Self-compacting lightweight aggregate machine-made sand concrete and preparation method thereof

A lightweight aggregate and machine-made sand technology, which is applied in the field of lightweight aggregate concrete, can solve the problems of tight supply of natural sand, high concrete water demand, and easy floating of aggregate, so as to solve the problem of tight supply, easy floating, and demand The effect of high water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

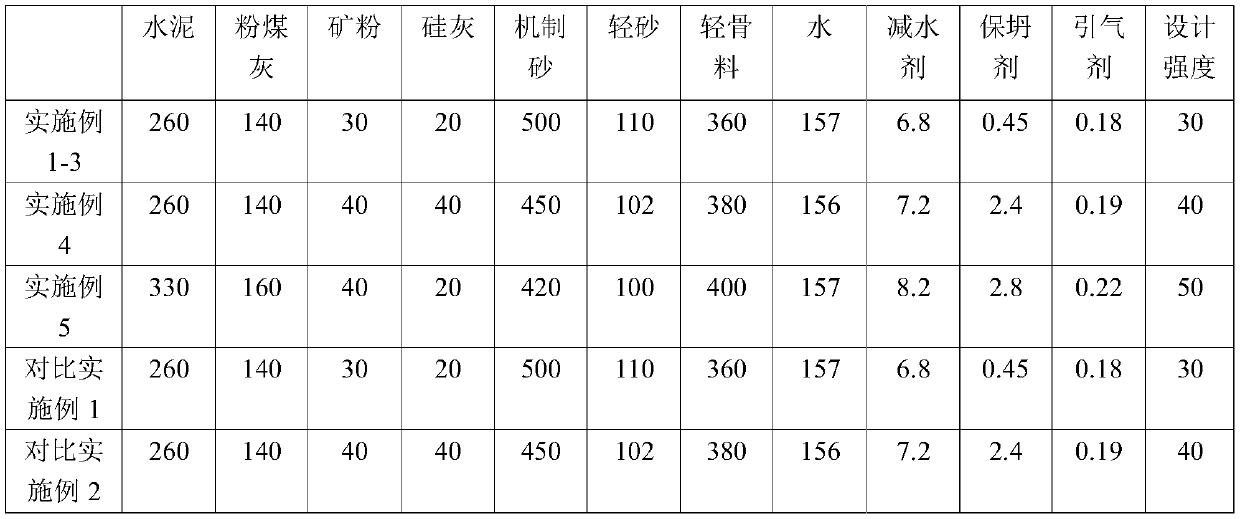

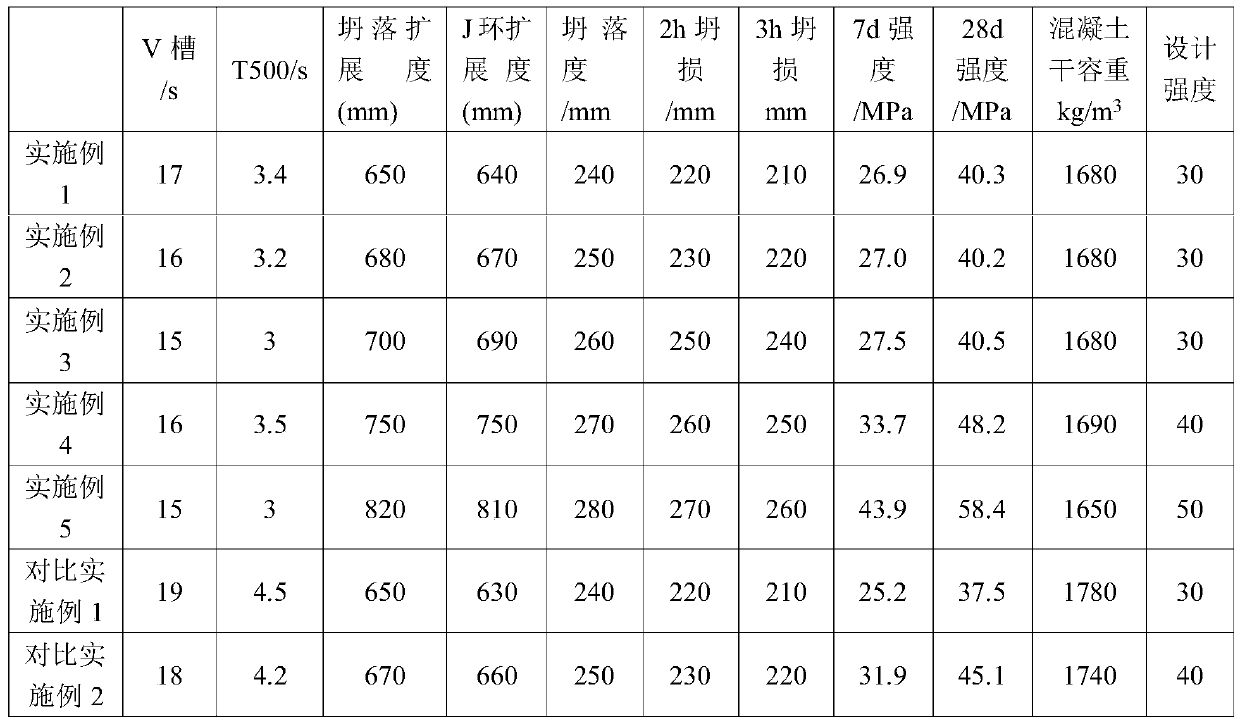

[0023] Embodiment 1-5, the ratio of comparative example 1-2 is as follows:

[0024]

[0025] in:

Embodiment 1

[0026] In Example 1, the slump-preserving agent is compounded with isopentenol polyoxyethylene ether TPEG, acrylic acid and a composite molecular weight regulator in a ratio of 15:5:2, and the air-entraining agent is obtained by compounding rosin, caustic soda, triethanolamine, dodecane Sodium base sulfate is obtained by compounding in a ratio of 5:10:5:20;

Embodiment 2

[0027] In Example 2, the slump-preserving agent is compounded with isopentenol polyoxyethylene ether TPEG, acrylic acid and a composite molecular weight regulator in a ratio of 20:10:5, and the air-entraining agent is obtained by using rosin, caustic soda, triethanolamine, dodecane Sodium base sulfate is obtained by compounding in a ratio of 1:1:15:10;

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com