Rotary activating oven for preparing high-quality coal-based activated carbon

A technology of coal-based activated carbon and activation furnace, which is applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc. It can solve the problems of rotary furnace wear resistance and high temperature resistance and water vapor preheating, which are not fully considered and not fully considered. , to avoid accumulation and ensure the effect of activation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

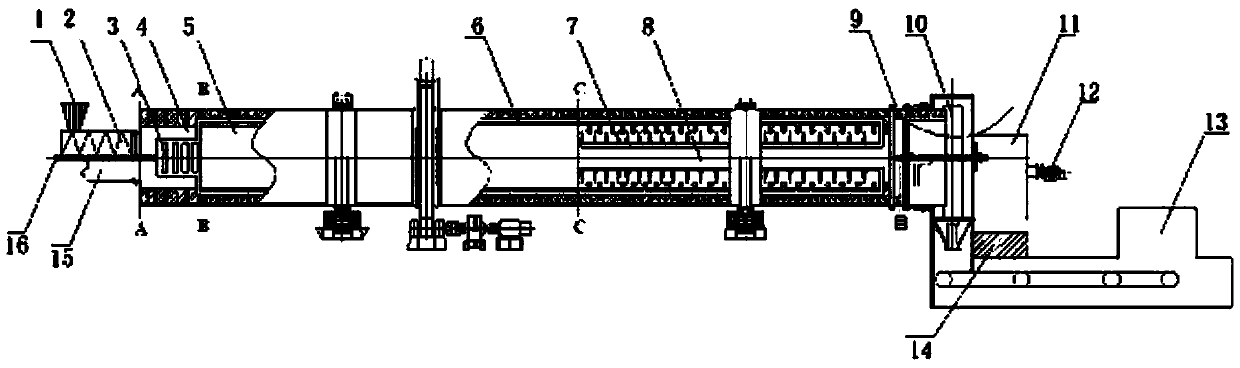

[0025] Embodiment, the working principle of the rotary activation furnace for preparing high-quality coal-based activated carbon,

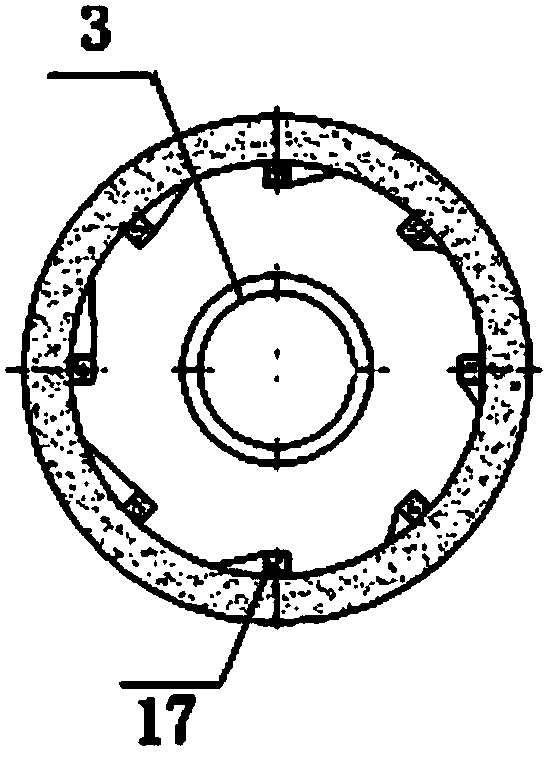

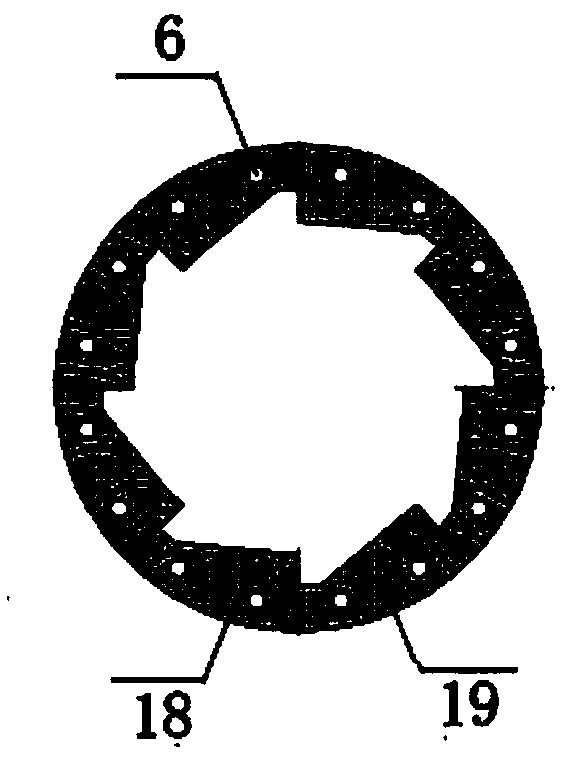

[0026] In the entire rotary activation furnace system, the activated raw material is in countercurrent contact with the mixture of water vapor and hot flue gas. The activated raw material prepared by the carbonization section first passes through the feeding hopper 1, and then enters the rotary activation through the screw feeder 2. inside the furnace, and then pass through the guide section 4 in turn (see the structure of the guide section figure 2 ), raising material preheating section 5 (see the structure of raising material preheating section image 3 ) and activation section 8 (the activation section structure see Figure 4 ), and finally reach the discharge section 9 (for the structure of the discharge section, see Figure 5 ), the right side of the discharge section 9 is connected with the discharge device 10, and then enters the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com