Wireless ultrasonic probe assembly for flaw detection of crawler-type steel rail and flaw detection method of wireless ultrasonic probe assembly

An ultrasonic and crawler-type technology, which is used in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and railway car body parts. Complicated problems, to achieve high driving speed, avoid missed detection, and reduce detection voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation of the present invention is not limited thereto.

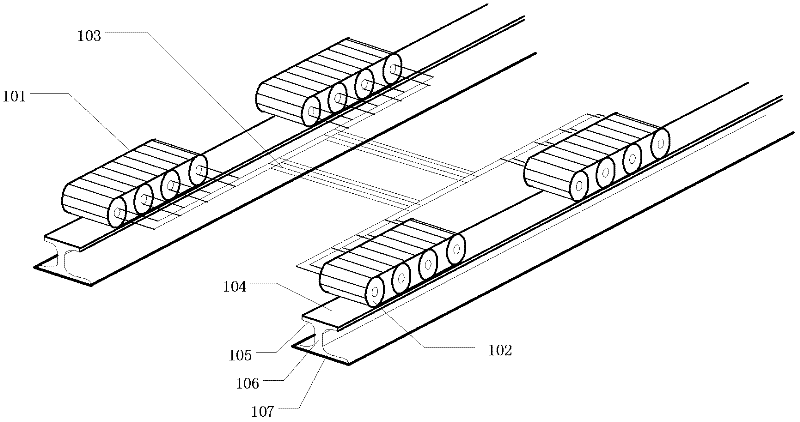

[0047] like figure 1 As shown, it is a working diagram of the wireless ultrasonic probe assembly 101 for crawler rail flaw detection according to the present invention. The ultrasonic probe assembly 101 for flaw detection of crawler rails according to the present invention has no power device itself, and four sets of ultrasonic probe assemblies 101 for flaw detection of crawler rails are jointly connected to the flaw detection trolley support 103 through the wheel shafts of the tensioning pulleys 102 in the crawler belts, forming a structure A flaw detection trolley is connected to the chassis of the high-speed rail flaw detection trolley. The ultrasonic probe assembly 101 shown in the figure for flaw detection of crawler rails uses four tensioning wheels 102 to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com