Patents

Literature

573 results about "Iodine value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

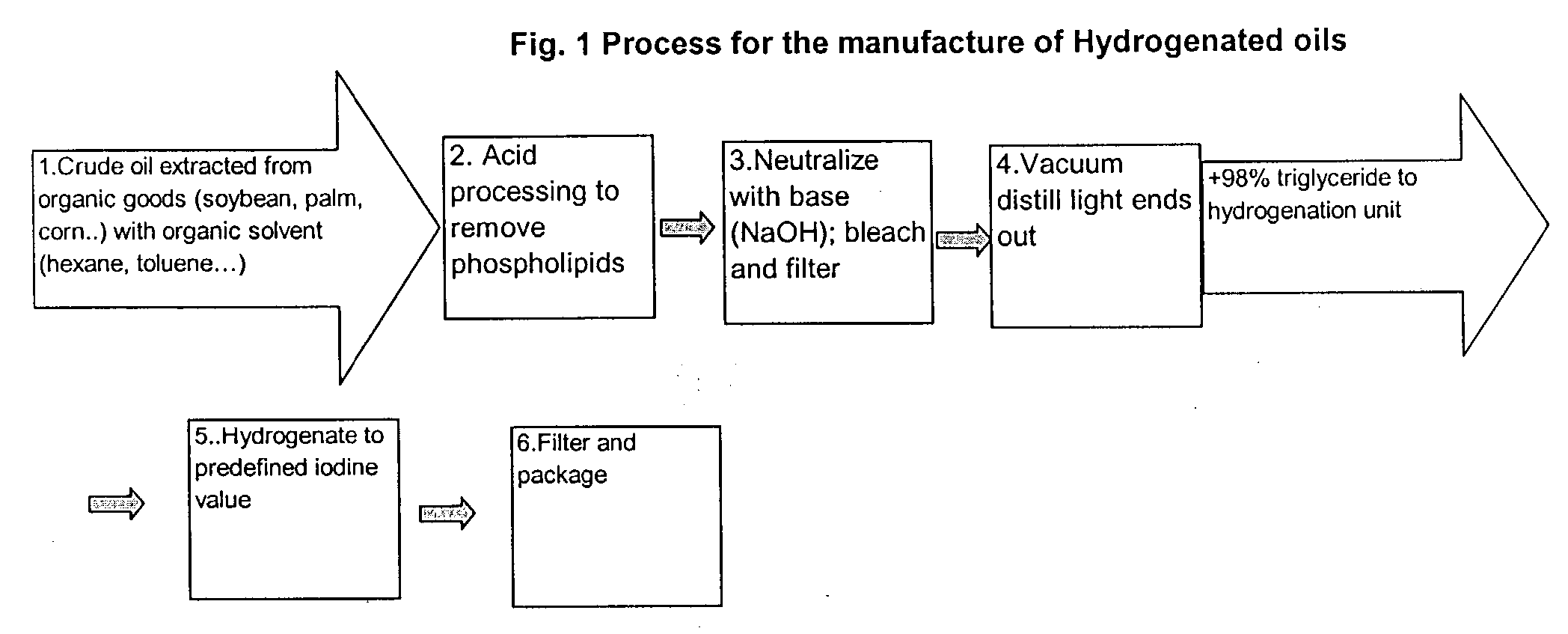

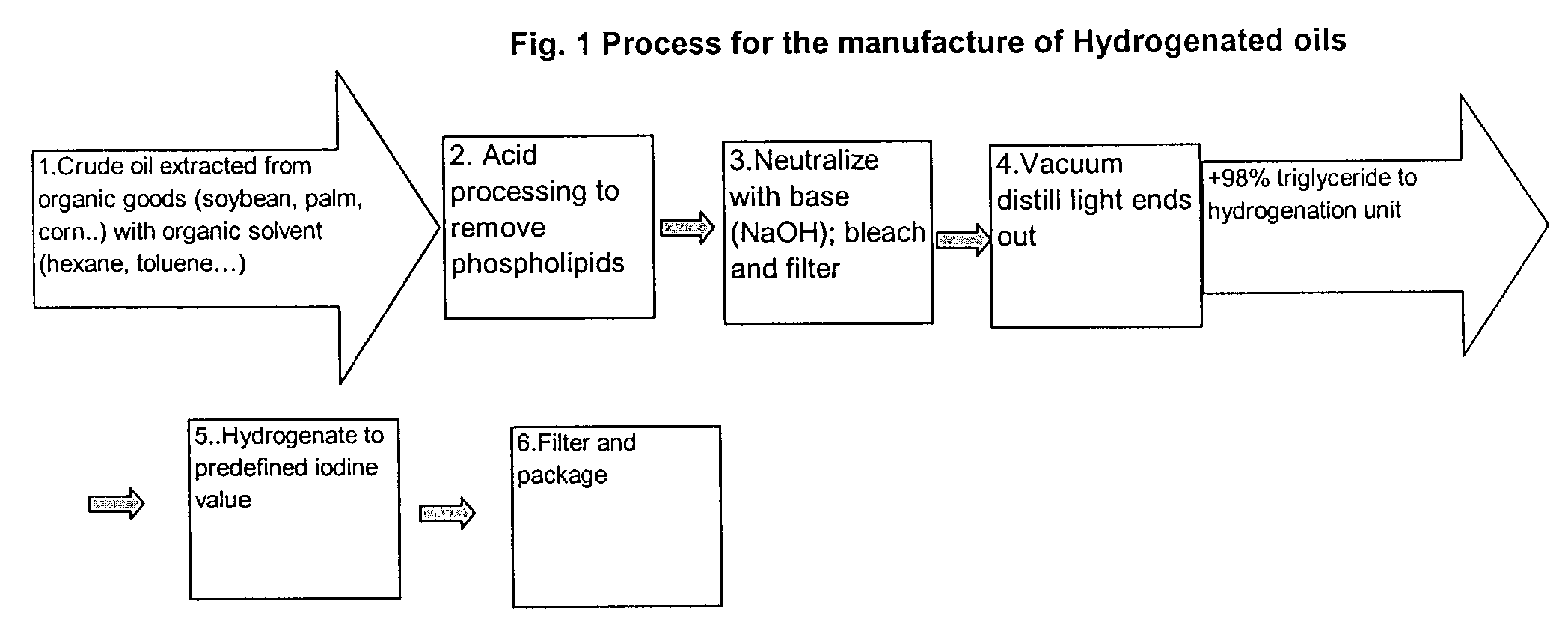

The iodine value (or iodine adsorption value or iodine number or iodine index) in chemistry is the mass of iodine in grams that is consumed by 100 grams of a chemical substance. Iodine numbers are often used to determine the amount of unsaturation in fatty acids. This unsaturation is in the form of double bonds, which react with iodine compounds. The higher the iodine number, the more C=C bonds are present in the fat. It can be seen from the table that coconut oil is very saturated, which means it is good for making soap. On the other hand, linseed oil is highly unsaturated, which makes it a drying oil, well suited for making oil paints.

Soybean wax candles

InactiveUS6599334B1Increase profitWithout and crackingSolid fuelsCapillary burnersVegetable oilAlpha-olefin

A solid fuel candle which is highly adapted for use both in a container and also as a free-standing candle includes at least 85 percent hydrogenated soybean oil, approximately 0 to 4 percent synthetic wax composition, approximately 0 to 4 percent of a second hydrogenated vegetable or petroleum oil, approximately 0 to 10 percent fragrance or scent, and approximately 0 to 3 percent dye. The hydrogenated vegetable oil most preferably has an iodine value of approximately 50 and a melting point of approximately 125 degrees Fahrenheit, with a free fatty acid content of less than one-tenth of one percent. The synthetic wax composition is most preferably formed from alpha olefin monomers and oligomers under free radical conditions at relatively low pressures to yield a highly branched polymer wax having congealing and melting points lower than the starting alpha olefin material and a higher molecular weight.

Owner:ANDERSON JILL M

Wax for hot melt adhesive applications

InactiveUS6890982B2Produced economicallyProperty securityNon-macromolecular adhesive additivesFilm/foil adhesivesTG - TriglycerideStearic acid

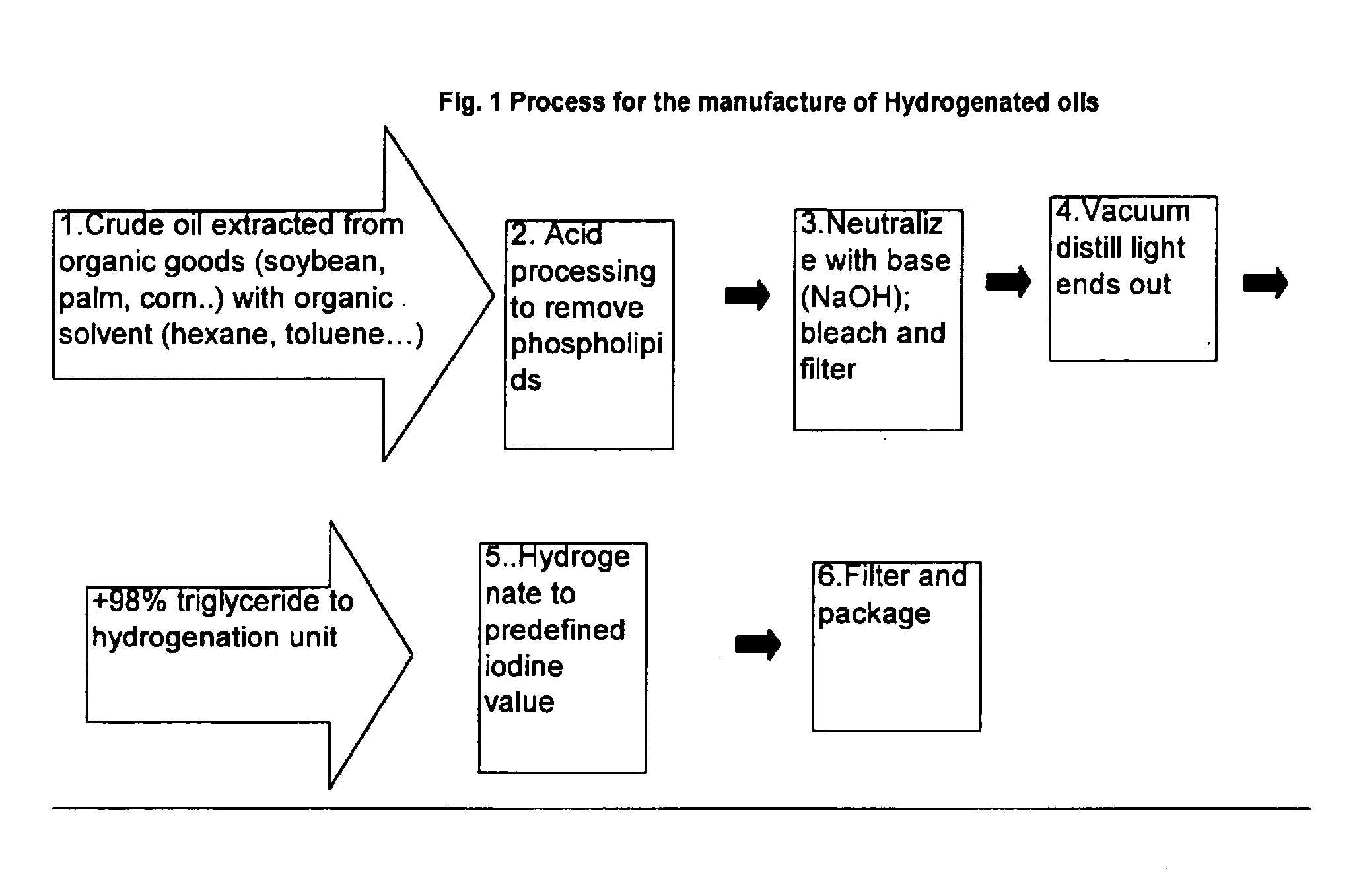

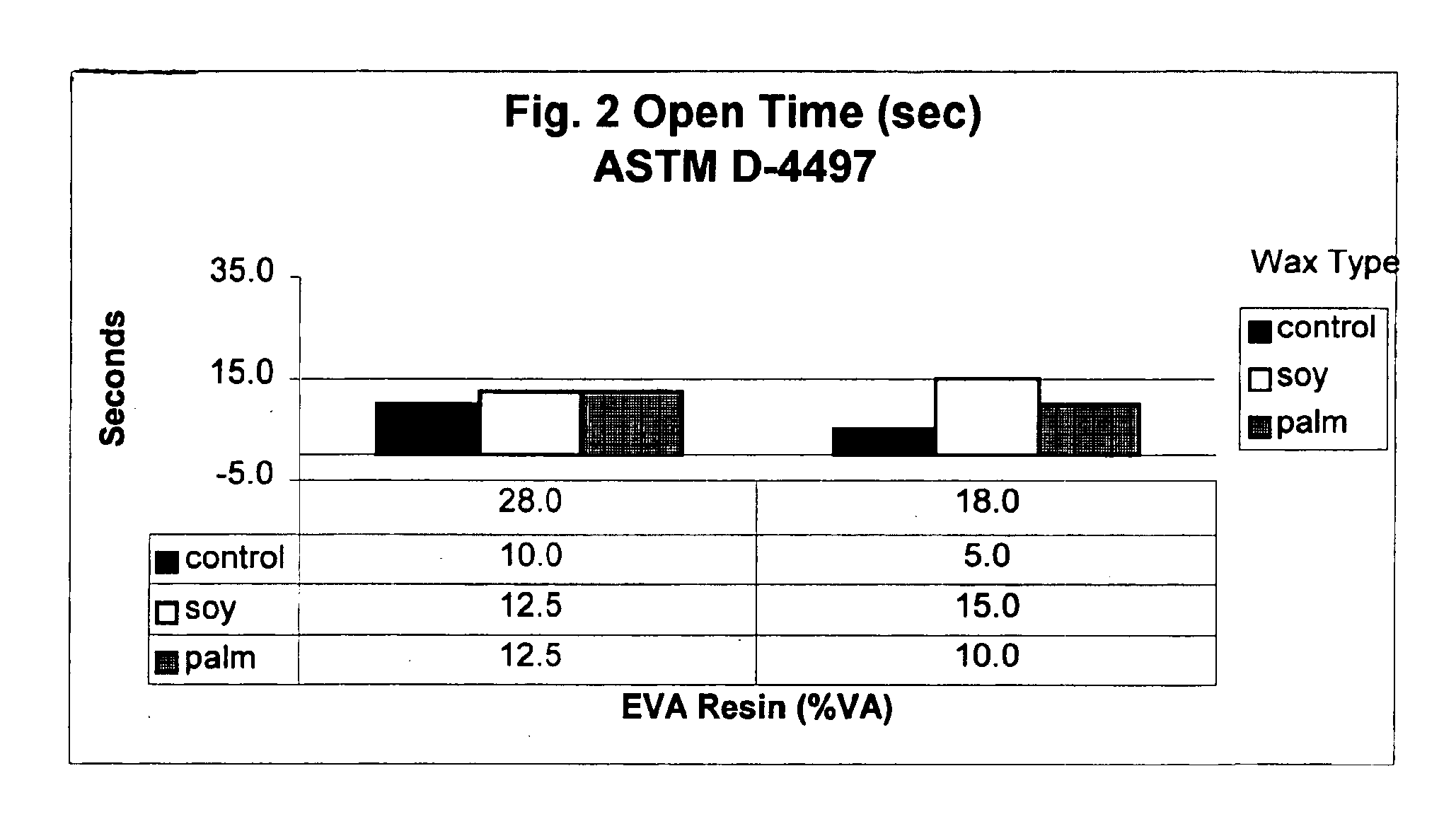

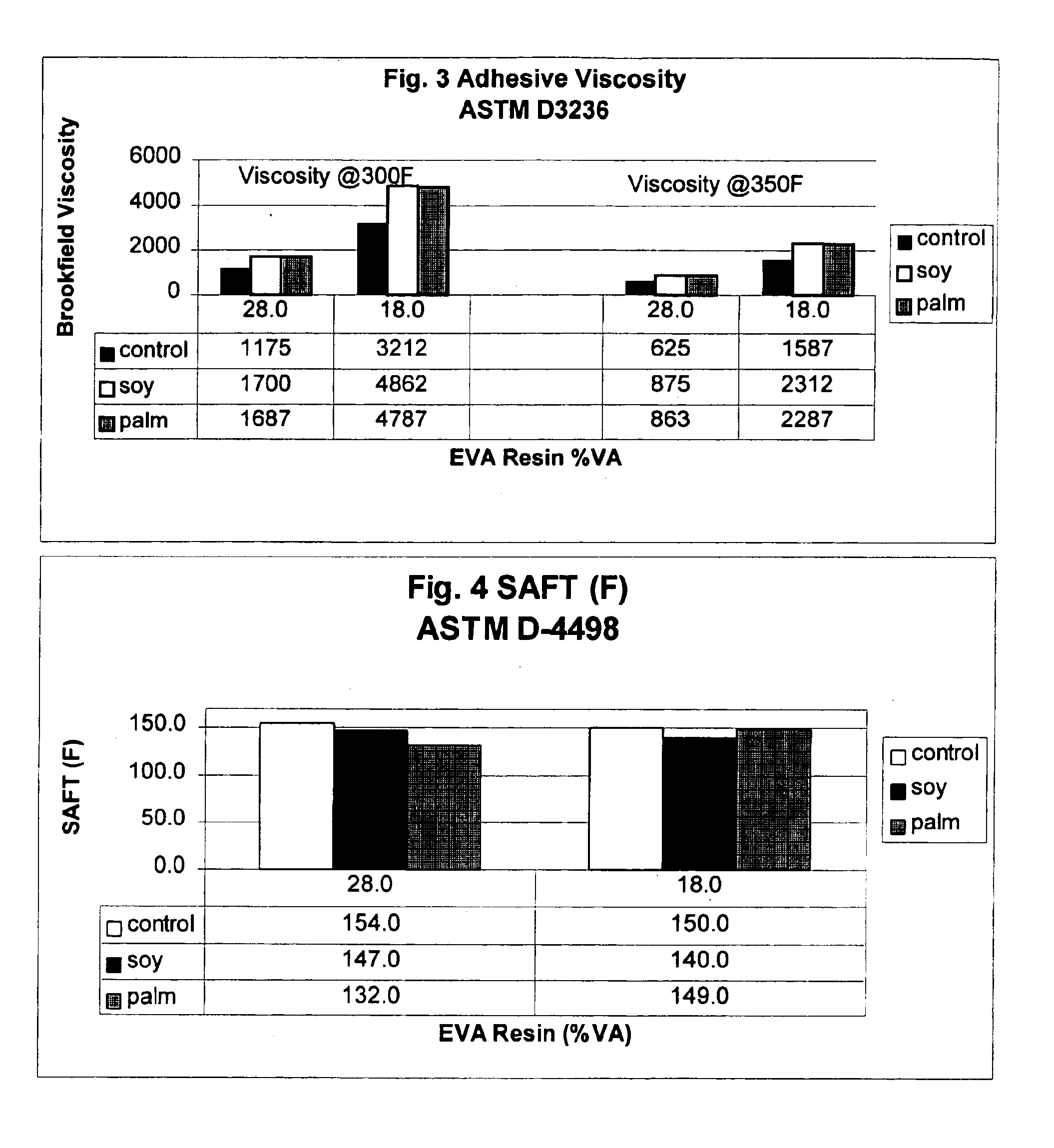

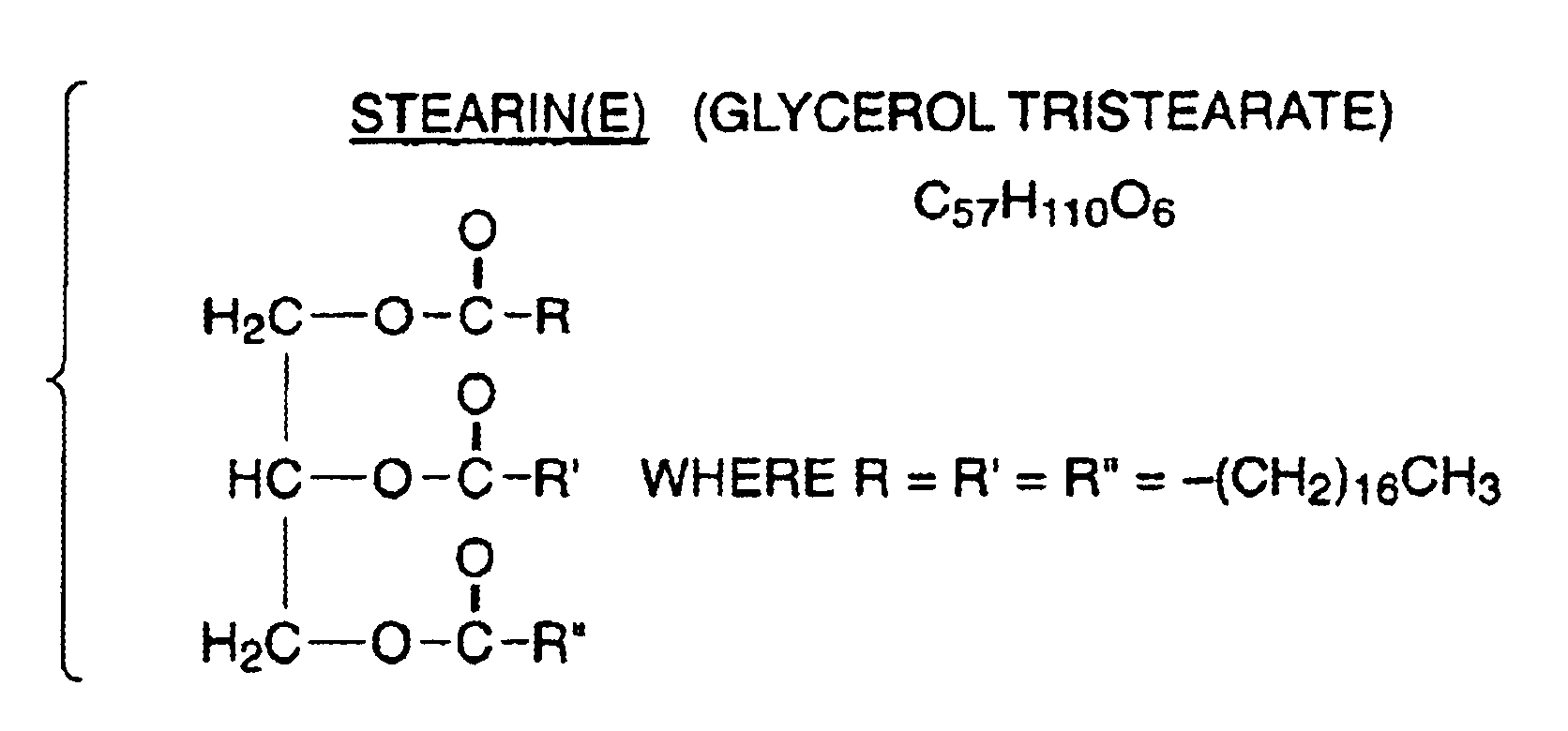

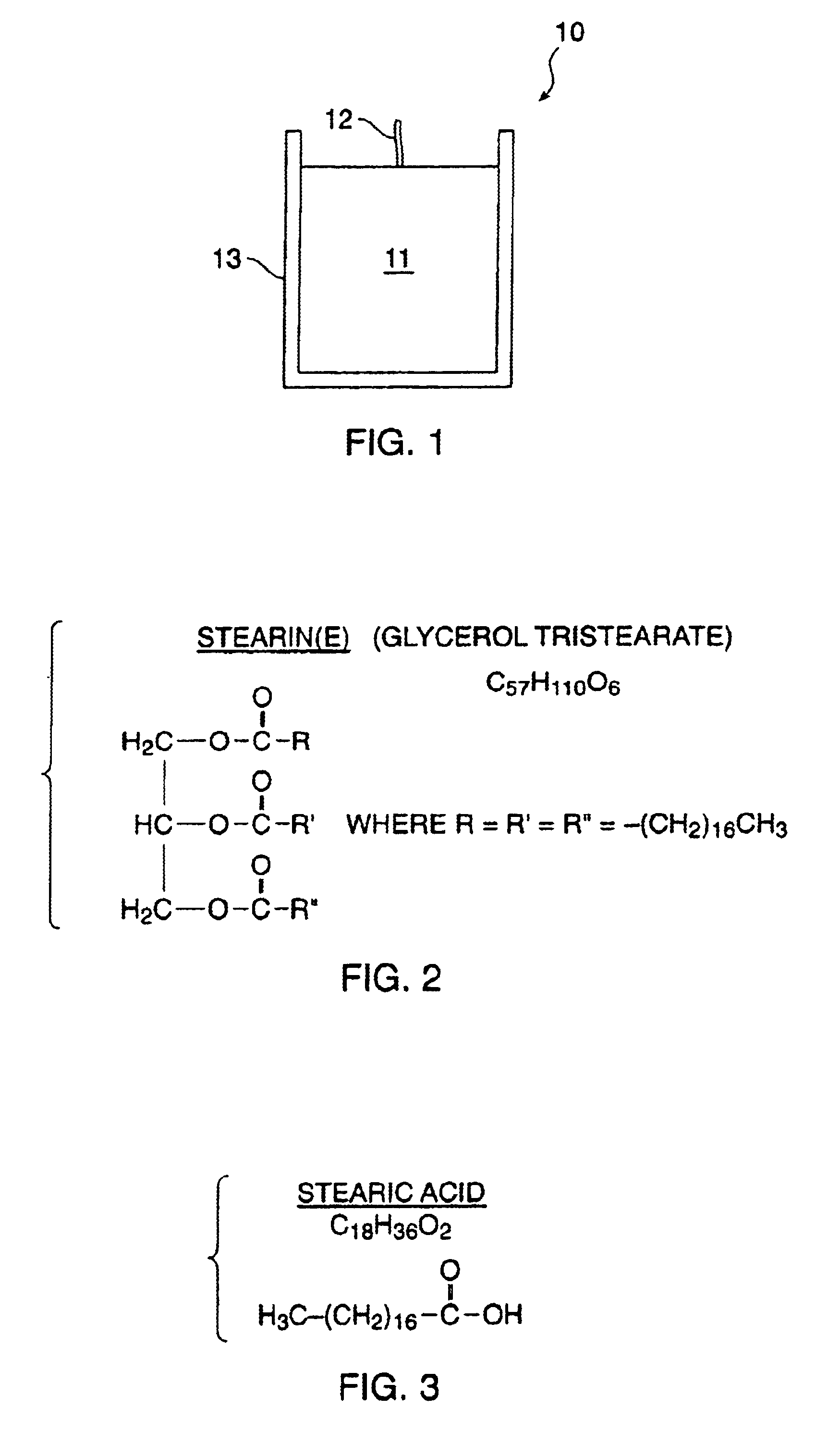

Waxes prepared from hydrogenated plant oils, such as palm and soybean, are used as substitutes for petroleum derived waxes in hot-melt adhesive compositions. Unlike petroleum-derived or synthetic waxes, adhesive compositions comprising these waxes, which are obtained from naturally derived, renewable resources, achieve adhesion performance similar to conventional adhesives containing petroleum-derived waxes. The inventive waxes have a low iodine value (between 2-5), and melting points between approximately 120-165 degrees F. (Mettler Drop Point). These waxes comprise a triglyceride whose fatty acids are predominantly stearic acid (C18). The naturally derived waxes are used as an alternative to petroleum and synthetically derived waxes in the manufacture of adhesives used to bond paper, wood, glass, plastic and metal in a variety of manufacturing operations.

Owner:MARCUS OIL & CHEM

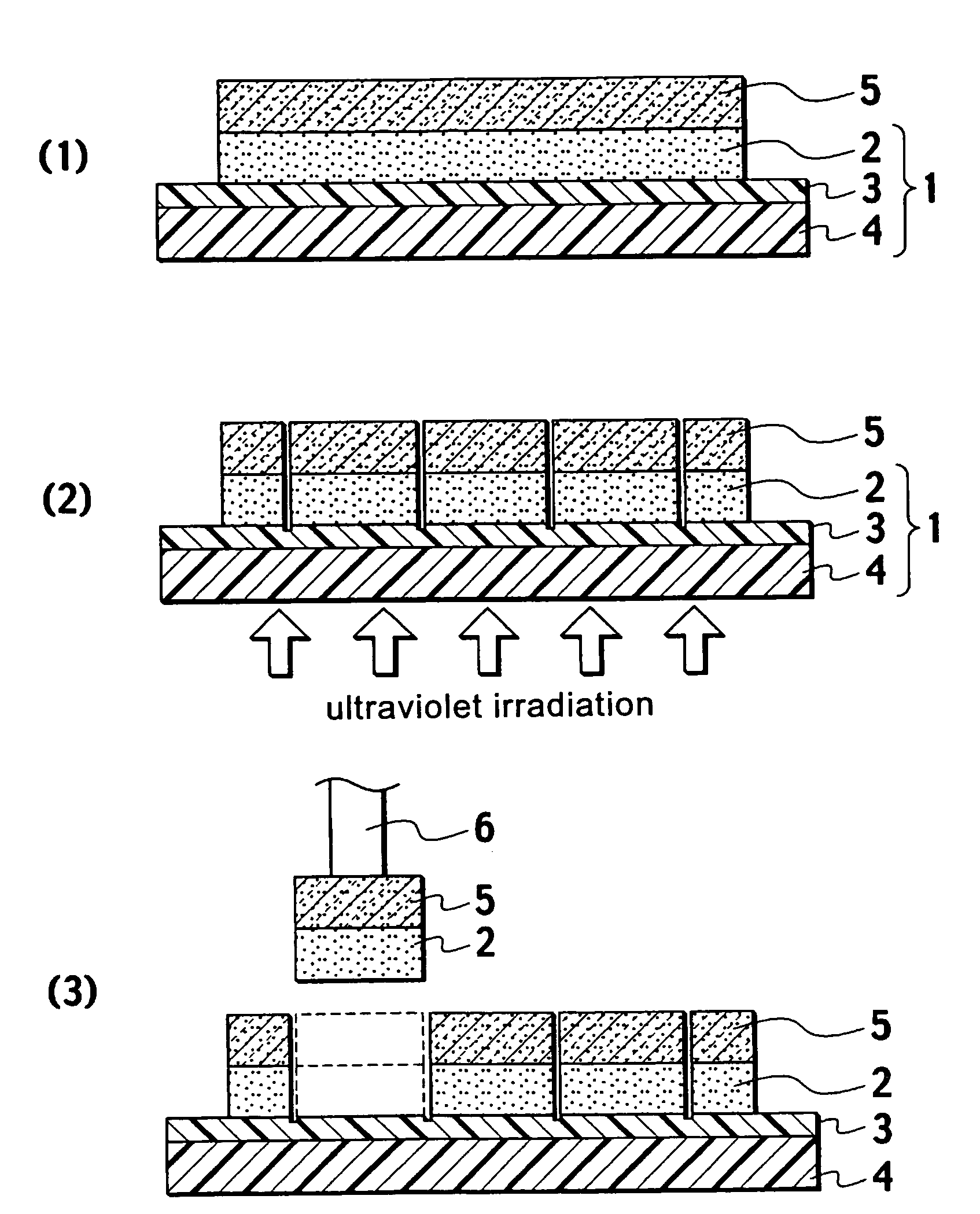

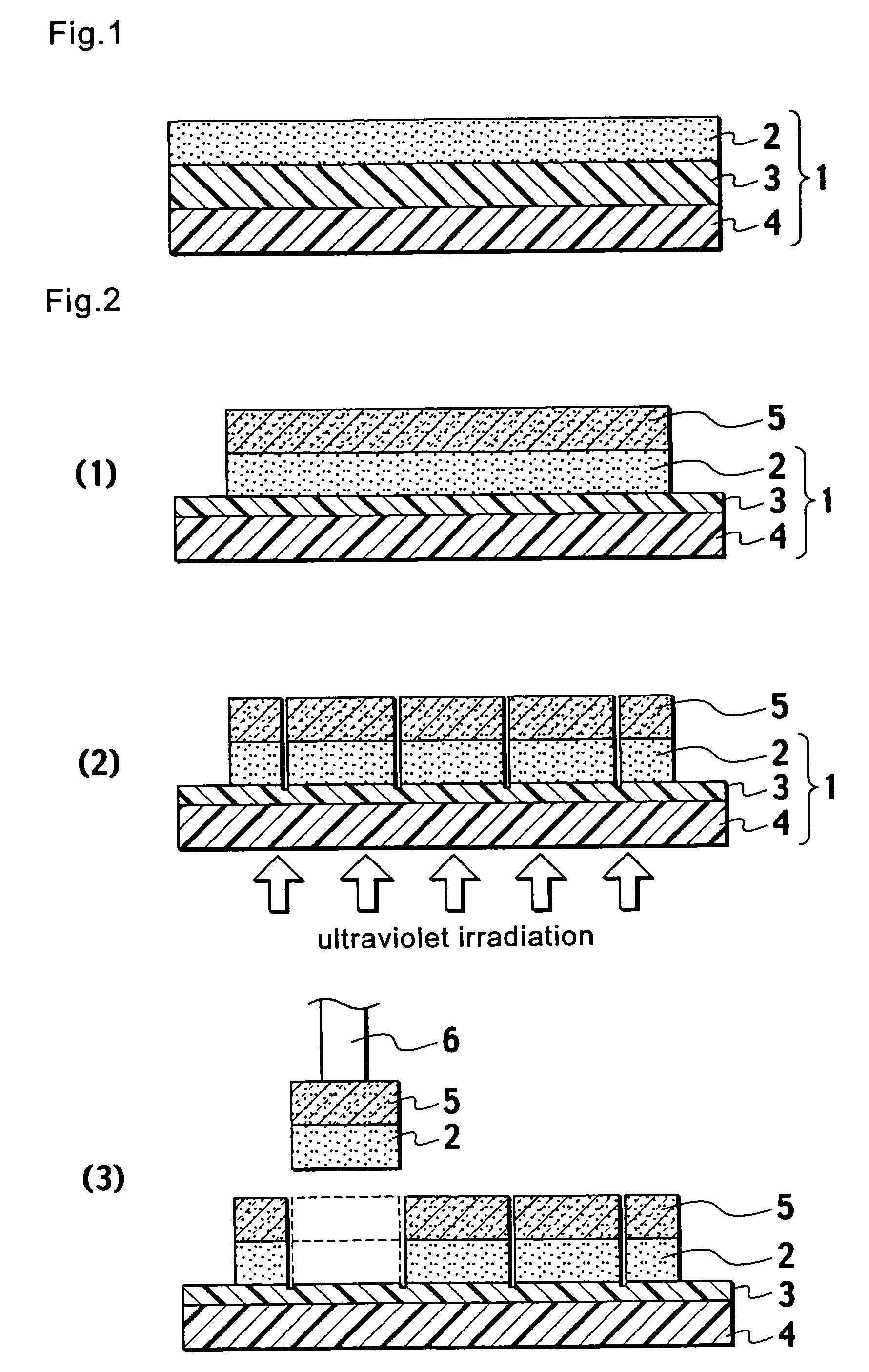

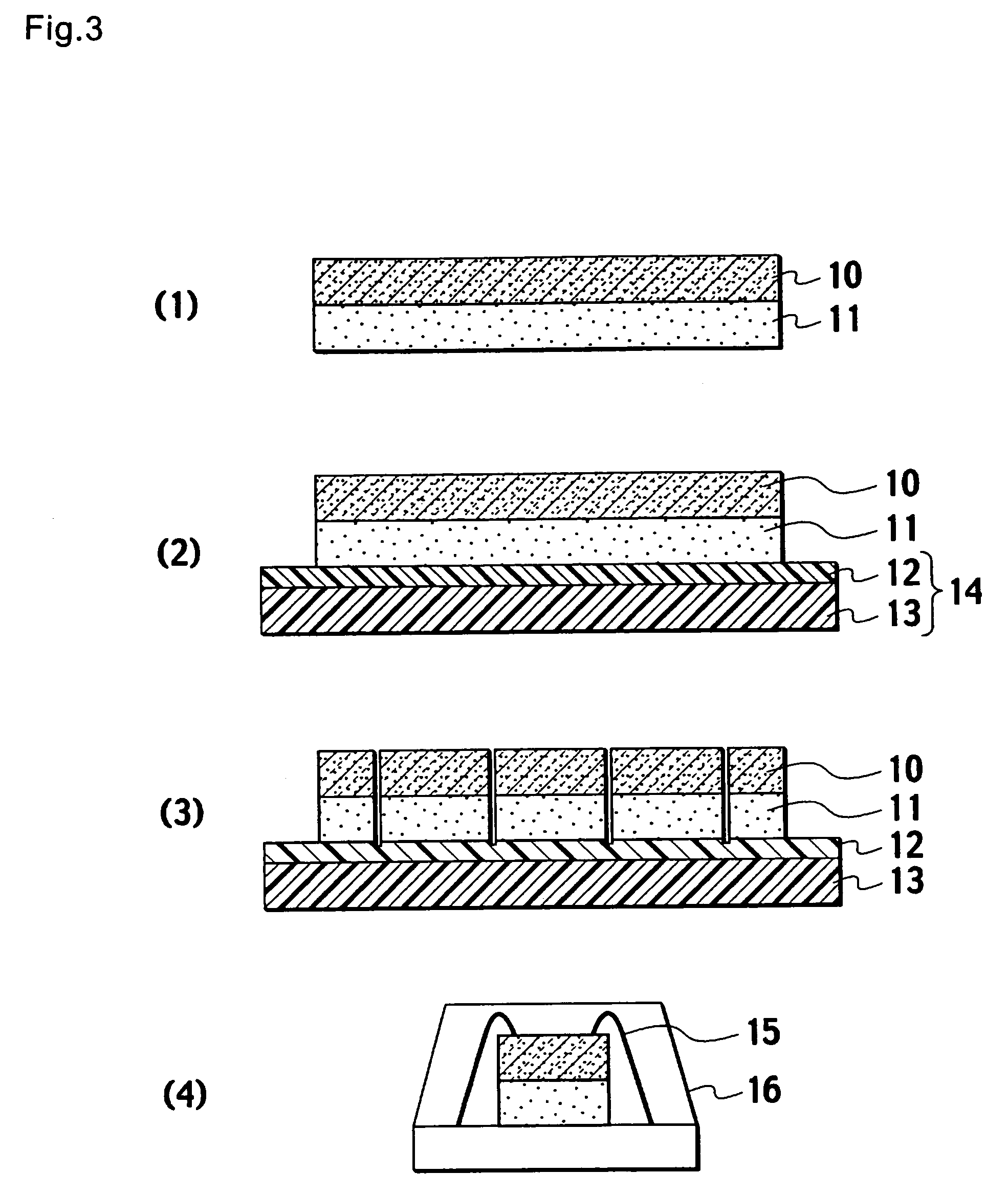

Dicing/die bonding sheet

ActiveUS20070026572A1Satisfactory adhesivenessEasy to separatePolyureas/polyurethane adhesivesSynthetic resin layered productsEpoxyDicing tape

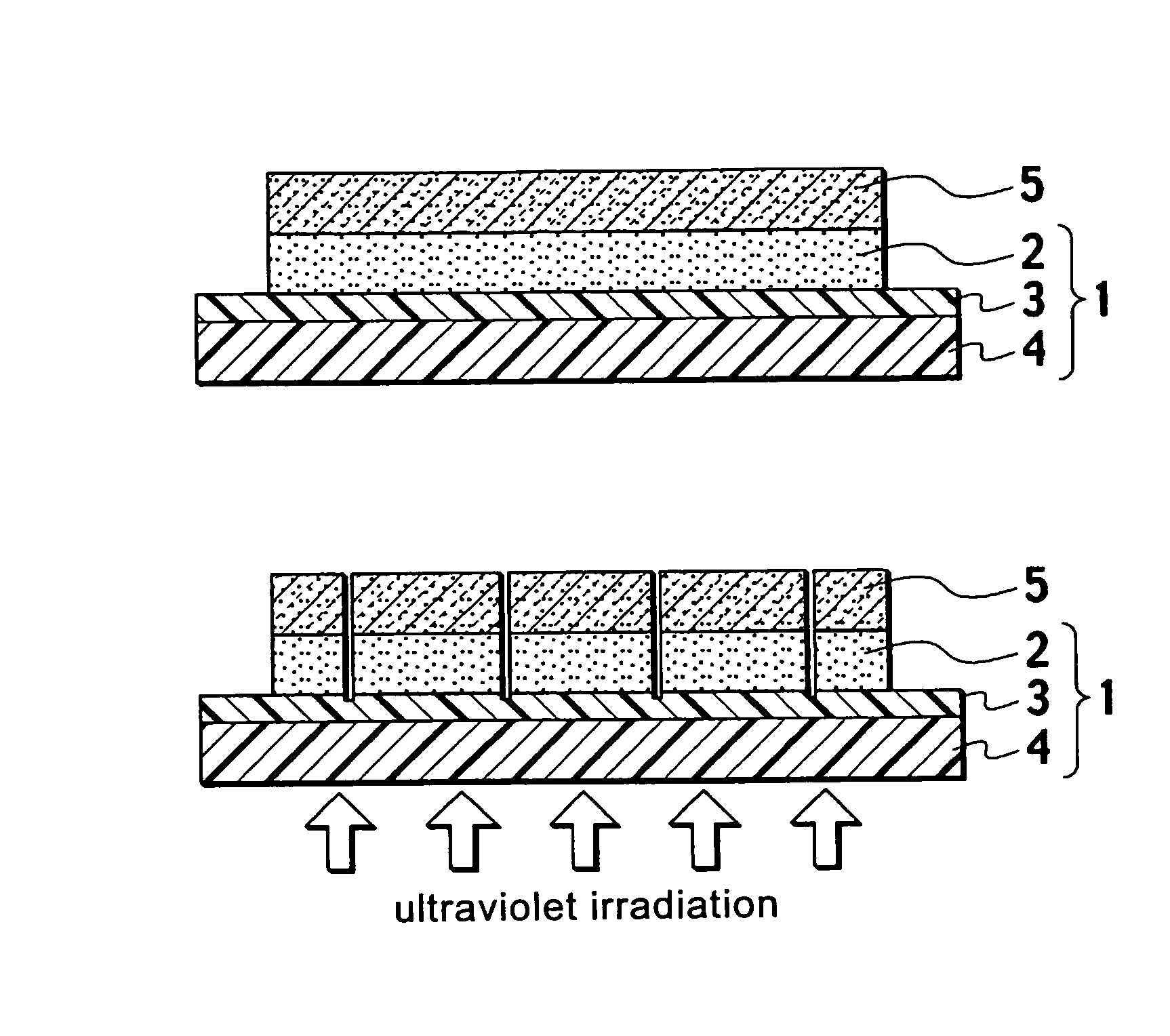

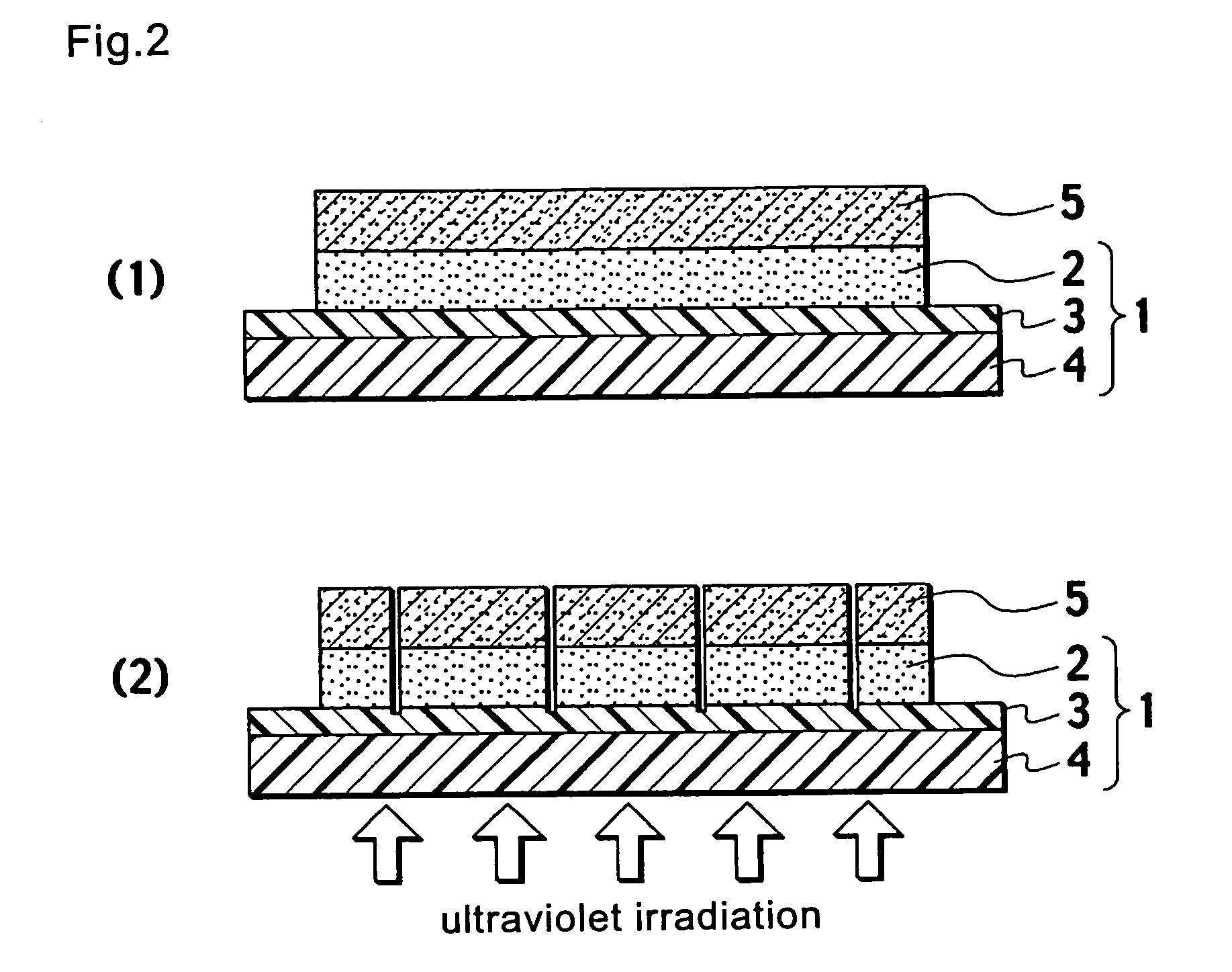

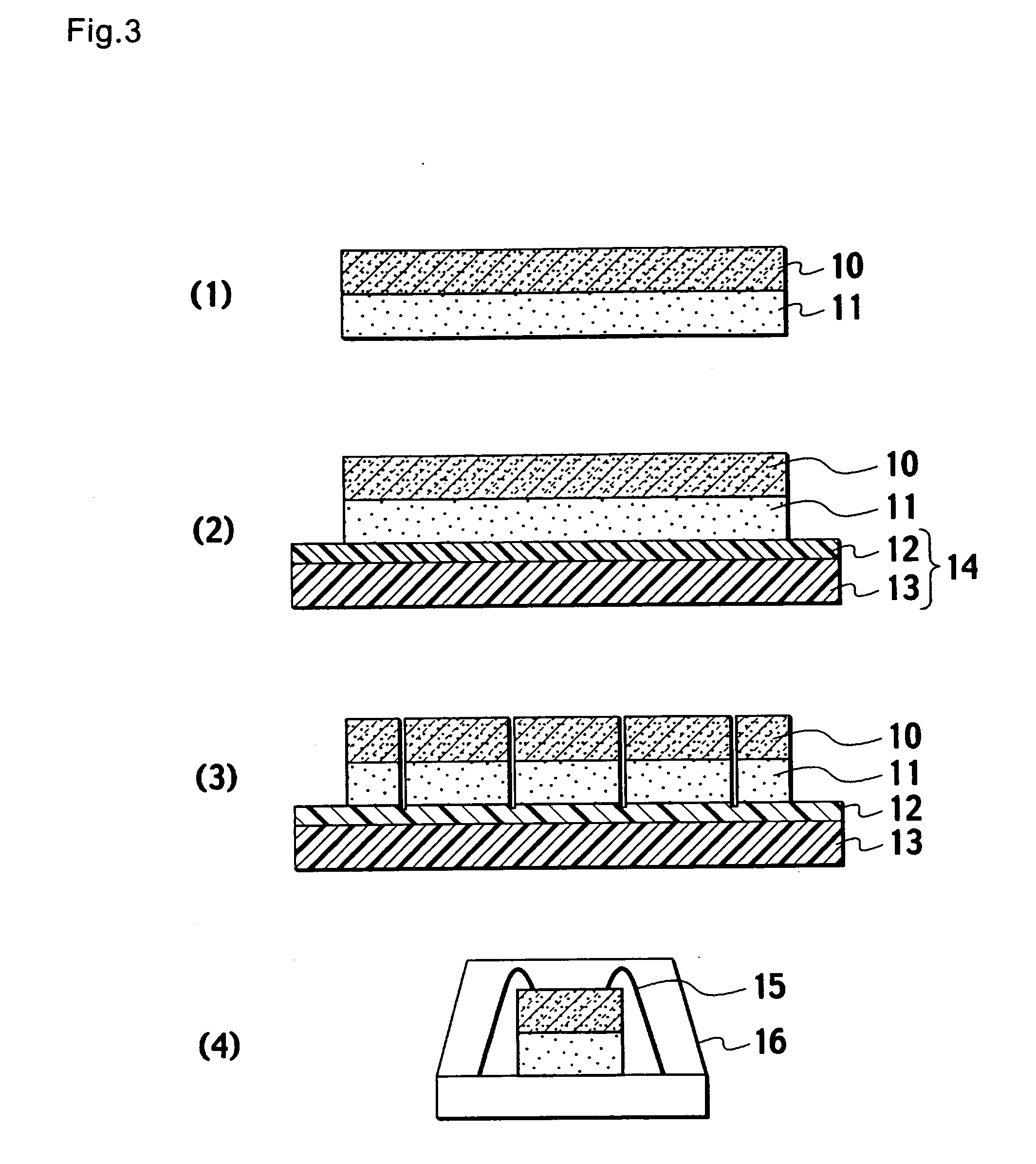

The present invention provides a dicing / die bonding sheet which can be used as a dicing tape during dicing, enables ready separation of the semiconductor element and the adhesive layer from the pressure-sensitive adhesive layer during pickup, and in which the adhesive layer has satisfactory adhesiveness as a die bonding material. A dicing / die bonding sheet in which the pressure-sensitive adhesive layer comprises a compound (A), containing intramolecular, radiation curable carbon-carbon double bonds with an iodine value of 0.5 to 20, and at least one compound (B) selected from a group consisting of polyisocyanates, melamine-formaldehyde resins, and epoxy resins, and the adhesive layer comprises an epoxy resin (a), a phenolic resin (b) with a hydroxyl equivalent of at least 150 g / eq., an epoxy group-containing acrylic copolymer (c), comprising from 0.5 to 6% by weight of glycidyl acrylate or glycidyl methacrylate, and with a weight average molecular weight of at least 100,000, a filler (d), and a curing accelerator (e).

Owner:RESONAC CORP +1

Hydrogenation catalyst of diesel production at most amount and production thereof

A maximum hydrogen catalyst of diesel oil and its production are disclosed. The catalyst consists of amorphous silica aluminum, modified beta molecular sieve, aluminum oxide, VIB family and VIII family metals. Modified beta molecular sieve has high silicon and crystallinity, small crystal grain and acidity. It has good cyclanes selective loop open and alkane isomerization. Its advantages include higher heavy oil hydrogen crack activity and middle oil selectivity, better diesel oil absorption and lower filtering point, and it improves density, colloidal matter, iodine value and color.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lube Base Oil, Process for Production Thereof, and Lubricating Oil Composition

ActiveUS20100041572A1High level of functionReduce energy lossTin organic compoundsGroup 5/15 element organic compoundsIodine valueEnergy loss

The present invention provides a lubricating base oil comprising saturated components of 90% by mass or greater, wherein the proportion of cyclic saturated components among the saturated components is not greater than 40% by mass, and by having a viscosity index of 110 or higher and an iodine value of not greater than 2.5. The lubricating base oil of the invention exhibits excellent viscosity-temperature characteristics and heat and oxidation stability while also allowing additives to exhibit a higher level of function when additives are included. The lubricating base oil of the invention is suitable for use in various lubricating oil fields, and is especially useful for reducing energy loss and achieving energy savings in devices in which the lubricating base oil is applied.

Owner:NIPPON OIL CORP +1

Additive to render gypsum board moisture resistant

InactiveUS20060196391A1Improve waterproof and moisture-proof performanceMore water resistantBuilding componentsCoatingsStearic acidMoisture barrier

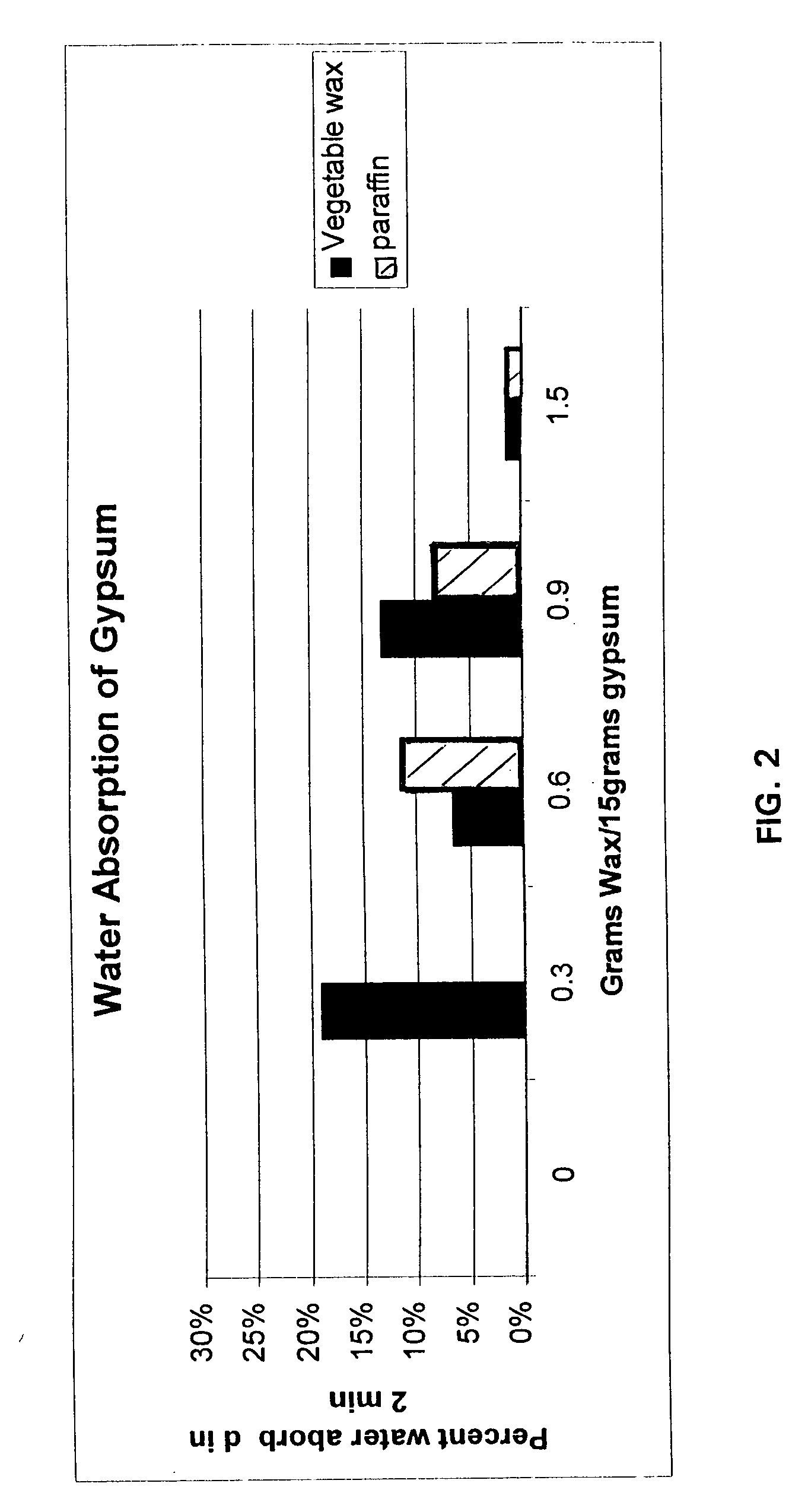

Waxes prepared from hydrogenated plant oils, such as palm and soybean, are used to render gypsum board resistant to water. Unlike petroleum-derived waxes used for the same purpose, vegetable derived waxes are renewable and readily converted into forms such as emulsions or powder that facilitate incorporation into gypsum board manufacturing. Such water resistant materials are characterized by enhanced moisture barrier properties. The compositions have a low iodine value (between 2-5), and melting points between approximately 120-185 degrees F. (Mettler Drop Point). The wax comprises a triglyceride whose fatty acids are predominantly stearic acid (C18). The composition is used as an additive in the manufacture of water resistant gypsum board.

Owner:HRD CORP

Method of treating flammable catalyst

A method used for manufacturing a catalyst used for hydrogenation treating and / or hydrogenation cracking a hydrocarbon flow or exhaust treating a thionic gas flow comprises heating a prevulcanized composition to 200-500 DEG C in the presence of hydrogen gas to form a sulfide of a metal, wherein said prevulcanized composition contains a prevulcanized catalyst loaded at a porous carrier and at least part of the catalyst is coated and / or infused by at least a containing oxygen hydrocarbon having at least 16 carbon atoms and an iodine value of not less than 60, with a condition that when said hydrocarbon is glycerin trifatty acid ester, the catalyst is not coated and / or infused by said hydrocarbon when or before it is prevulcanized, and when there is no hydrogen added existing in the catalyst coated and / or infused, said catalyst has undergone a heating treatment at not lower than 175 DEG C, with reduced self-heating characteristics of said catalyst.

Owner:CRI INT

Refrigerator oil, compressor oil composition, hydraulic fluid composition, metalworking fluid composition, heat treatment oil composition, lubricant composition for machine tool and lubricant composition

ActiveUS20100093568A1Improve the level ofImprove balanceGroup 4/14 element organic compoundsOrganic compound preparationChemical compositionMetalworking fluid

The present invention provides a refrigerating machine oil, a compressor oil composition, a hydraulic oil composition, a metalworking oil composition, a heat treating oil composition, a lubricating oil composition for machine tools and a lubricating oil composition which comprise a lubricating oil base oil having % CA of not more than 2, % CP / % CN of not less than 6 and an iodine value of not more than 2.5.

Owner:NIPPON OIL CORP

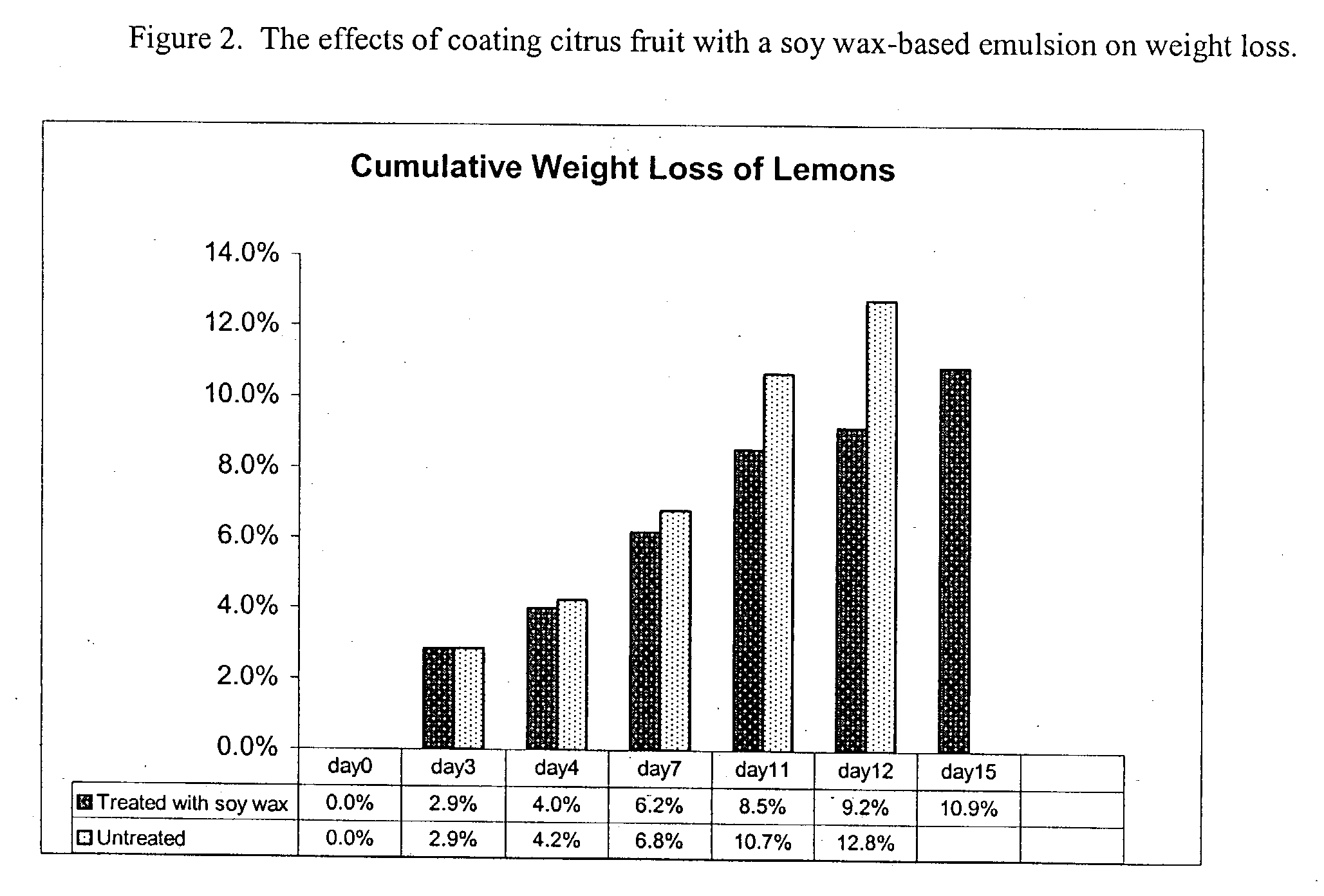

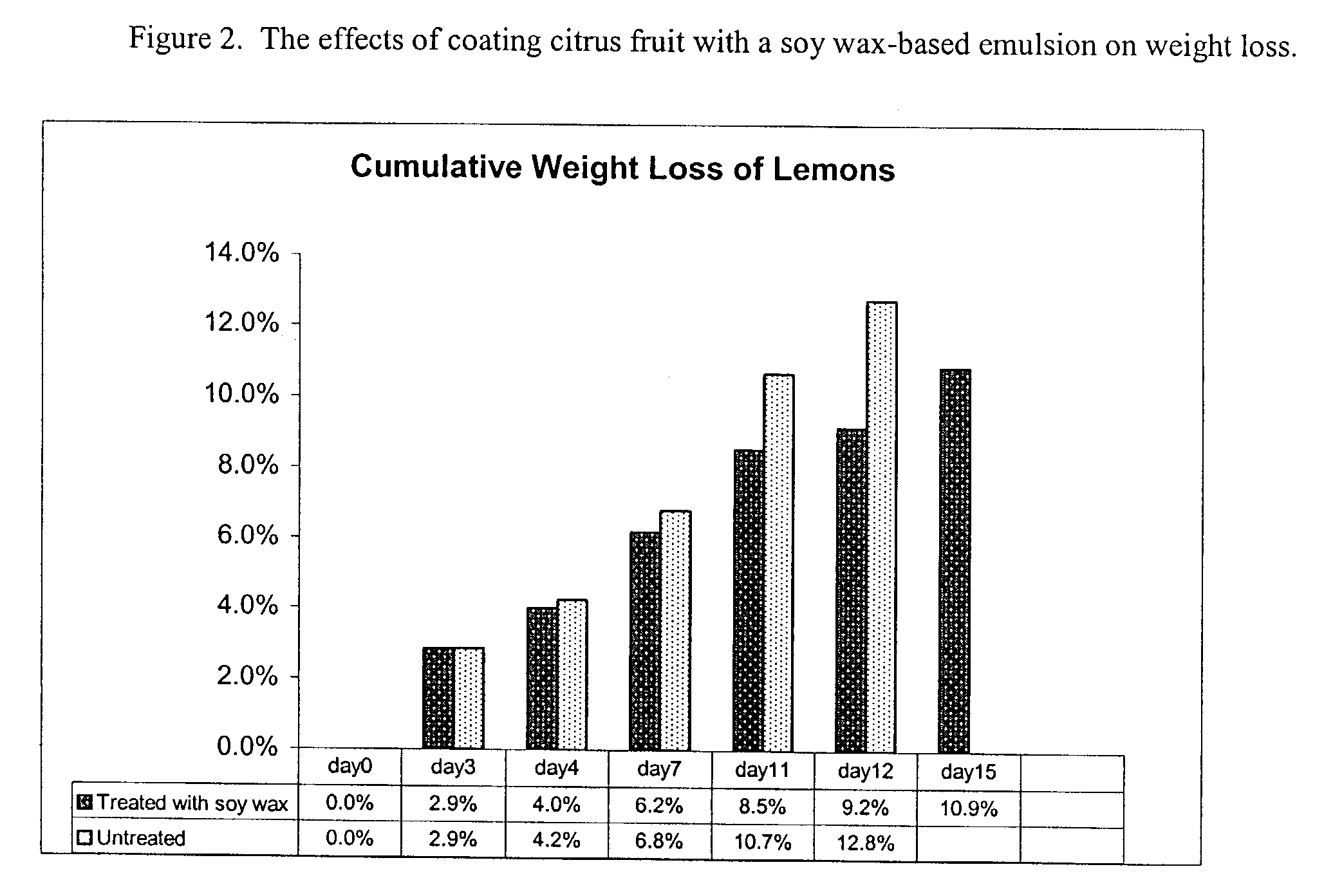

Novel wax emulsion coating applications

Waxes prepared from hydrogenated plant oils, such as castor, palm, and soybean, are used to prepare water based emulsions. The inventive waxes, obtained from naturally derived, renewable resources, were emulsified under anionic, cationic and nonionic conditions, producing emulsions having a solids content up to about 45% solids. When used to coat fibrous cellulosic articles, such as paperboard, the emulsions' performance was similar to emulsions containing petroleum-derived waxes. The inventive waxes have a low iodine value (between 2-5), and melting points between approximately 120-200 degrees F. (Mettler Drop Point). These waxes comprise a triglyceride whose fatty acids are predominantly stearic acid or ricinoleic acid. The inventive waxes are used as an alternative to petroleum-derived, or expensive naturally-occurring waxes in the manufacture of emulsions used in coatings, polishes, adhesives, paper products, paperboard and other manufacturing operations.

Owner:MARCUS OIL & CHEM

Antiperspirant/Deodorant Compositions

A composition comprising at least one active chosen from at least one antiperspirant active and at least one deodorant active; a first gellant chosen from at least one fatty alcohol and at least one hydrocarbon of the formula CnH2n+2, wherein n is about 20 to about 100, and the hydrocarbon is at least 90% linear; at least one soybean oil having an iodine value of greater than 0 to about 20; and at least one silicone.

Owner:COLGATE PALMOLIVE CO

Preparation process of oil extended rubber for tire, oil extended rubber for tire, and rubber composition and tire using the same

InactiveUS8044118B2High strengthReduce supplySynthetic resin layered productsSpecial tyresVegetable oilPetroleum

The present invention provides a process for preparing an oil extended rubber, in which an effect on environments can be taken into consideration, provision for the future decrease of petroleum supply can be satisfied, and further, strength is excellent without molecular breakage, an oil extended rubber obtained by the preparation process, and a tire using the oil extended rubber. A process for preparing an oil extended rubber, comprising (a) a step of preparing an oil-in-water type emulsion by emulsifying a vegetable oil having an iodine value of not less than 135 with a surfactant, (b) a step of mixing said emulsion and a modified natural rubber latex, and then aging the mixture, and (c) a step of coagulating the mixture obtained in the step (b) to obtain a lump of a rubber, an oil extended rubber obtained by the preparation process, and a rubber composition for a tire and a tire which use the oil extended rubber.

Owner:SUMITOMO RUBBER IND LTD

Low-soot, low-smoke renewable resource candle

A low soot, low smoke candle that in one embodiment is made of renewable resource material such as plant source material. The candle may include plant source triglycerides and free fatty acids. The free fatty acids may be plant source or other source. Lower iodine value source materials provide highly saturated triglycerides and free fatty acids that in turn are low soot, low smoke. Iodine values of 10 or less down to 1 and 0.5 or less are taught. Use of agricultural “waste” material provides economically priced source material.

Owner:CLEANWAX

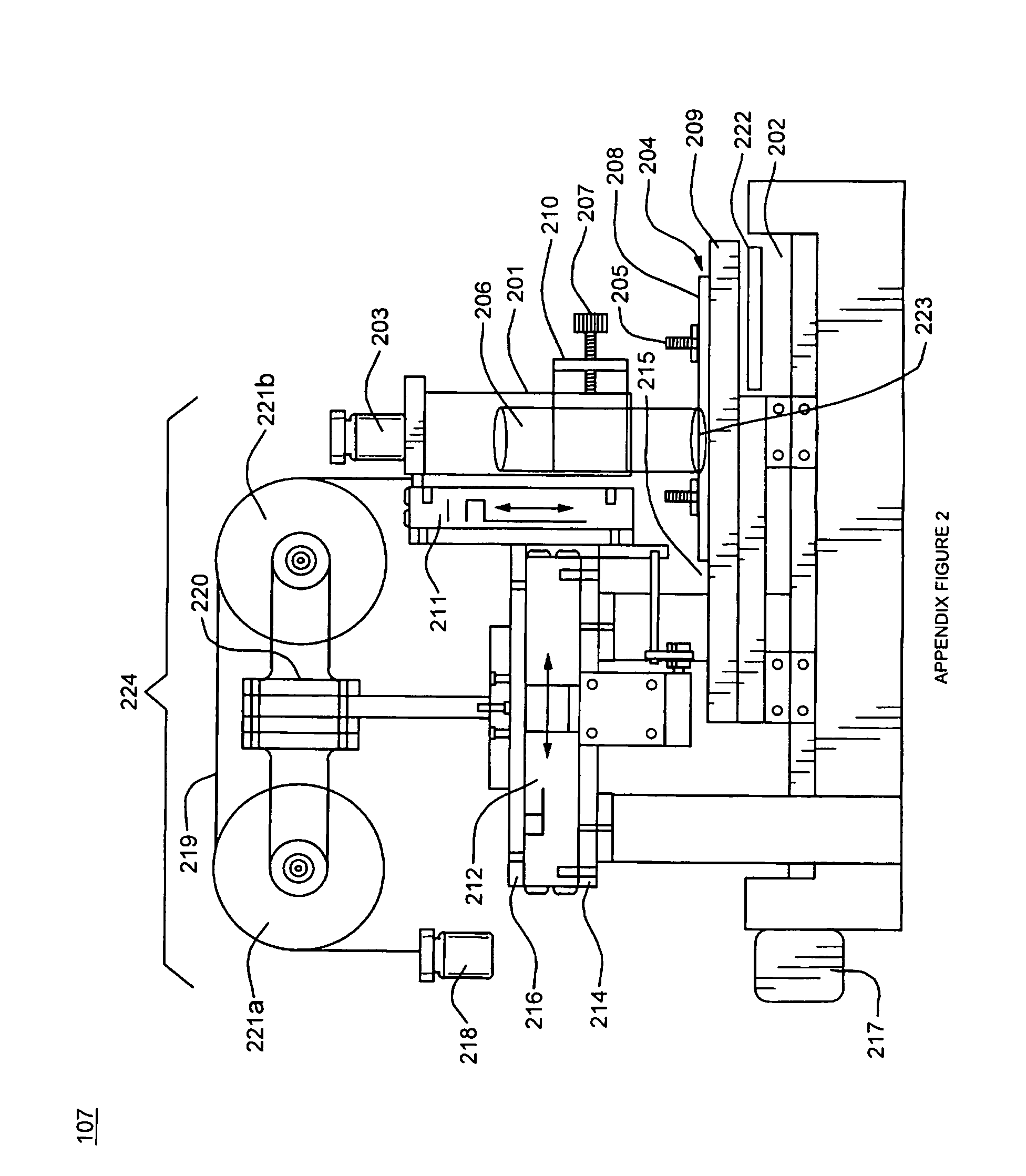

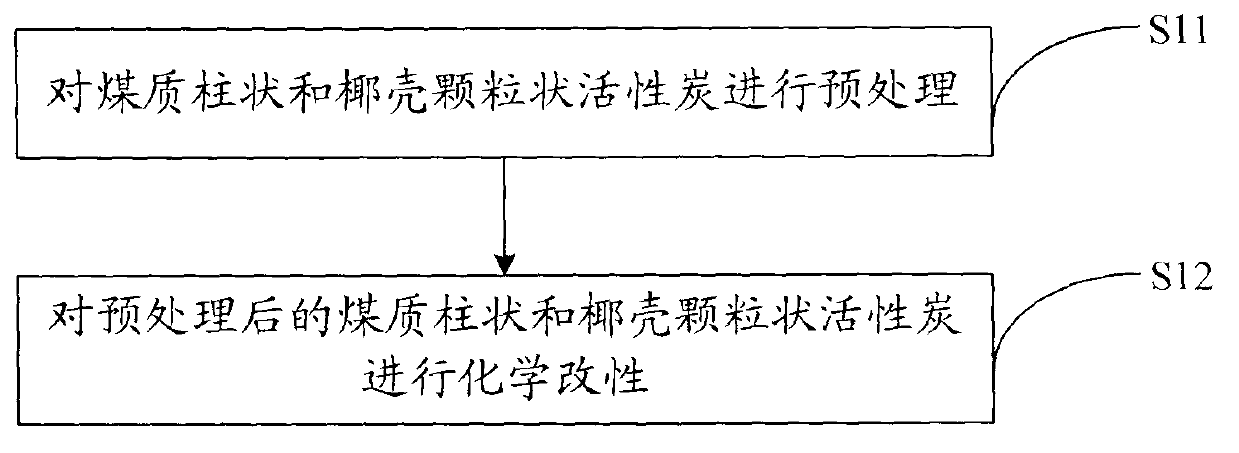

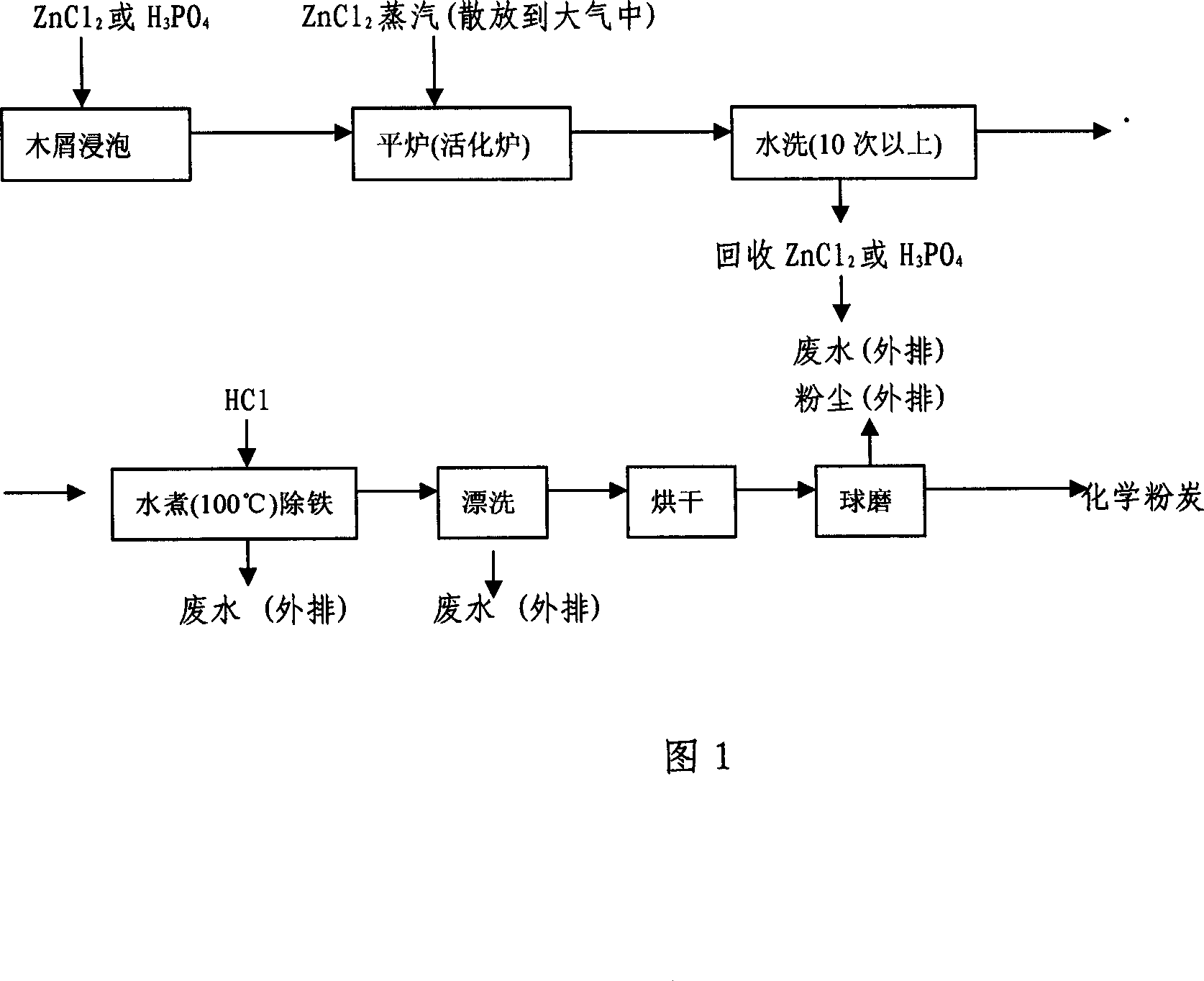

Preparation method of super-hydrophobic active carbon modified material

InactiveCN102989414ALarge hole volumeEasy to makeOther chemical processesAbsorption capacityLiquid water

The invention discloses a preparation method of a super-hydrophobic active carbon modified material. The material is prepared by applying a chemical liquid phase impregnation method, using trimethylchlorosilane as a modifier, using absolute methanol as a solvent, respectively using pre-processed coal columnar active carbon and coconut shell granulated active carbon as carriers, impregnating via liquid phase, drying in vacuum, and commonly blowing air and drying. The hydrophobic performance is respectively detected through a contact angle test and a liquid water adsorption experiment; and the adsorption is checked by using benzene adsorption experiment and an iodine value test. The invention has the advantages of simple preparation process, less material consumption and wild preparation condition; and the preparation method is carried out at room temperature. The prepared active carbon modified material has super-hydrophobic surface chemical performance and great pore volume, which makes up the shortcomings of easy absorption of moisture in the multi-pore carbon material with high humidity and small absorption capacity of the target organic matters; and the prepared active carbon modified material is easy to recycle and can be repeatedly recycled, so that the industrial cost is reduced and a foundation is further laid for the industrialized application.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

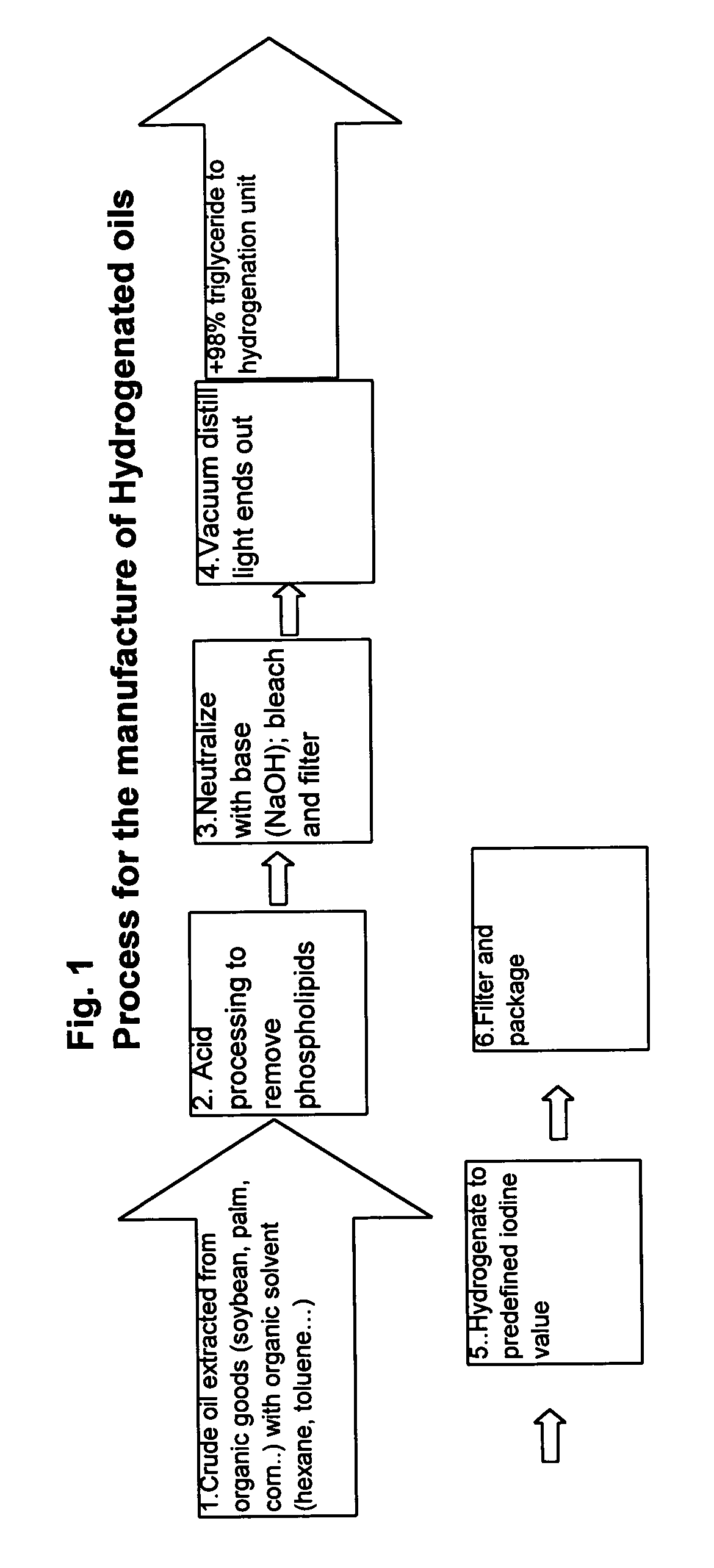

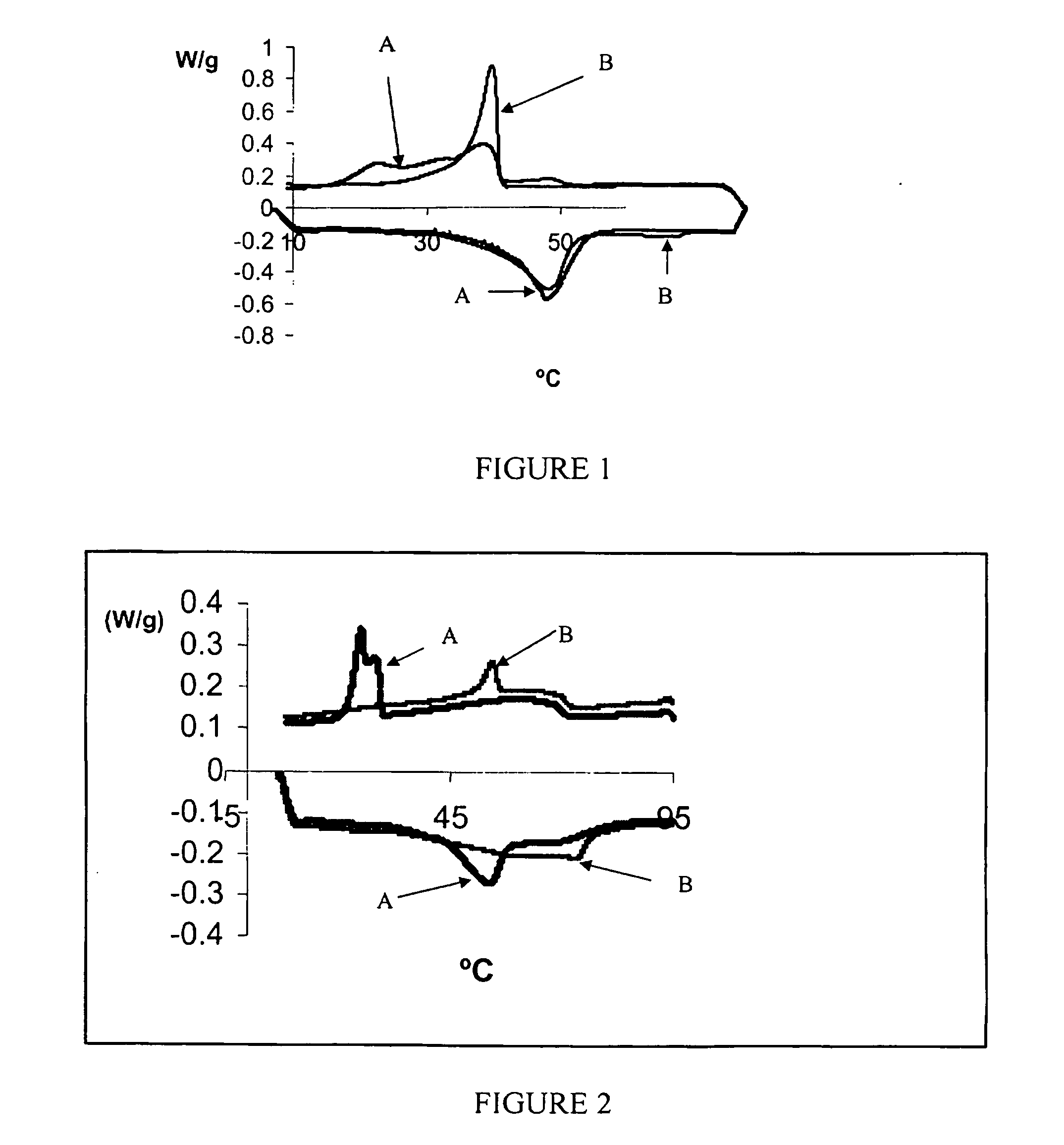

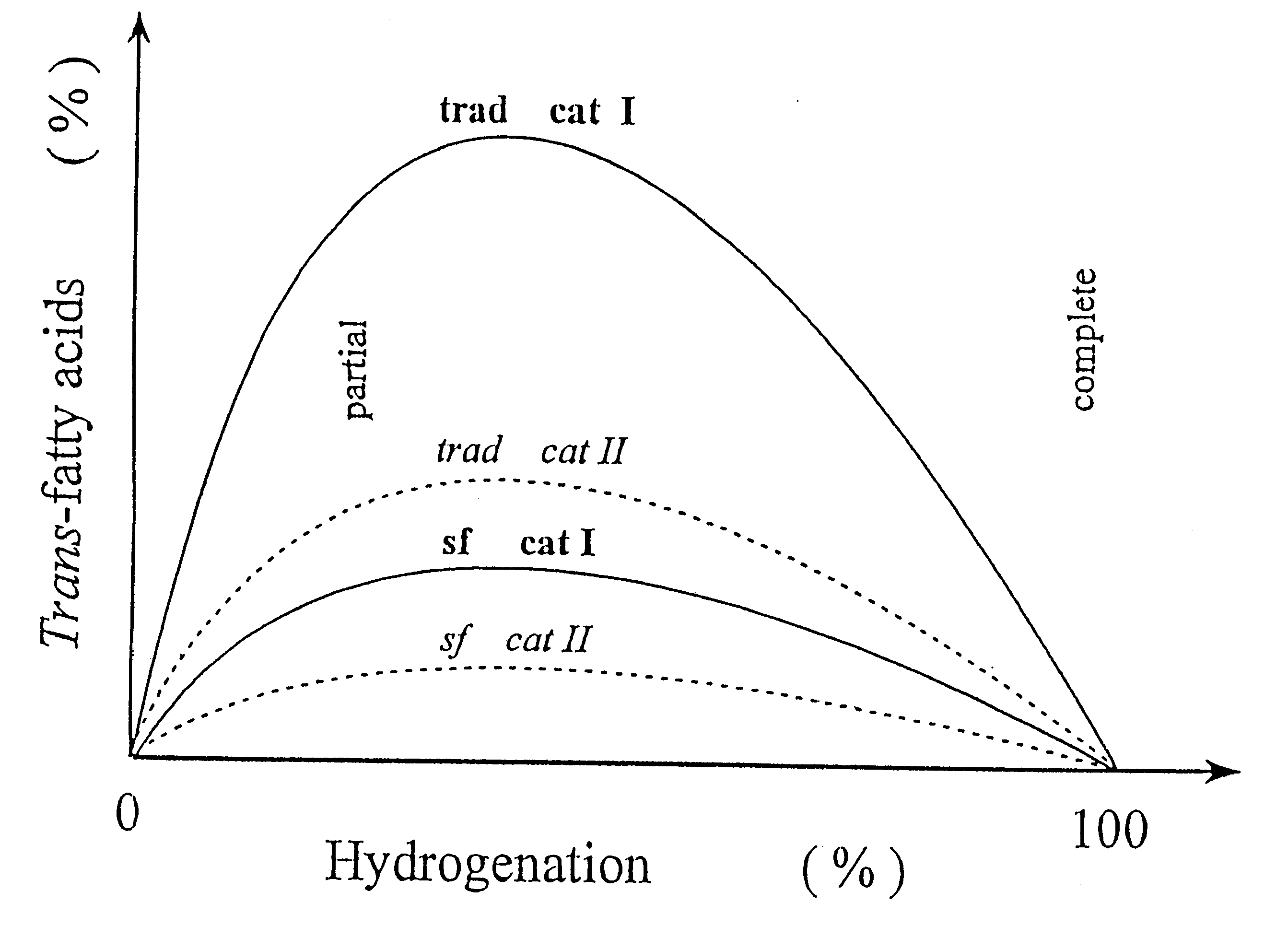

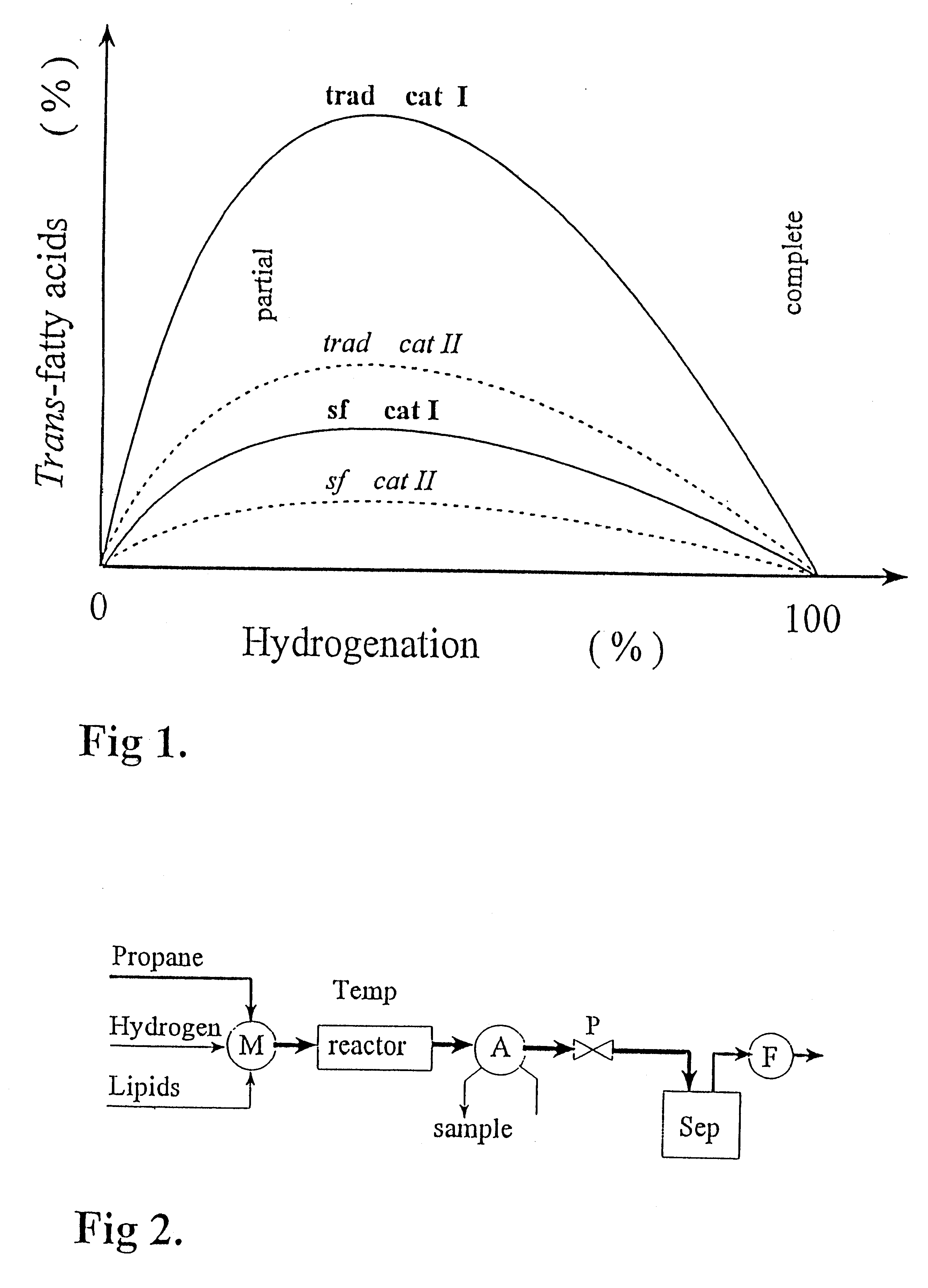

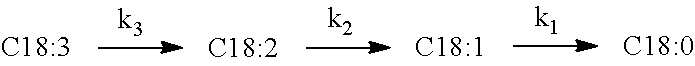

Partially hydrogenated fatty substances with a low content of trans fatty acids

A partially hydrogenated fatty substance produced by partial hydrogenation of a substrate, such as vegetable, animal or marine oil, said partially hydrogenated substance having a low content of trans fatty acids. When the hydrogenation degree is below 30% the trans-fatty acid concentration can be expressed in the following way: trans<=0.3x(initial IV-IV) in %. of the total amount of fatty acids, wherein IV refers to iodine value. When the hydrogenation degree is between 30 and 70% the trans-fatty acid concentration can be expressed with: trans<=0.09xinitial IV in % of the total amount of fatty acids. The partial hydrogenation is performed by a process in which the substrate, hydrogen gas and a solvent are mixed, and the whole mixture is brought into a supercritical or near-critical state. This substantially homogeneous super-critical or near-critical solution is led over the catalyst, whereby the reaction products formed, i.e. the hydrogenated substrates, will also be a part of the substantially homogeneous super-critical or near-critical solution.

Owner:POUL MOLLER LEDELSES OG INGENIORRADGIVNING APS

Copolymer rubber composition, rubber foamed product, and automotive sealant

Owner:SUMITOMO CHEM CO LTD

Wax emulsion coating applications

Owner:MARCUS OIL & CHEM

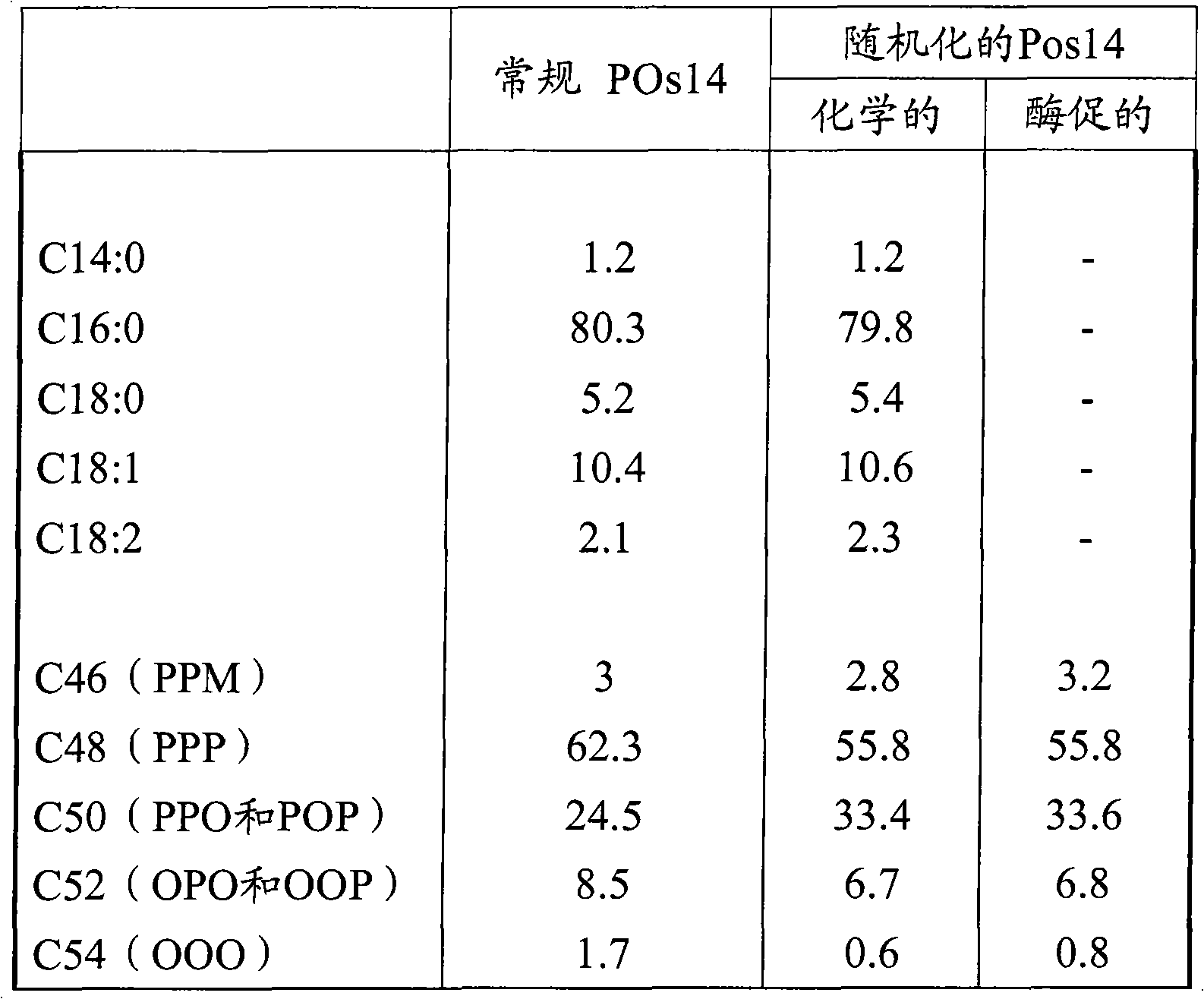

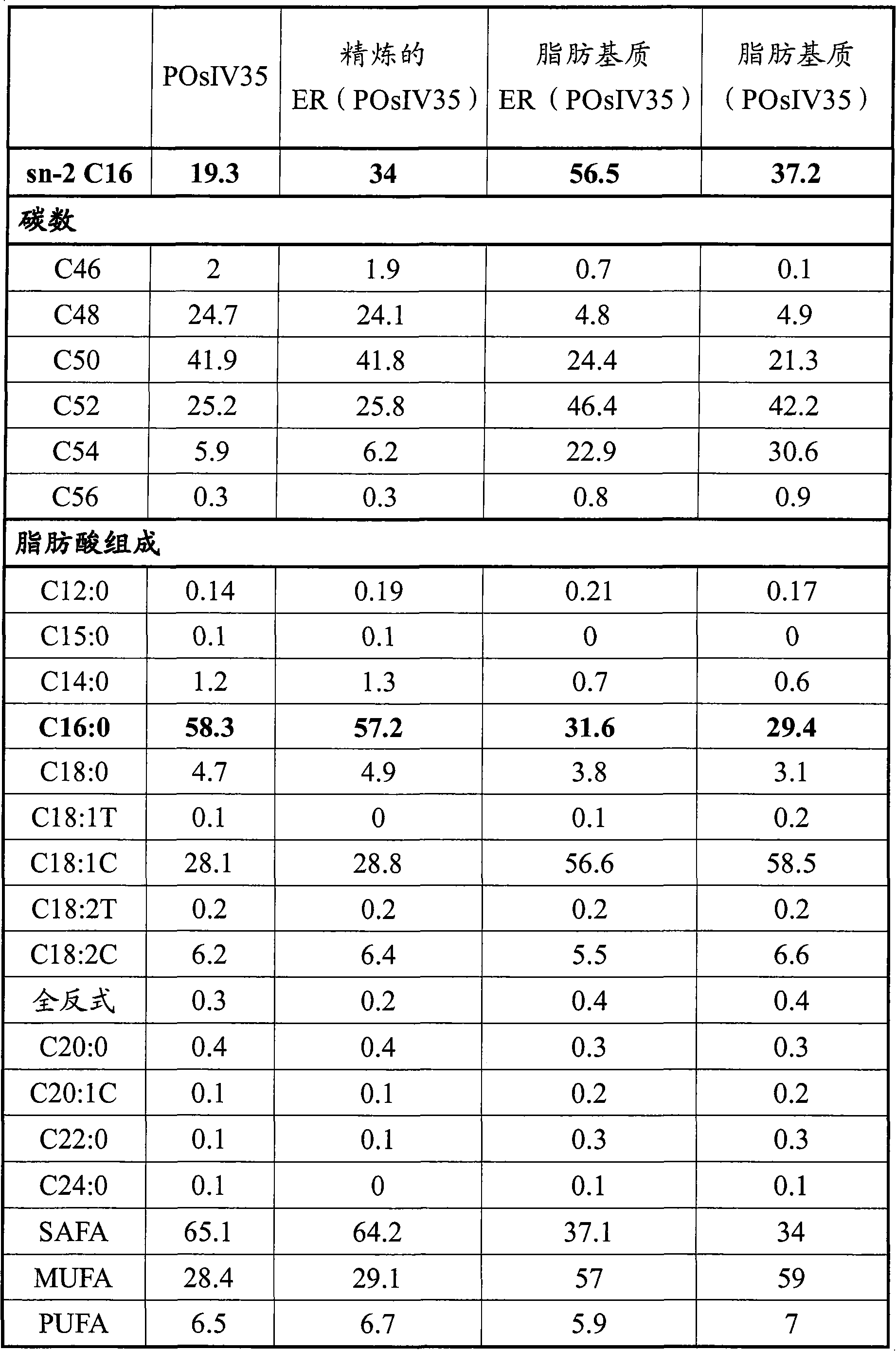

Process for producing a glyceride composition

ActiveCN101679909AFatty acid esterificationEdible oils/fatsTransesterificationOleic Acid Triglyceride

A process for the production of a composition comprising 1,3-dioleoyl-2-palmitoyl glyceride (OPO) comprises: providing one or more palm oil stearin fractions comprising tripalmitoyl glyceride and having an iodine value between about 18 and about 40; interesterifying the one or more palm oil stearin fractions to form a randomly interesterified palm oil stearin; subjecting the randomly interesterified palm oil stearin to enzymic transesterification with oleic acid or a non-glyceride ester thereof using an enzyme having selectivity for the 1- and 3- positions of a glyceride; and separating palmitic acid or palmitic non-glyceride esters from the product obtained in (iii) to form a composition comprising OPO glyceride.

Owner:LODERS CROKLAAN

Laundry product

InactiveUS20060019866A1Overcome disadvantagesProvide benefitsAnionic surface-active compoundsSurface-active non-soap compounds and soap mixture detergentsWater solubleLaundry

A unit dose fabric treatment system comprises (a) a water soluble container and (b) a liquid fabric treatment composition disposed in the water soluble container, the fabric treatment composition comprising two or more alkali metal fatty acid soaps derived from unsaturated fatty acid soaps formed from fatty acids having a iodine value greater than 20; and saturated fatty acid soaps formed from saturated fatty acids having an iodine value less than 5.

Owner:CONOPCO INC D B A UNILEVER

Method for producing epoxy fatty acid methyl ester by using illegal cooking oil

InactiveCN102161938AHigh speedEasy to control and adjust the dosageFatty acid esterificationPreparation by alcoholysisEpoxyDistillation

Owner:河北金谷增塑剂有限公司

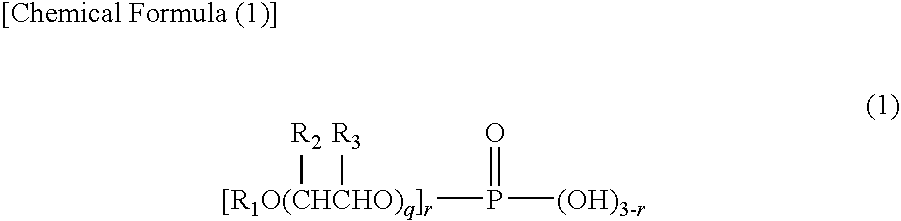

Composite method of isopentenol polyoxyethylene ether

InactiveCN101928392AStrong dispersion retention abilitySimple processEther preparation from oxiranesPolymer scienceEthylene oxide

The invention discloses a preparation method of isopentenol polyoxyethylene ether. Isopentenol and ethylene oxide are served as raw materials; in the presence of catalyst, the raw materials react for 5-40 hours to obtain the isopentenol polyoxyethylene ether at the reaction temperature of 70-160 DEG C. The isopentenol polyoxyethylene ether has the molecular weight of 200-6000 and the iodine value of 3.9-123; the mass ratio of isopentenol to ethylene oxide in the raw materials is 1:0.0143-0.754; and the mass of the catalyst is 0.03-0.5% of total mass of the raw materials of isopentenol and ethylene oxide. The invention has simple and reasonable technology. Because the invention has the structural particularity of branched chain methyl, molecular space steric hindrance is increased, and the composite polycarboxylic acid high-efficiency water reducer has strong cement particle dispersibility holding capacity. Thus, the product has the advantages of low dosage, high water-reducing ratio, good strengthening effects, good durability and the like, does not erode reinforcing steel bars and protects environment.

Owner:ZHEJIANG HUANGMA TECH

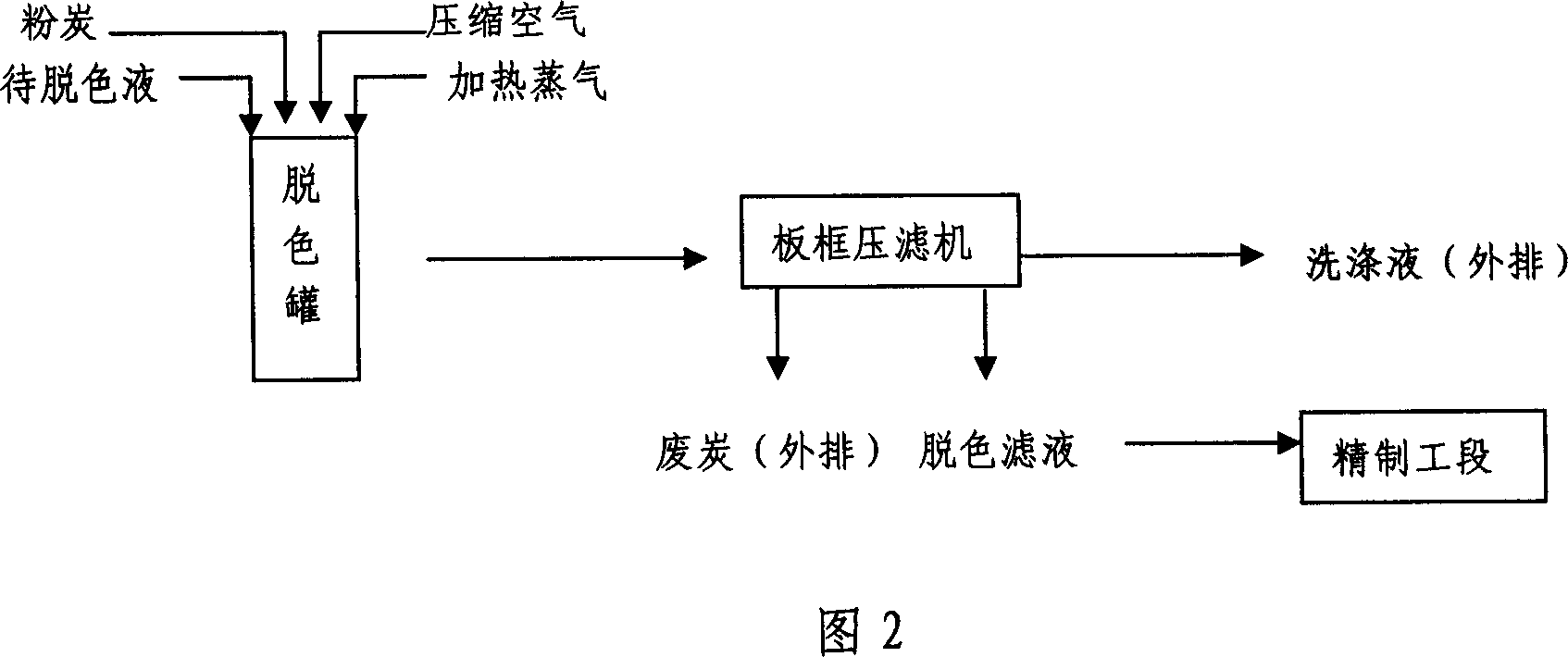

Granule decoloration active carbon and preparation method thereof

ActiveCN101054176AExcellent ability to remove macromolecular pigmentsGood decolorizationOther chemical processesActivation methodPhosphoric acid

The present invention relates to special active carbon for caramel decolorization and the preparation method thereof. The solid nutshell or coal serves as raw material which is processed by a physical chemistry immersion activation method to create active carbon. The immersion liquid is a water solution mainly comprising phosphoric acid, sodium hydroxide, magnesia and zinc chloride, wherein the proportioning by weight of each component is phosphoric acid: sodium hydroxide: magnesia: zinc chloride = 1:0.8~2.0:0.5~1.0:1~1.5. The obtained active carbon has an iodine value of 800~1000 mg / g, a caramel decolorization ratio of 80~100%, and a mechanical strength of 95%. The material is subjected to carbonizing, immersing, drying and activating treatment to create the active carbon product. The active carbon of the present invention has excellent decolorization property for macromolecule pigment, higher mechanical strength as general physical carbon, and wide application range. The traditional powdery carbon is replaced by granular activated carbon, the decolorizing pot is replaced by decolorizing column, the active carbon is changed from the disposable usage to the repeated and regenerated usage, and the decolorizing system can be continuously operated for a long time.

Owner:CHAOYANG SHENYUAN ACTIVE CARBON

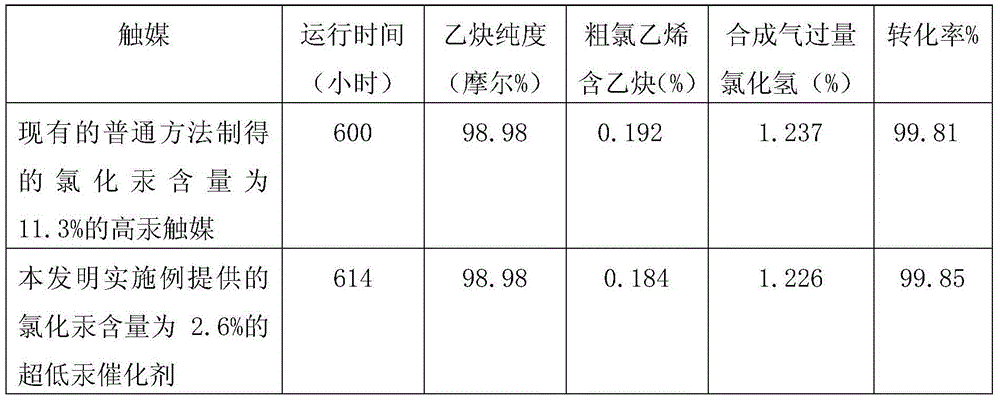

Ultralow-mercury catalyst and production process thereof

InactiveCN103551139AReduce manufacturing costLow in Mercury ChlorideCatalyst carriersPreparation by halogen halide additionVoid ratioPotassium

Owner:SHIJIAZHUANG KECHUANG ADDITIVES CO LTD

Crosslinkable Rubber Composition and Cross-Linked Rubber

ActiveUS20100168302A1Small compression setUniform mechanical strengthGroup 4/14 element organic compoundsLayered productsCross-linkPolymer science

A crosslinkable rubber composition comprising 0.2 to 10 parts by weight of an aromatic secondary amine-based anti-aging agent and 0.5 to 20 parts by weight of a polyamine-based crosslinking agent with respect to 100 parts by weight of a nitrile rubber including an α,β-ethylenically unsaturated nitrile unit and an α,β-ethylenically unsaturated dicarboxylic acid monoester unit, and with iodine value of 120 or less. The present invention can provide a crosslinkable rubber composition, providable of a cross-linked rubber excellent in a variety of properties such as mechanical strength and small in compression set, and a cross-linked rubber obtained by cross-linking the rubber composition.

Owner:ZEON CORP

Polyol made from partialy hydrogenated, fully epoxidized natural oils

InactiveUS20110065821A1Low densityResistant to yellowingFatty acid hydrogenationFatty acid oxidationVegetable oilGram

A method is disclosed for making a polyol comprising: fully-epoxidizing a partially hydrogenated vegetable oil to obtain a fully-epoxidized vegetable oil derivative having an iodine value less than 4 g I2 / 100 gram, an EOC of from 4.0 to 5.7% and a Gardner color value of 2 or less; and then reacting the fully-epoxidized vegetable oil derivative with a ring opener to form a polyol having a hydroxyl number from 40 to 80 mg KOH / gram, a number average molecular weight of at least 1500 Daltons, a dynamic viscosity less than 10 pascal-seconds, and an EOC below 3.0 wt %.

Owner:CARGILL INC

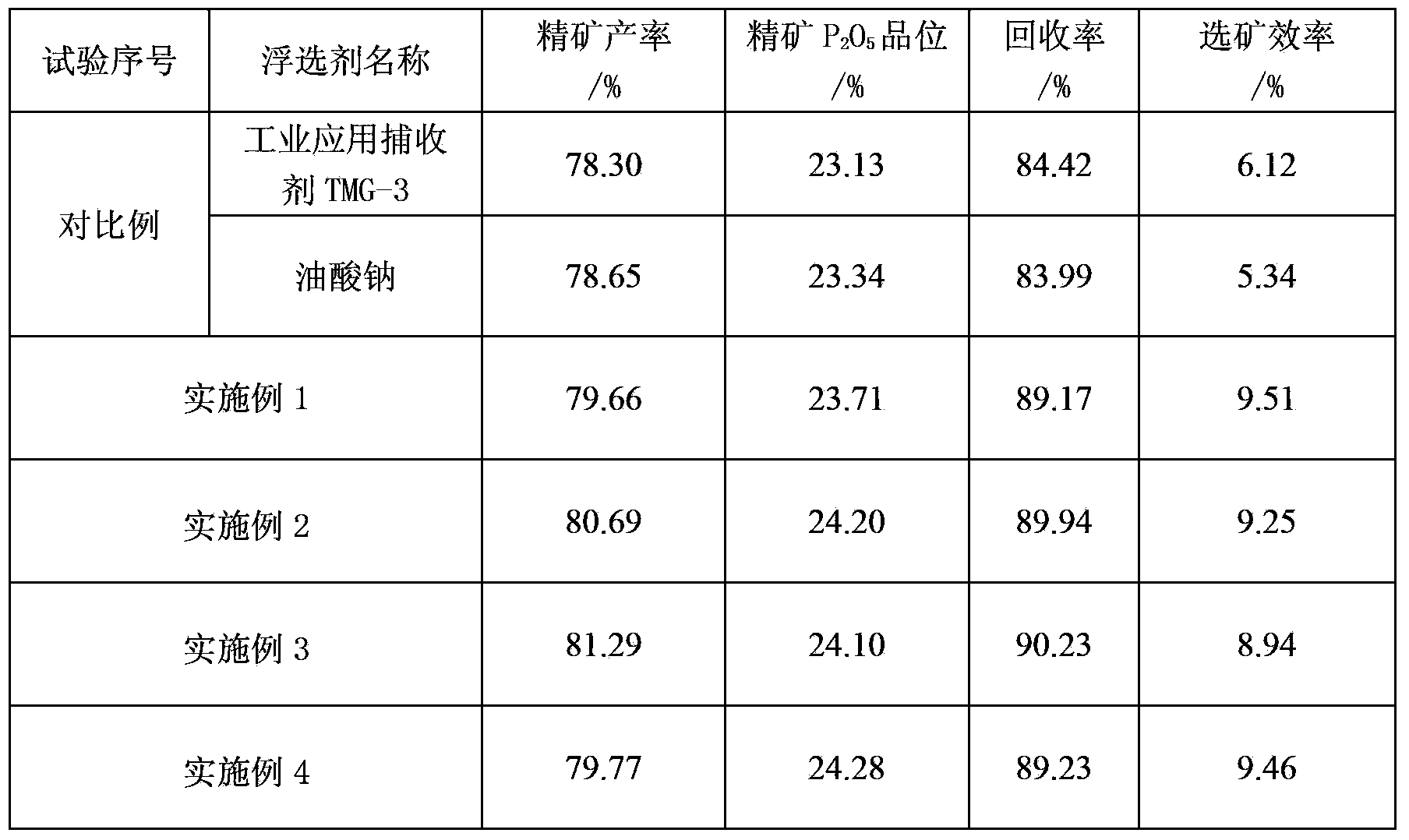

Collophanite positive floatation collecting agent and preparation method thereof

The invention belongs to a collophanite floatation technology and relates to a collophanite positive floatation collecting agent and a preparation method thereof. The collophanite positive floatation collecting agent is prepared by the following steps: (1) performing fatty acid amide esterification reaction on fatty acid with iodine value of 135 and monoethanolamine to obtain a mixture containing fatty acid and monoethanolamine; (2) performing saponification reaction on the mixture and a sodium hydroxide solution to obtain a saponification mixture; (3) adding a surfactant into the saponification mixture and stirring uniformly to obtain the collophanite positive floatation collecting agent, wherein the fatty acid comprises 3.7 percent of stearic acid C18:0, 27.92 percent of oleic acid C18:1, 57.32 percent of linoleic acid C18:2, 2.61 percent of linolenic acid C18:3 and 8.45 percent of palmitic acid C16; the surfactant is OP-10. The collecting agent has good solubility, good selectivity and strong collecting ability and can realize normal-temperature floatation of the collophanite. In addition, the collecting agent has the advantages of wide source of raw materials, low price, simple preparation process and wide popularization and application value.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

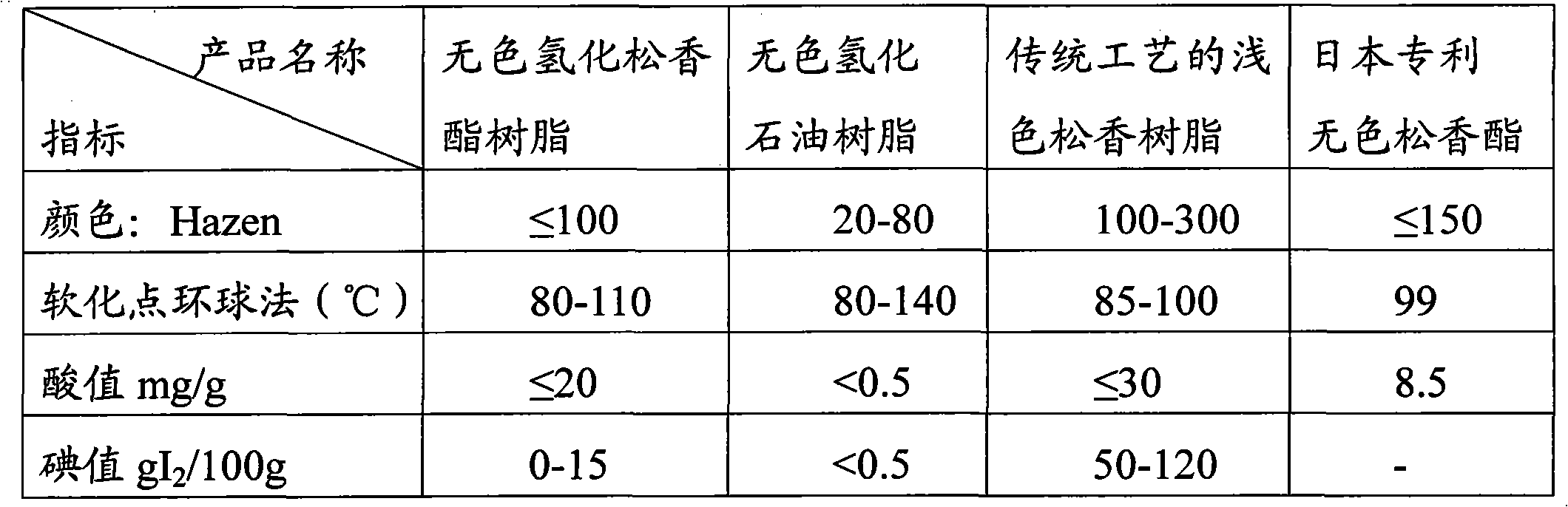

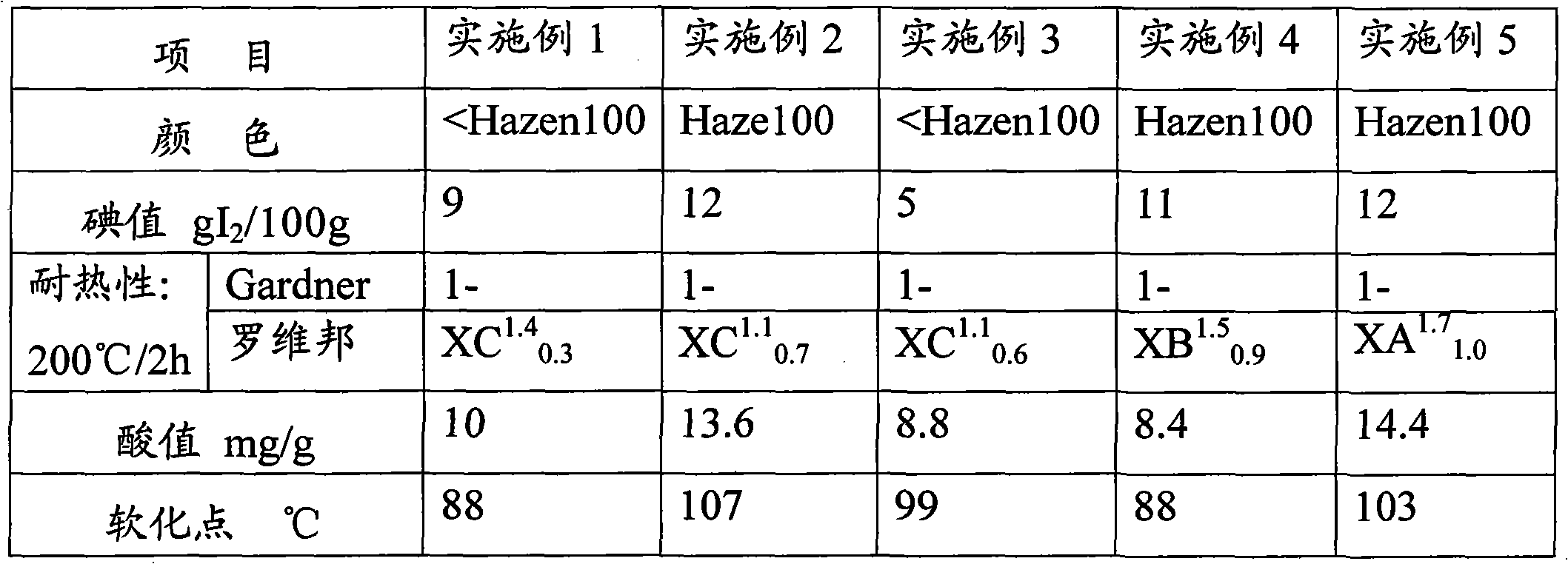

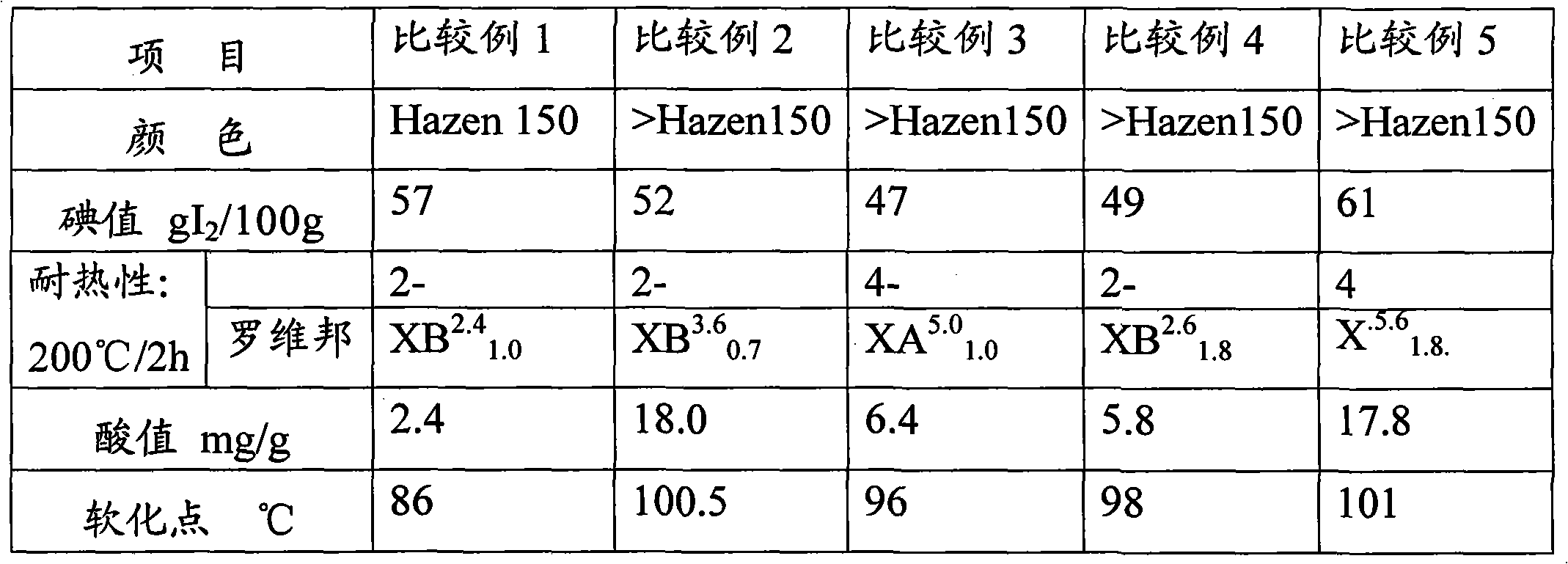

Method for preparing colorless hydrogenated rosin ester resin

ActiveCN102002321AHigh purityReduced chance of poisoningNatural resin chemical modificationAdhesiveDistillation

The invention relates to a method for preparing colorless hydrogenated rosin ester resin. Rosin ester obtained by esterifying rosin purified through distillation is used as a raw material, catalytic hydrogenation is carried out under the action of a solvent and a high activity catalyst, the solvent is separated through distillation, and the colorless hydrogenated rosin ester resin is obtained. The product comprises the following key indexes of: no more than 100 of Hasson color number, no more than 20 mg / g of acid value, 80 to 110 DEG C of softening point and 0 to 15 gI2 / 100g of iodine value. The product can substitute a colorless hydrogenated petroleum resin product to be applied to the high-end adhesive. The method for preparing the colorless hydrogenated rosin ester resin is simple and easy, and the prepared product has the advantages of shadow color, lower iodine value, higher stability and lower preparation cost when being compared with the traditional products.

Owner:广西梧州日成林产化工股份有限公司

Process for preparing furfural by using agricultural by-products of high and crude fiber plants

InactiveCN102659723AImprove productivityHigh iodine valueOrganic chemistryCarbon compoundsFiberPhosphoric acid

The invention discloses a process for preparing furfural by using agricultural by-products of high and crude fiber plants. The process includes the steps of 1) conducting pretreatment of raw materials; 2) hydrolyzing pretreated raw materials in a hydrolyzing tank, and using an acid catalyst formed by mixing sulfuric acid and phosphoric acid during the hydrolytic process; 3) introducing high-temperature steam into the hydrolyzing tank, heating up the hydrolyzing tank, and conducting gap stripping for hydrolysis products of furfural; and 4) feeding gas stripped furfural to into a furfural phase splitter to obtain coarse furfural and furfural residues. According to the process, the acid catalyst combining the sulfuric acid and the phosphoric acid is used for hydrolyzing the raw materials, and the hydrolytic process is assisted by ultrasonic treatment simultaneously, so that the productivity of the furfural is improved, the residue amount of the sulfuric acid is a little, the production of sulfur oxides in the subsequent activating process of furfural residues is reduced, and the environmental pollution is reduced. Besides, the invention also provides a process for producing activated carbon adsorbents by using the furfural residues. The process includes the steps of drying the furfural residues, screening, roasting, hardening activating and steam curing, the obtained activated carbon specific surface is large, the iodine value is high and the adsorption capacity is high.

Owner:北京博能康成科技有限公司

Preparation method of methyl epoxidized fatty acid

The invention relates to a method for preparing epoxy fatty acid methyl ester based on ionic liquid catalysis, comprising the following steps that: 100 portions of fatty acid methyl ester with the iodine value of more than 80 or biodiesel oil, 10 to 30 portions of methanoic acid, and 1 to 10 portions of ionic liquid catalyst are evenly mixed, and then are stirred to increase the temperature to between 50 and 70 DEG C; 30 to 70 portions of hydrogen peroxide with the concentration of between 28 and 55 percent is dripped and is controlled to finish within two hours; the heat insulation is continued for 3 to 6 hours, and the reaction is stopped when the epoxy value of the product is up to more than 3.0. The catalyst is removed, and epoxy fatty acid methyl ester is obtained by quickly and centrifugally separating. The method is characterized in that: ionic liquid is used as the catalyst; compared with the prior method using concentrated sulfuric acid as the catalyst, the process has the advantages of quick reaction speed, short process flow, simple post-treatment, low corrosiveness, clean process, repeatedly used catalyst and so on, and has strong industrial application prospect.

Owner:FUJIAN NORMAL UNIV

Cross-Linkable Nitrile Rubber Composition and Cross-Linked Rubber

ActiveUS20090186977A1Improve machinabilityConvenience to workOther chemical processesGranular deliveryCross-linkPolymer science

A cross-linkable nitrile rubber composition comprising a nitrile rubber (A1) including an α,β-ethylenically unsaturated nitrile monomer unit and having iodine value of 120 or less, silica (B1) having CaO value determined by X-ray fluorescence composition analysis of 0.5 wt % or more, and a crosslinking agent (C1). According to the present invention, a cross-linkable nitrile rubber composition, capable of giving a highly-saturated cross-linked nitrile rubber having excellent mechanical properties such as elongation and small compression set, and excellent in workability, and a cross-linked rubber obtained by crosslinking the rubber composition can be provided.

Owner:ZEON CORP

Dicing/die bonding sheet

ActiveUS7517724B2Satisfactory adhesivenessEasy to separatePolyureas/polyurethane adhesivesSynthetic resin layered productsEpoxyDicing tape

Owner:RESONAC CORPORATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com