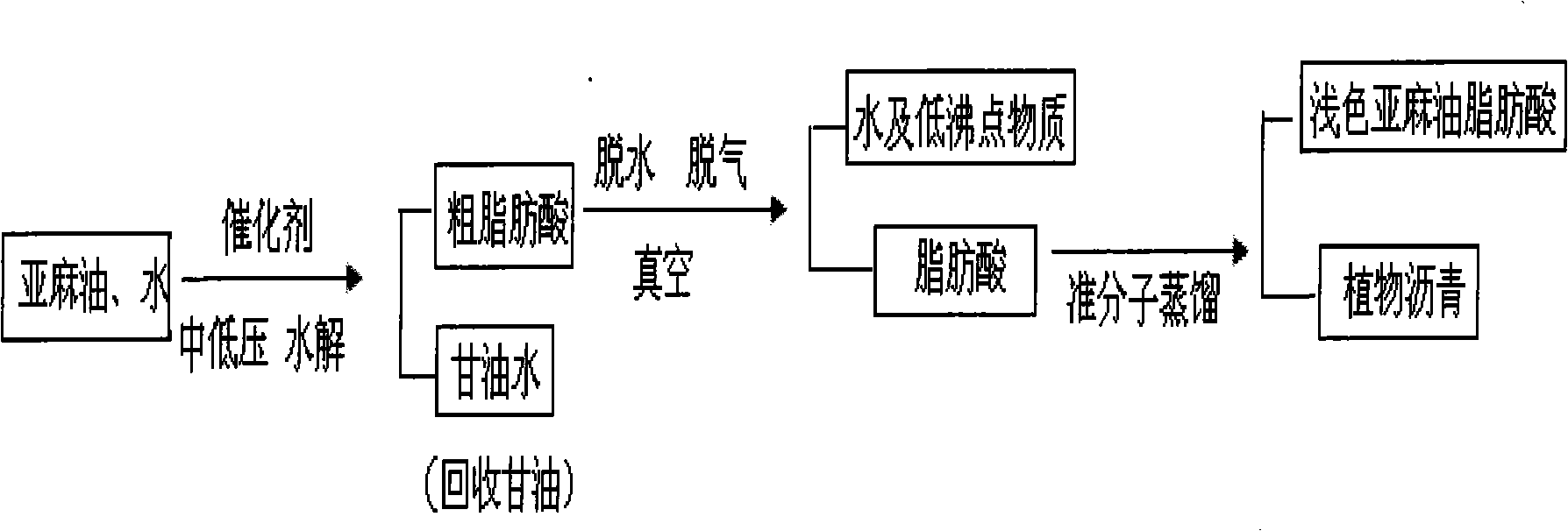

Method for preparing linseed oil fatty acid with light color

InactiveCN101831356AIodine value has no effectNo thermal polymerizationFatty acids production/refiningPollutant emissionsLinseed oil

The invention relates to a method for preparing linseed oil fatty acid with a light color, which adopts a production process of low-medium pressure catalytic hydrolysis and linseed oil fatty acid flash evaporation decoloration to produce the linseed oil fatty acid with the light color. The fatty acid prepared by the method has a light color and high iodine value; and the method is low in process cost, free from pollutant discharge and adopts an environmentally-friendly process.

Owner:安徽省瑞芬得油脂深加工有限公司

Preparation method of activated carbon for cigarette, activated carbon for cigarette and application

The invention discloses a preparation method of an activated carbon for cigarettes and a product of the activated carbon for cigarettes and an application. According to the method, a jute rod is used as a raw material, the jute rod is carbonized and then pulverized into granules, under water vapor with flow rate of 450-480 g / h, after activation for 1-3 hours at 800-900 DEG C, the activated carbon for cigarettes is obtained after discharging, sealing and cooling. As the result shows, the activation rate of the activated carbon for the cigarettes obtained by the method can reach 47%, specific surface area is 996.38 m<2> / g, strength is 92.7f%, apparent density is 0.32g / Ml, ash content is 4.31, and water content is 5.12%, pH value is 7.67, which all reach or exceed national tobacco industry standard for the activated carbon for cigarettes; besides, the activated carbon has high iodine adsorption value (1184mg / g), methylene blue adsorption value (195.88 mg / g) and phenol adsorption value (202.04mg / g), and excellent pore structure, and is especially beneficial for removal of harmful gases in small molecules of the cigarettes.

Owner:CHINA TOBACCO GUANGDONG IND

Marine vegetarian paste and preparation method thereof

The invention relates to the technical field of vegetarian meat food, in particular to a seafood vegetarian meat sauce and a preparation method thereof. Sugar, soy sauce, salt, monosodium glutamate seasoning, adding chitosan antioxidant, through a series of processes to make seafood vegetarian meat sauce with both nutrition and delicious effects; the beneficial effects of the invention are: health care, seafood taste; rich nutrition, strips Seaweed contains high iodine content, which can be used to treat "goiter" caused by iodine deficiency. Seaweed has the function of softening and resolving hard masses; it has dual functions of supplementing nutrition and health care; adding pure natural antioxidants makes eating more at ease; not only can It maintains a taste no less than that of fresh products, and has a long shelf life.

Owner:FOSHAN JUCHENG BIOCHEM TECH RES & DEV CO LTD

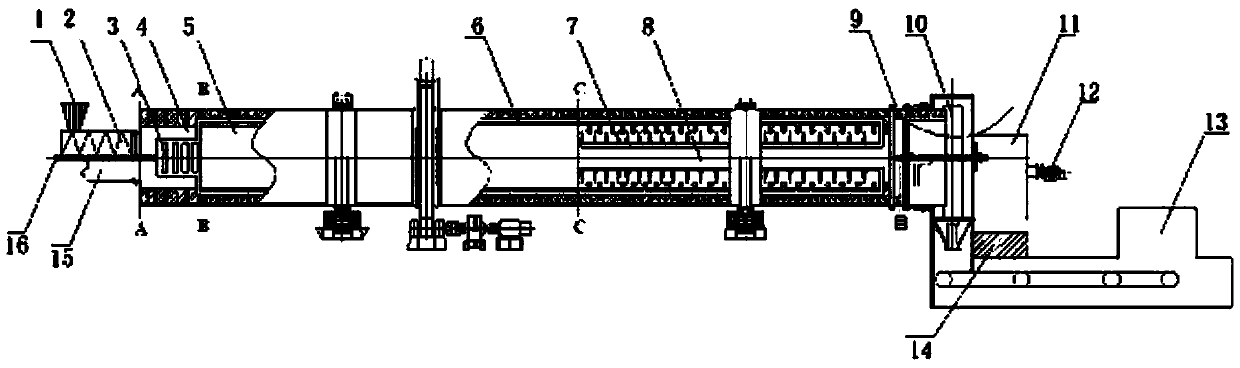

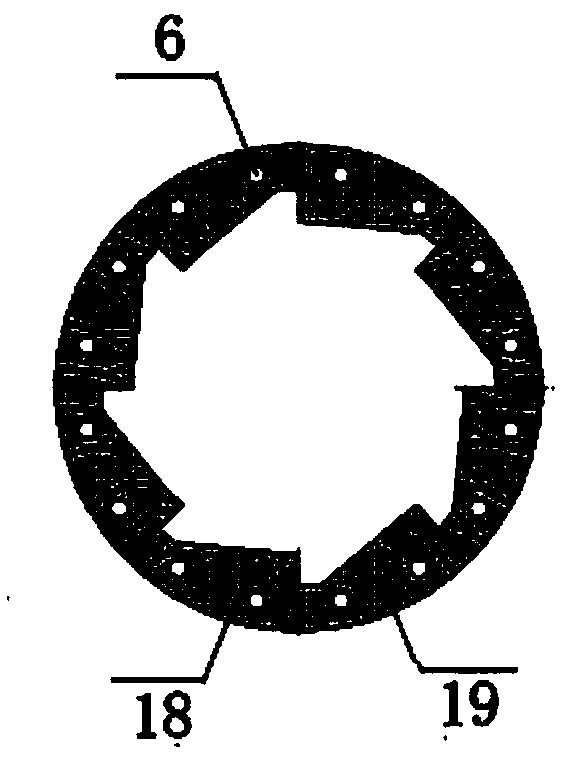

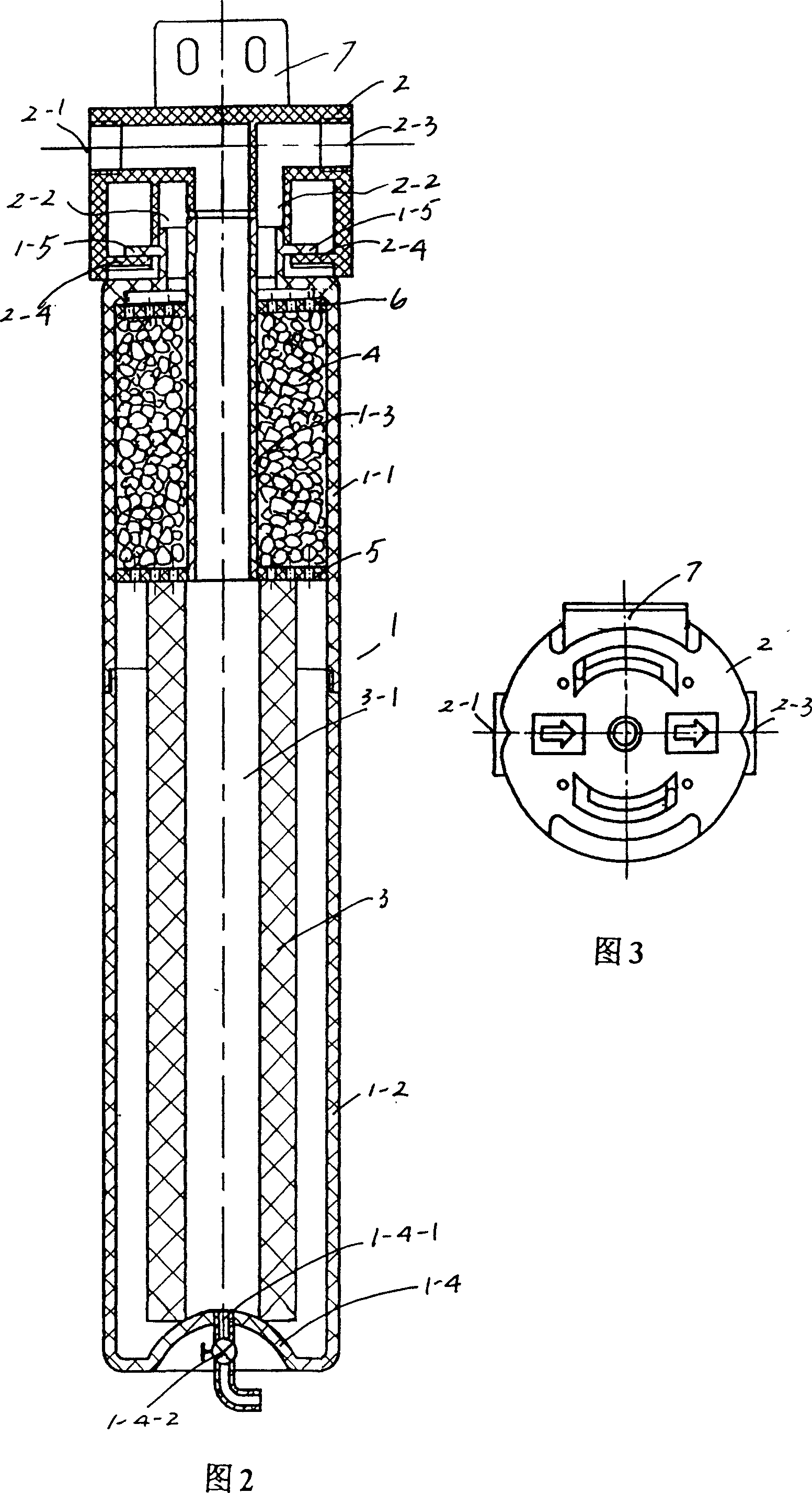

Rotary activating oven for preparing high-quality coal-based activated carbon

The invention discloses a rotary activating oven for preparing high-quality coal-based activated carbon, and belongs to the field of production equipment of activated carbon. The rotary activating oven comprises a steam preheating device, an activating device, a feeding and discharging system and a main body part of the rotary activating oven, wherein the interior of the rotary activating oven isdivided into four sections: a material guiding section, a material ejecting and preheating section, a carbonized material activating section and a discharging section; the temperatures of water vaporin three sections are sequentially raised, and finally water vapor with the temperature of 800 to 900 DEG C is effectively and quickly contacted and activated with a carbonized material; meanwhile, the carbonized material activating section adopts a special geometrical structure formed by refractory castable and a silicon carbide material, so that stacking of a coal material can be effectively avoided, and full reaction and contact between the water vapor and the coal material are ensured; besides, an activating material and high-temperature water vapor are fully activated at high temperature.Compared with the conventional rotary activating oven, a product obtained by the activating oven has higher iodine value and greater specific area, can effectively increase the capacity of activatedcarbon and can be used for producing high-quality coal-based activated carbon.

Owner:TSINGHUA UNIV

An Improved Urethane Alkyd Resin

PendingUS20190330418A1Avoid premature gelationImprove solubilityPolyurea/polyurethane coatingsPolyester coatingsEpoxySilanes

The present invention relates to the formulation and process of preparing a functionalized urethane alkyd resin. More particularly, the invention relates to a siliconized urethane alkyd resin obtained from an alkyd based on semi drying / drying Oils or their fatty acids having high iodine number of 120-170 (gm I2 / 100 gm) followed by grafting of epoxy alkyl alkoxy silane or silanol functional silicone resin into the alkyd backbone and subsequent urethanization of the organosilane grafted alkyd. Siliconized urethane alkyd thus obtained were incorporated in solvent borne pigmented coating compositions and found suitable for preparing air drying 1 pack coatings providing excellent corrosion resistance, weathering and mechanical properties when applied on variety of substrates such as mild steel, corroded mild steel, other metals, alloys, glass, wood and cementitious etc.

Owner:ASIAN PAINTS

Method for investigating purity of retrieved ethanediol

InactiveCN1869664AImprove accuracyGood precisionMaterial analysis by observing effect on chemical indicatorChemical analysis using titrationWater bathsC constant

The invention is a testing method of recovered glycol purity, weighing 0.6-0.8g of glycol sample and placing it into 250 ml volumetric flask and diluting with water to scale and shaking uniformly; using pipette to absorb 5 ml of solution obtained and adding in 250 ml iodine measuring flask and absorbing 20 ml of high-iodine solution and adding in the iodine measuring flask and shaking uniformly; placing for 30 min in 45 deg.C constant temperature water bath and taking out and cooling to room temperature; adding in 10 ml of 20% KI solution and 100 ml of water, and placing in dark place for 10 min and titrating with 0.1 mol / L Na2S2O3 to buff; adding in 1 ml of 1% starch indicator and continuing titrating until blue disappears, able to directly reflect concrete value of glycol purity and accurately find measuring proportion to new glycol without special instrument, and the invention has characters of simple and convenient, rapid, highly accurate and good precision.

Owner:PETROCHINA CO LTD

Preparation and application of iodine removing material

InactiveCN105311973ASolving practical operational problems of adsorptionAdjust adsorptionSemi-permeable membranesOther chemical processesComposite filmUltimate tensile strength

The invention aims at providing a preparation method and application of a novel iodine removing composite film. Aiming at solving an actual operation problem of ion exchange resin adsorption in industrial actual application, the invention provides the preparation method of an iodine adsorbing material; and the material can be used for directing adsorbing iodine ions from water. By controlling the content ratio of ion exchange resin and polyether sulfone, the adsorption capability and intensity of the material are adjusted; and when the iodine adsorbing material is applied to high-iodine water treatment, the removing rate of iodine is up to be more than 90% after 2 hours.

Owner:OCEAN UNIV OF CHINA

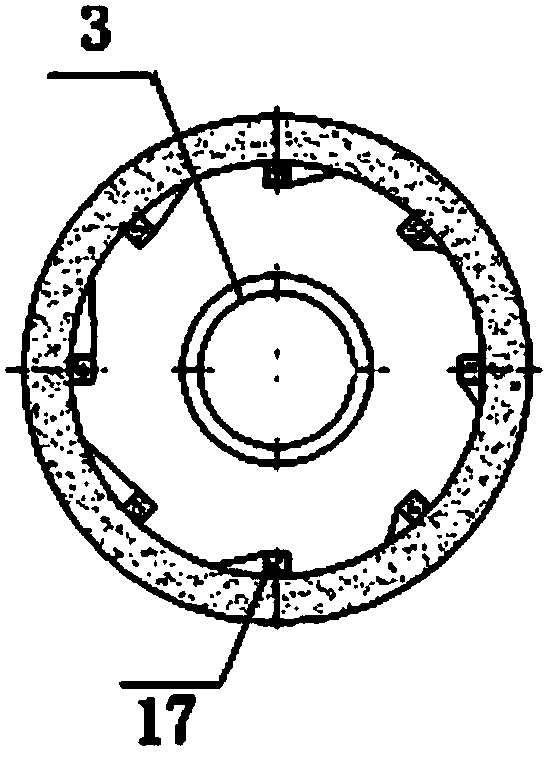

Method for preparing purified water and apparatus therefor

InactiveCN1621357AShort processImprove purification effectSemi-permeable membranesOther chemical processesHollow fibreFiber

The present invention is purified water preparing method and apparatus, and belongs to the field of water processing technology. The present invention treats material water through two stages of filtering and detoxicating, and in the detoxicating stage, detoxicating mixture of high purity Cu-Zn alloy grain and active high-iodine and silver-carrying active carbon grain is used. The water purifying apparatus includes one casing separated into upper and lower parts; one superfine hollow fiber filtering barrel, one first filtering board, one detoxicating mixture layer and one second filtering board successively arranged inside the casing; and one cover. Water is filtered in the filtering barrel and detoxicated with the detoxicating mixture before being led out via the purified water outlet in the end cap. The present invention has high water purifying effect.

Owner:卢寅岳

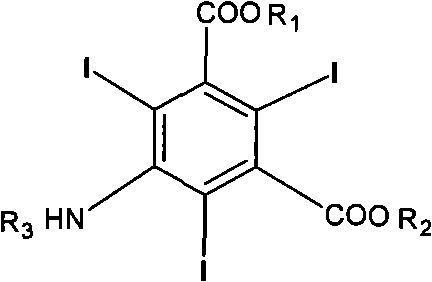

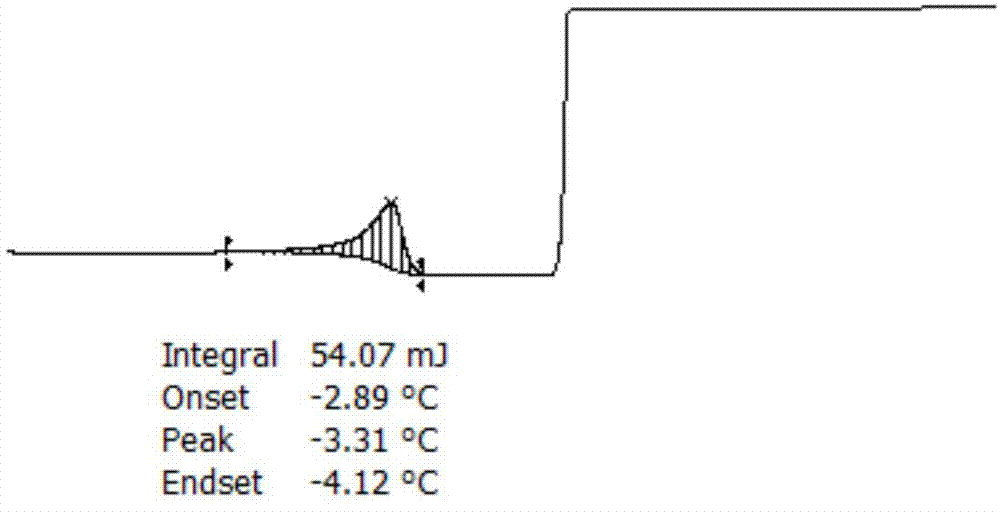

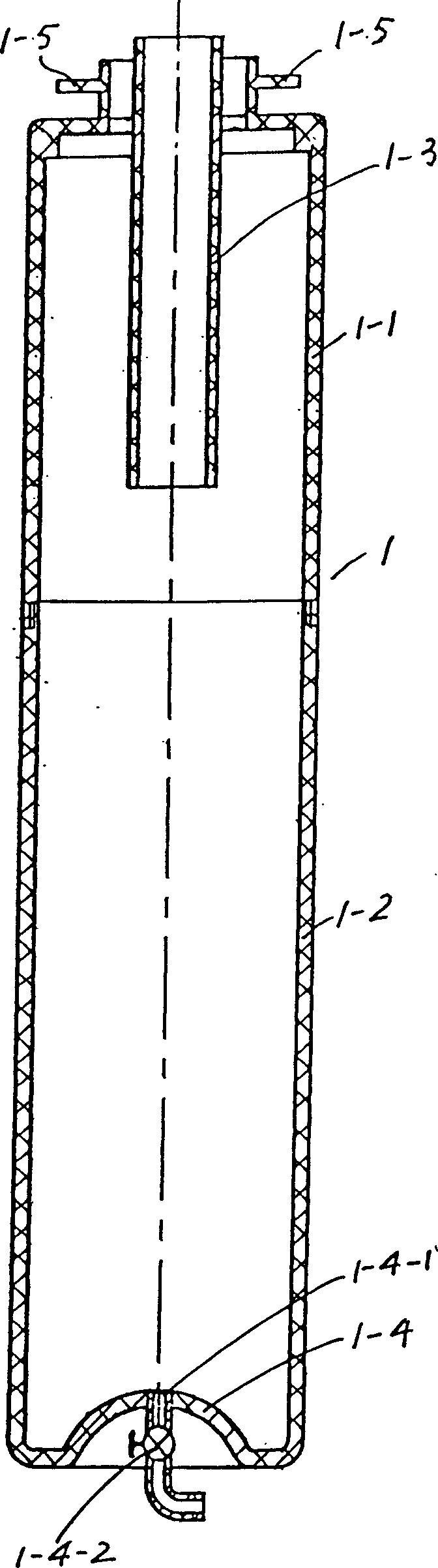

Preparation method of 4-amino-7-iodo pyrrolo [2, 1-f] [1, 2, 4] triazine

The invention discloses a preparation method of 4-amino-7-iodo pyrrolo [2, 1-f] [1, 2, 4] triazine, which comprises the following steps: reacting 4-amino pyrrolo [2, 1-f] [1, 2, 4] triazine with an iodine-containing substance and an oxidant to obtain 4-amino-7-iodo pyrrolo [2, 1-f] [1, 2, 4] triazine; wherein the iodine-containing substance is iodine or a hydroiodate; the oxidantis at least one ofpotassium hydrogen persulfate composite salt, hydrogen peroxide, m-chloroperoxybenzoic acid, tert-butyl hydroperoxide, sodium hypochlorite, ammonium persulfate and sodium persulfate. According to thepreparation method disclosed by the invention, the preparation is simpler, and the 4-amino-7-iodo pyrrolo [2, 1-f] [1, 2, 4] triazine can be obtained in one step; the preparation method has the characteristics of readily available and cheap raw materials, simple process, mild reaction conditions, high product yield, high iodine atom utilization rate and the like.

Owner:威海同丰海洋生物科技有限公司

Sea-tangle bean product and its processing method

The kelp-soybean food is produced with kelp, soybean, salt, pungent and scenting seasoning, gourmet and water, and through cutting kelp into strips, boiling kelp and soybean, mixing boiled kelp and soybean, adding salt, gourmet and seasoning via stirring to produce the kelp-soybean food. The kelp-soybean food has high iodine content, bright color, good taste and rich nutrients.

Owner:纪仁忠

Mixed-layered bismuth—oxygen—iodine materials for capture and waste disposal of radioactive iodine

Materials and methods of synthesizing mixed-layered bismuth oxy-iodine materials, which can be synthesized in the presence of aqueous radioactive iodine species found in caustic solutions (e.g. NaOH or KOH). This technology provides a one-step process for both iodine sequestration and storage from nuclear fuel cycles. It results in materials that will be durable for repository conditions much like those found in Waste Isolation Pilot Plant (WIPP) and estimated for Yucca Mountain (YMP). By controlled reactant concentrations, optimized compositions of these mixed-layered bismuth oxy-iodine inorganic materials are produced that have both a high iodine weight percentage and a low solubility in groundwater environments.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Method for quickly flocculating and removing blue-green algae in water body

ActiveCN104140152AQuick deathChange cell structureFatty/oily/floating substances removal devicesLiquid separationFlocculationAluminium chlorohydrate

The inventions relates to a method for quickly flocculating and removing blue-green algae in a water body. After being diluted to be at the concentration of 20-100 ppm, high-iodine strontium aluminate is evenly sprinkled on the surface of the water body, and polymeric aluminum with the concentration being 20-50 ppm is evenly sprinkled on the surface of the water body 20-60 minutes later after the high-iodine strontium aluminate is used; after the blue-green algae in the water body is flocculated to form pieces, the blue-green algae are fished mechanically or manually. Thus, the water body is prevented from being polluted, and the glue-green algae can be flocculated to be fished conveniently.

Owner:WUHAN EZHENGNONG SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of 4-amino-7-iodo pyrrolo [2, 1-f] [1, 2, 4] triazine Preparation method of 4-amino-7-iodo pyrrolo [2, 1-f] [1, 2, 4] triazine](https://images-eureka.patsnap.com/patent_img/38df9147-b7e5-4d17-b309-b04db4f2c9b0/HDA0002736858720000011.png)

![Preparation method of 4-amino-7-iodo pyrrolo [2, 1-f] [1, 2, 4] triazine Preparation method of 4-amino-7-iodo pyrrolo [2, 1-f] [1, 2, 4] triazine](https://images-eureka.patsnap.com/patent_img/38df9147-b7e5-4d17-b309-b04db4f2c9b0/BDA0002736858710000021.png)

![Preparation method of 4-amino-7-iodo pyrrolo [2, 1-f] [1, 2, 4] triazine Preparation method of 4-amino-7-iodo pyrrolo [2, 1-f] [1, 2, 4] triazine](https://images-eureka.patsnap.com/patent_img/38df9147-b7e5-4d17-b309-b04db4f2c9b0/BDA0002736858710000041.png)