Collophanite positive floatation collecting agent and preparation method thereof

A technology of positive flotation and colloidal phosphate rock, applied in flotation, solid separation, etc., can solve the problems of difficult to effectively remove silicate minerals, complex mineral intercalation relationship, low low temperature flotation efficiency, etc., to achieve a strong market Promotion value, good chemical stability, good flotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

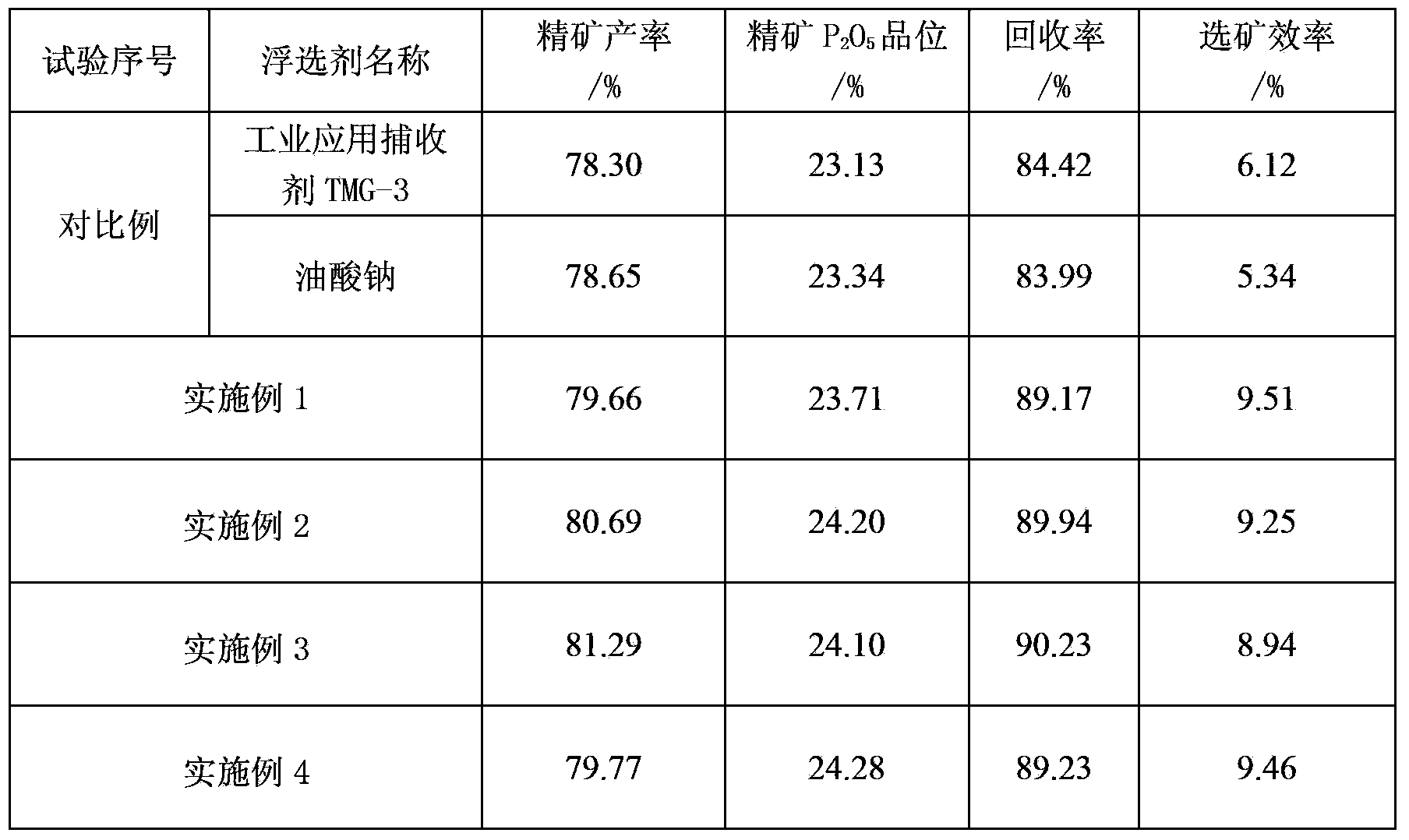

Examples

Embodiment 1

[0033] A collophanite flotation collector and a preparation method thereof, the specific preparation steps are as follows:

[0034] (1) Weigh 40 grams of fatty acids with an iodine value of 135 (including 1.48 grams of hard fatty acid, 11.168 grams of oleic acid, 22.928 grams of linoleic acid, 1.044 grams of linolenic acid, and 3.38 grams of palmitic acid), and 3 grams of monoethanolamine. Heat to 80°C, mix in a flask, and then put into a constant temperature water bath with magnetic stirring, the reaction temperature is controlled at 80°C, and the reaction time is 90min.

[0035] (2) Weigh 4g of sodium hydroxide in a beaker and dissolve it in 16g of water, heat to 80°C, weigh 20g of the mixture obtained in step 1 with a beaker, heat to 80°C, slowly add the sodium hydroxide solution into the mixture and stir, The temperature was controlled at 80°C, and the saponification reaction time was 20 minutes.

[0036] (3) Weigh the surfactant OP-104g, and slowly add it to the reaction...

Embodiment 2

[0039] A collophanite flotation collector and a preparation method thereof, the specific preparation steps are as follows:

[0040] (1) Weigh 40.0 grams of iodine value 135 fatty acids (including 1.48 grams of hard fatty acid, 11.168 grams of oleic acid, 22.928 grams of linoleic acid, 1.044 grams of linolenic acid, 3.38 grams of palmitic acid) and 4.0 grams of monoethanolamine, and heat them separately to 85°C, mixed in a flask, and placed in a constant temperature water bath with magnetic stirring, the reaction temperature was controlled at 85°C, and the reaction time was 105 minutes.

[0041] (2) Weigh 5g of sodium hydroxide in a beaker and dissolve it in 15g of water, and heat to 75°C; weigh 20g of the mixture obtained in step 1 in a beaker, and heat to 75°C; slowly add the sodium hydroxide solution into the mixture and stir, the temperature The temperature is controlled at 75°C, and the saponification reaction time is 25 minutes.

[0042] (3) Weigh 4.44g of surfactant OP-...

Embodiment 3

[0045] A collophanite flotation collector and a preparation method thereof, the specific preparation steps are as follows:

[0046] (1) Weigh 40 grams of fatty acids with an iodine value of 135 (including 1.48 grams of hard fatty acid, 11.168 grams of oleic acid, 22.928 grams of linoleic acid, 1.044 grams of linolenic acid, and 3.38 grams of palmitic acid) and 2.5 grams of monoethanolamine, and heat them separately to 100°C, mixed in a flask, put into a constant temperature water bath with magnetic stirring, the temperature was controlled at 100°C, and the stirring time was 120min.

[0047] (2) Weigh 6g of sodium hydroxide in a beaker and dissolve it in 14g of water, heat to 85°C, weigh 20g of the mixture obtained in step 1 in a beaker, heat to 85°C, slowly add the sodium hydroxide solution into the mixture and stir, the temperature The temperature is controlled at 85°C, and the saponification reaction time is 20 minutes.

[0048] (3) Weigh 105g of surfactant OP-10, and slowl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com