Patents

Literature

215 results about "Isopentenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isopentenol is an enol that is 3-methylbut-1-ene in which one of the terminal hydrogens is replaced by a hydroxy group. It derives from a hydride of an isopentane . Ontology Summary from ChEBI

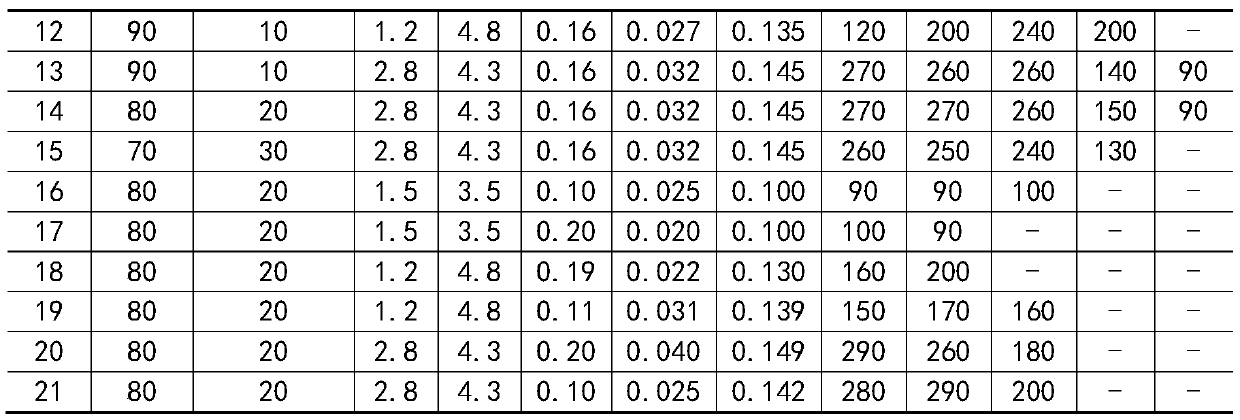

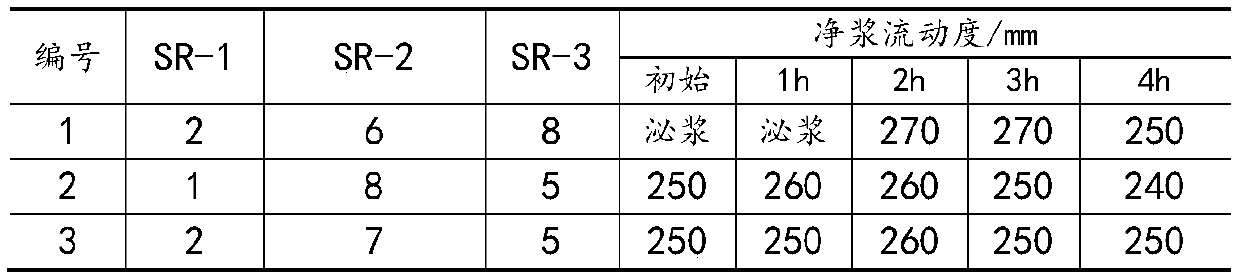

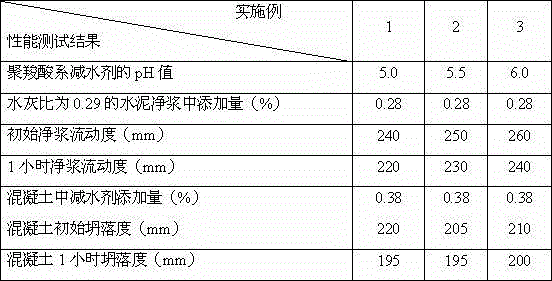

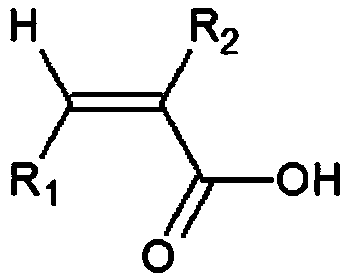

High slump retaining type polycarboxylic acid water reducing agent with sustained-release effect and preparation method thereof

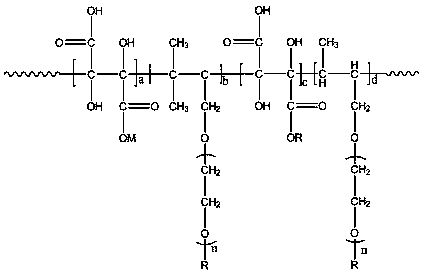

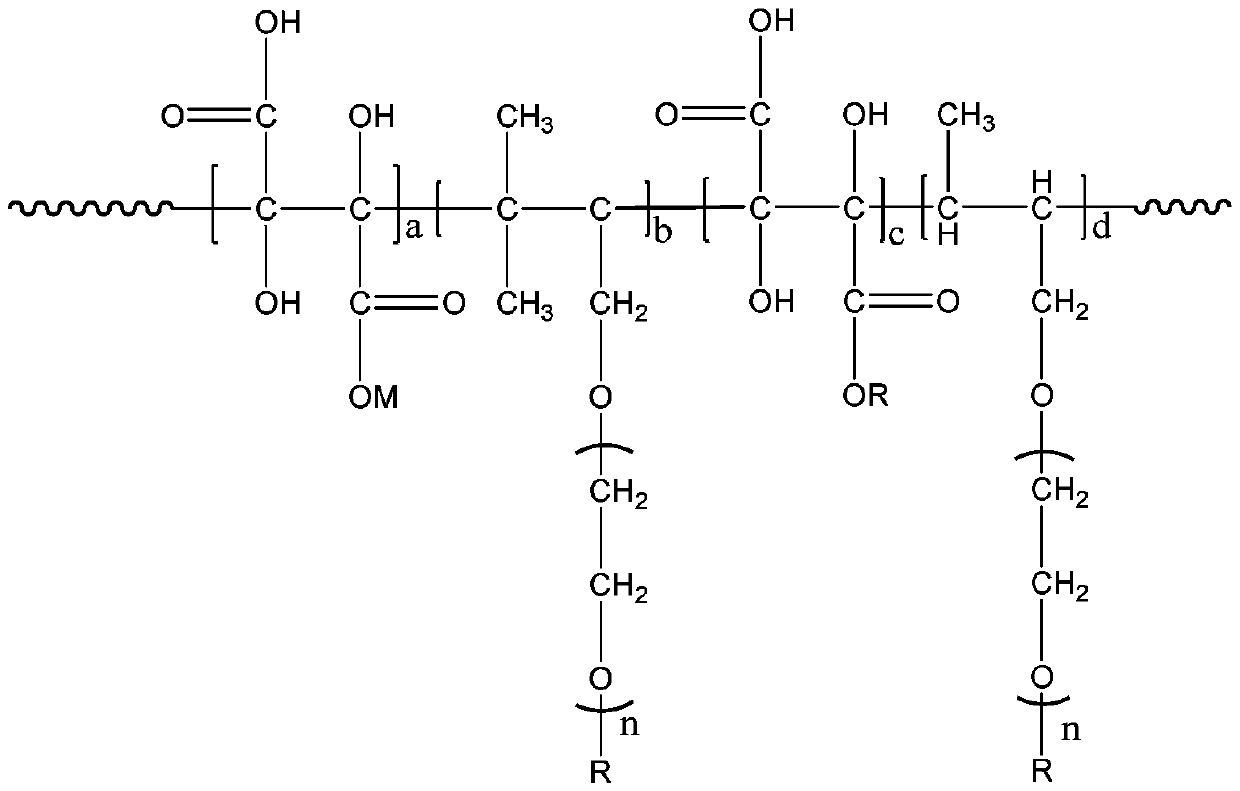

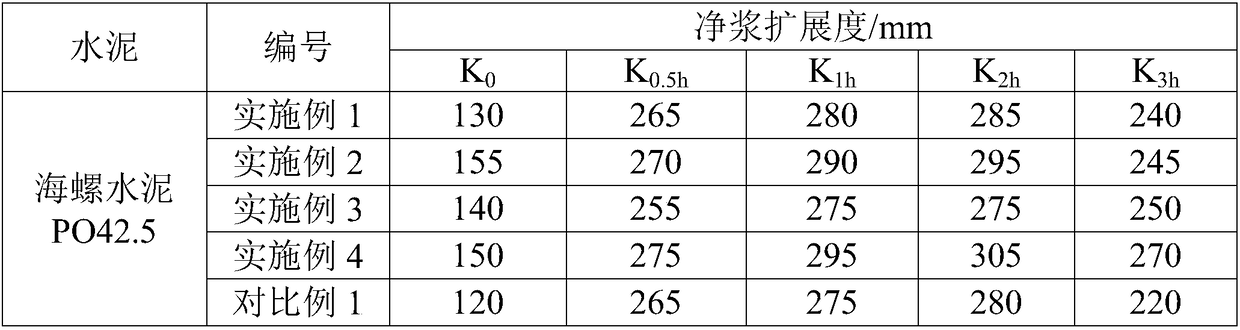

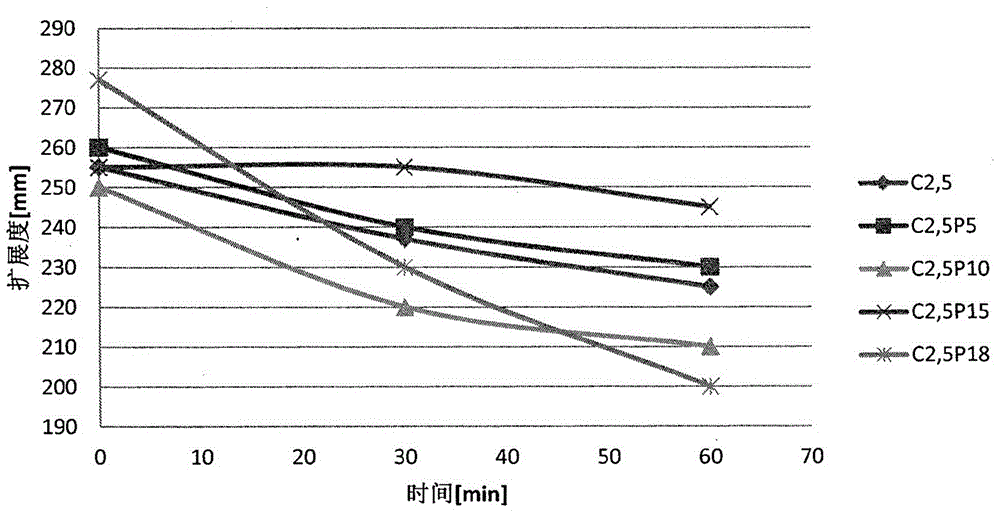

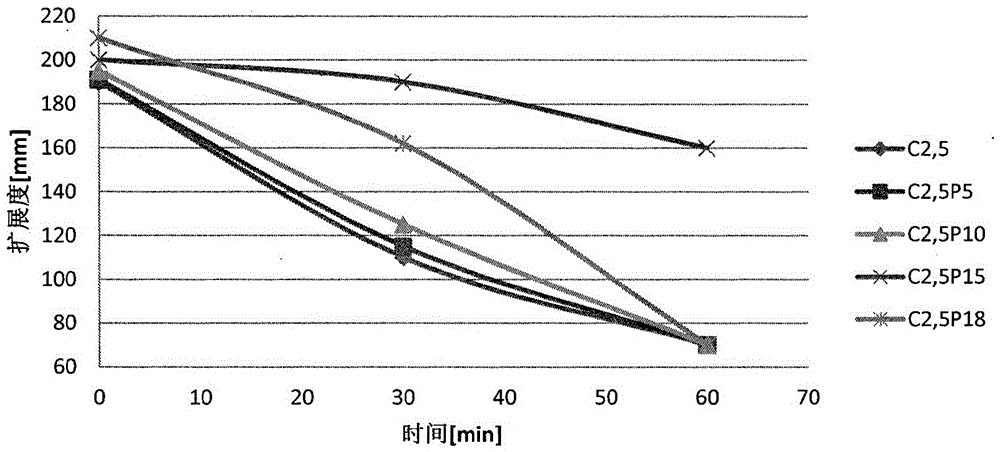

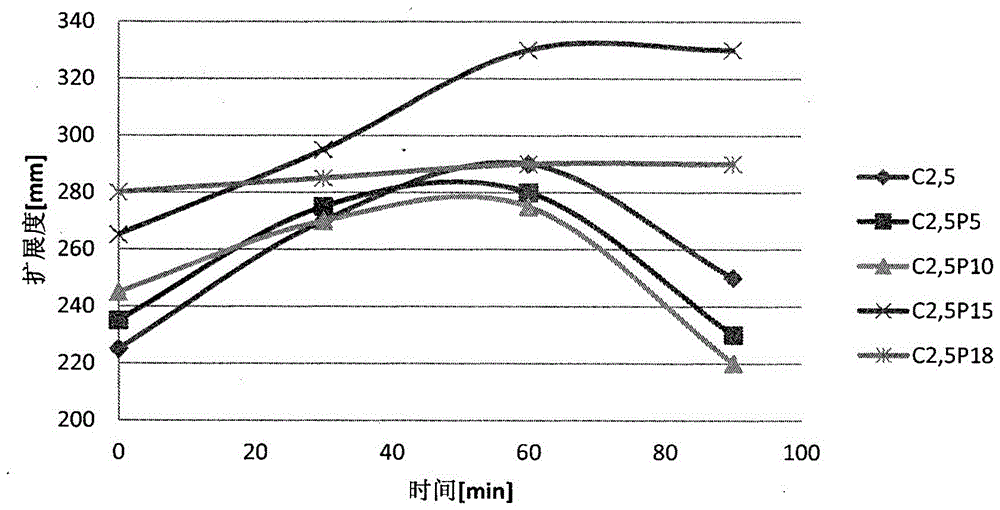

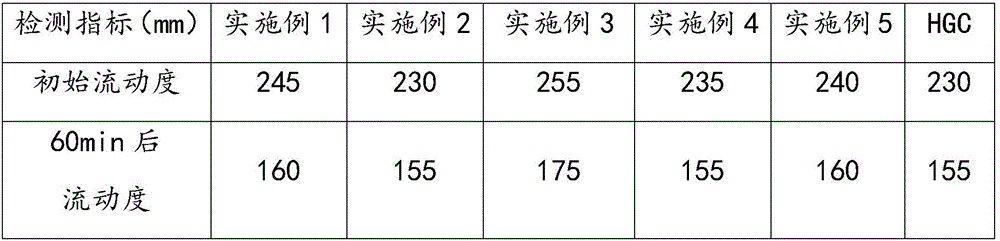

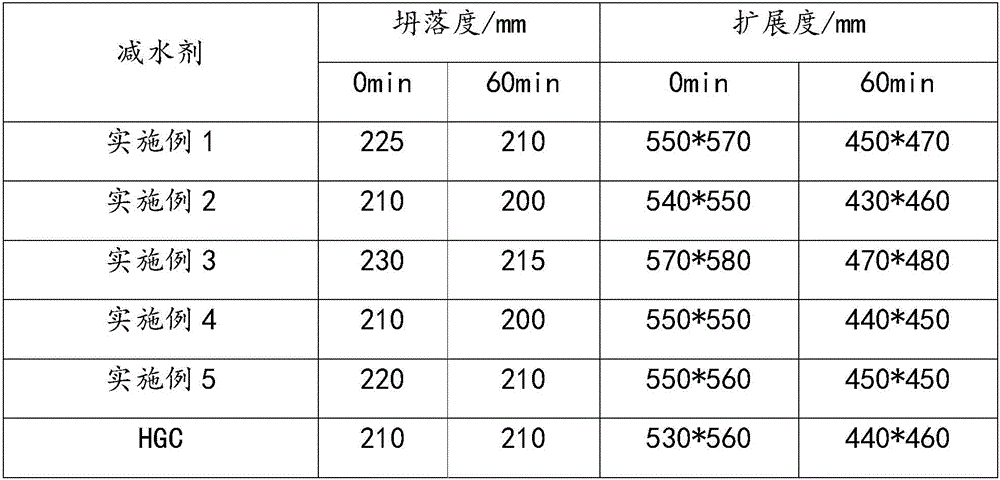

The invention relates to a high slump retaining type polycarboxylic acid water reducing agent with a sustained-release effect and a preparation method thereof. The preparation method is characterized by comprising the following steps of: preserving 5-30 mol% of monomer A, 30-60 mol% of monomer B, 20-55 mol% of monomer C at 60-80 DEG C for 1-3 h under the effect of an initiator, a chain transfer agent and a polymerization inhibitor; copolymerizing the monomers to obtain a polymer with molecular weight of 30000-100000; and then adding alkali to neutralize the polymer, wherein the total amount of the monomers A, B and C is 100 mol%; the monomer C comprises a slump retaining auxiliary 1 and a slump retaining auxiliary 2 according to a mol ratio of 1:20-13:20; the monomer A is isopentene alcohol polyoxyethylene ether, allyl polyethylene glycol, 1-methyl-2-allyl polyethylene glycol or allyl poly diglycidyl ether with polymerization degree n of 20-60; and the monomer B is acrylic acid or methacrylic acid. The high slump retaining type polycarboxylic acid water reducing agent with the sustained-release effect, provided by the invention, has the advantages of excellent slump retaining property, substantially no loss for slump degree within 3 h and wide applicability.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

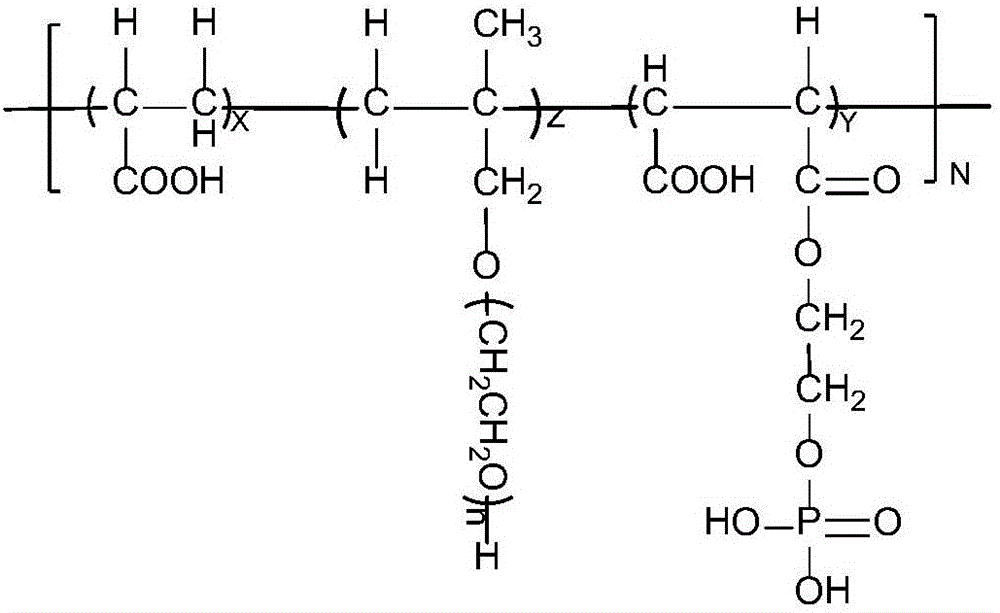

Phosphoric-acid-base modified polycarboxylic-acid water reducer with high adaptability and preparation method thereof

The invention discloses a phosphoric-acid-base modified polycarboxylic-acid water reducer with high adaptability and a preparation method thereof. The water reducer is prepared from the following raw materials: isopentenol polyoxyethylene ether, hydrogen peroxide, acrylic acid, an unsaturated phosphoric acid monomer, deionized water, a reducing agent, and a chain transferring agent. The chain transferring agent is one of mercaptoethanol, mercaptoacetic acid and mercaptopropionic acid. The unsaturated phosphoric acid monomer is prepared from 2-phosphono-1,2,4-butanetricarboxylic acid, p-toluenesulfonic acid and hydroquinone. The preparation method for the water reducer comprises adding isopentenol polyoxyethylene ether and deionized water into a reaction vessel, uniformly stirring, heating, keeping warm, adding oxygen peroxide, then dropwise adding a material solution by employing a constant-flow pump, continuing to keep warm for reacting for 1-1.5 h after dropwise adding of the material solution is finished, naturally cooling to room temperature, and adjusting the pH value of the obtained product to 5-6 by using an alkaline solution. The phosphoric-acid-base modified polycarboxylic-acid water reducer possesses good sulfate ion resisting capability and sludge resisting capability, thereby satisfying engineering demand.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

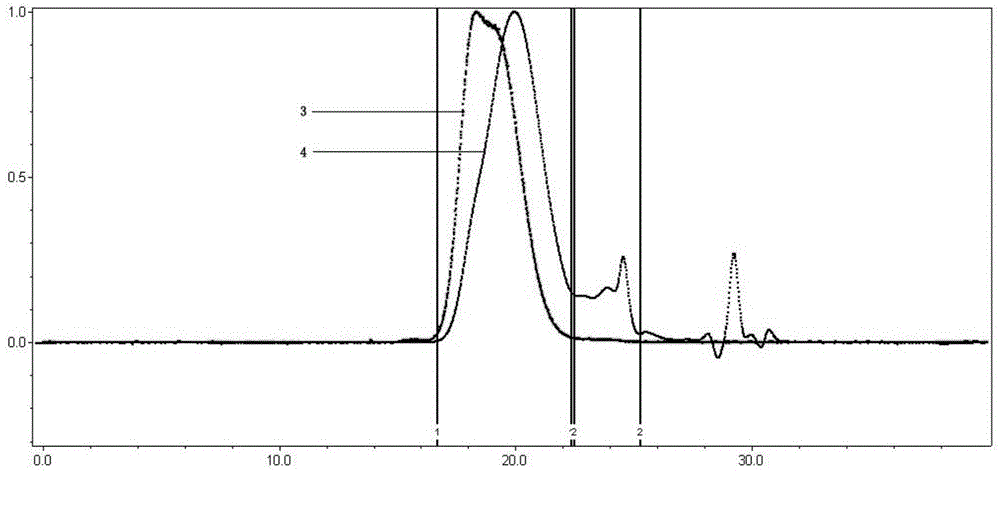

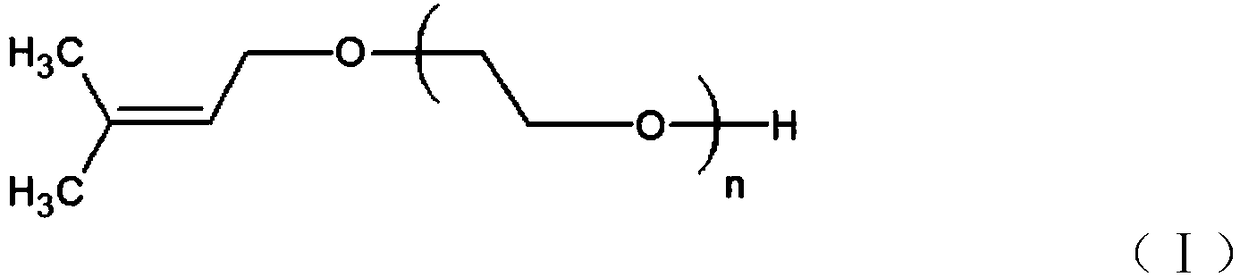

Composite method of isopentenol polyoxyethylene ether

InactiveCN101928392AStrong dispersion retention abilitySimple processEther preparation from oxiranesPolymer scienceEthylene oxide

The invention discloses a preparation method of isopentenol polyoxyethylene ether. Isopentenol and ethylene oxide are served as raw materials; in the presence of catalyst, the raw materials react for 5-40 hours to obtain the isopentenol polyoxyethylene ether at the reaction temperature of 70-160 DEG C. The isopentenol polyoxyethylene ether has the molecular weight of 200-6000 and the iodine value of 3.9-123; the mass ratio of isopentenol to ethylene oxide in the raw materials is 1:0.0143-0.754; and the mass of the catalyst is 0.03-0.5% of total mass of the raw materials of isopentenol and ethylene oxide. The invention has simple and reasonable technology. Because the invention has the structural particularity of branched chain methyl, molecular space steric hindrance is increased, and the composite polycarboxylic acid high-efficiency water reducer has strong cement particle dispersibility holding capacity. Thus, the product has the advantages of low dosage, high water-reducing ratio, good strengthening effects, good durability and the like, does not erode reinforcing steel bars and protects environment.

Owner:ZHEJIANG HUANGMA TECH

Polycarboxylate superplasticizer and preparation method thereof

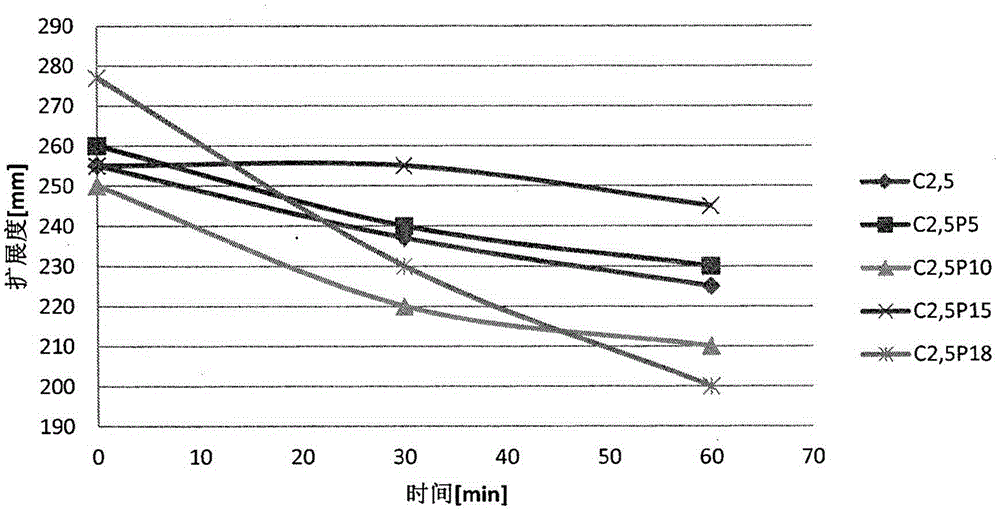

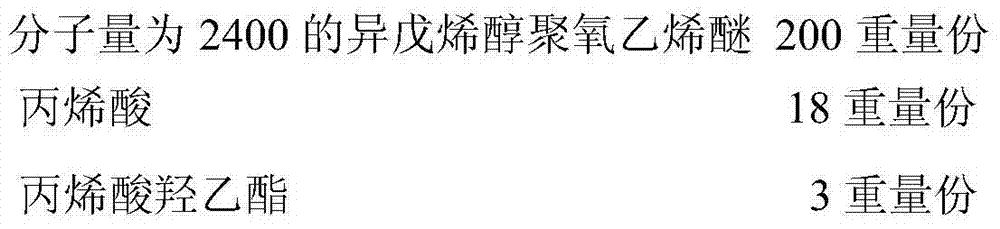

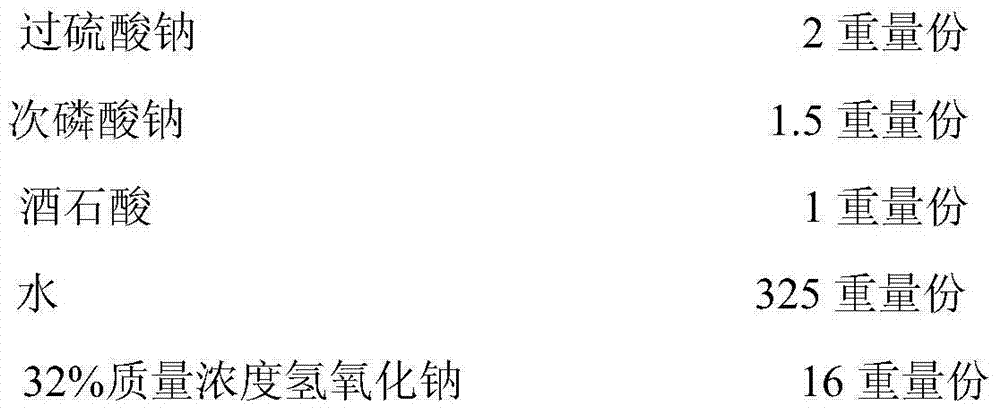

The invention discloses a polycarboxylate superplasticizer and a preparation method thereof. The raw materials of the polycarboxylate superplasticizer comprise the following components in parts by weight: 190-200 parts of a polyether monomer, 15-25 parts of unsaturated acid, 1-5 parts of hydroxyl alkyl acrylate, 1.5-3.5 parts of an oxidizing agent, 1-3 parts of sodium hypophosphite, 0.5-2.5 parts of tartaric acid, 325 parts of water and 11-21 parts of 30-32% sodium hydroxide by mass concentration, wherein the polyether monomer is 600-3000 methylallyl polyoxyethylene-polyoxypropylene or isopentenol polyoxyethylene ether. The preparation method of the polycarboxylate superplasticizer, disclosed by the invention, is carried out in a temperature range of 5-40 DEG C and can be used for solving the problem that the initiating efficiency is relatively low at a relatively low temperature when a single reducing agent is used, meanwhile, the dropwise adding time can be shortened, the production cycle is shorter, the energy consumption is relatively low and the production cost is lowered.

Owner:KZJ NEW MATERIALS GROUP CO LTD +2

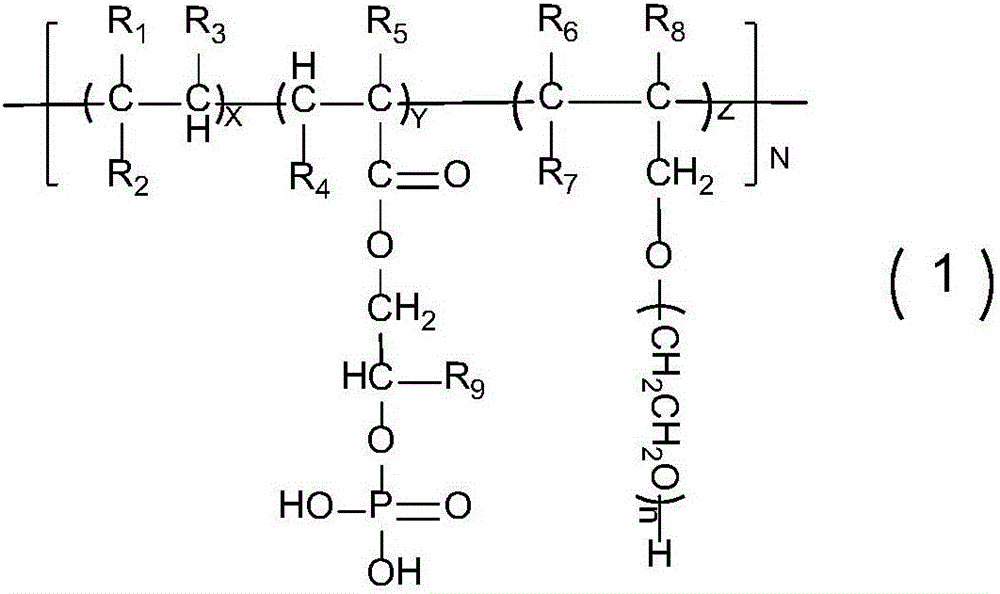

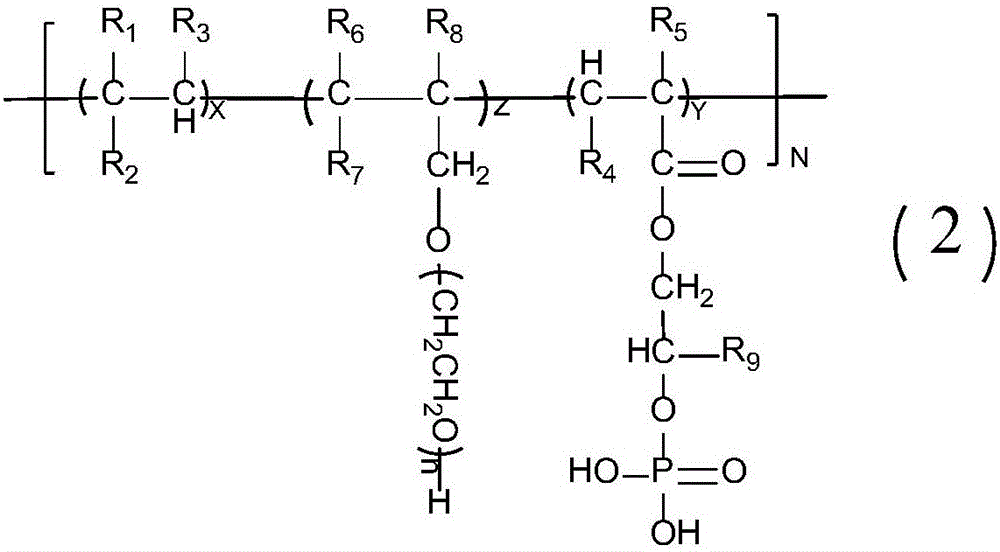

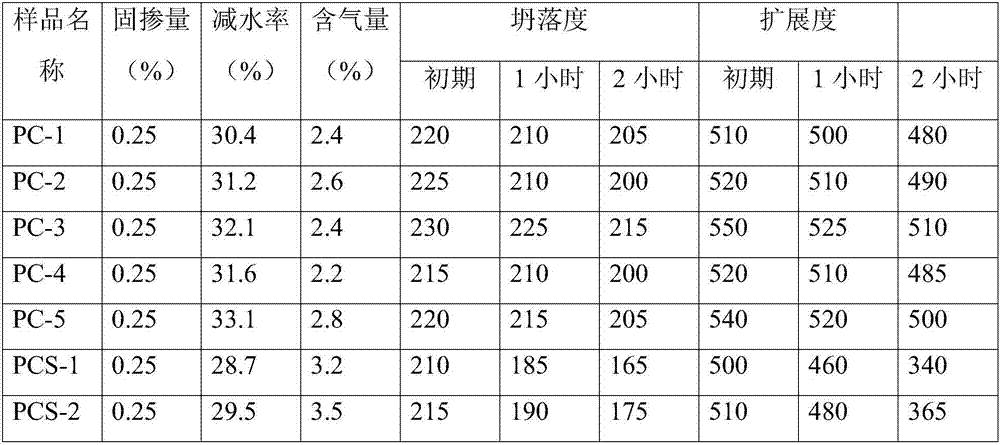

Phosphate-based high slump loss resistant type polycarboxylate high-performance water reducing agent and preparation method thereof

InactiveCN105837761AHigh carboxyl contentSlow down the hydration processOrganic compound preparationCarboxylic acid esters preparationAcid derivativeChain transfer

The invention relates to a structural formula and a preparation method of a phosphate-based high slump loss resistant type polycarboxylate high-performance water reducing agent. The method includes: performing esterification reaction of alcohol and a mixture of one or more of unsaturated acids and unsaturated acid anhydrides, performing phosphorylation of a phosphatizing agent and prepared unsaturated acid ester, subjecting prepared phosphate and isobutene or TPEG, a chain transfer agent and a mixture of one or more of unsaturated acids and unsaturated acid derivatives to free radical polymerization reaction at the normal temperature, and after reaction is finished, adding an alkali solution to regulate a pH to be 7-9 to obtain the phosphate-based high slump loss resistant type polycarboxylate high-performance water reducing agent. The water reducing agent has the advantages of excellent performances, low admixing quantity, high water reducing rate, excellent slump loss resistance, high cement adaptability, insensitivity to mud content of concrete materials and the like.

Owner:GUANGDONG FUTE NEW MATERIALS TECH CO LTD

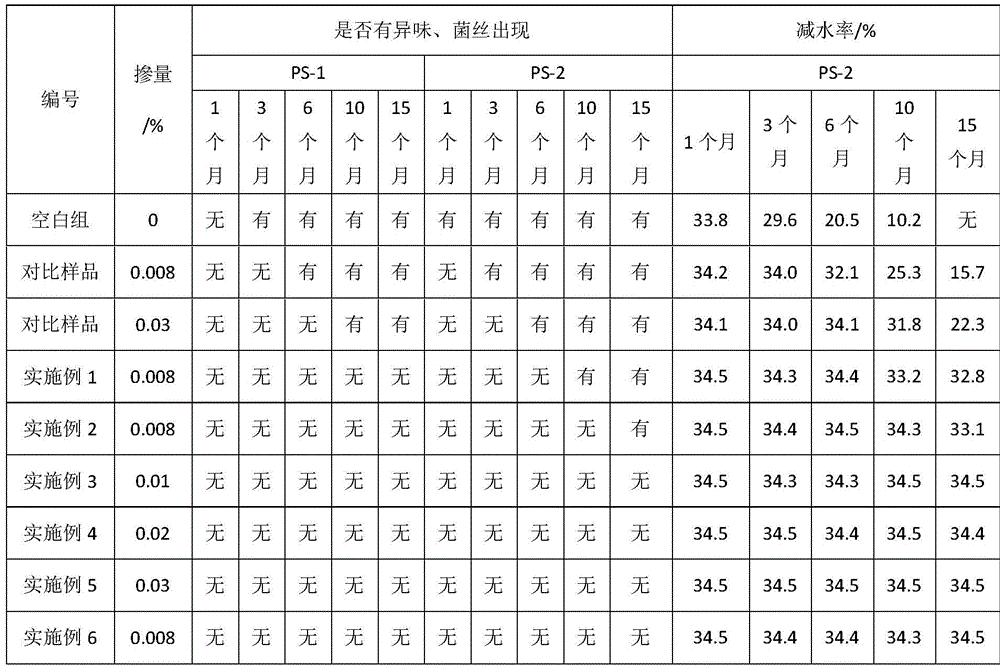

Preparation method of antibacterial preservative for polycarboxylate-type water reducing agent

The invention relates to a preparation method of an antibacterial preservative for a polycarboxylate-type water reducing agent. The preparation method comprises the following specific steps: carrying out a free radical polymerization reaction on isopentenol polyoxyethylene ether, alkyl glycine betaine and dimethyl fumarate under the action of an initiator, a reducing agent and a chain transfer agent; adding fluconazole in a reaction process to prepare the antibacterial preservative. The preservative is formed through carrying out free radical polymerization on an antibacterial preservation monomer and polyoxyethylene ether, has a molecular structure which is similar and compatible with the polycarboxylate-type water reducing agent and belongs to a macromolecular liquid polymer; the antibacterial preservative has remarkable mildew-proof and sterilization effects for long-period storage of the polycarboxylate-type water reducing agent; the antibacterial preservative has no chloride ions and good compatibility, and is green and environmentally friendly; a water reducing performance of the polycarboxylate-type water reducing agent can be free of influences for 15 months.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

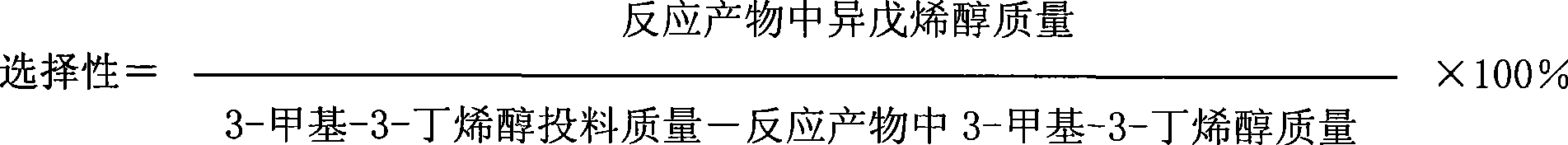

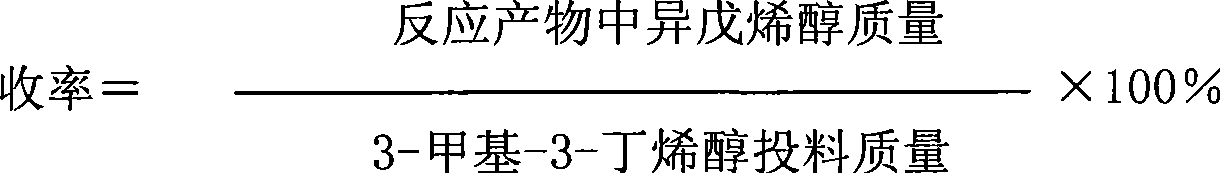

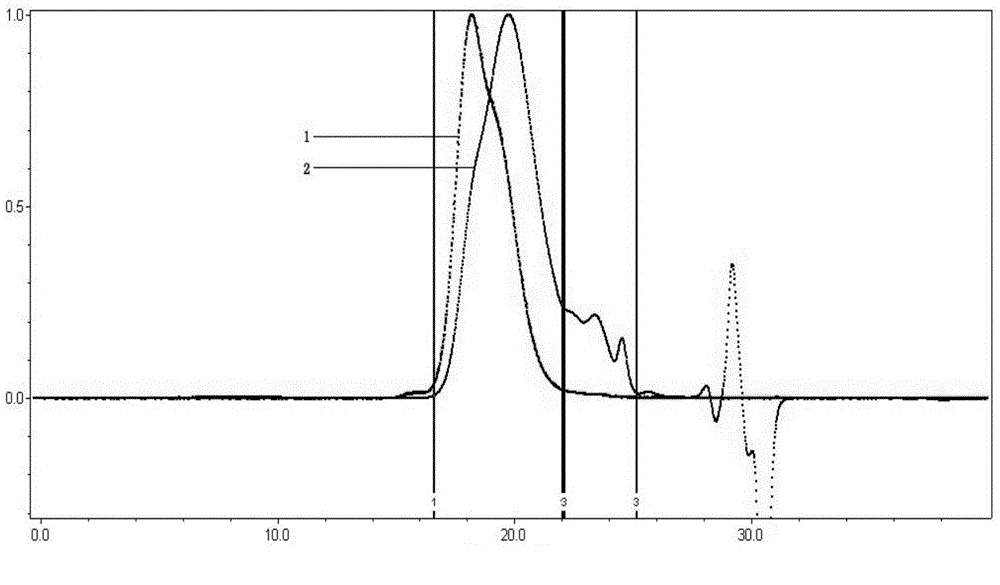

Method for preparing isopentenol from 3-methyl-3-butenol

ActiveCN101544538ALow content of active ingredientsReduce manufacturing costPreparation by isomerisationIsomerizationHydrogen

The invention relates to a method for preparing isopentenol from 3-methyl-3-butenol, which performs isomerization reaction on a raw material of 3-methyl-3-butenol to generate the isopentenol in the presence of a catalyst in an atmosphere containing hydrogen, wherein the reaction pressure is normal pressure, the reaction temperature is between 50 and 90 DEG C, the reaction time is between 25 and 40 minutes, the catalyst uses Al2O3 as a carrier, a load active component is metal Pd, the content of the Pd in the catalyst in percentage by weight is between 0.1 and 2.0 percent, the particle size of the catalyst is between 80 and 200 meshes, and the weight ratio of the raw material to the catalyst is 30-100:1. Compared with the prior art, the method has obvious improvement, the catalyst is simpler, and the content of the active component is lower, thus the preparation is easier and the cost is lower; the reaction condition is mild; and on the premise of ensuring the selectivity and the product yield of a perfect product, the reaction time is greatly shortened. The reduction of the preparation cost of the catalyst and shortening of the reaction time finally reduce the overall production cost greatly.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Early strength type ether polycarboxylate superplasticizer and preparation method thereof

The invention discloses an early strength type ether polycarboxylate superplasticizer and a preparation method thereof, and relates to the technical field of building materials. The superplasticizer is prepared from the following raw materials in parts by weight: 20-30 parts of an isopentenol polyethylene glycol monomethyl ether macromonomer with a polymerization degree of 27, 50-60 parts of an isopentenol polyethylene glycol monomethyl ether macromonomer with a polymerization degree of 113, 6.5-8.6 parts of acrylic acid or a derivative monomer thereof, 0.3-1.5 parts of a chain transfer agent, 0.4-0.6 part of an initiator, 2.5-3.5 parts of 2-acrylamido-2-methyl-1-propane sulfonic acid and 125-135 parts of deionized water. The early strength type ether polycarboxylate superplasticizer disclosed by the invention has the beneficial effects of small doping amount, remarkable early strength effect, high water reduction rate, small slump loss, environmental protection, smaller molecular weight distribution and higher free radical polymerization conversion rate, and the early strength of concrete prepared by a synthetic sample of the early strength type ether polycarboxylate superplasticizer disclosed by the invention is better than that of the concrete using a common superplasticizer.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

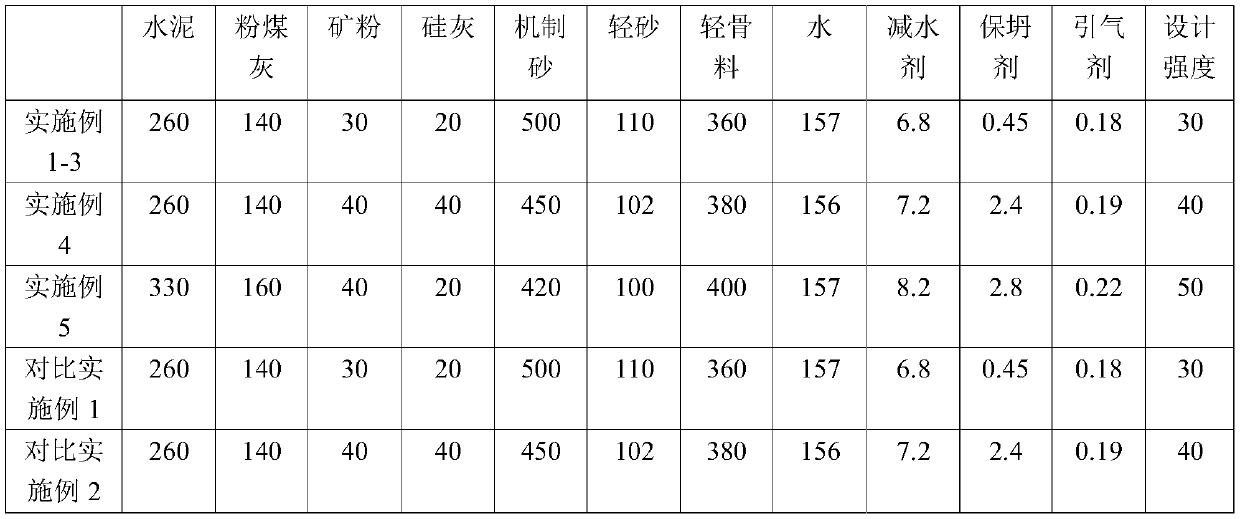

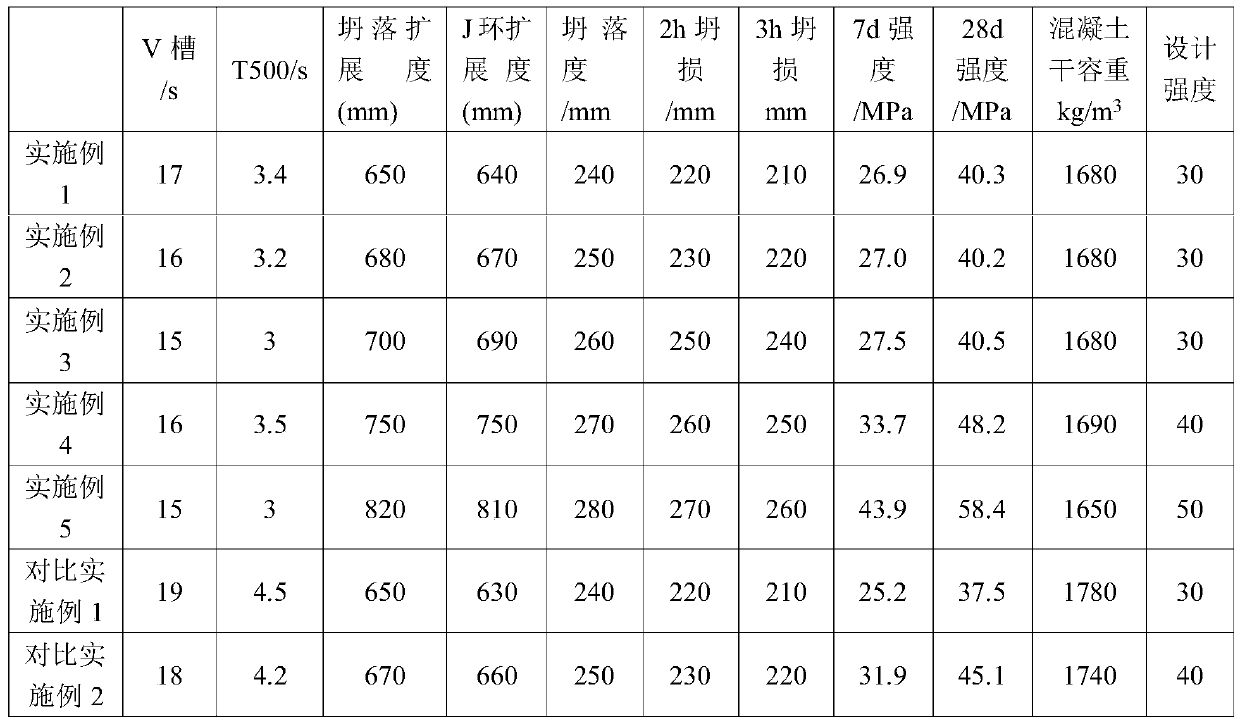

Self-compacting lightweight aggregate machine-made sand concrete and preparation method thereof

InactiveCN110240446ASolve the problem of insufficient resources and tight supplyImprove cohesionCeramicwareRosinWater reducer

The invention discloses self-compacting lightweight aggregate machine-made sand concrete. The sand concrete comprises the following raw materials in parts by weight: 260-330 parts of concrete, 140-160 parts of fly ash, 30-40 parts of mineral powder, 20-40 parts of silica fume, 420-500 parts of machine-made sand, 100-110 parts of light sand, 360-400 parts of lightweight aggregate, 150-160 parts of water, 6.8-8.3 parts of a water reducer, 0.45-2.8 parts of a slump preserving agent and 0.18-0.22 part of an air entraining agent, wherein the slump preserving agent is obtained by compounding isopentenol polyoxyethylene ether (TPEG), acrylic acid and a compound molecular weight regulator, the air entraining agent is a rosin soap type air entraining agent obtained by compounding rosin, caustic soda, triethanolamine and sodium lauryl sulfate. The machine-made sand is used to replace natural sand, and the concrete prepared by a secondary mixing method solves the problems of easy flotation of lightweight aggregate concrete aggregate, shortage of natural sand supply, and high water demand rate, easy separation and poor pumpability of lightweight aggregate machine-made sand concrete.

Owner:中建西部建设贵州有限公司

Preparation method of high-thixotropy early-strength type polycarboxylate superplasticizer

ActiveCN105504180APromotes early hydrationPromotes the function of hydration reactionVinyl etherSuperplasticizer

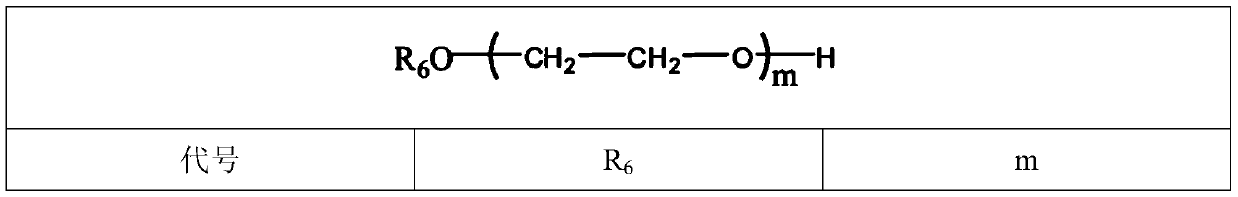

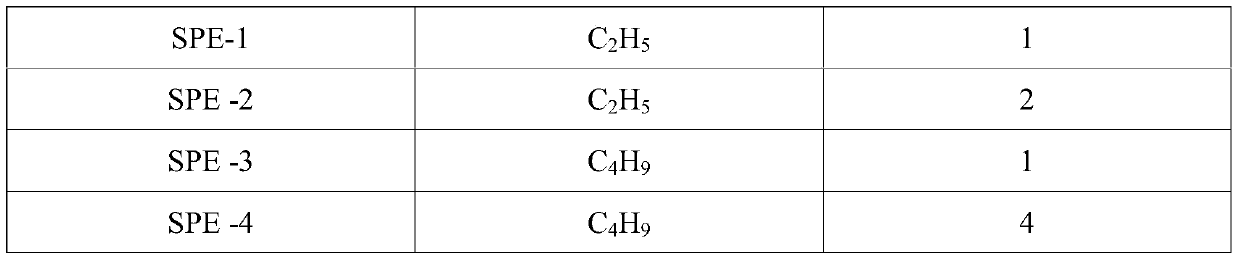

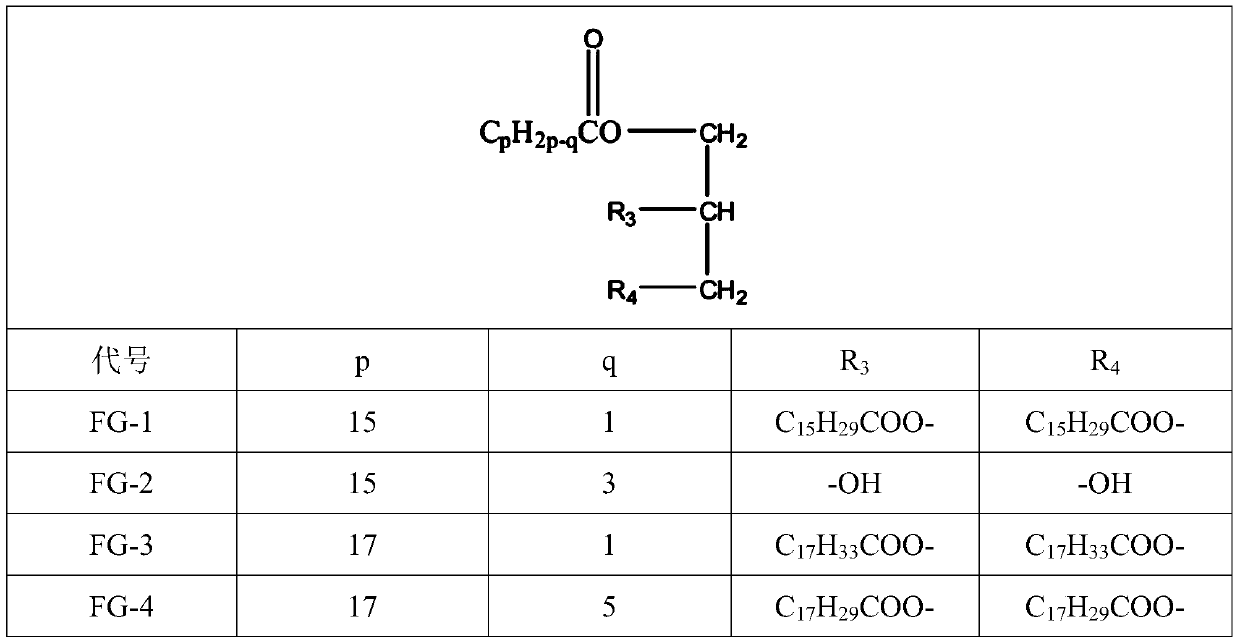

The invention discloses a preparation method of a high-thixotropy early-strength type polycarboxylate superplasticizer. The preparation method comprises the following steps of (1) adding isobutene polyoxyethylene ether and / or isopentene polyoxyethylene ether, micromolecular polyether, unsaturated fatty acid glyceride, a quaternary ammonium salt monomer and an oxidant into water, and stirring the mixture under 15 to 30 DEG C until the mixture is dissolved; (2) preparing a first solution by a reducing agent and water, preparing a second solution by a chain transfer agent and the water, and preparing a third solution by unsaturated monocarboxylic acid, an unsaturated carboxylic ester monomer and the water; (3) dropping the first solution, the second solution and the third solution in materials in step (1) within 3 to 4 hours at the same time, and carrying out a heat-preservation reaction for 1 to 1.5 hours under 35 to 40 DEG C after dropping is completed; (4) adding an alkaline modifier to neutralize the pH (Potential Of Hydrogen) to be 6 to 7 after the reaction of the materials in step (3) is completed, thus obtaining the high-thixotropy early-strength type polycarboxylate superplasticizer. The high-thixotropy early-strength type polycarboxylate superplasticizer prepared by the invention has an excellent thixotropic property.

Owner:KZJ NEW MATERIALS GROUP CO LTD

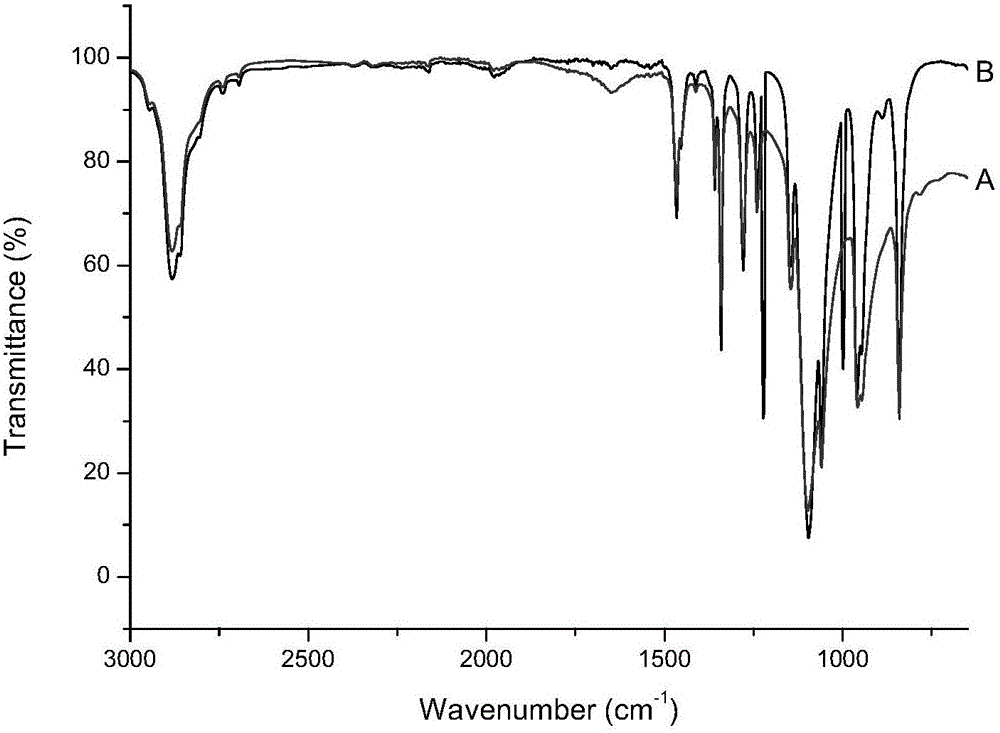

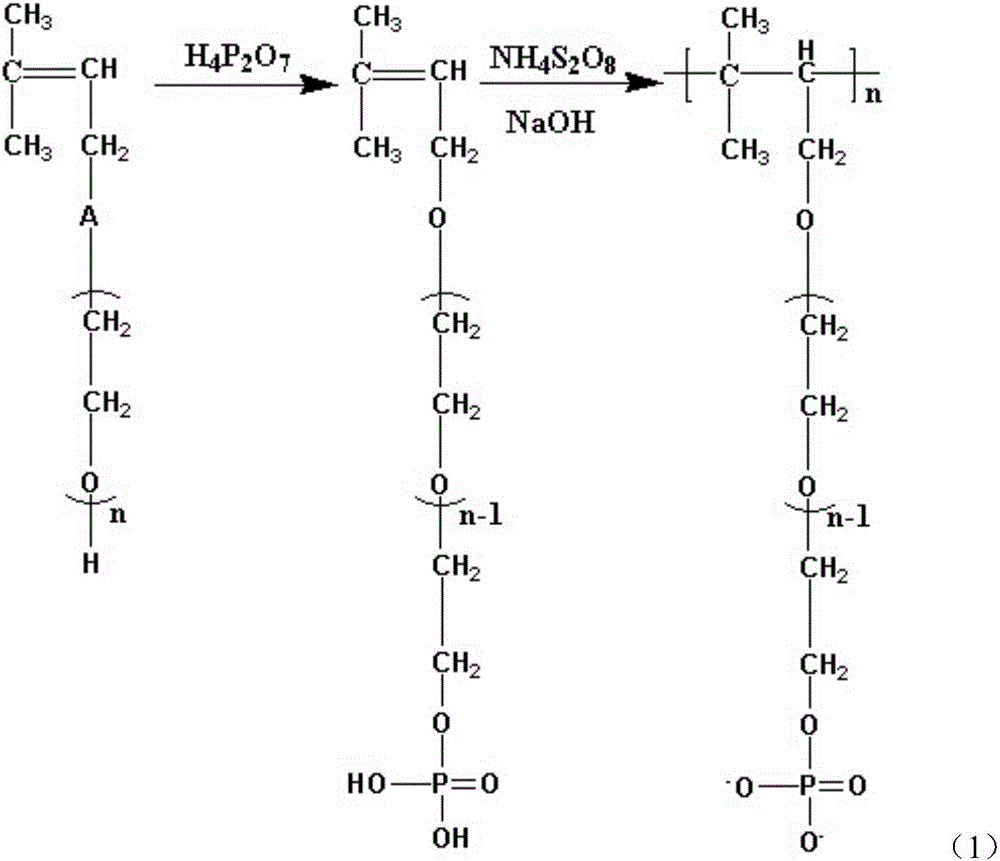

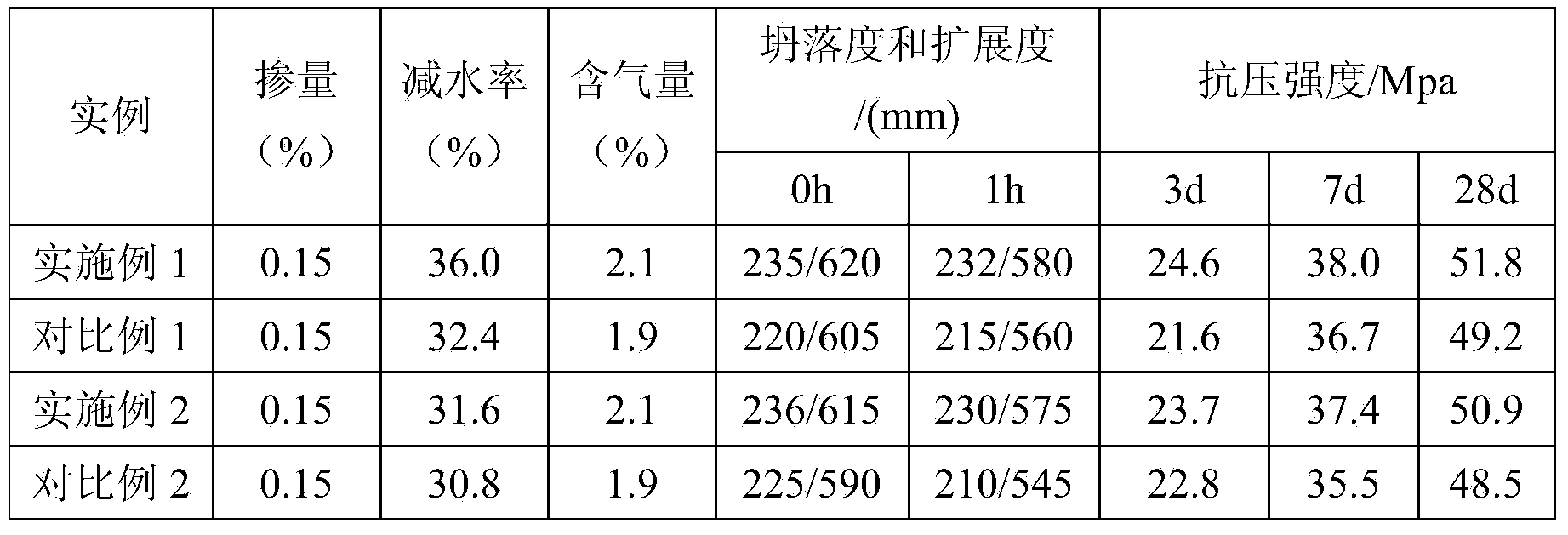

Preparation method for polyphosphate water-reducing agent

InactiveCN105837768AImprove adsorption capacityHigh anionic charge densityPhosphoric Acid EstersPropanoic acid

The invention discloses a preparation method for a polyphosphate water-reducing agent. The preparation method is characterized by comprising the following steps: subjecting isoamylenol polyoxyethylene ether and pyrophosphoric acid to a phosphate esterification reaction so as to obtain isoamylenol polyoxyethylene ether phosphate monomer; and then with ammonium persulfate as an initiator and mercaptopropionic acid as a conditioning agent, carrying out free radical homopolymerization in an aqueous solution so as to obtain the polyphosphate water-reducing agent. The preparation method is simple; a single, cheap and low-cost raw material is used in the method; and the obtained polyphosphate water-reducing agent is nonvolatile and basically nontoxic, and has good biodegradability, a water-reducing rate and slump loss resistance.

Owner:HEFEI UNIV OF TECH

Polycarboxylate-type water reducing agent

The invention discloses a water reducing agent raw material, namely an ethylene oxide-propylene oxide ternary-block polyether macromonomer, as well as a water reducing agent prepared from the raw material. The preparation of the water reducing agent comprises the following processes: mixing iso-pentenol polyoxyethylene ether and a sodium alcoholate catalyst, heating to 80-115 DEG C and dealcoholizing; heating to 110-130 DEG C, controlling pressure to be 0.25-0.40Mpa and adding ethylene oxide; adding propylene oxide at unchanged system temperature and unchanged pressure; heating to 130-160 DEG C, controlling pressure to be 0.35-0.60Mpa, and adding ethylene oxide again; and after reaction, adding a weak acid neutralizer, thereby obtaining the ethylene oxide-propylene oxide ternary-block polyether macromonomer. Due to the use of a ternary-block system, the functional adjustment on a branched chain is easy to perform, and the adaptability and the slump loss resistance of a polycarboxylate-type water reducing agent monomer are enhanced greatly.

Owner:WUHAN UNIV OF TECH

Water reducing agent with concrete workability adjusting function and synthetic method thereof

ActiveCN103819628AHas water retention capacityReduce surface tensionPotassium persulfateUltimate tensile strength

The invention discloses a water reducing agent with a concrete workability adjusting function. The water reducing agent is prepared from the following components: a. isopentenol polyoxyethylene ether, b. acrylic acid or methylacrylic acid or a mixture of the acrylic acid and the methylacrylic, c. maleic anhydride, d. sodium p-styrenesulfonate, e. ammonium persulfate or potassium persulfate or a mixture of the ammonium persulfate and the potassium persulfate, and f. sodium methallyl sulfonate, wherein the molar ratio of the using amount of a to b to c to d to f is 1:(1-1.5):(1.5-2.5):(0.2-0.25):(0.3-0.6); the using amount of e is 0.5 to 1.0 percent of the total weight of a, b and c. The water reducing agent provided by the invention has water retention capacity and has the function of reducing the surface tension of concrete so as not to influence the viscosity and the flowability of the concrete, and also can guarantee normal condensation and strength development of the concrete.

Owner:大连市铭源全科技开发有限公司

High-performance polycarboxylic acid water reducing agent and preparation method therefor

The invention discloses a high-performance polycarboxylic acid water reducing agent and a preparation method therefor. The water reducing agent comprises the following ingredients in parts by weight: 300-350 parts of macromonomer, 38-50 parts of agent A, 2.5-5.5 parts of agent B, 4.8-5.8 parts of agent C and 550-650 parts of deionized water, wherein the macromonomer is any one or a mixture of both of methyl allyl alcohol polyoxyethylene ether and isopentenol polyoxyethylene ether; the agent A comprises acrylic acid or a mixture of acrylic acid and at least one of micromonomers; the micromonomers comprise one or several of acrylamide, methacrylic acid, maleic acid, N-vinyl pyrrolidone, 4-vinyl pyridine, fumaric acid, vinyl acetate, 2-acrylamide-2-methyl propanesulfonic acid and sodium methylallylsulfonate; the agent B comprises 1.2-1.8 parts by weight of reducing agent and 1.5-3.6 parts by weight of chain transfer agent; and the agent C is an initiator. The high-performance polycarboxylic acid water reducing agent disclosed by the invention has high water reducing rate and good slump retaining capability, the entrained air volume is lower than that of commercially available products, and the whole production process has no need of heating and is energy-saving and environmentally friendly.

Owner:南宁新泰瑞科建材股份有限公司

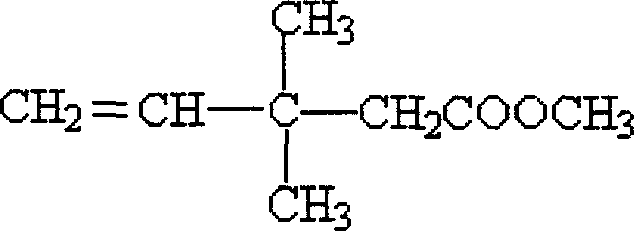

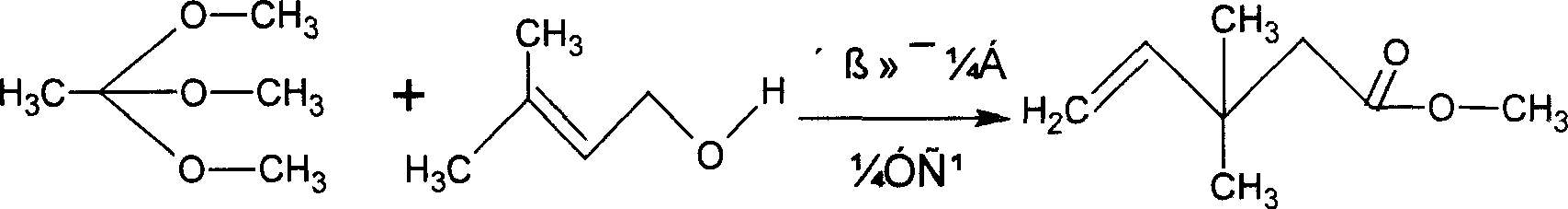

Method of preparing 3,3-dimethyl-4-pentenoic acid methyl ester with industrial scale

InactiveCN1907947AEasy to separateHigh reaction yieldPreparation by ester-hydroxy reaction4-pentenoic acidAcetic acid

The invention belongs to the industrial scale production methods for methyl pentenoate, involving a synthesis method for methyl pantenate through a reaction of isopentenol with methyl orthoacetate through catalytic synthesis under pressure. The molar ratio of isopentenol : methyl orthoacetate : catalyst is 1:1.0~2.0 : 0.01~0.1. The reaction conditions include stirring pressure of 1~3.2MPa and temperature of 150~250DEG C, and the reaction time of 6~10h. The catalysts are removed after cooling and the final product is obtained by distilling the filtrate. The catalyst is solid anhydrous zinc chloride, nickel sulfate, nickel acetate, copper acetate, anhydrous cupric chloride, or anhydrous ferric chloride. The invention has the advantages of simple catalyst separation as using solid catalyst, short reaction time as reacting at high temperature and pressure, high yield of 88%, low production cost, high product content above 99%, simple process, and less wastes.

Owner:YINGKOU YINGXIN CHEM TECH CO LTD

Cement-based polycarboxylate superplasticizer mother liquor with ultralong-acting slump loss resistance and application thereof

The invention relates to cement-based polycarboxylate superplasticizer mother liquor with ultralong-acting slump loss resistance and application thereof. The cement-based polycarboxylate superplasticizer mother liquor is composed of super-slow-release type polycarboxylate superplasticizer mother liquor, slow-release type polycarboxylate superplasticizer mother liquor and water-reducing type polycarboxylate superplasticizer mother liquor. The raw materials of the three kinds of mother liquor all include isopentenol polyoxyethylene ether, polyethylene glycol monomethyl ether methacrylate, acrylic acid, hydroxyethyl acrylate, an oxidizing agent, a reducing agent and a chain transfer agent. The cement-based polycarboxylate superplasticizer mother liquor can realize application of a high-fluidity cement-based material to a high-temperature operation environment, meets the requirements of cement for long-distance transportation and high-long-distance pumping, has no adverse influence on setting time and setting strength, is prepared from simple and easily available raw materials and simple in production process, and does not need to be compounded with other types of water reducing agentsfor use in the later period.

Owner:CNBM ZHONGYAN TECH

Polycarboxylic cement grinding aid and preparation method thereof

The invention relates to a polycarboxylic cement grinding aid and a preparation method thereof. The polycarboxylic cement grinding aid comprises isopentenol polyoxyethylene ether, acrylic acid, methacrylic acid, 2-acrylamide-2-methylpropanesulfonic acid, sodium methylacrylsulfonate, sodium allysulfonate, hydrogen peroxide, ammonium persulfate, L-ascorbic acid, sodium formaldehyde sulfoxylate dihydrate, mercaptoacetic acid, mercaptopropionic acid, sodium hydroxide and water. The preparation method comprises the following steps: adding isopentenol polyoxyethylene ether, hydrogen peroxide, ammonium persulfate, sodium methylacrylsulfonate, sodium allysulfonate and water to a reaction kettle; processing acrylic acid, methacrylic acid, 2-acrylamide-2-methylpropanesulfonic acid and water to prepare a solution A, and processing L-ascorbic acid, sodium formaldehyde sulfoxylate dihydrate, mercaptoacetic acid, mercaptopropionic acid and water to obtain a solution B; and heating the reaction kettle to 30DEG C, adding the solution A and the solution B in a dropwise manner, and carrying out a polymerization reaction to obtain the final product. The molecular structure of the polycarboxylic cement grinding aid synthesized in the invention contains various functional groups, so the grinding efficiency is effectively improved, energy consumed in the grinding process is reduced, the early strength and the later strength of cement are improved, and the compatibility of cement and a concrete additive is guaranteed.

Owner:河南新汉材料科技有限公司

Anti-crack high slump loss resistance concrete polycarboxylate superplasticizer

The invention discloses an anti-crack high slump loss resistance concrete polycarboxylate superplasticizer, being prepared from the following components in parts by weight: 25-35 parts of isopentenol polyethylene glycol monomethyl ether macromonomer, 40-50 parts of isopentenol polyethylene glycol monomethyl ether macromonomer, 3.5-4.5 parts of 2-propylene acyl amino-2-methyl-1-propane sulfonic acid, 4-5 parts of allyl polyoxyethylene ether, 3-5 parts of maleic anhydride, 2.5-3.5 parts of dimethyl fumarate, 3-5 parts of hydroxyalkyl acrylate, 4-8 parts of sodium hypophosphite, 0.5-1.5 parts of tartaric acid, 80-83 parts of water and 15-21 parts of sodium hydroxide. The anti-crack high slump loss resistance concrete polycarboxylate superplasticizer has good adaptability to cement, is less in amount of admixture and high in water-reducing rate, is capable of reducing water cement ratio and improving fluidity, is low in slump loss and remarkable in early strengthening effect, and is capable of improving the compactness of concrete, saving cement, improving the working performances of the concrete and improving the durability of the concrete.

Owner:HUNAN CONSTR ENG GRP COR +1

Anti-mud type low-slump-loss polycarboxylic acid water reducing agent and preparation method thereof

The invention discloses an anti-mud type low-slump-loss polycarboxylic acid water reducing agent and a preparation method thereof, and relates to the technical field of synthesis of concrete admixtures. Specifically, from the effect of a molecular structure and an initial pH value of a reaction system on the performance of a product, during a synthesis process, tartaric acid is selected as an adjusting catalyst of the initial pH value of the reaction system in a kettle, monomers succinic acid monoethyl propionyl oxyethyl ester and 2-allyloxy sodium ethanesulfonate having a special water reducing function, monomers cis-1-propylene phosphonic acid and 2-allyloxy sodium ethanesulfonate having a special anti-mud function, and monomers methoxyethyl acrylate, succinic acid monoethyl propionyl oxyethyl ester and isopentenol polyoxyethylene ether with the molecular weight M of 1400 having a special slump retaining function are introduced; after the reaction is finished, an organic alkali diethanolisopropanolamine is used for neutralizing, and the anti-mud type low-slump-loss polycarboxylic acid water reducing agent is synthesized. The reducing agent has the advantages of low alkali content, fast early strength achieving of concrete, and high strength, can significantly improve the workability and the slump retention of the concrete prepared by high-mud-content aggregates, has relatively good anti-mud ability, and also has the advantages of low gradual loss of newly blended concrete, high strength of hardened concrete, good durability and the like.

Owner:HEBEI SANKAISHENFA SCI & TECH CORP LTD

Viscosity reduction high efficiency water-reducing polycarboxylate superplasticizer and preparation method thereof

The invention relates to a viscosity reduction high efficiency water-reducing polycarboxylate superplasticizer and a preparation method thereof. The superplasticizer is prepared by intermittent dropwise adding of macromonomers like TPEG monomer, unsaturated hydroxy acid monomer or its derivative, or unsaturated acid with a trans-structure for free radical polymerization reaction under the action of a reductant, an oxidant and a chain transfer agent. The anchoring group and side chain in the superplasticizer are molecular structures in block distribution, and can give full play to electrostaticrepulsion and steric-hinerance effect. In addition, the hydroxyl, carboxyl and other polar groups introduced by the unsaturated hydroxy acid monomer or its derivative monomer increase the proportionof hydrophilic groups and reduce the surface tension of the cement pore solution. In addition, in terms of the trans-structural body represented by fumaric acid and dihydroxyfumaric acid derivatives,because of the special structure, i.e. the stiffness of the monomer itself and the distribution of two carboxyl groups on the opposite side of the side chain, a stretching structure easily exhibits inspace to reduce the possibility of molecular chain entanglement and significantly increase the adsorption effect of the polycarboxylate superplasticizer on the cement surface, thereby enhancing the viscosity reduction effect of the polycarboxylate superplasticizer.

Owner:HUNAN UNIV

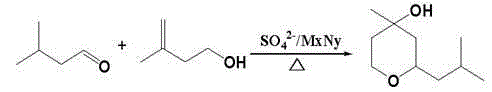

Method for compounding lily-of-the-valley pyran through reaction under static bed loaded solid superacid catalysis

ActiveCN105175372AHigh yieldGood choiceOrganic chemistryPhysical/chemical process catalystsPtru catalystAcid catalysis

The invention provides a preparation method of lily-of-the-valley pyran by using a static bed loaded with a solid superacid catalyst. The method comprises the steps of selection of a static bed, weighing of raw materials, feeding of the raw materials and reaction in the static bed; in the step of weighing of the raw materials, the mass ratio of isovaleraldehyde to allylic alcohols is 1 to 0.93-1; in the step of reaction in the static bed, for the static bed loaded solid superacid catalyst, the length ranges from 80 cm to 280 cm, the gas flow rate ranges from 0.2 m / s to 3 m / s, and the pressure ranges from 0.015 MPa to 0.3 MPa. According to the preparation method, static bed loaded solid superacid serves as the catalyst to prepare the lily-of-the-valley pyran for the first time, the product yield is high, according to the allylic alcohols, the yield ranges from 95.1% to 96.3%, and according to the isovaleraldehyde, the yield ranges from 80.2% to 86.2%; the content of a gas phase of a product is over 99%; the method has the advantages of being good in selectivity, high in reaction efficiency, long in service life, less in amount of three wastes and the like, and the raw material product is prone to separation.

Owner:SHANDONG NHU PHARMA

Method for preparing methylcrotonaldehyde from isopentenol through catalyzed oxidation

ActiveCN109422632AEfficient oxidation productionStable oxidation productionOrganic compound preparationCarbonyl compound preparationActive componentDehydrogenation

The invention provides a method for oxidatively preparing methylcrotonaldehyde from isopentenol through catalyzed oxidation by a loaded gold catalyst. A catalyst is an Al2O3 loaded gold catalyst or abimetallic catalyst prepared from gold and cheap metal. An alumina support of the catalyst is modified with alkali metals such as Na, Mg, K and Cs, and one or two of Au, Pd, Ag and Cu are loaded as active ingredients. Au serves as a primary active ingredient, the loaded percent of Au is 0.1% to 5%, and the loaded percent of secondary active components such as Ag and Cu is 0.1% to 2%. The catalystis applied to a reaction for preparing 3-methyl-2-crotyl-1-aldehyde (methylcrotonaldehyde) from 3-methyl-2-crotyl-ol (isopentenol) through oxidative dehydrogenation, the oxidative dehydrogenation of the 3-methyl-2-crotyl-ol can be achieved at a relatively low temperature, and the selectivity of the product, i.e., methylcrotonaldehyde reaches up to 98%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Room-temperature synthetic type polycarboxylic high performance water-reducing agent and preparation method thereof

The invention relates to a room-temperature synthetic type polycarboxylic high performance water-reducing agent and a preparation method thereof. The room-temperature synthetic type polycarboxylic high performance water-reducing agent is prepared form the following components including isopentenol polyoxyethylene ether, acrylic acid, methacrylic acid, sodium allylsulfonate, sodium methallyl sulfonate, hydrogen peroxide, ammonium persulfate, L-ascorbic acid, sodium dithionite, mercaptoacetic acid, mercaptopropionic acid, sodium hydroxide and water. The room-temperature synthetic type polycarboxylic high performance water-reducing agent is suitable for synthesis and production at room temperature, is high in product water-reducing rate and good in slump loss resistant property, has wide market prospect as the production process has a series of advantages of saving energy, lowering consumption, improving the efficiency, being green and environment-friendly and the like and is widely suitable for high-quality concrete of commercial concrete in various grades, high-speed railways, expressways, large bridges, precast elements, airports, port construction and the like.

Owner:河南新汉材料科技有限公司

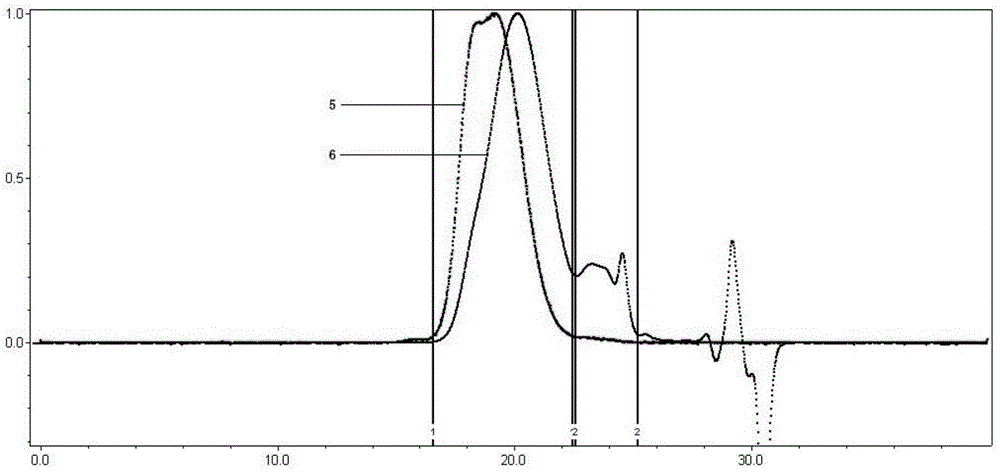

Method for synthesizing slow-release polycarboxylate water reducing agent

The invention discloses a method for synthesizing a slow-release polycarboxylate water reducing agent. The method comprises the following steps: with isopentenol polyoxyethylene polyoxypropylene ether, maleic anhydride and hydroxyethyl acrylate as raw materials, hydrogen peroxide as an initiator, sodium formaldehyde sulfoxylate and ferrous sulfate as co-catalysts and mercaptopropionic acid or mercaptoacetic acid as a molecular weight regulator, initiating free radical polymerization at 5-40 DEG C, and adding water into a monomer and the maleic anhydride according to a ratio to prepare a water solution A; adding the initiator and the ferrous sulfate into the solution A in proportion; dropwise adding a solution B prepared from the molecular weight regulator and the sodium formaldehyde sulfoxylate in proportion into the solution A; dropwise adding a water solution C prepared by adding water into the hydroxyethyl acrylate into the solution A; dropwise adding the solution B after dropwise adding the solution C for 2-5 minutes; dropwise adding the solution C for 0.5-2 hours; finishing the adding of the solution B within 15-30 minutes after finishing the adding of the solution C; after finishing the adding of the solution B, reacting for another 0.5-1 hour, and preparing the 40% water reducing agent by using water.

Owner:吉林众鑫化工集团有限公司

High-solid-content ether slump-retaining polycarboxylate superplasticizer preparation method

The invention discloses a high-solid-content ether slump-retaining polycarboxylate superplasticizer preparation method. The method includes steps: dissolving isopentenol polyoxyethylene ether into water, heating at 60-80 DEG C to melt, cooling to 20-30 DEG C, sequentially adding pre-prepared chain transfer agent solution and initiator A solution, adjusting stirring speed to 200-300r / min, dropwiseadding singly or doubly, wherein monomer-containing solution is subjected to dropwise adding for 2.5-3h, and initiator B solution is subjected to double dropwise adding for 3-3.5h, the first 1h reaction temperature rise in a reactor is controlled to be lower than 4 DEG C in a reaction process, and the whole reaction temperature does not exceed 40 DEG C; keeping the temperature for 1-2h after dropwise adding, and adopting caustic soda flakes to adjust product pH value to 7+ / -1 to obtain high-concentration ether slump-retaining polycarboxylate superplasticizer mother liquor in solid content of 80% and in state of thick liquid. Concrete mixed by adoption of the superplasticizer is great in slump retaining performance, and cost in production, transporting and storage processes is saved. In addition, products are green, environmentally friendly and free of formaldehyde, and discharging of waste gas, wastewater and industrial residues in the production process is avoided.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD +1

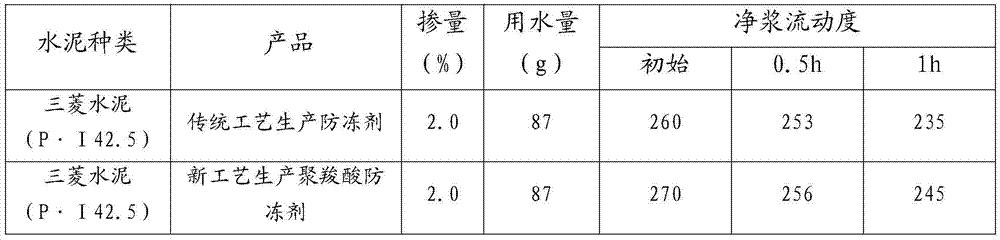

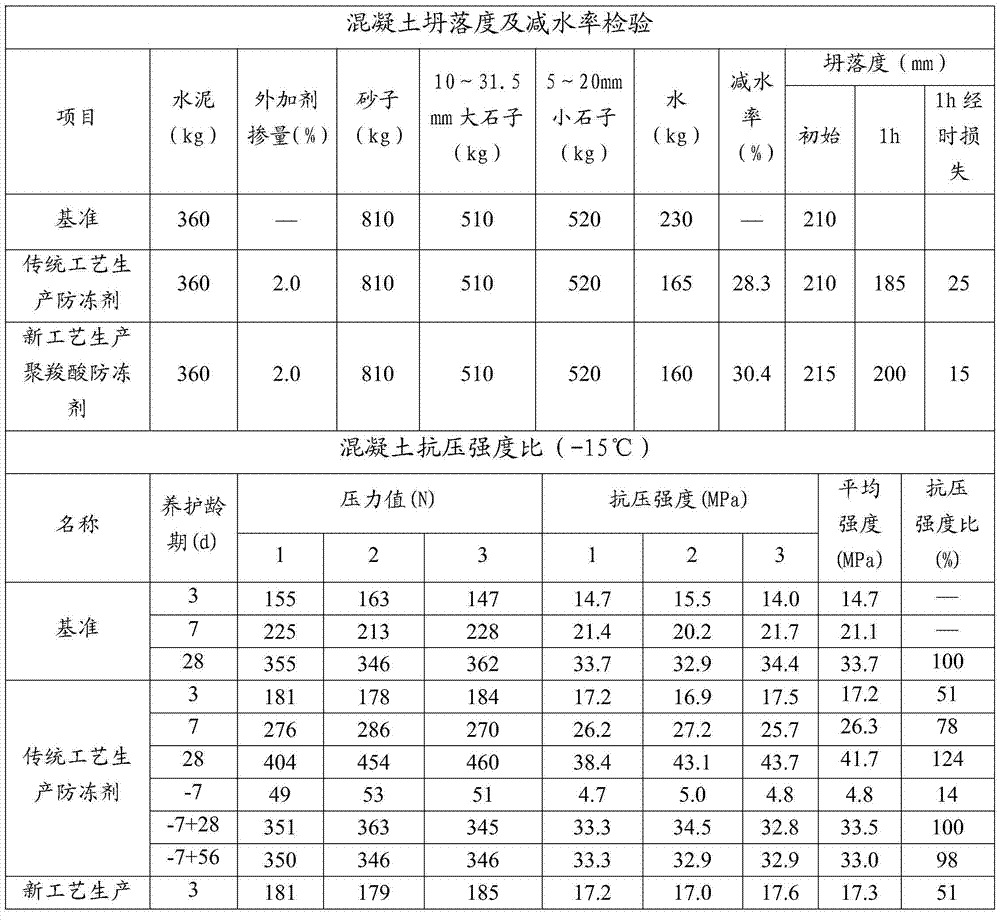

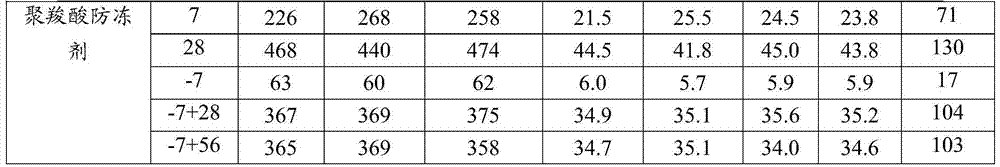

Anti-freezing type polycarboxylic acid high-performance water reducer and preparation method thereof

ActiveCN103922628AExcellent antifreeze and antirust effectImprove adaptabilityVitamin CSynthesis methods

The invention discloses an anti-freezing type polycarboxylic acid high-performance water reducer and a preparation method thereof. The anti-freezing type polycarboxylic acid high-performance water reducer is prepared from the following materials in parts by weight: 25-35 parts of acrylic acid, 10-20 parts of mercaptoacetic acid, 30-50 parts of isopentenol polyoxyethylene ether, 1-10 parts of hydrogen peroxide, 1-10 parts of vitamin C, 1-5 parts of white sugar, 0.5-2 parts of sodium dodecyl sulfate, 1-10 parts of sodium nitrite, 1-5 parts of calcium chloride, 1-3 parts of air entraining agent and 25-60 parts of water. The invention further provides a preparation method of the water reducer. The production process in the invention is simple to operate, free of heating and pure water, low in energy consumption, green and environment-friendly, realizes zero pollution and zero emission in the production process, is a green synthesis method, and satisfies novel environment health requirements.

Owner:SHANDONG DAYUAN IND

Phosphoric acid-modified polycarboxylate water reducer with high adaptability and preparation method thereof

The invention discloses a phosphoric-acid-base modified polycarboxylic-acid water reducer with high adaptability and a preparation method thereof. The water reducer is prepared from the following raw materials: isopentenol polyoxyethylene ether, hydrogen peroxide, acrylic acid, an unsaturated phosphoric acid monomer, deionized water, a reducing agent, and a chain transferring agent. The chain transferring agent is one of mercaptoethanol, mercaptoacetic acid and mercaptopropionic acid. The unsaturated phosphoric acid monomer is prepared from 2-phosphono-1,2,4-butanetricarboxylic acid, p-toluenesulfonic acid and hydroquinone. The preparation method for the water reducer comprises adding isopentenol polyoxyethylene ether and deionized water into a reaction vessel, uniformly stirring, heating, keeping warm, adding oxygen peroxide, then dropwise adding a material solution by employing a constant-flow pump, continuing to keep warm for reacting for 1-1.5 h after dropwise adding of the material solution is finished, naturally cooling to room temperature, and adjusting the pH value of the obtained product to 5-6 by using an alkaline solution. The phosphoric-acid-base modified polycarboxylic-acid water reducer possesses good sulfate ion resisting capability and sludge resisting capability, thereby satisfying engineering demand.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

Method for low-temperature synthesis of polycarboxylate water reducer by using isoamyl alcohol polyether

The invention relates to a method for low-temperature synthesis of a polycarboxylate water reducer by using isoamyl alcohol polyether, belonging to the technical field of water reducer preparation. The method comprises the following steps: by adopting isoamyl alcohol polyether and acrylic acid as raw materials, firstly forming an isoamyl alcohol polyether solution by dissolving isoamyl alcohol polyether into deionized water under heating conditions, respectively dropwise adding an acrylic acid aqueous solution and a mixed solution of a mercaptan type water-soluble chain transfer agent and a free radical type initiating agent into the isoamyl alcohol polyether solution, adjusting the temperature of a system, then performing copolymerization, and adding an alkaline regulator to obtain a finished polycarboxylate water reducer. A technical scheme disclosed by the invention has the advantages of high monomer utilization rate, more effective components of the water reducer, low cost and the like.

Owner:ZHEJIANG LYUKEAN CHEM

Method for preparing polycarboxylate superplasticizer

InactiveCN106632884ALow reaction temperatureShorten the production cycleSuperplasticizerAqueous solution

The invention relates to a method for preparing a polycarboxylate superplasticizer. The method comprises the following steps: dissolving isopentenol polyoxyethylene ether in running water so as to form a polyether solution with the mass concentration of 40-55%; adding an active aid, uniformly stirring, and adding an oxidant; dropwise adding acrylic acid aqueous solution and a mixed aqueous solution of a chain transfer agent and a reducing agent; regulating the pH value of the system, wherein the molar ratio of the isopentenol polyoxyethylene ether to the acrylic acid is 1:(3.1-7), the addition amount of the active aid accounts for 1-5% of the mass of the isopentenol polyoxyethylene ether, the addition amount of the chain transfer agent accounts for 0.05-1.5% of the mass of the isopentenol polyoxyethylene ether, the addition amount of the oxidant accounts for 1-3% of the mass of the isopentenol polyoxyethylene ether, and the addition amount of the reducing agent accounts for 0.06-0.8% of the mass of the isopentenol polyoxyethylene ether. The method disclosed by the invention is simple in process, convenient to operate, low in cost and suitable for normal temperature production, and the defects of the preparation method of the existing polycarboxylate superplasticizer are overcome.

Owner:湖北江城子建材科技有限公司

Preparation method and application of Al2O3-modified SO4<2->/SnO2 solid acid catalyst

InactiveCN108722443AReduce pollutionExtension of timeOrganic chemistryOrganic compound preparationAir atmospherePhosphoric acid

The invention discloses a preparation method of an Al2O3-modified SO4<2-> / SnO2 solid acid catalyst and application thereof to an aldol reaction. At present, in the aldol reaction of isopentenyl aldehyde and isopentenyl alcohol, an acid-catalyzed reaction is performed by using liquid acid such as phosphoric acid, so that operating units are increased and more wastewater is produced. The preparationmethod of the solid acid catalyst comprises the following steps: a), dissolving soluble aluminum salt and soluble tin salt in water, and dispersing in an alcohol compound; b), dropwise adding an alkaline compound, leaving to stand for aging at room temperature, and filtering; c), immersing in sulfuric acid, and then filtering; d), calcinating in an air atmosphere. Through use of the solid acid catalyst, the time of the condensation reaction is significantly shortened and the conversion rate is significantly increased; in addition, the catalyst can be reused after being filtered, and the original activity thereof is still maintained without a deactivation phenomena, so that not only the production efficiency is greatly improved, but also the environmental pollution is reduced.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com