Patents

Literature

250results about How to "Easy to float" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

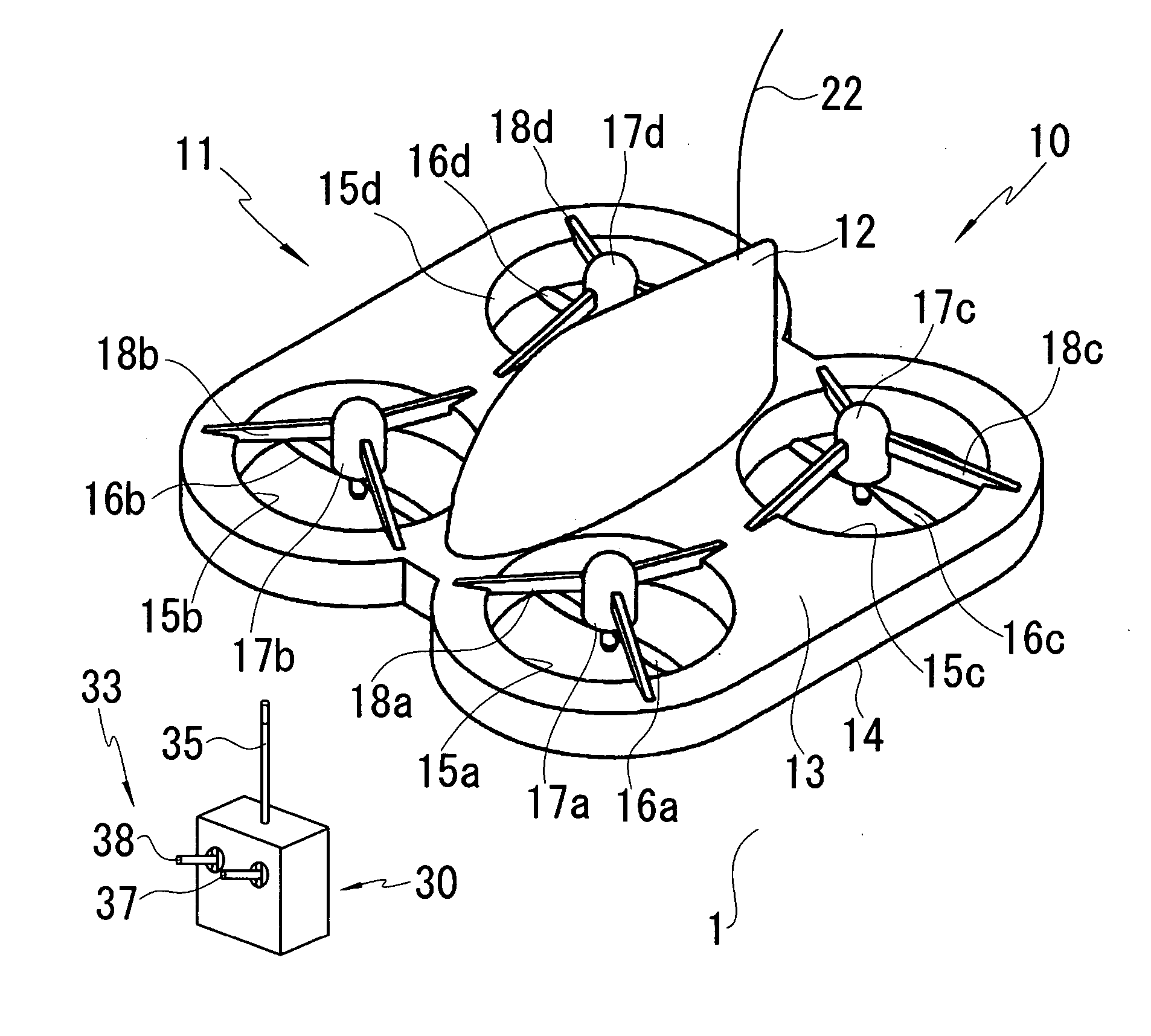

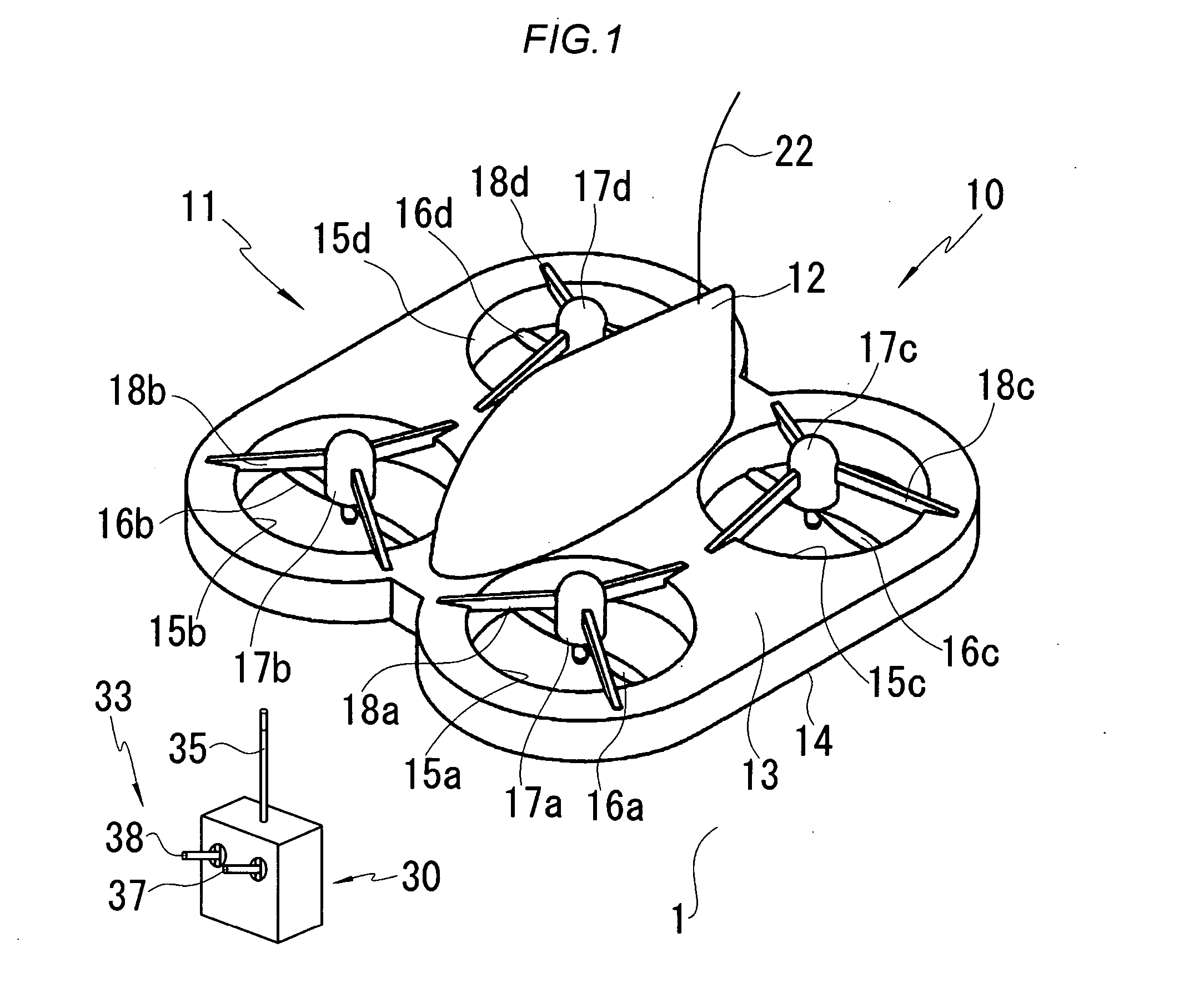

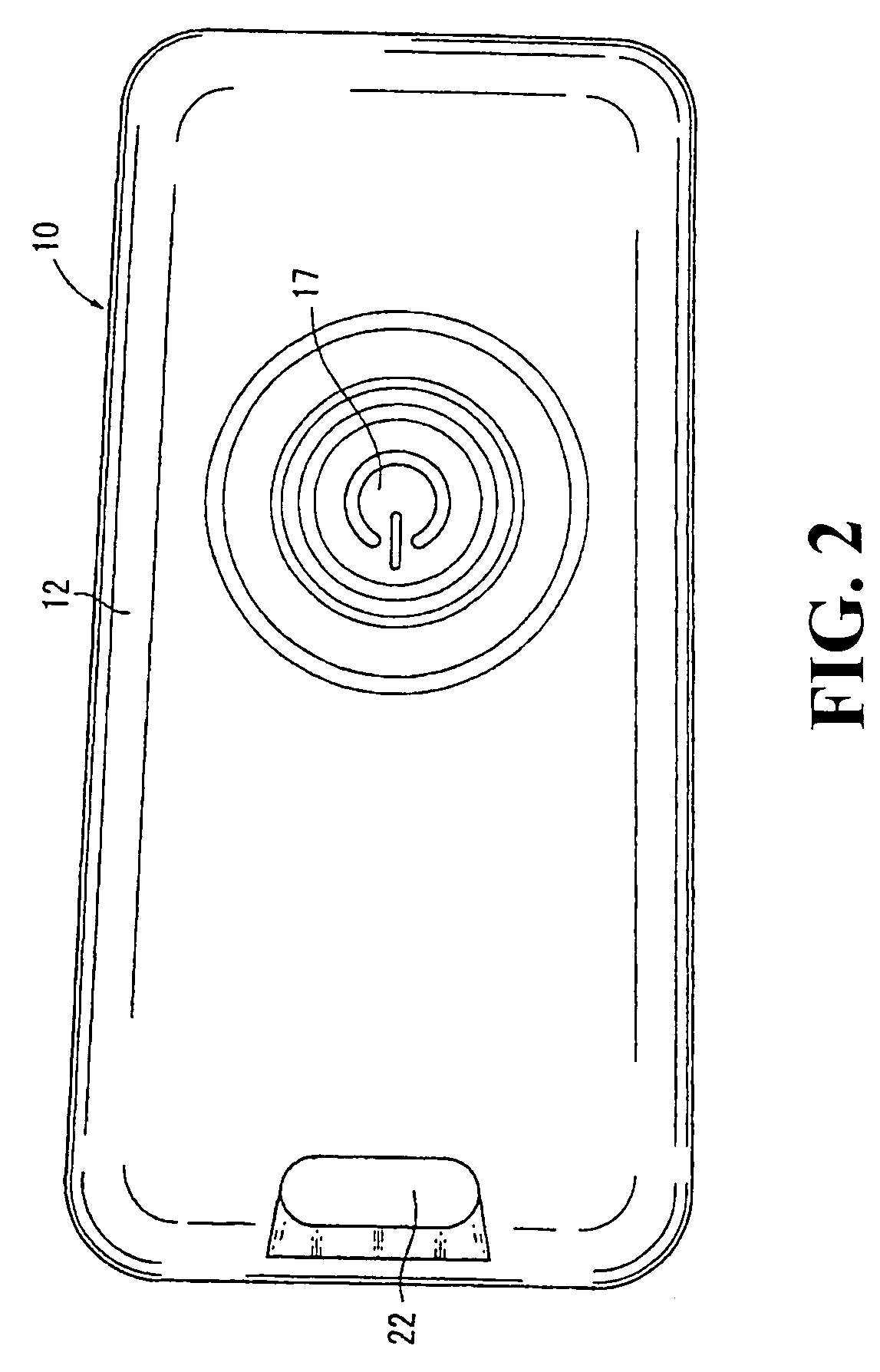

Radio control flying toy

InactiveUS20070105474A1Easy to controlEasy to floatToy aircraftsRemote-control toysPropellerControl unit

There is disclosed a radio control flying toy in which an airframe can be easily floated and a running direction can be easily controlled. The toy is provided with: an airframe 11 formed into a rectangular plate shape having a flat bottom surface on a lower side; first to fourth propellers 16a, 16b, 16c, and 16d which are disposed in four corners forming at least a quadrangular shape on the lower side of the airframe 11 and which feed air toward a bottom-surface side to float the airframe 11; first to fourth driving means 17a, 17b, 17c, and 17d which drive the first to fourth propellers 16a, 16b, 16c, and 16d, respectively; a control unit 20 which individually controls driving outputs of the first to fourth driving means 17a, 17b, 17c, and 17d, respectively; a transmitter 30 for transmitting a control signal for flight from the outside to the control unit 20; and a battery 21 which supplies power to the first to fourth driving means 17a, 17b, 17c, and 17d and the control unit 20.

Owner:TAIYO KOGYO CORPORATION

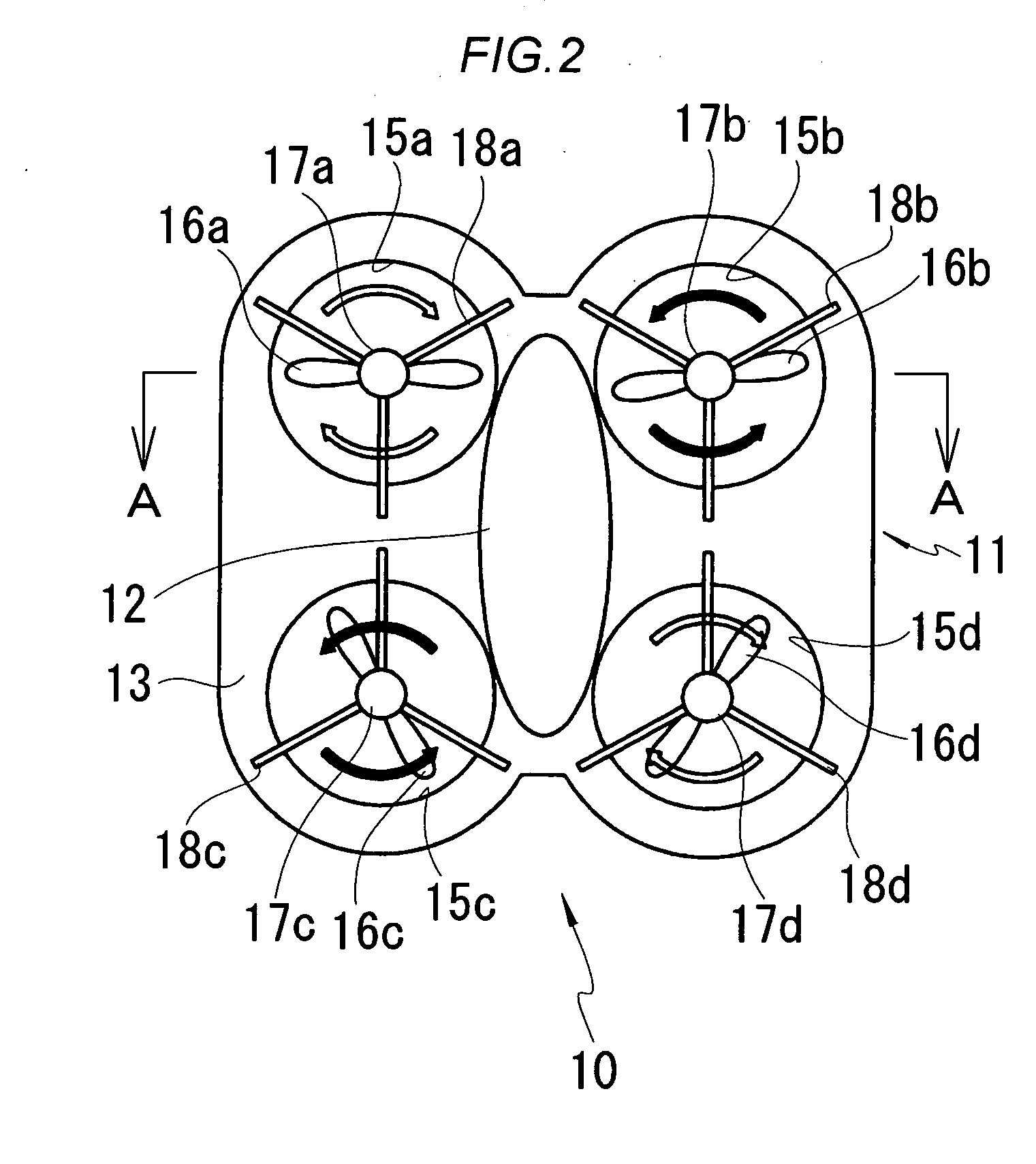

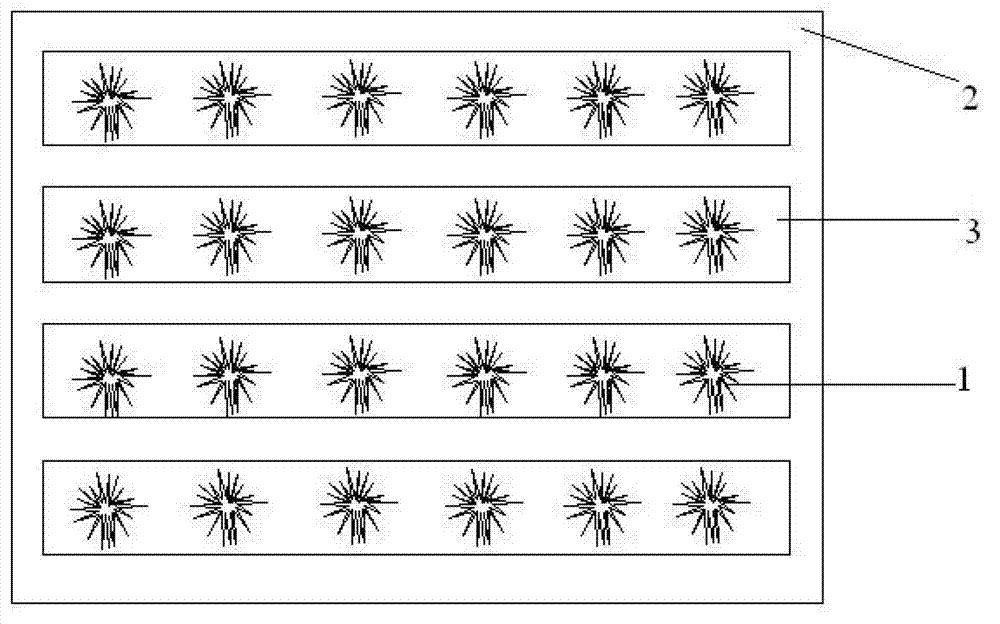

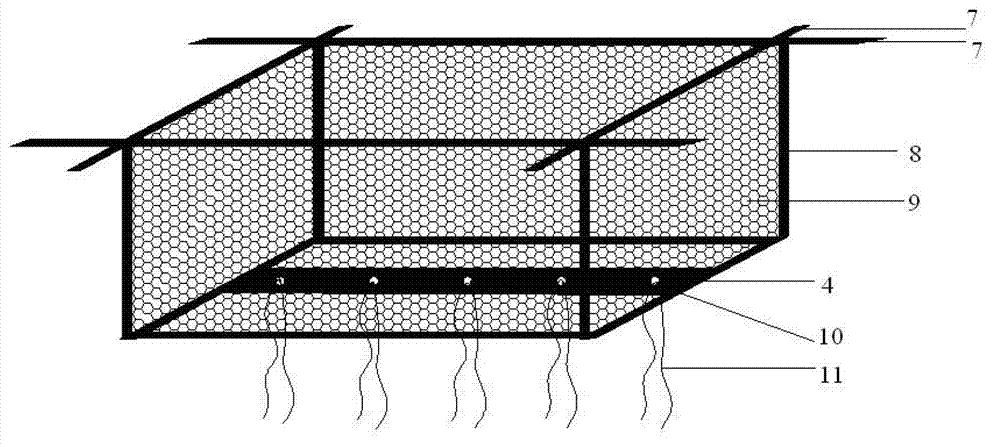

Carbon fiber wetland type ecological floating bed and arrangement method thereof

InactiveCN102826657AImprove water qualityFacilitate down-effectTreatment with aerobic and anaerobic processesSustainable biological treatmentConstructed wetlandFiber

The invention relates to a carbon fiber wetland type ecological floating bed and an arrangement method thereof, belonging to the field of sewage treatment. The carbon fiber wetland type ecological floating bed comprises a bed body, a biological carbon fiber material, floating bed plants and a wetland tank, wherein the wetland tank is arranged in the bed body; the interior of the wetland tank is filled with a porous light-weight artificial wetland filler; the floating bed plants are planted in the middle of the filler; and the biological carbon fiber material is hung on a suspension rod at the bottom of the wetland tank. According to the carbon fiber wetland type ecological floating bed, the processes of the ecological floating bed, bio-contact oxidation and the artificial wetland are reasonably combined to ensure that sewage is firstly subjected to bio-contact oxidation to degrade most pollutants, then the sewage is intercepted and further degraded through the wetland structure, and finally, through the absorption effect of plant roots, the quality of the sewage is better improve; and meanwhile, the reasonable layout of plants can be used for achieving the purposes of beautifying the environment, improving the ecological diversity and promoting the degradation effect on the pollutants of the whole floating bed system.

Owner:BEIJING UNIV OF CHEM TECH +1

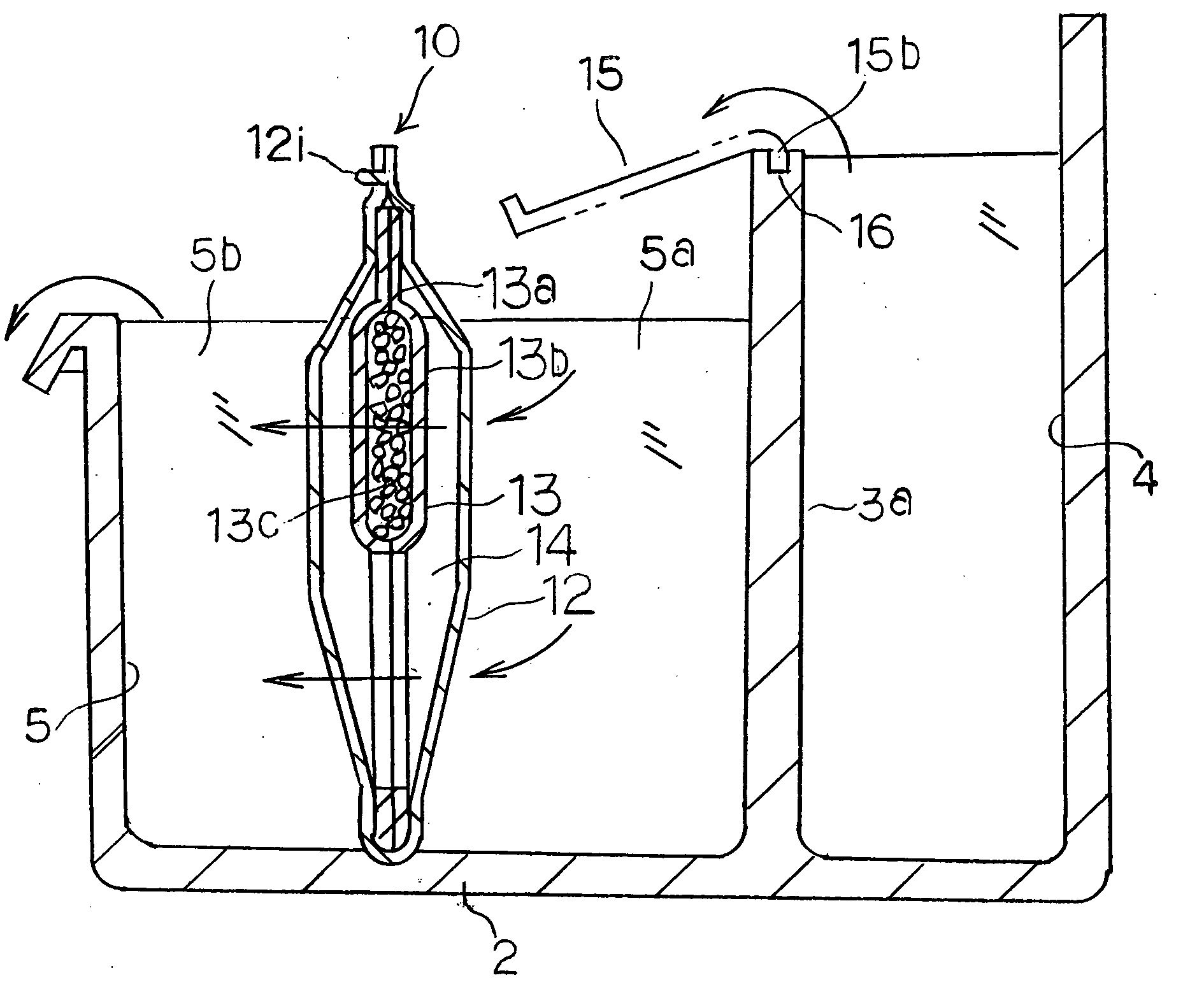

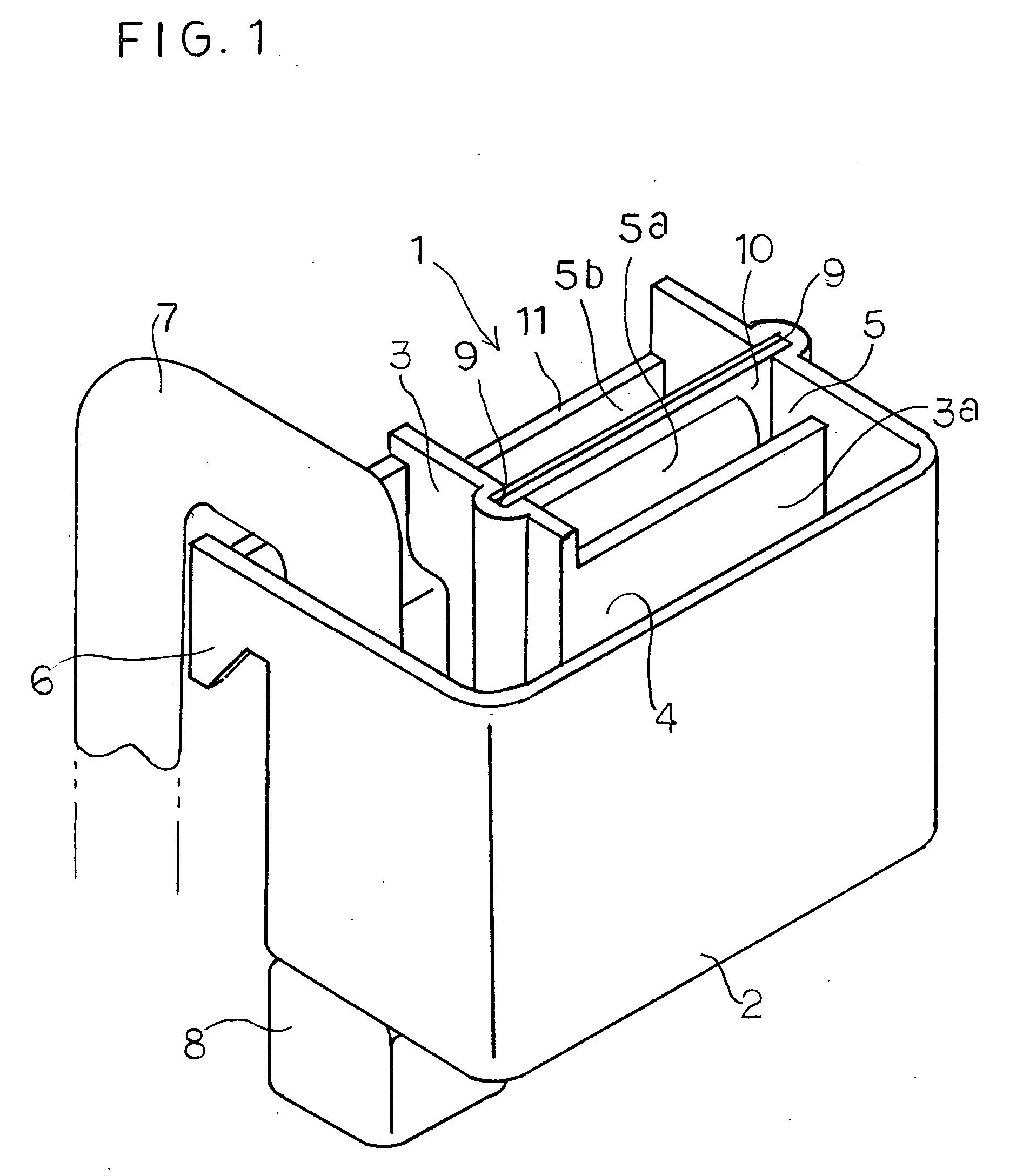

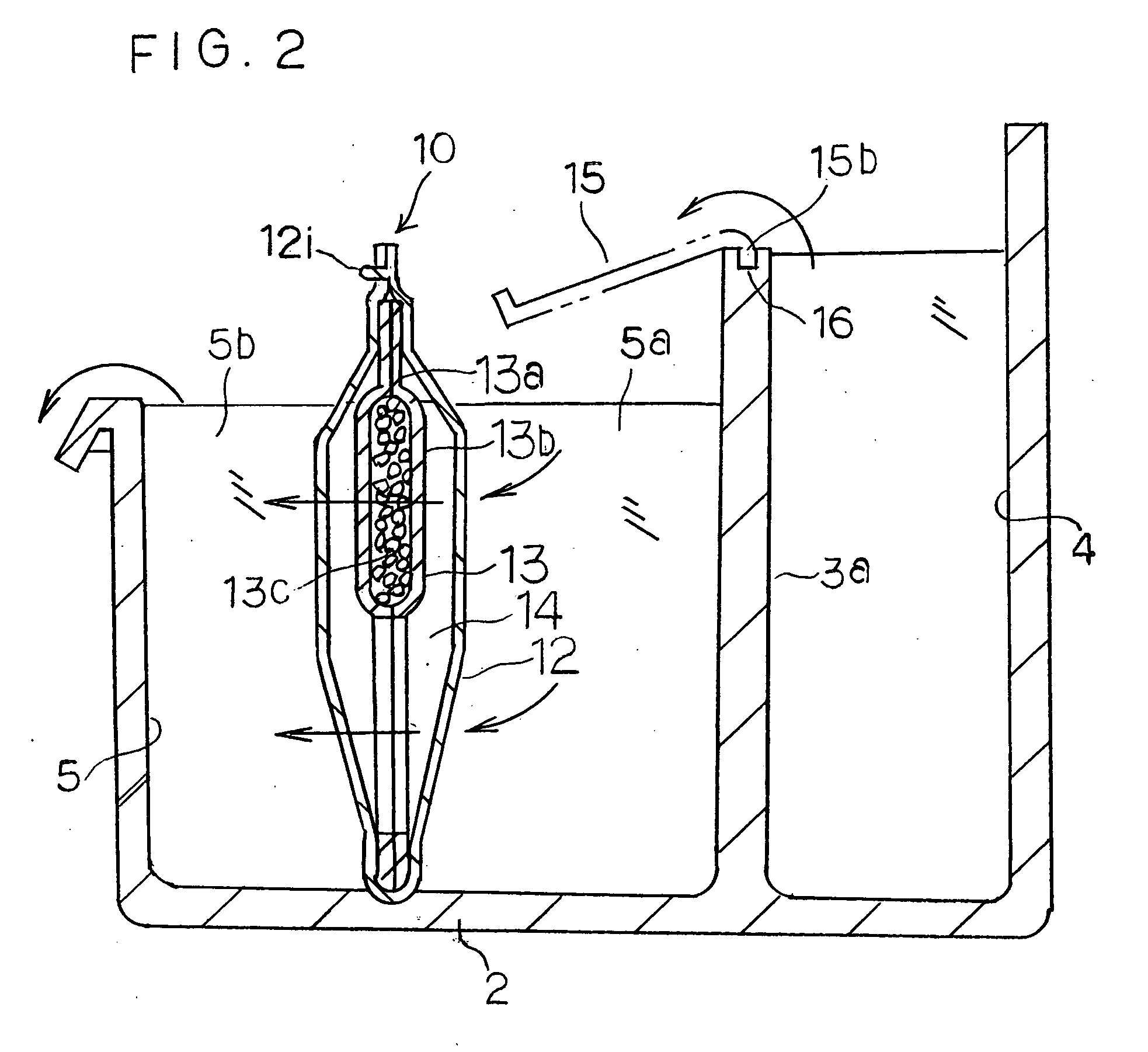

Water tank filter and purifier

InactiveUS20040222137A1Removed satisfactorilyEasy to floatPisciculture and aquariaLoose filtering material filtersInterior spaceEngineering

A water tank filter having a double structure including an inner filter having a small pore size for trapping fine particles of filth from tank water and situated within a hollow outer filter having a large pore size for trapping coarse particles of filth. The inner filter is situated in roughly the upper half of the internal space of the outer filter. Disclosed also is a water tank purifier including the water tank filter. The water tank filter and purifier can effectively remove both coarse and fine particles of filth from a water tank. The filter does not quickly get clogged, and is easy to handle.

Owner:YUGEN KAISHA HOUSEKI NO ANGEL

High oil absorption composite material containing cellulose waste filler and preparation method thereof

ActiveCN101550261AGood oil absorption performanceMany types of oil absorptionDispersed mediaCellulose

The invention relates to a high oil absorption composite material containing cellulose waste filler and a preparation method thereof. The composite material takes acrylic ester multipolymer high oil absorption resin as base material, in which the cellulose waste in the shape of island is uniformly dispersed in the base material. The preparation includes the following steps of: the preparation of the base material, namely the acrylic ester multipolymer high oil absorption resin; the preparation of the cellulose waste filler; the blending of the high oil absorption resin and the cellulose waste filler to prepare the high oil absorption composite material. Compared with the prior art, the composite material has the following advantages of excellent oil absorption performance, the availability to absorb a plurality of oils, high oil absorption percentage and good fat-binding performance. The key technology of the invention lies in the acrylic ester multipolymer oil absorption resin, which has wide raw material source, takes water accounting for 60-80 percent as dispersing medium, and the technology is simple and easily controllable. The filler is natural cellulose waste with the particle diameter of 0.25-0.035mm. The waste can be bagasse, corn cob, peanut shells and sawdust powder, and has wide source, belongs to resource recycling area, conforms to the national policy of sustainable development and is simple, safe and environment-friendly in preparation process.

Owner:飞潮(上海)新材料股份有限公司

Aqueous antistatic epoxy floor paint and preparation method and application thereof

InactiveCN101818015ANon-volatileLower surface resistivityEpoxy resin coatingsElectrically-conductive paintsFiberEpoxy

The invention discloses aqueous antistatic epoxy floor paint and a preparation method and application thereof. The preparation method comprises the following steps of: mixing 40 to 45 parts of epoxy resin, 1 to 4 parts of active thinner, 12 to 18 parts of color paste, 0.05 to 0.2 part of dispersant, 0.05 to 0.2 part of wetting agent, 0.1 to 0.5 part of flatting agent, 0.1 to 0.5 part of antifoaming agent, 0.01 to 0.1 part of defoamer, 0.5 to 2 parts of organic wax powder, 2 to 6 parts of quartz powder, 20 to 30 parts of calcium carbonate and 5 to 10 parts of conductive fiber to obtain a component A; mixing 50 to 80 parts of aqueous curing agent, 0.5 to 2 parts of aqueous film-forming aid, 20 to 50 parts of water and 0.05 to 0.2 part of flatting agent uniformly to obtain a component B; mixing the component A and the component B uniformly in a substance mole ratio of active hydrogen content in the aqueous curing agent to epoxy group content in the epoxy resin of 1: 1 to obtain the aqueous antistatic epoxy floor paint with low resistance, high hardness and abrasion resistance.

Owner:GUANGZHOU LEOBO PAINT TECH

Natural hair dye prepared by using phytochrome curcumin and hair dyeing method of natural hair dye

InactiveCN102423286AImprove dyeing effectEasy to floatCosmetic preparationsHair cosmeticsPolyolHair dyes

The invention relates to a hair dye, in particular to a natural hair dye prepared by using phytochrome curcumin and a hair dyeing method of the natural hair dye. The hair dye comprises an agent A and an agent B, and is characterized in that: the agent A contains 0.1 to 10 weight percent of curcumin, 20 to 50 weight percent of polyol, 1 to 5 weight percent of thickening agent, 1 to 10 weight percent of surfactant and the balance of water, and the pH value is regulated to be 3 to 7; and the agent B contains 1 to 10 weight percent of metal ion mordant, 1 to 5 weight percent of thickening agent, 1 to 10 weight percent of surfactant, 0.1 to 0.3 weight percent of natural essence and the balance of water, and the pH value is regulated to be 3 to 7. The hair dyeing method comprises the following steps of: uniformly spreading the agent A on the hair when the hair is dyed, and dyeing the hair for 10 to 40min at the temperature of between normal temperature and 60 DEG C; and uniformly spreading the agent B on the hair, mordanting for 10 to 20min, cleaning the hair and blow-drying. The curcumin has a good dyeing effect and also has the effects of resisting bacteria and protecting skin. Reagents which are toxic to human bodies are not used in the hair dye, and substances which are toxic to the human bodies are also not generated in the hair dyeing process, so the hair dye is high in safety. The adopted curcumin is insoluble in water and cannot fall off easily in the washing process, so the hair dye has a good dyeing effect, and the color of the dyed hair can be kept for a long time.

Owner:JIANGNAN UNIV

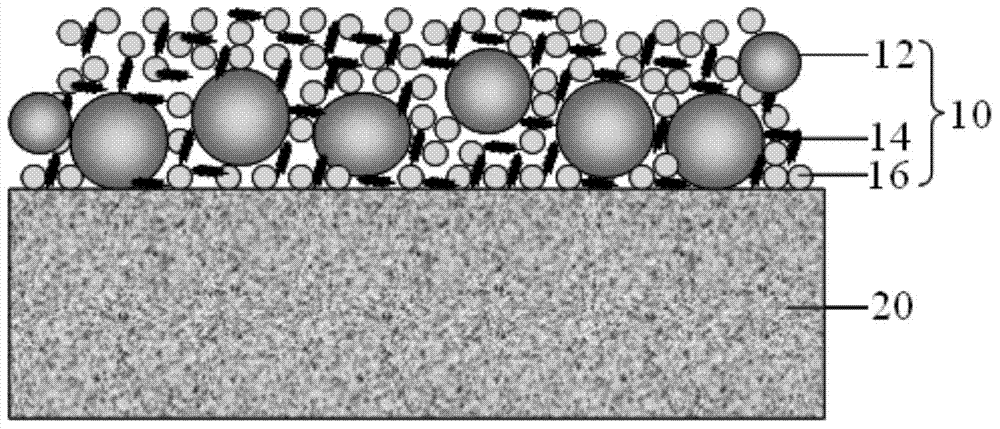

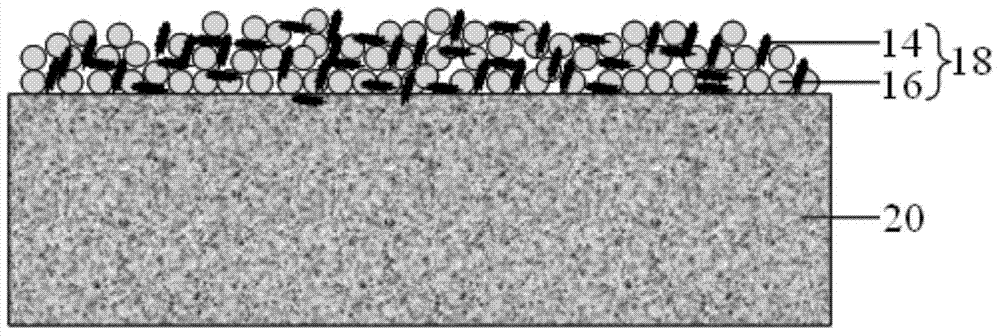

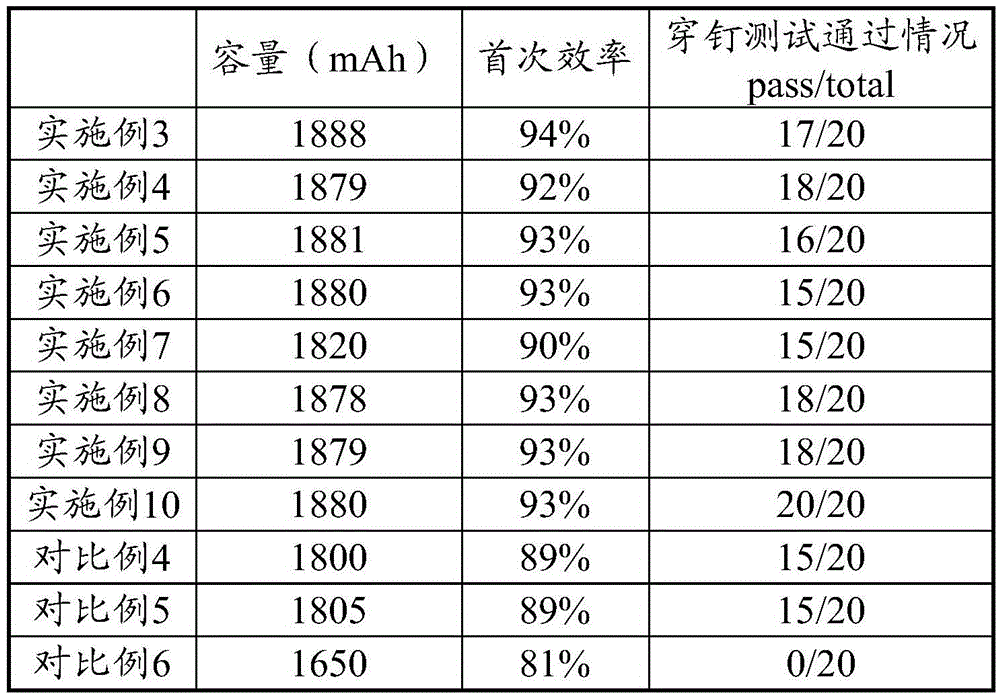

Lithium ion battery lithium-enriching technology and lithium ion battery prepared by the technology

ActiveCN104332657AEasy to prepareUniform dispersionElectrode manufacturing processesFinal product manufactureSurface layerSlurry

The invention discloses a lithium ion battery lithium-enriching technology and a lithium ion battery prepared by the technology. The lithium-enriching technology comprises the following steps: evenly pre-mixing lithium powder and EC powder under a dry state at a temperature which is lower than the melting point of EC, then heating the mixture to a temperature which is higher than the melting point of EC to melt EC powder to evenly disperse lithium powder in the EC solvent so as to obtain lithium powder slurry; painting the obtain lithium powder slurry on at least one of the positive electrode sheet, the negative electrode sheet, or the diaphragm of a lithium ion battery, and then cooling to a temperature that is lower than the EC melting point so as to obtain a positive electrode sheet, negative electrode sheet and / or diaphragm containing a lithium-enriched surface layer. Compared to the prior art, the lithium-enriching technology has the advantages of simple preparation method, even dispersing effect, and no destruction on the surface protective layer of lithium powder during the dispersing process, moreover, the lithium-enriched layer does not to be dried after painting, and thus the phenomenon that lithium powder is oxidized and released into the air during the high temperature baking process is effectively avoided.

Owner:DONGGUAN AMPEREX TECH +1

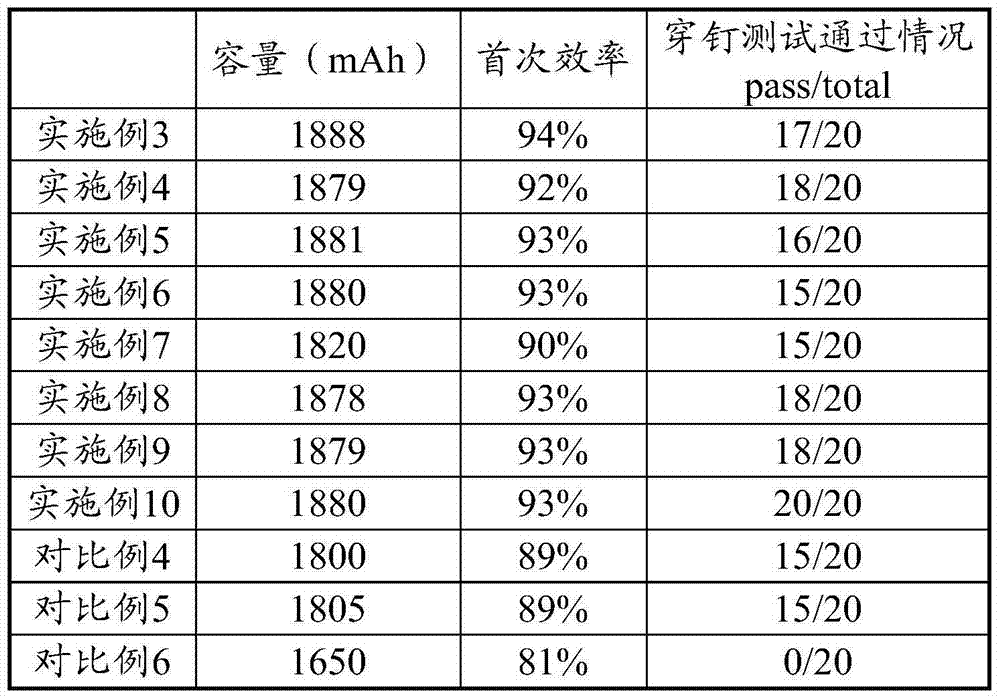

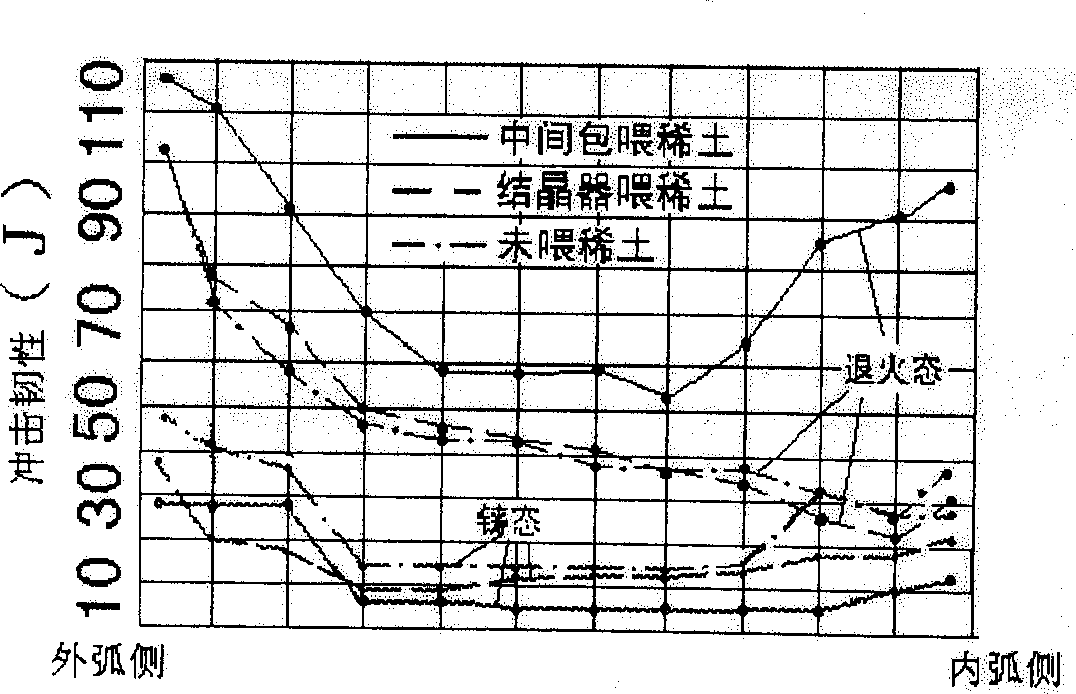

Conticasting technology for feeding rare-earth wires into tundish

A technology for feeding the rare-earth wire into conticasting tundish features that the molten steel flows from ladle into tundish and then into the crystallizer under the control of stopper, and the rare-earth wire comes into molen steel near the stopper in the tundish and is molten. Its advantages are uniform distribution of rare earth is molten steel, high effect on modifying sulfide, high rate of finished products and impact toughness, for conticast plate, and simple operation.

Owner:NANJING UNIV OF SCI & TECH +1

Heavy anticorrosion super weatherproof powder coating as well as preparation method and application thereof

ActiveCN103173073AEasy to floatProtect against agingAnti-corrosive paintsPowdery paintsEpoxyFluorocarbon

The invention relates to a heavy anticorrosion super weatherproof powder coating. The heavy anticorrosion super weatherproof powder coating comprises the following components of: an epoxy resin particle system containing epoxy resin and an adaptive curing agent A and a fluorocarbon resin particle system containing fluorocarbon resin and an adaptive curing agent B, wherein the weight part ratio of the epoxy resin particle system to the fluorocarbon resin particle system is (6-4):(4-6). The heavy anticorrosion super weatherproof powder coating provided by the invention has excellent weatherproof and anticorrosion properties and also can realize automatic stratification after once coating is carried out, and construction is simple.

Owner:NINGBO SOUTH SEA CHEM

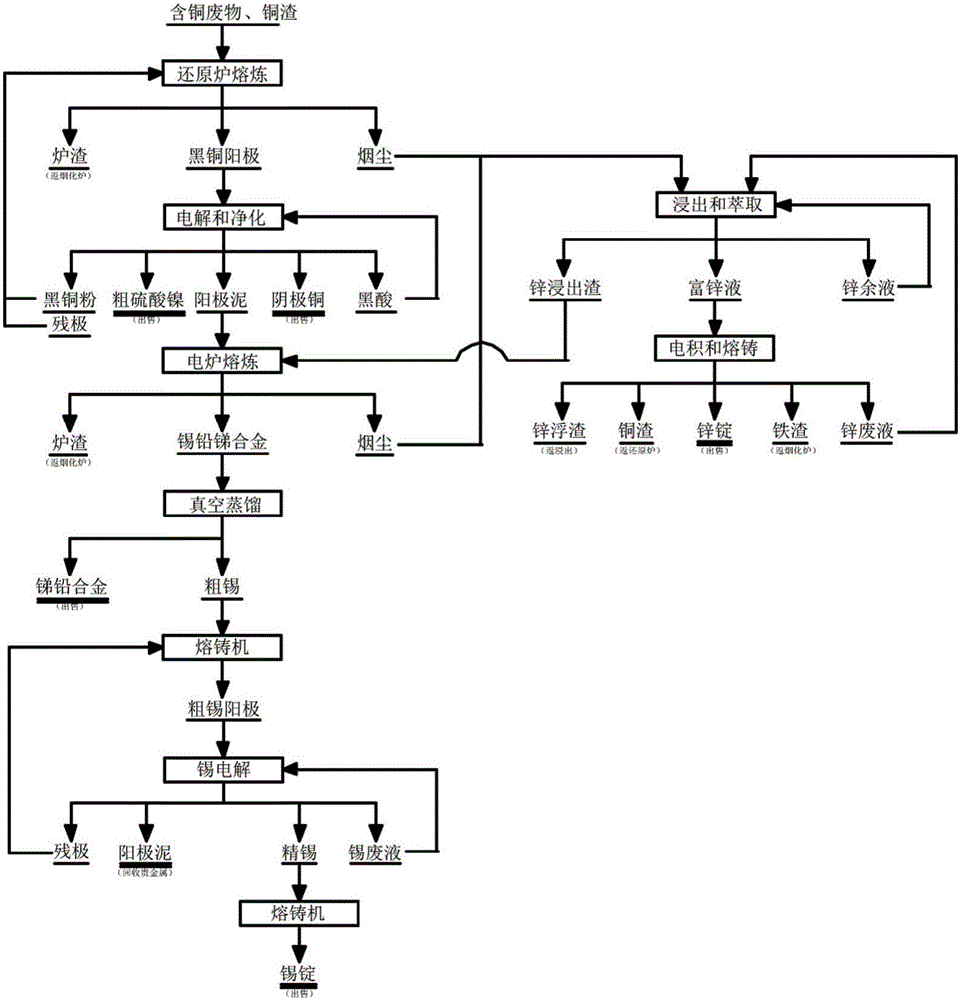

Full-path full-valence separation method for multifarious metal

ActiveCN105695744AInnovative technologyHigh recycling valuePhotography auxillary processesProcess efficiency improvementAntimonyRaw material

The invention discloses a full-path full-valence separation method for multifarious metal. Low-grade waste containing copper and copper slag serves as a raw material. The separation method comprises the following main steps that 1, the raw material is subjected to reduction smelting through a regeneration reduction furnace so that a black copper anode can be obtained, the raw material is subjected to electrolytic refining so that a metal cathode copper product and a crude nickel sulfate product can be obtained, and thus copper and nickel in the raw material are separated and recycled; 2, slag is leached out of copper anode mud and zinc and is subjected to reduction smelting through an electric furnace so that tin-lead-antimony alloy can be obtained, the tin-lead-antimony alloy is smelted through a vacuum furnace to be separated so that a antimony-lead alloy product and crude tin can be obtained, the crude tin is subjected to electrolytic refining so that refined tin can be obtained, that is, a tin ingot product is obtained, and hence tin, lead and antimony are separated and recycled; 3, a zinc ingot product is obtained by recycling smelting fume through a 'leaching- extraction- electrodeposition' method, so that the zinc, the tin and the lead are separated, and the zinc is recycled; and 4, tin anode mud is sent to a precious metal recycling factory as a precious metal enrichment material. According to the full-path full-valence separation method for the multifarious metal, the multifarious metal is completely separated, and remarkable economic benefits, environmental benefits and social benefits are achieved.

Owner:江西自立环保科技有限公司

High-fluidity pumping ceramsite concrete and preparation method thereof

The invention provides high-fluidity pumping ceramsite concrete and a preparation method thereof. A formula of the concrete comprises cement, coal ash, water, fine aggregate, limestone flour, pumping aid, ceramsites, ceramic sand, redispersable emulsion and hydroxypropyl methyl cellulose. The method comprises the following steps: reasonably selecting respective raw materials and usage thereof according to a unit weight of concrete to be prepared, soaking the ceramsites to a saturated water absorption state in advance, then mixing with other raw materials, and stirring to prepare the ceramsite concrete. By controlling the grain size of the ceramsites and a fineness modulus of the fine aggregate, the redispersable emulsion and hydroxypropyl methyl cellulose are cooperatively added to promote the cementation of the cementing materials such as the cement, the coal ash and the limestone flour with the ceramsites, and the cohesiveness and water retaining property of the concrete are increased, and the problems of easy floating, layering and separation of the ceramsites in the ceramsite concrete are effectively solved, moreover, separation and layering of the ceramsites can be effectively avoided by using the ceramsite concrete produced according to the invention, and slump loss in a material transporting and waiting process is obviously reduced.

Owner:重庆富普新材料有限公司

Preparation method of leafing aluminum paste

InactiveCN103613960ALow densityEasy to floatPigment treatment with organosilicon compoundsPigment pastesFiltrationPrimary screening

The invention discloses a preparation method of leafing aluminum paste, which comprises the following steps: selection of ball mill, selection and proportioning of solvent oil, mixing, primary ball milling, secondary ball milling, primary screening, secondary screening, pressure filtration, material supplementation, and kneading to obtain the finished product. The aluminum paste produced by the method has low density, and thus, can easily float on the paint surface; and the preparation method increases the whiteness and brightness of the aluminum paste, greatly enhances the stability of the aluminum paste and greatly prolongs the storage time of the aluminum paste.

Owner:嘉兴市华源铝制品有限公司

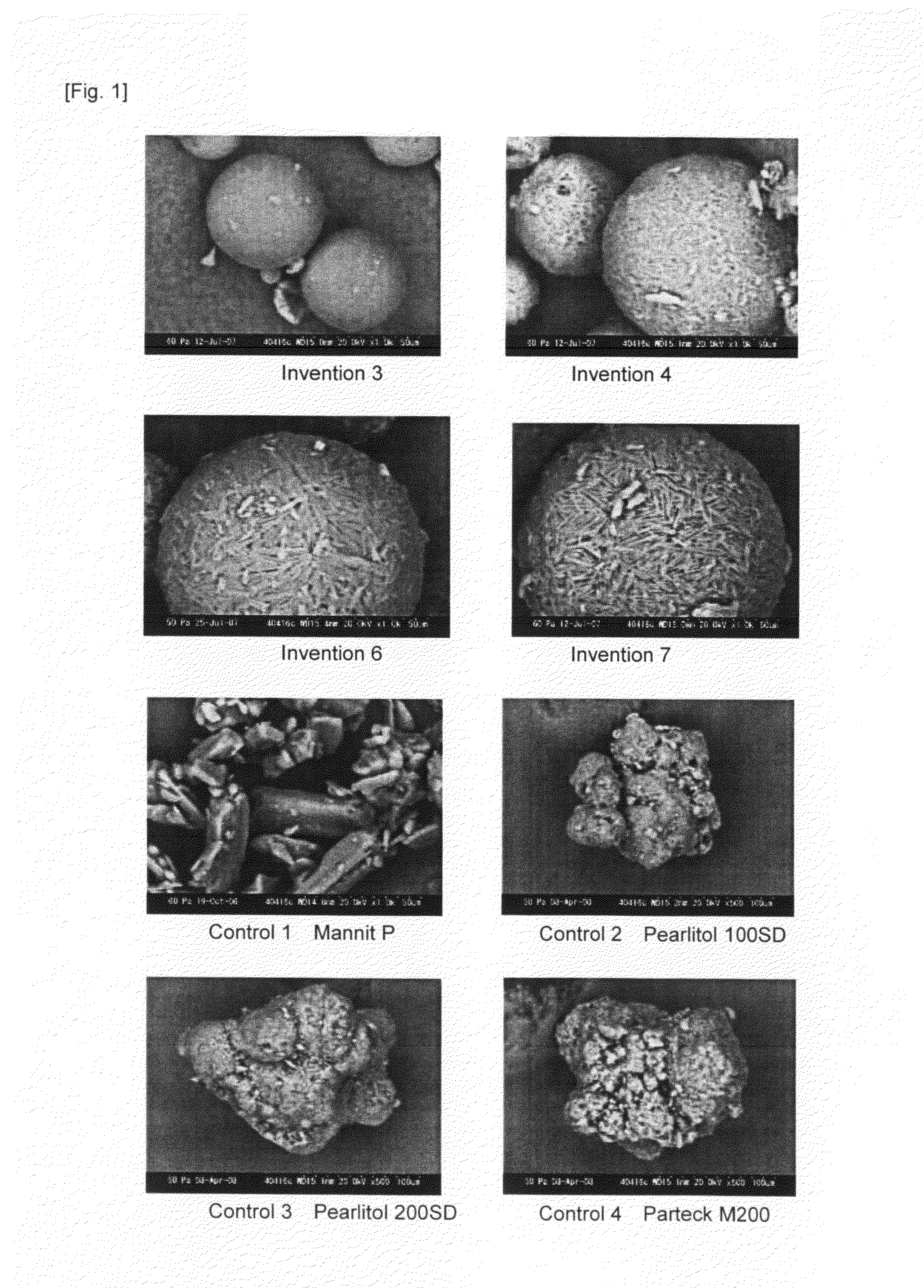

Spherical particle of crystalline mannitol

InactiveUS20100167052A1Improve liquidityHigh oil absorptionPowder deliverySynthetic resin layered productsMANNITOL/SORBITOLHardness

[Summary][Problems] To provide extremely-spherical-three-dimensional-shaped particles of crystalline mannitol containing large hollows and gaps inside.[Solution] Spherical particles of crystalline mannitol made by spray drying, extremely spherical (having an aspect ratio of 1.0 to 1.2), high oil absorption rates according to test method A, wherein powder has a mean particle diameter of 15 to 165 μm, a loose bulk density of 0.35 to 0.60 and an angle of repose of 30 to 50 degrees, and has a hardness of 7 to 20 kgf, when directly compressed.

Owner:MITSUBISHI SHOJI FOODTECH CO LTD

Method and apparatus for treating oil containing wastewater

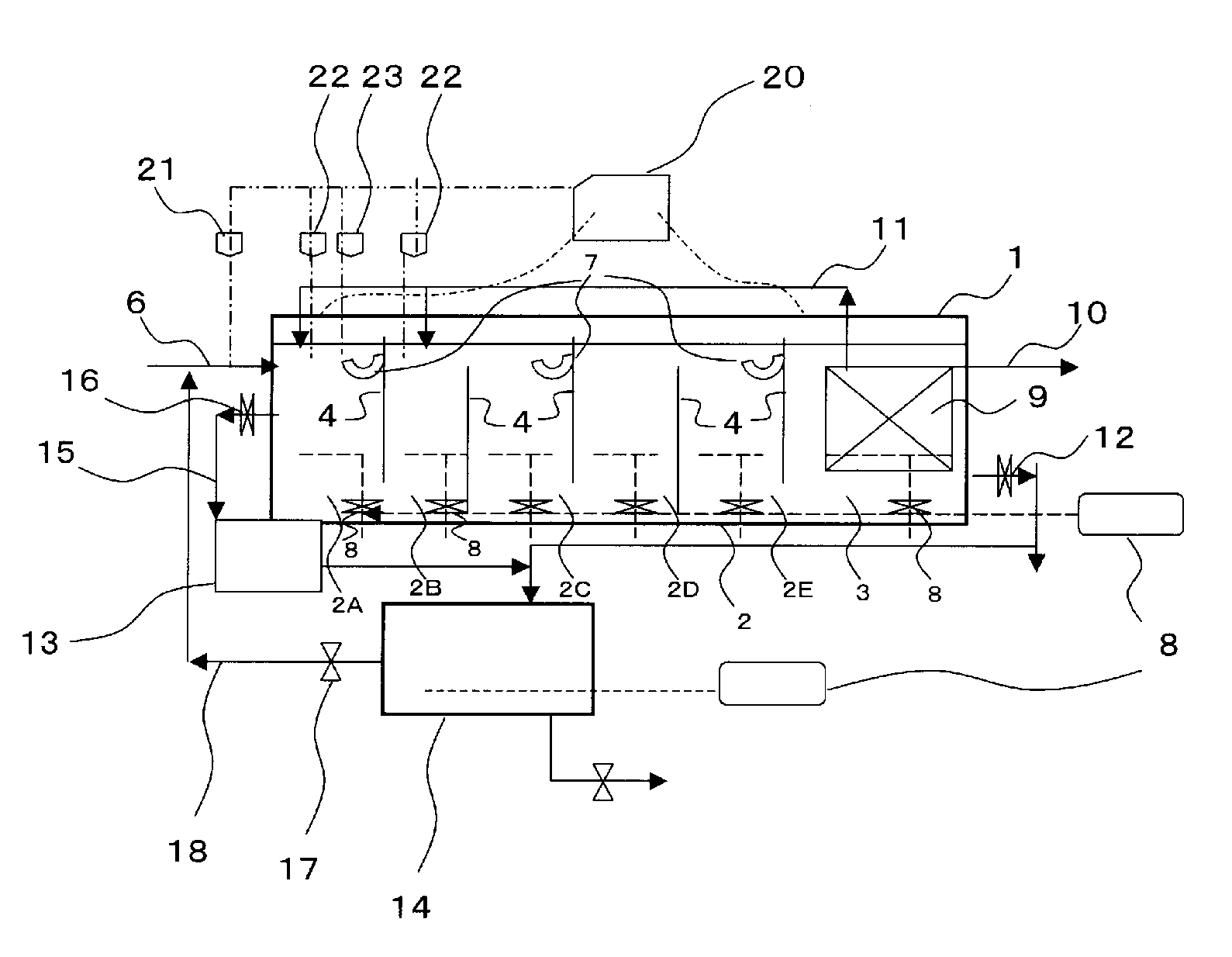

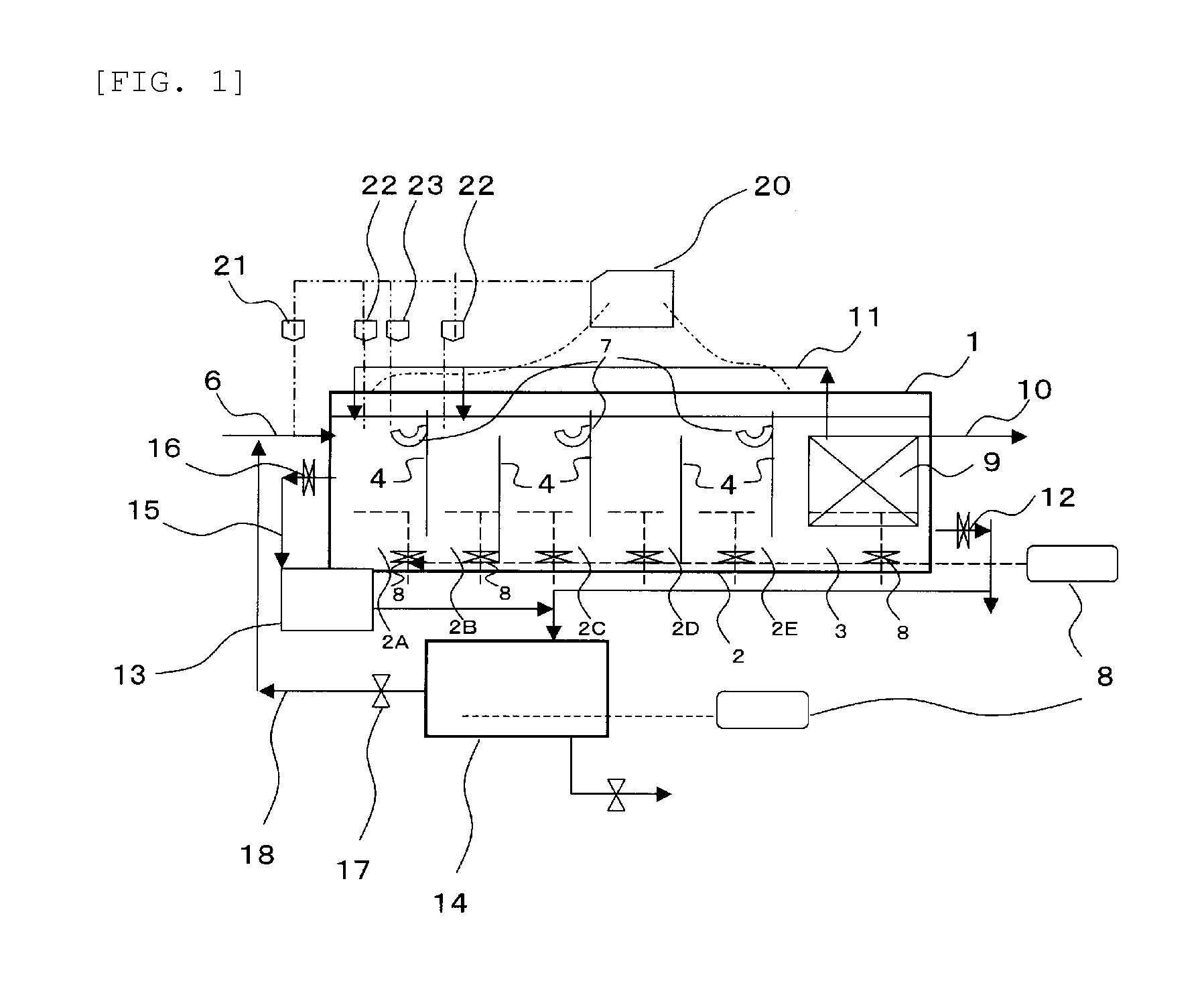

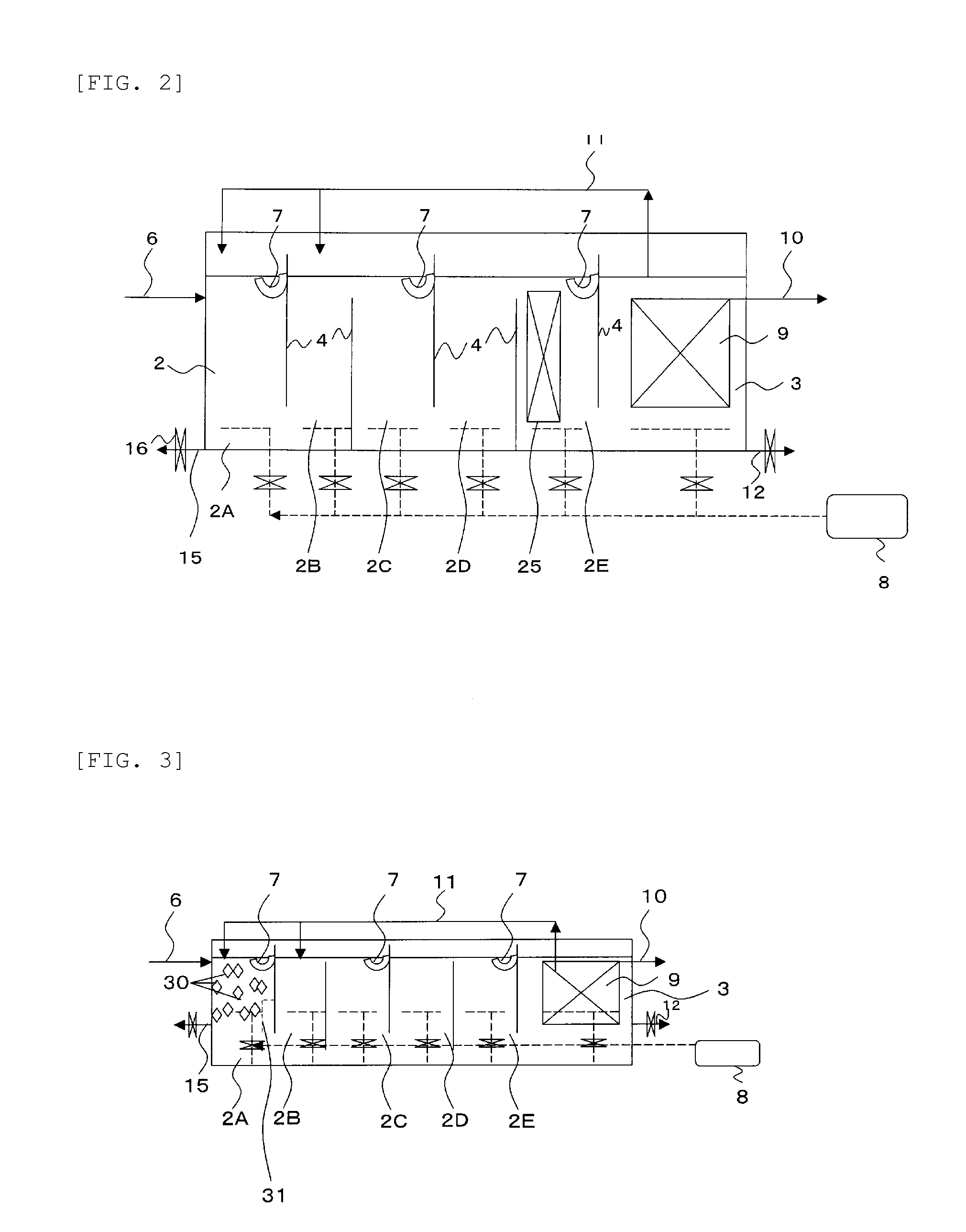

InactiveUS20140332465A1Guaranteed uptimeEliminate the effects ofWater treatment parameter controlTreatment using aerobic processesWater useActivated sludge

It relates to a treatment of oil-containing waste water using a membrane biological reactor membrane biological reactor biological reactor (MBR), and it is to provide a new treatment apparatus which is capable of suppressing a reduction in biological treatment activity and suppressing an effect on a separation membrane.Provided is a membrane biological reactor having a biological reaction chamber and a membrane separation chamber, in which the it has a configuration that, within the biological reaction chamber, at least one partition is installed to have a first reaction chamber, a second reaction chamber, and if necessary, an additional reaction chamber so as to form an upflow and downflow flow path, an aeration device and a scum / oil skimmer are installed at least in the first reaction chamber, and a mixture liquid containing activated sludge is withdrawn from the membrane separation chamber and distributed and returned at least to the first reaction chamber and the second reaction chamber.

Owner:SWING

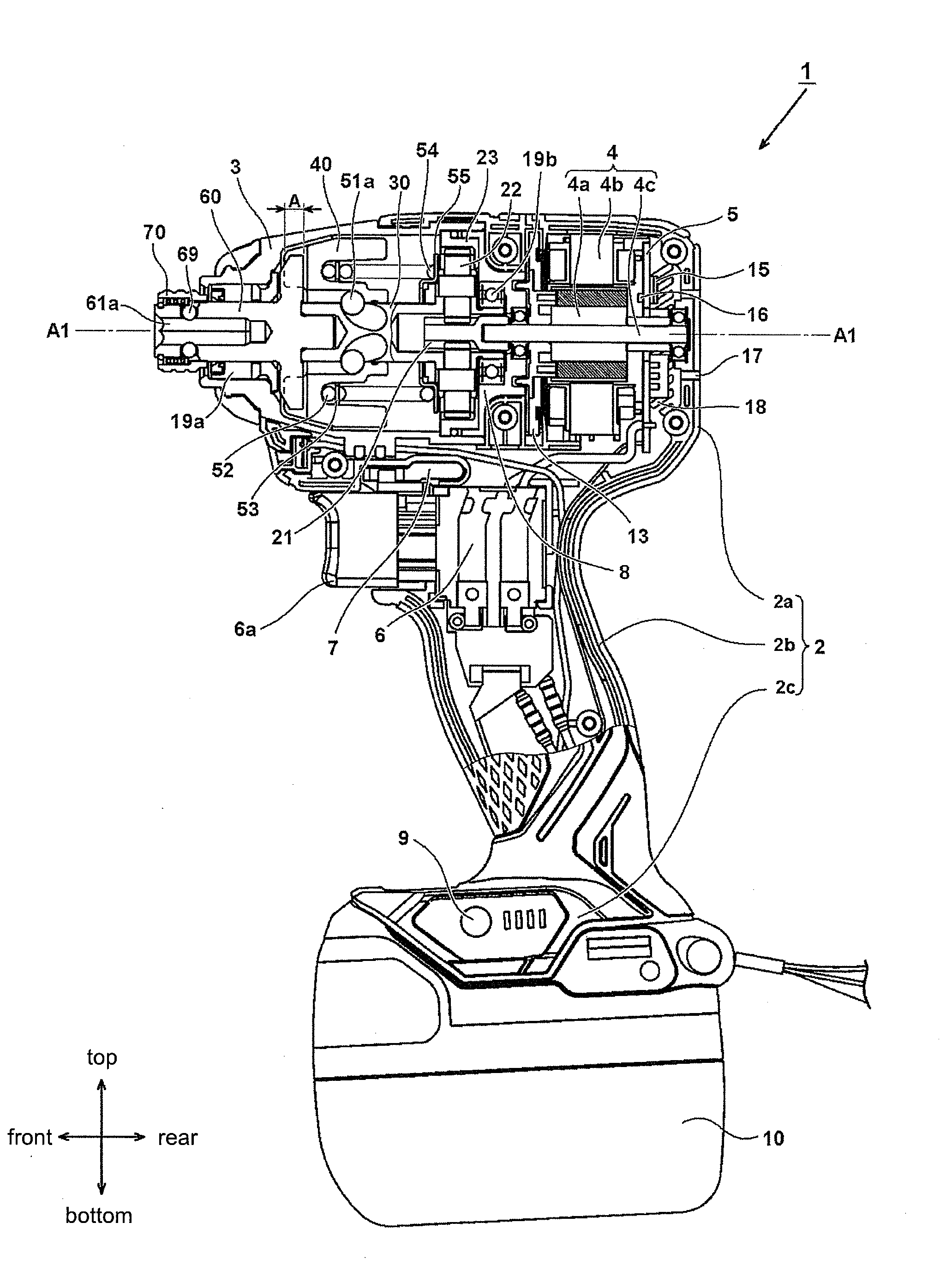

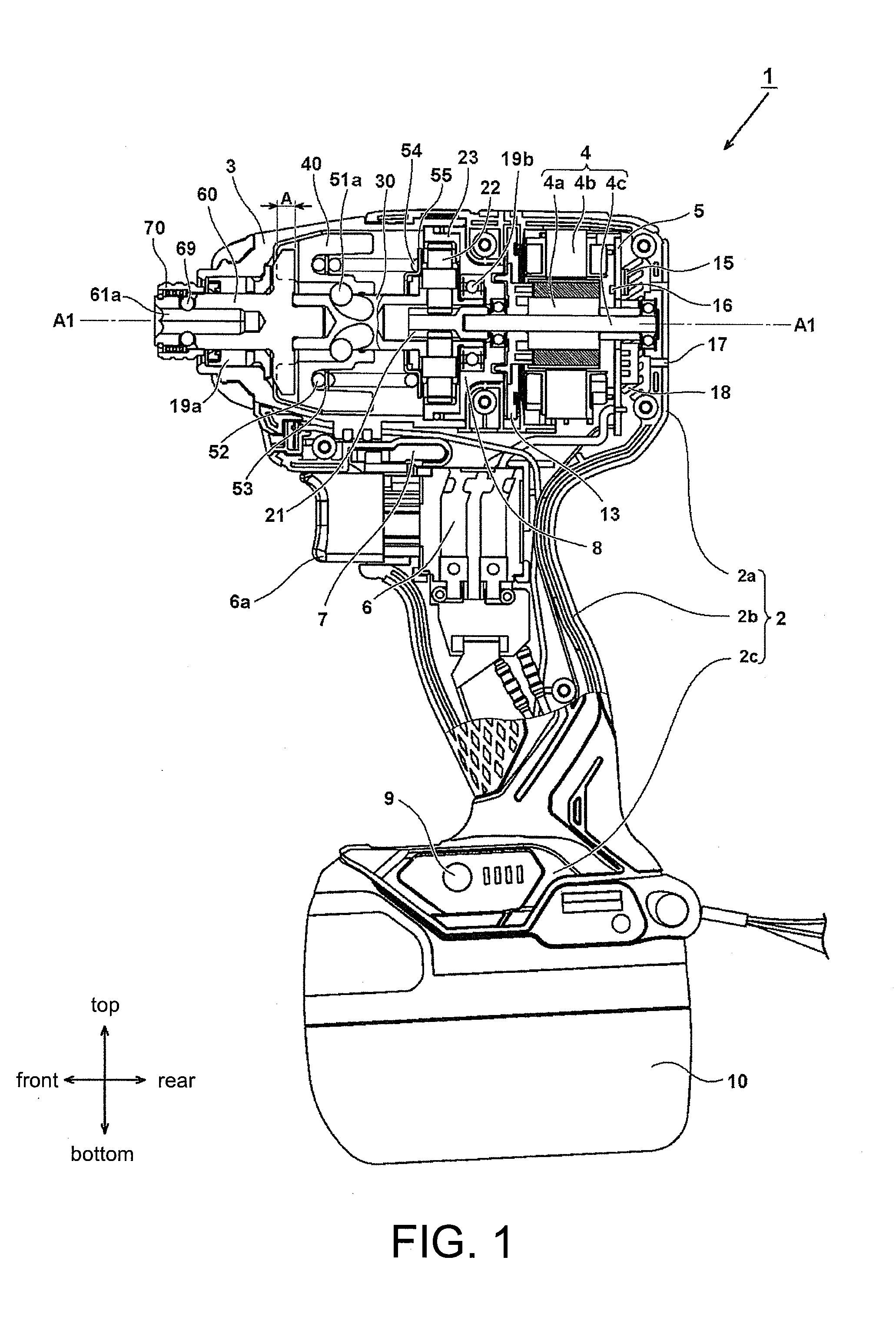

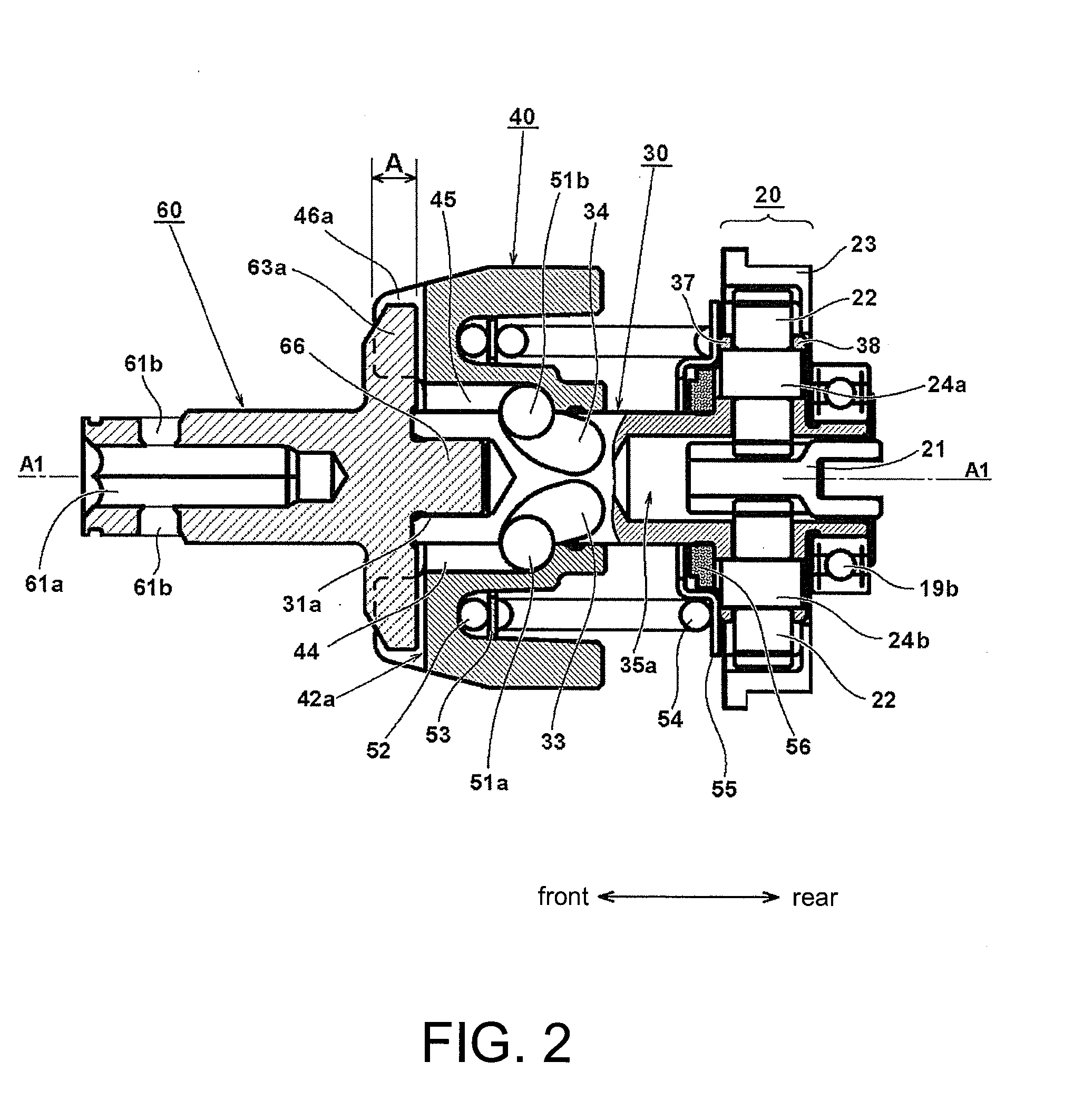

Electric tool

InactiveUS20170036327A1Preventing cam-outShorten the timePortable power-driven toolsPower driven toolsPower toolHigh torque

Provided is an impact type electric tool. A striking mechanism is used, which uses a hammer having striking claws that are equally arranged in the rotational direction and an anvil having struck claws. A relationship between a striking energy E, which the hammer has right before striking the anvil, and a disengaging torque TB, which is applied between the hammer and the anvil right before the hammer is disengaged from the anvil, is set as 5.3×TB<E<9.3×TB in the case of three claws and set as 9.3×TB<E<15.0×TB in the case of two claws, so as to perform striking by skipping one of the claws of the hammer and the anvil when a high torque is required. Accordingly, the electric tool achieves output of a high torque while maintaining a favorable operational feeling during striking.

Owner:HITACHI KOKI CO LTD

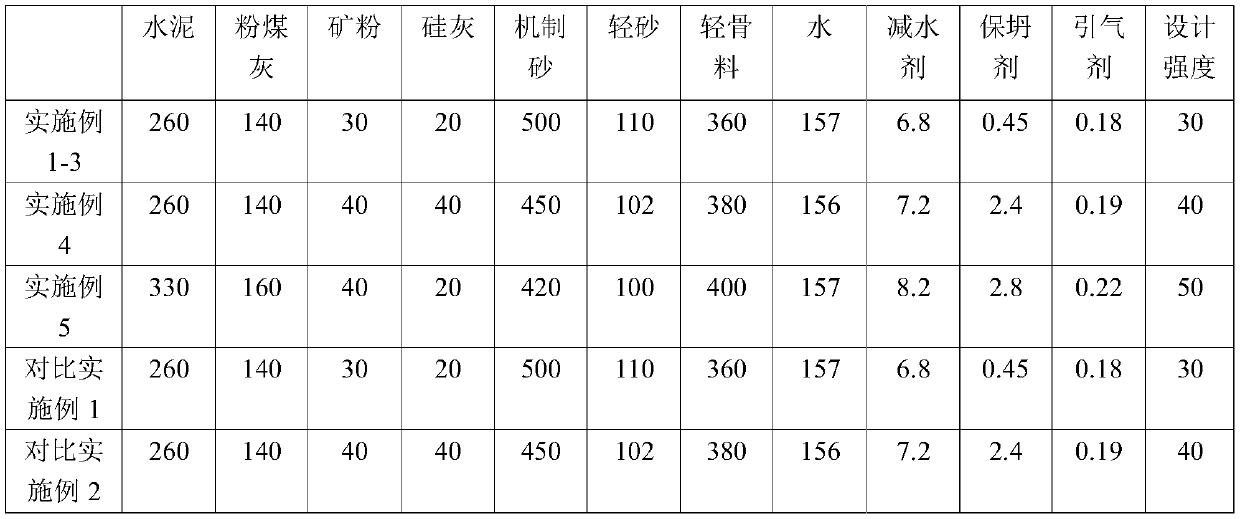

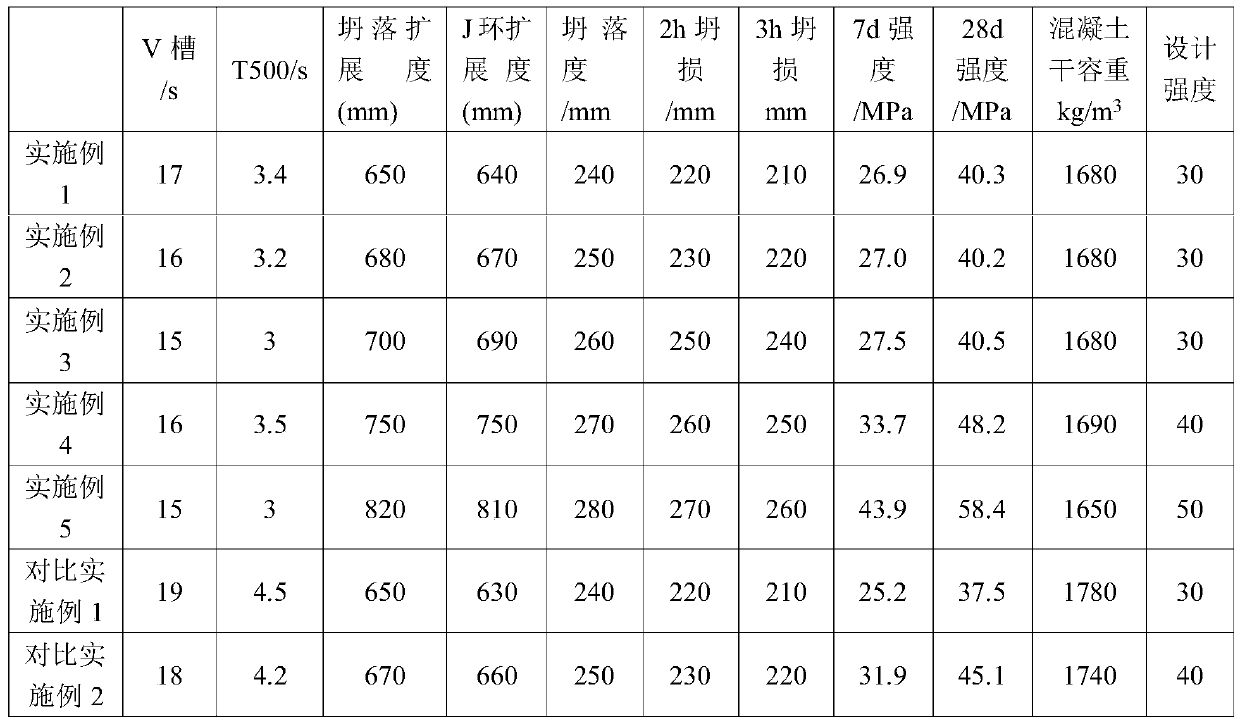

Self-compacting lightweight aggregate machine-made sand concrete and preparation method thereof

InactiveCN110240446ASolve the problem of insufficient resources and tight supplyImprove cohesionCeramicwareRosinWater reducer

The invention discloses self-compacting lightweight aggregate machine-made sand concrete. The sand concrete comprises the following raw materials in parts by weight: 260-330 parts of concrete, 140-160 parts of fly ash, 30-40 parts of mineral powder, 20-40 parts of silica fume, 420-500 parts of machine-made sand, 100-110 parts of light sand, 360-400 parts of lightweight aggregate, 150-160 parts of water, 6.8-8.3 parts of a water reducer, 0.45-2.8 parts of a slump preserving agent and 0.18-0.22 part of an air entraining agent, wherein the slump preserving agent is obtained by compounding isopentenol polyoxyethylene ether (TPEG), acrylic acid and a compound molecular weight regulator, the air entraining agent is a rosin soap type air entraining agent obtained by compounding rosin, caustic soda, triethanolamine and sodium lauryl sulfate. The machine-made sand is used to replace natural sand, and the concrete prepared by a secondary mixing method solves the problems of easy flotation of lightweight aggregate concrete aggregate, shortage of natural sand supply, and high water demand rate, easy separation and poor pumpability of lightweight aggregate machine-made sand concrete.

Owner:中建西部建设贵州有限公司

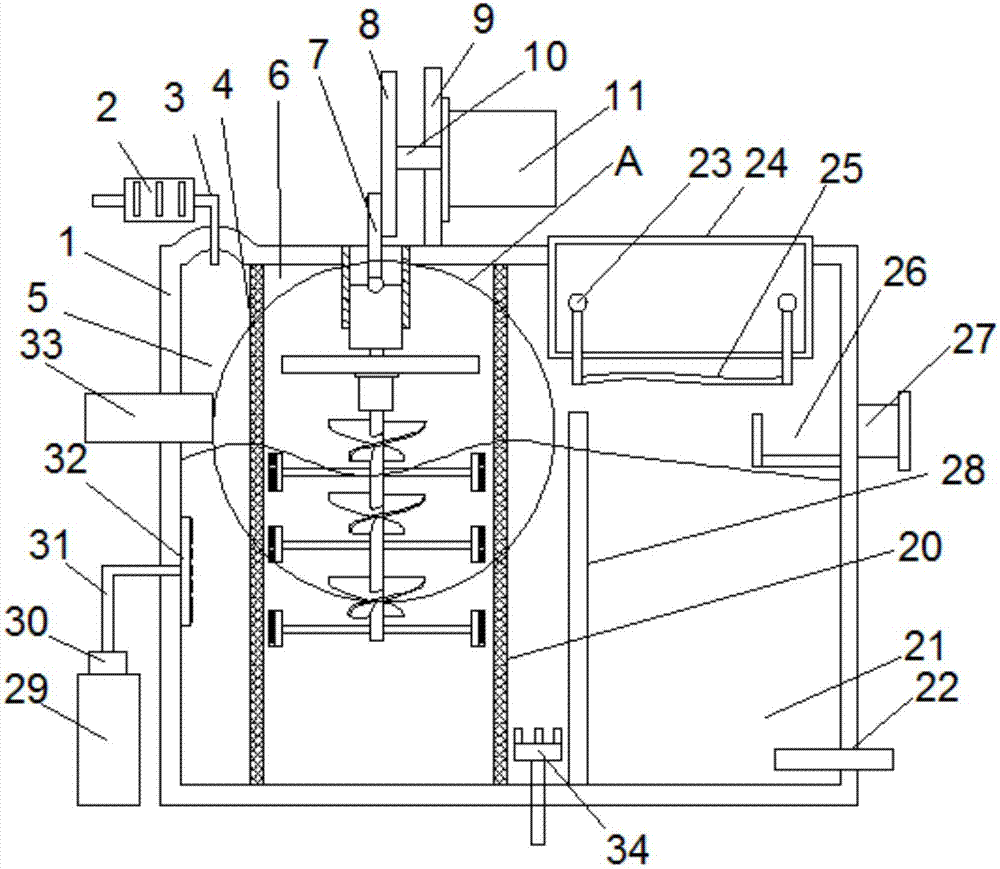

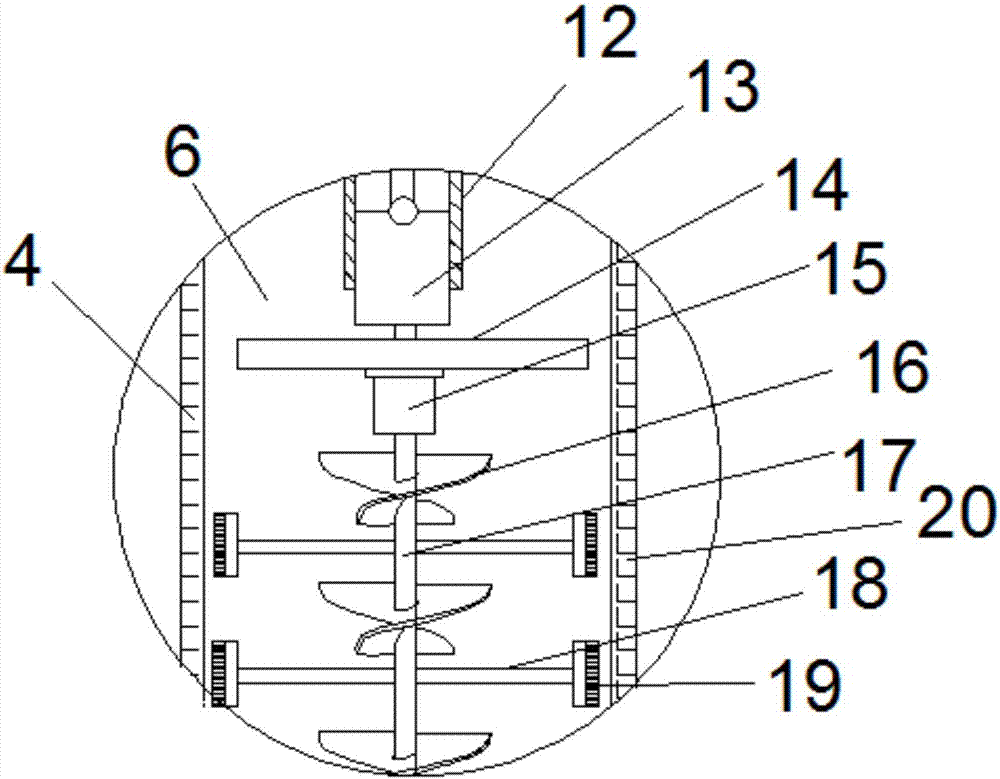

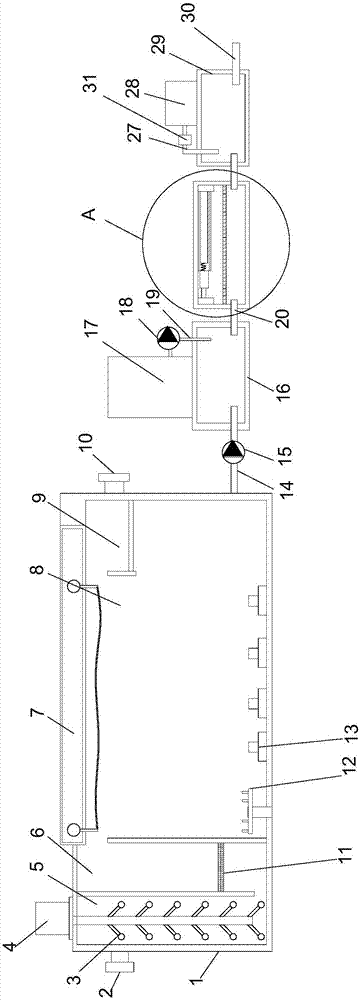

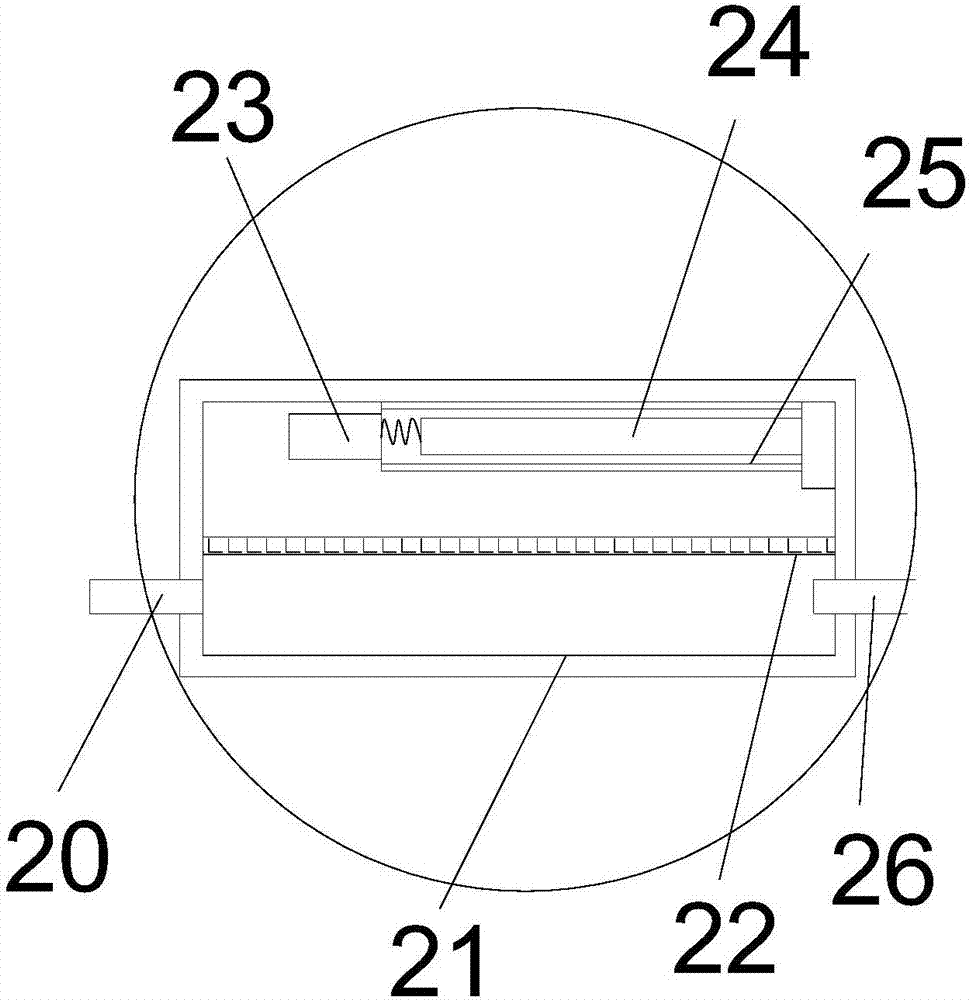

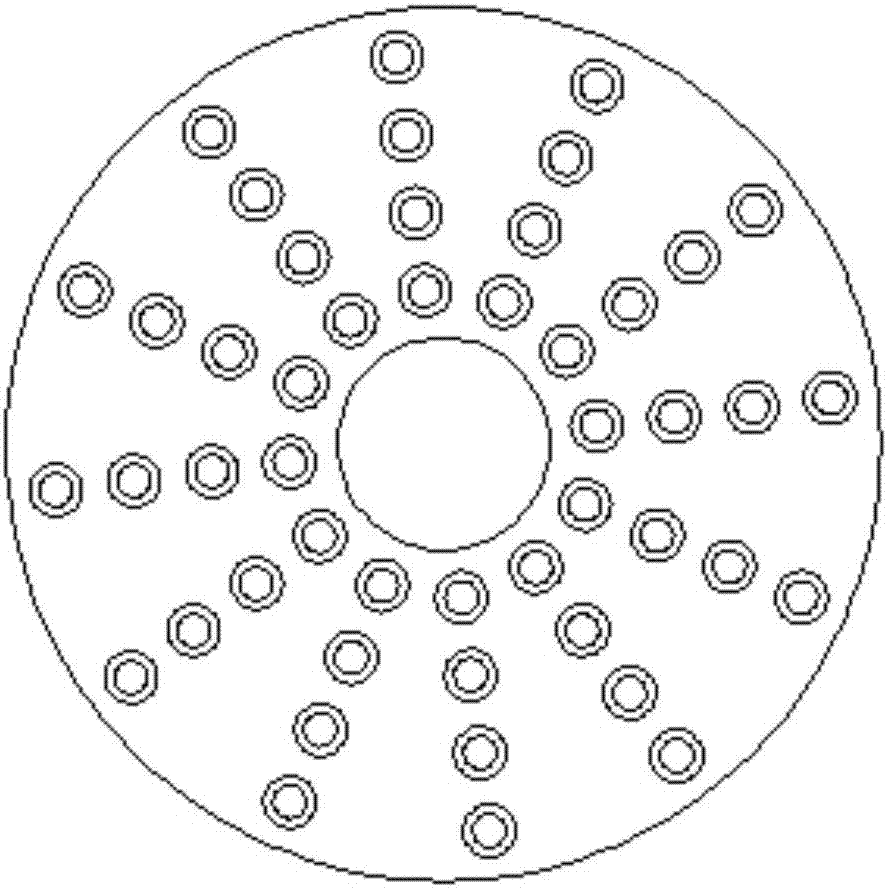

Integrated high-efficiency sewage treatment equipment

InactiveCN107010765AReasonable structural designEasy to useWater/sewage treatment with mechanical oscillationsDispersed particle separationEngineeringSewage treatment

The invention discloses integrated high-efficiency sewage treatment equipment which comprises a box body, wherein the interior of the box body is sequentially partitioned into a water inlet chamber, a mixing chamber and a water purification chamber from the left to the right by virtue of a first filtering net and a second filtering net; the first filtering net is positioned on the left side of the second filtering net; the upper end of the water inlet chamber communicates with a biological deodorization device through an exhaust pipe; a sewage inlet pipe communicating with the water inlet chamber is arranged at the upper end on the left side of the water inlet chamber; a sprayer is arranged in the water inlet chamber in the lower end of the sewage inlet pipe; the sprayer communicates with the output end of a liquid pump outside the left side of the box body through a conveying pipe; and the input end of the liquid pump communicates with a foam cleaning agent storage tank at the lower end of the liquid pump. The integrated high-efficiency sewage treatment equipment disclosed by the invention is reasonable in structural design and is capable of completing the operations of mixing sewage and foam cleaning agents, stirring, deodorizing, filtering, performing air-flotation treatment, removing residues and scraping mud at a time, the sewage treatment effect is improved, the first filtering net and the second filtering net can be automatically cleaned, blockage is avoided, and the replacement frequency and the maintenance costs of the first filtering net and the second filtering net can be reduced.

Owner:合肥图腾龙企业管理事务所(有限合伙)

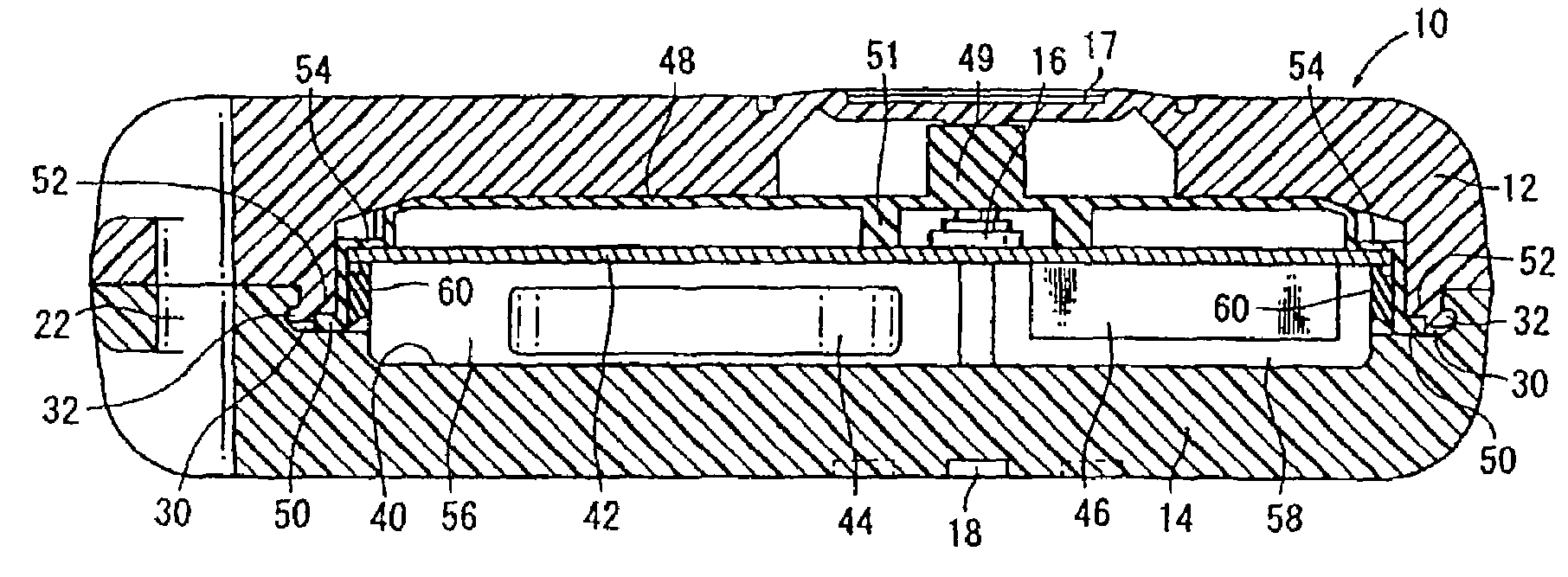

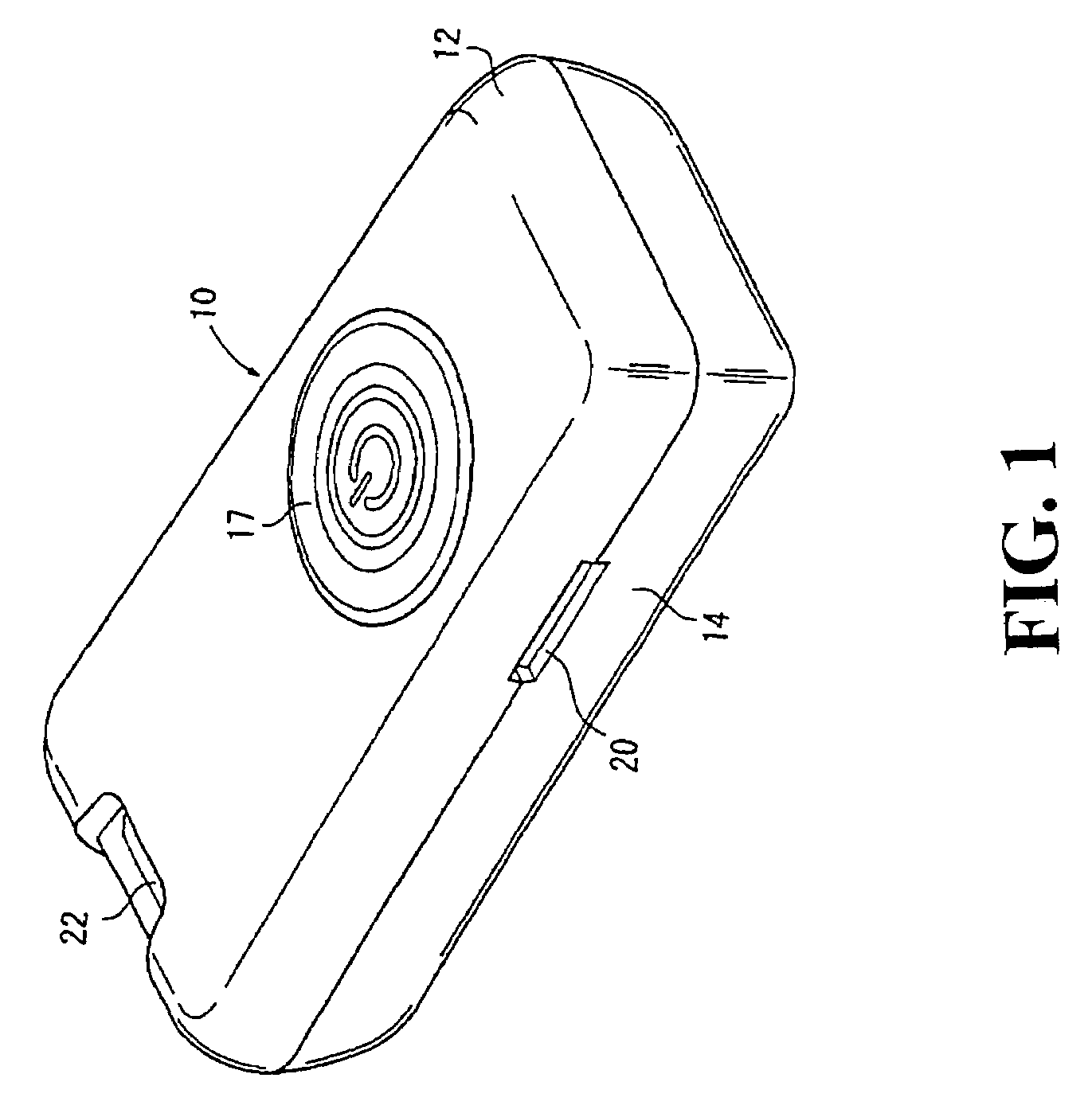

Portable electronic key

InactiveUS7423867B2Easy to floatAvoid lostInput/output for user-computer interactionElectrophonic musical instrumentsElectronElectrical equipment

A portable electronic key easily findable even if dropped into water. The portable electronic key includes an upper cover and a lower cover, a hermetically sealed space is formed, in which electrical equipment such as a board, a battery, and an antenna are arranged. The upper cover and the lower cover are formed of foam resin, and a grain pattern is given to surfaces thereof. A specific gravity of the entire electronic key is set at 1 or less, thus enabling the portable electronic key to float on the surface of the water.

Owner:HONDA MOTOR CO LTD

Al-Mg-Ca-Fe alloy contg. micro-carbon, low silicon, low phosphorous, low-sulphur used for steelmaking

The invention relates to a micro low carbon, low silicon, low phosphor, and low sulfur Al-Mg-Ca-Fe alloy used in steel-making. It uses as deoxidizer and contains 20-85wt% Al, 5-20wt% Mg, 1-15wt% Ca, C less than 0.02wt%, Si less than 1.0wt%, P less than 0.02wt%, S less than 0.02wt%, the rest is Fe. It is smelted from line frequency furnace. The invention has the advantage of easy to use, stable, and could improve the recovery factor of the metal element. The molten steel treated by the deoxidizer has good fluidity, high work rates, high benefits, etc. The deoxidizer could discharge the impurity, and it has good mechanical behavior, good quality, long useful life and good social benefit.

Owner:本溪冶炼集团有限公司

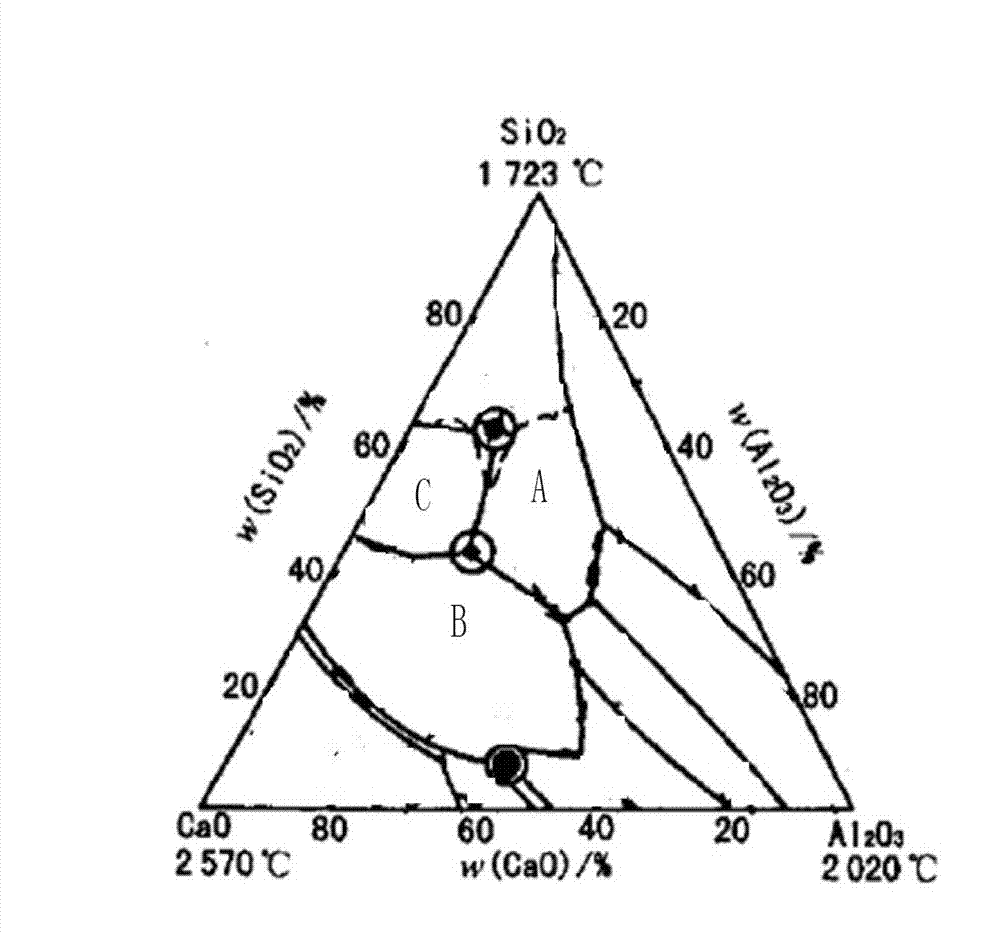

Novel process of steelmaking deoxidization by utilizing precipitator dust of refining furnace

ActiveCN103031409ALow slagging temperatureHigh speedRecycling and recovery technologiesElectric arc furnaceAlloy

The invention provides a novel process of steelmaking deoxidization by utilizing precipitator dust of a refining furnace, comprising the steps of 1, under the circumstance that the blowing process of a converter or an electric furnace is finished, the carbon end-point composition W[C] %=0.1-0.6% and the tapping temperature is 1580-1620 DEG C during the tapping, connecting the bottom to blow argon gas 2-4min before the tapping and carrying out gas stirring at the speed of 150-480L / min; and 2, after the tapping of the liquid steel in the converter or the electric furnace, starting to continuously add tons of steel aluminium blocks or alloy to carry out deoxidization, and when the quantity of the liquid steel is 7-17t in a steel ladle, starting to add the precipitator dust of the refining furnace along with the steel flow of the tapping of the furnace, wherein the adding quantity of the steel aluminium blocks or alloy is confirmed according to carbon content of the liquid steel before the tapping, the tapping time of the furnace is 2-8min, the adding of the precipitator dust of the refining furnace needs to be finished in 3-4min and the adding quantity is 1.2-6kg / ton of steel. According to the invention, the precipitator dust of the refining furnace is adopted as the deoxidizing agent, so that the novel process is suitable for silicon killed steel and silicon-aluminium killed steel.

Owner:XINJIANG BAYI IRON & STEEL

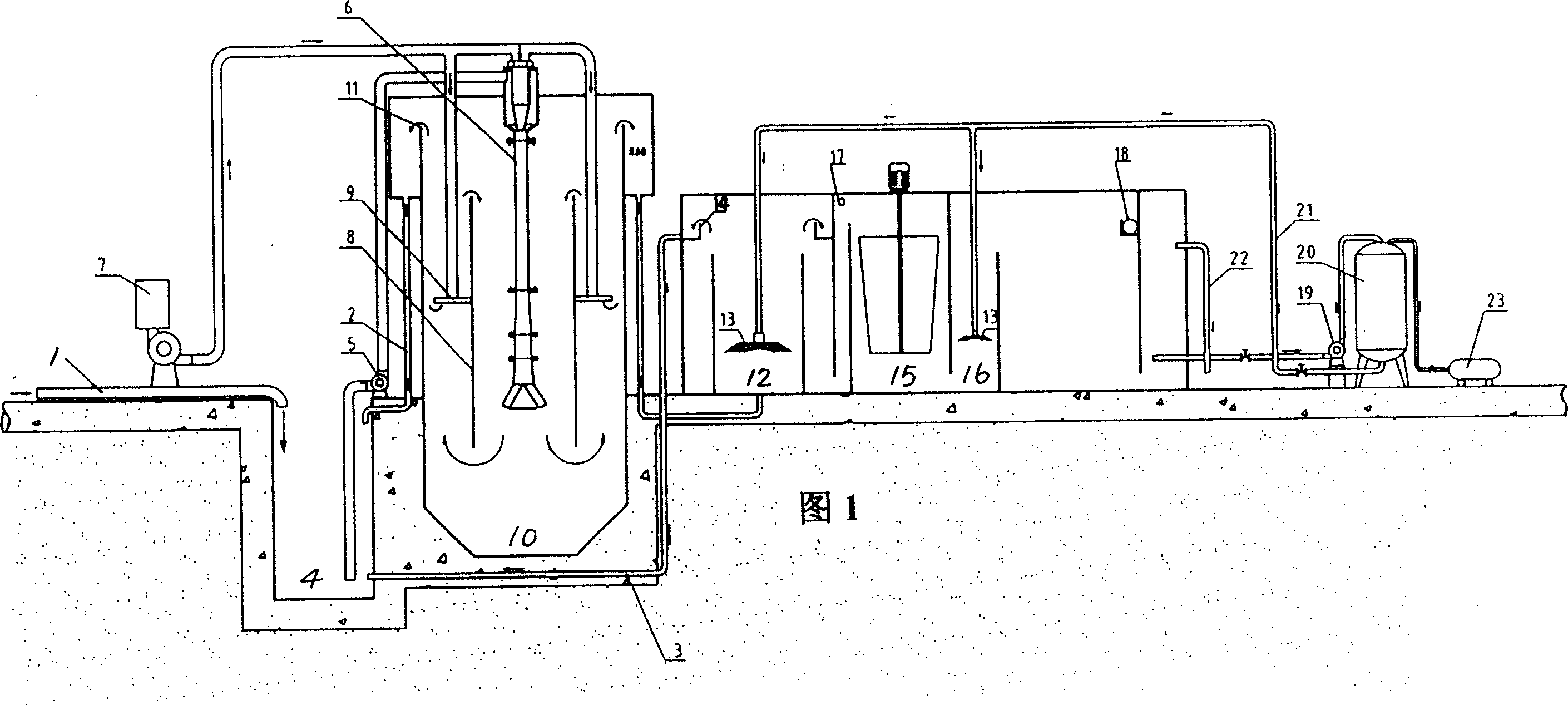

Mixed aeration type biological treating system

InactiveCN1986451AUniform loadWell mixedTreatment using aerobic processesSustainable biological treatmentRefluxSludge

The mixed aeration type biological treating system features that there are one circular biochemical pond set beside the mixing pond, which has one inside ejector and two overflow grooves in the top including one connected to the mixing pond via an outside circulating pipe; one first stage air floating pond connected to the other overflow groove and to the mixing pond via a sewage reflux pipe; one second stage air floating pond connected to the first stage air floating pond; one blower connected to the circular biochemical pond via ventilating pipeline; and one shallow aeration pipe in the outlet of the ventilating pipeline. The present invention has combined inside-pond circulation and outside-pond circulation, greatly raised impact resistance, and increased chemical-adding coagulating and air floating pond for raised treating capacity.

Owner:上海达源环境科技工程有限公司

RH (relative humidity) treatment method for low silicon-aluminum killed steel

The invention relates to the technical field of continuous casting refining treatment, and in particular relates to an RH (relative humidity) treatment method for low silicon-aluminum killed steel. The method is characterized in that the method is suitable for <C> greater than or equal to 0.010% and less than or equal to 0.05%, <Si> greater than or equal to 0.03% and less than or equal to 0.05%, and argon-blown silicon less than or equal to 0.008% after discharge of steel from a converter, SiO2 oxidized by low carbon ferrosilicon and Al2O3 in molten steel are reacted through rimmed steel by RH so as to produce deoxidized product aluminum silicate, and fine Al2O3 inclusion adhere to the aluminum silicate in floating upward process, so that the purpose of purifying the molten steel is achieved. Compared with the prior art, the method has the beneficial effects of meeting the requirement of upper limit of 0.03% of the end product silicon of low silicon-aluminum killed steel, reducing the phenomenon of flocculation caused by producing RH low silicon-aluminum killed steel through a middle sheet billet chamber machine, and lowering the inclusion rate of a steel board, and the cold rolling inclusion rate of defect is lowered to 0.26% from 0.46%.

Owner:ANGANG STEEL CO LTD

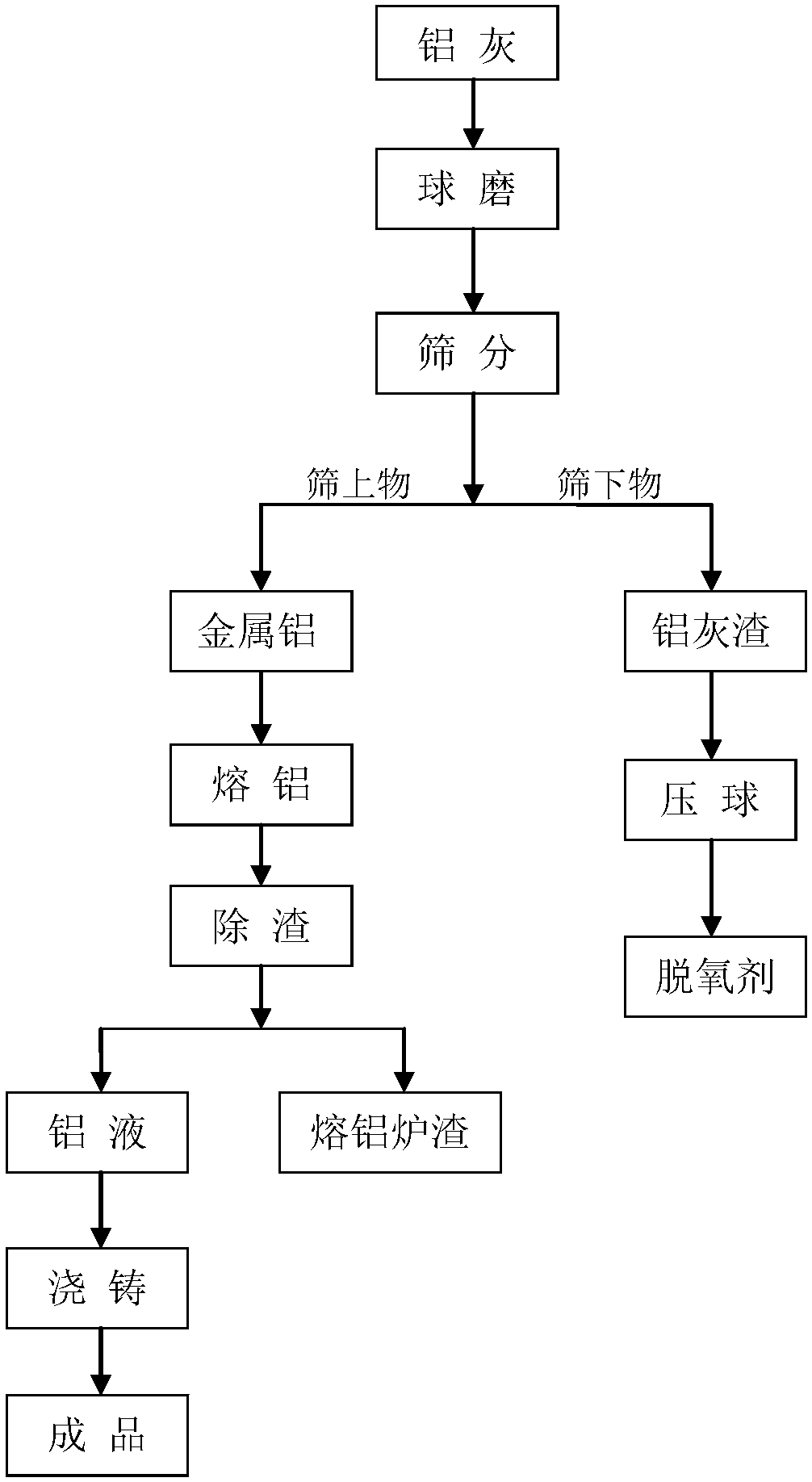

Metallic aluminum deoxidizing agent and preparation method thereof

InactiveCN108285949AHigh deoxygenation rateGood deoxidation operabilityProcess efficiency improvementMetallic aluminumMolten steel

The invention relates to the technical field of metallurgy, in particular to a metallic aluminum deoxidizing agent and a preparation method thereof. The deoxidizing agent is made of aluminum scruff ash, aluminum ash clinker is obtained by means of ball milling and screening and then is put into a ball pressing machine for pressing and curing, and accordingly the metallic aluminum deoxidizing agentcan be obtained. When the method is used for preparing the deoxidizing agent, the technology is simple, wasting of resources can be effectively reduced, cost input of deoxidizing ingredients is reduced, and waste can be recycled and reutilized. The deoxidizing agent obtained through the method can be applied to the working procedures of ladle refining and molten steel purifying of steel works, deoxidizing and desulfuration capacity is high and the metallic aluminum deoxidizing agent can be widely applied and popularized.

Owner:青海源通工贸有限公司

Yttrium rare earth magnesium composite nodulizer

Owner:LONGYI HEAVY RARE EARTH MATERIAL LONGNAN COUNTY

Method for manufacturing alkali-free glass substrate and alkali-free glass substrate

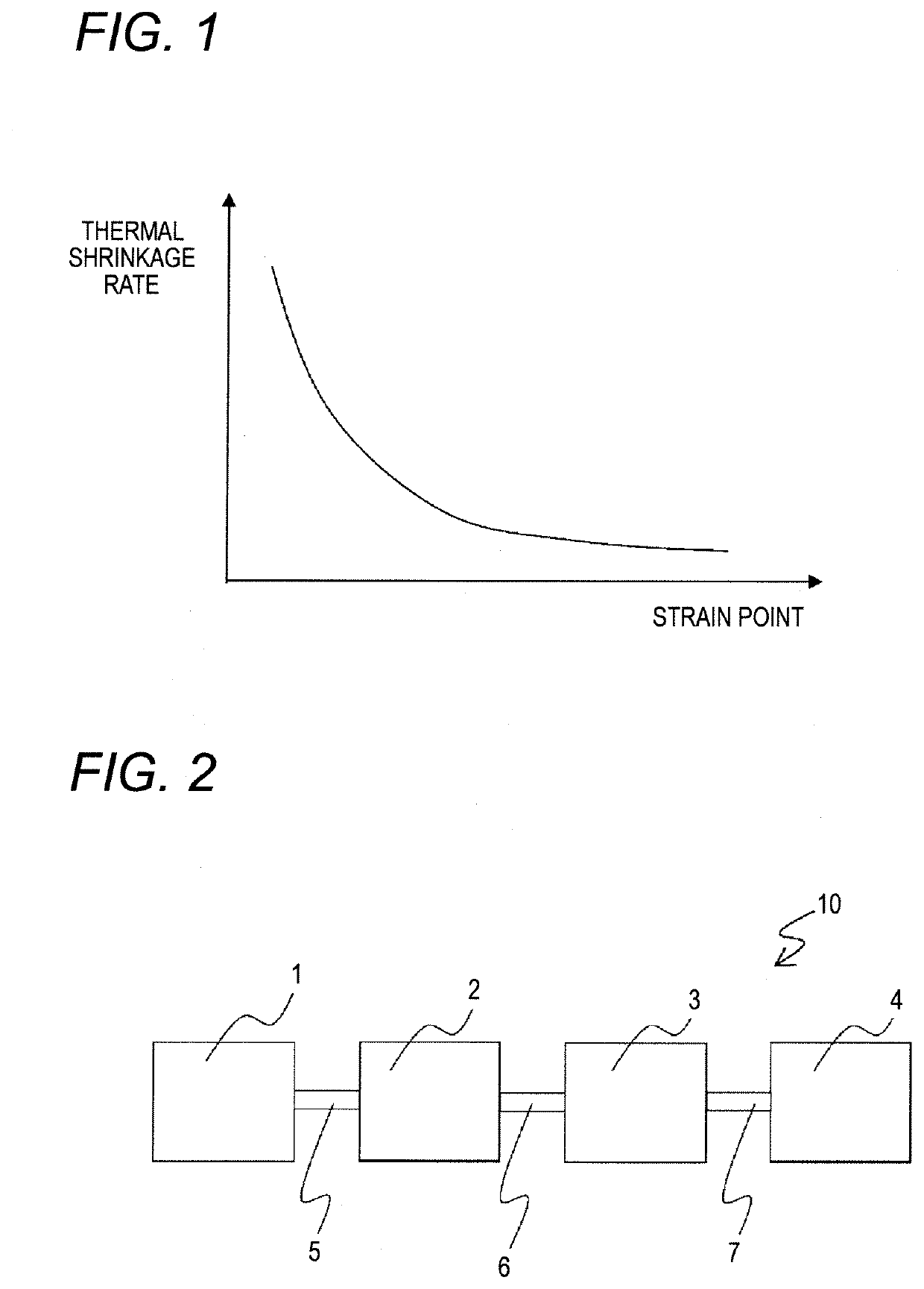

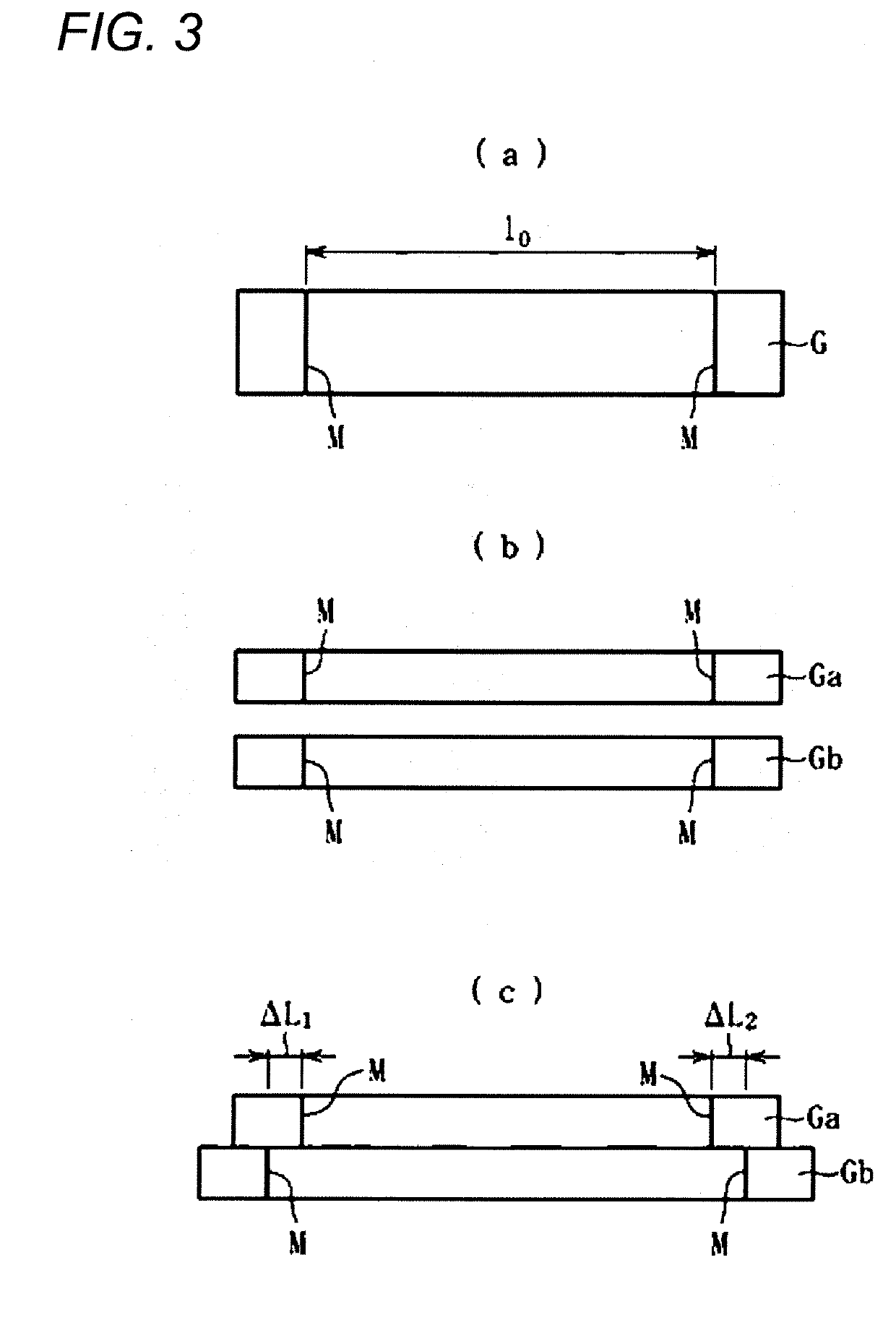

ActiveUS20200199012A1Low heat shrinkagePoint becomes highGlass furnace apparatusTank furnacesAlkali freePhysical chemistry

Provided is an alkali-free glass substrate having a high strain point and excellent bubble count, and a method for manufacturing the alkali-free glass substrate. The method includes: a batch preparing process of preparing a raw material batch so as to obtain alkali-free glass containing, in mass %, 50 to 80% of SiO2, 15 to 30% of Al2O3, 0 to 4.5% of B2O3, 0 to 10% of MgO, 0 to 15% of CaO, 0 to 10% of SrO, 0 to 15% of BaO, 0 to 5% of ZnO, 0 to 5% of ZrO2, 0 to 5% of TiO2, 0 to 15% of P2O5 and 0 to 0.5% of SnO2 as a glass composition; a melting process of melting the prepared raw material batch; a fining process of fining the molten glass; and a forming process of forming the fined glass into a sheet shape. The raw material batch is melted such that a bubble enlarging temperature of the obtained glass is lower than a maximum temperature of the fining process.

Owner:NIPPON ELECTRIC GLASS CO LTD

Composite solid self-lubricating alloy powder for scraping plate machine chute and preparing method thereof

ActiveCN104858423ANot suitable for cracksEasy to floatMetallic material coating processesMelting tankHexagonal boron nitride

The invention relates to composite solid self-lubricating alloy powder for a scraping plate machine chute and a preparing method thereof. The powder is characterized in that the alloy powder comprises, by mass, 10%-13% of chrome, 4%-6% of nickel, 0.5%-1% of manganese, 1%-2% of molybdenum, 0.5%-1% of boron, 0.25%-0.5% of silicon, 1%-3.5% of rare earth oxide, 2%-8% of tungsten carbide, 2%-8% of carton, 2%-8% of hexagonal boron nitride, and the balance iron. By means of the composite solid self-lubricating alloy powder for the scraping plate machine chute and a preparing method thereof, the problem that the nonmetal phase in the alloy powder is prone to floating easily in a weld pool due to the small density feature in a laser cladding process is solved, and meanwhile, control over the size and granularity of grains is achieved. The alloy power is suitable for the laser cladding process, cracks are not likely to generate on a lubricating cladding layer after laser cladding is conducted, and meanwhile, the composite solid self-lubricating alloy powder has the good grain abrasion wear resistance, anti-corrosion performance and self-lubricating performance.

Owner:西安奥奈特固体润滑工程学研究有限公司

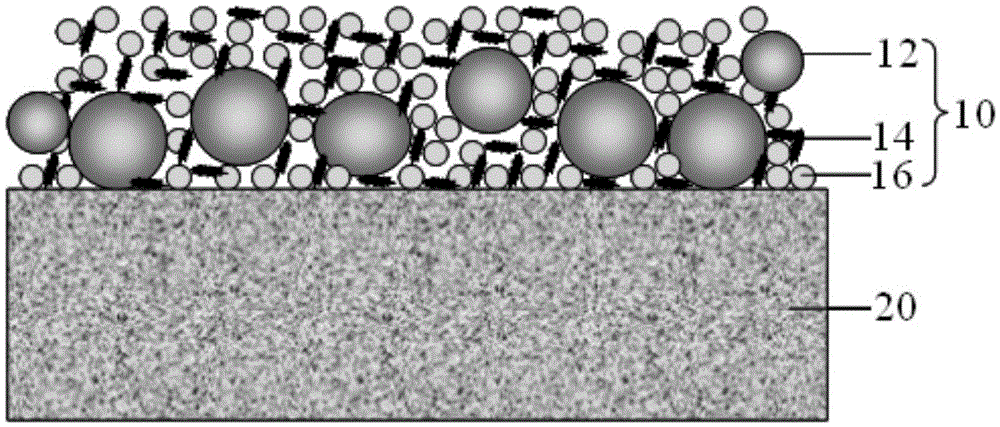

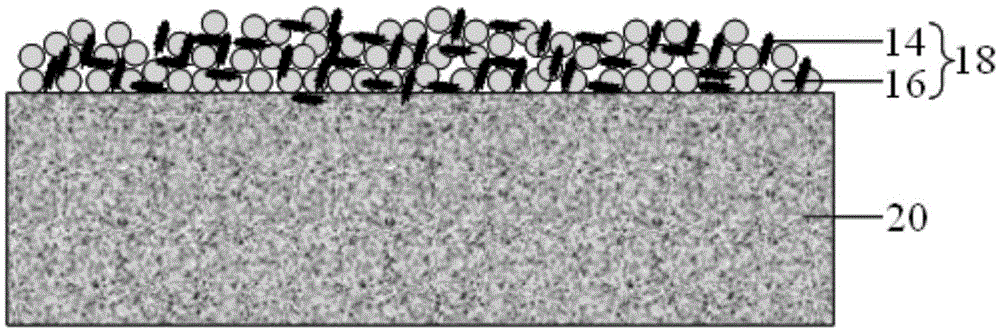

Lithium-rich technology for lithium-ion batteries and lithium-ion batteries prepared using the technology

ActiveCN104332657BWell mixedEasy to floatElectrode manufacturing processesFinal product manufactureElectrical batteryPhysical chemistry

The invention discloses a lithium-ion battery lithium-enriched process and a lithium-ion battery prepared by using the process. The steps of the lithium-enriched process are: at a temperature lower than the melting point of EC, lithium powder and EC powder are mixed in a dry powder state Premix evenly, and then heat up to a temperature higher than the melting point of EC to solvate the EC powder, thereby obtaining a lithium powder slurry in which the lithium powder is uniformly dispersed in the EC solvent; coating the prepared lithium powder slurry on the lithium On at least one of the positive electrode sheet, negative electrode sheet, and separator of the ion battery, and then cooled to a temperature lower than the melting point of EC to obtain a positive electrode sheet, a negative electrode sheet, and / or a separator whose surface layer is a lithium-rich layer. Compared with the prior art, the lithium-rich process of the present invention not only has the advantages of simple preparation method, uniform dispersion effect, and no damage to the protective film on the surface layer of lithium powder during the dispersion process, but also does not need to be dried after coating the lithium-rich layer, effectively avoiding The oxidation and floating of lithium powder in the air during the high temperature baking process are prevented.

Owner:DONGGUAN AMPEREX TECH +1

High strength steel wire for arc additive manufacturing, and preparation method thereof

ActiveCN110172644AStable manufacturingGood formabilityAdditive manufacturing apparatusUltimate tensile strengthHigh strength steel

The invention relates to a high strength steel wire for arc additive manufacturing, and a preparation method thereof. The high strength steel wire comprises the following components by mass: 0.09%-0.14% of C, 0.6%-1.0% of Si, 1.5%-2.0% of Mn, 0.5%-0.8% of Mo, 2.0%-3.0% of Ni, 0.3%-0.6% of Cr, no more than 0.1% of Al, no more than 0.02% of P, no more than 0.02% of S, no more than 5 ppm of H and thebalance Fe. Inclusions are less during arc additive manufacturing by using the high strength steel wire, and the continuous forming requirements of the arc additive manufacturing can be met; and thearc additive manufacturing accumulation state has high strength and plasticity.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Comprehensive sewage treatment device

InactiveCN107032542ALight weightTo achieve the treatment effectWater treatment parameter controlWater/sewage treatment by irradiationProcess mechanismWastewater

The invention discloses a sewage comprehensive treatment device, comprising a treatment box, the inside of the treatment box is separated from left to right by a partition into a stirring and crushing cavity, a sediment cavity and a dissolved air cavity connected in sequence, and the left upper end of the treatment box is A sewage inlet pipe connected to the stirring and crushing chamber is provided; a stirring device is provided in the stirring and crushing chamber, and a stirring motor is provided at the upper end of the treatment tank to drive the stirring device to rotate; a horizontally arranged filter screen is provided at the lower end of the sediment chamber The left side of the lower end of the dissolved air chamber is provided with a dissolved air nozzle, and the dissolved air nozzle communicates with an external dissolved air tank, and the right side of the described dissolved air nozzle is provided with a plurality of ultrasonic generators at intervals, and the upper end of the described dissolved air chamber is provided with There is an air flotation processing mechanism. The invention has reasonable structural design and convenient use, can realize effective treatment of sewage in small medical institutions through stirring and pulverizing, sedimentation, air flotation treatment and multiple disinfection treatment of sewage, has high treatment efficiency, good treatment effect and strong practicability.

Owner:安徽世绿环保科技有限公司

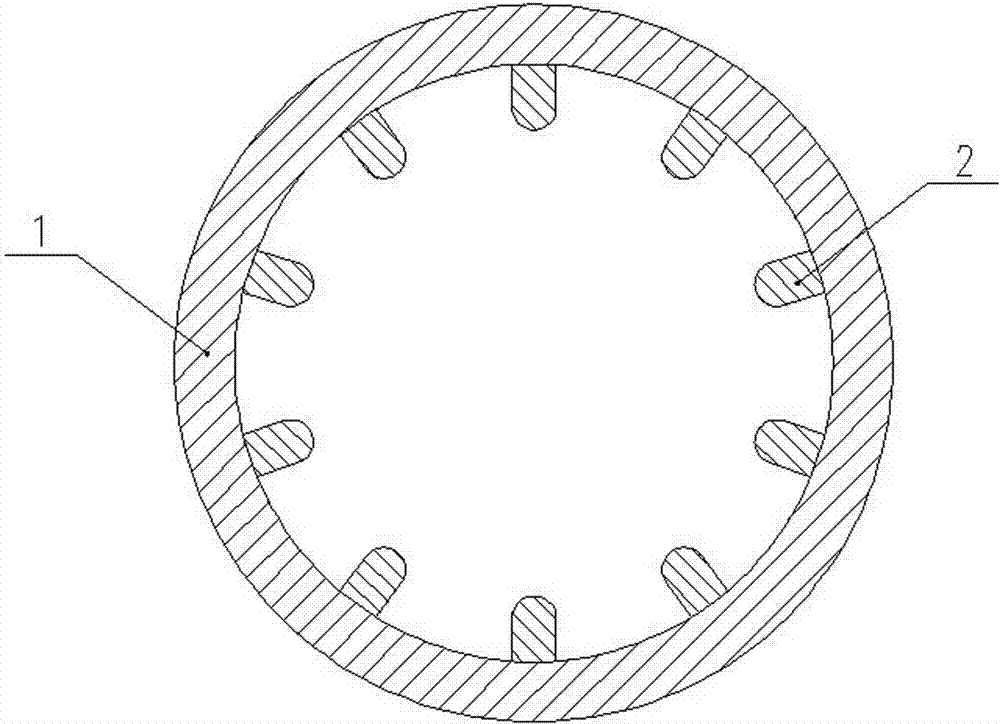

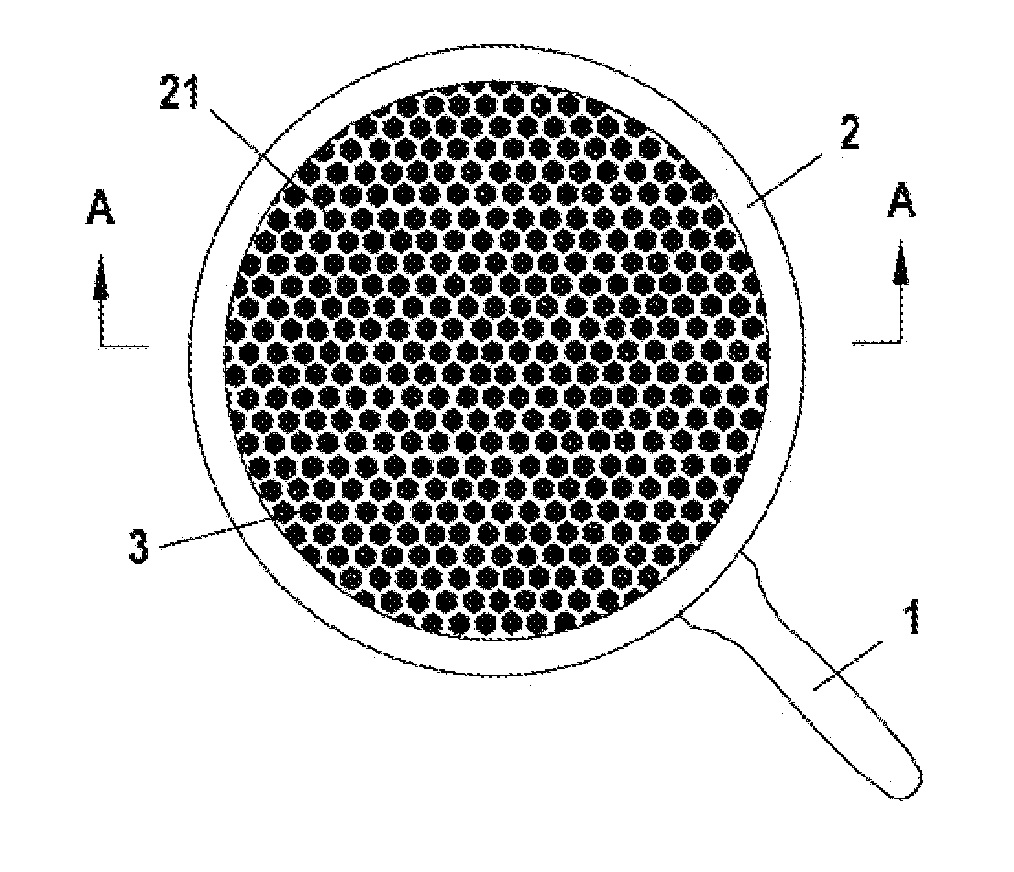

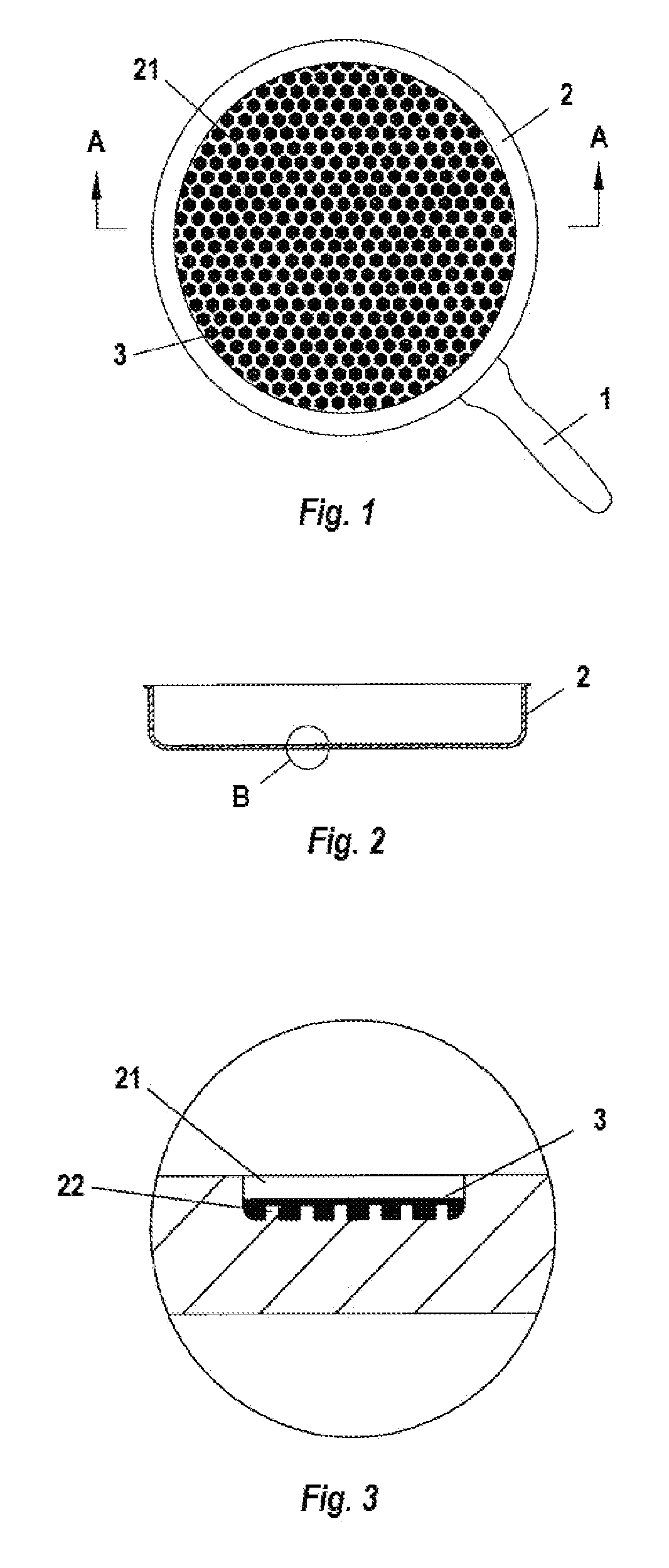

Cooking vessel with nonstick coating

The invention relates to a cooking vessel having a non-stick coating, a handle and a vessel body. According to the invention, the inner surface of the vessel body is provided with a multiplicity of oil wells, the inner side of which wells is provided with studs of which the height is less than the depth of the oil wells, wherein the upper surface of the oil wells is provided with a non-stick coating, and the thickness of the non-stick coating is greater than the height of the studs and at the same time less than the depth of the oil wells.

Owner:LEE CHANGHO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com