Preparation method of leafing aluminum paste

A technology of aluminum silver paste and floating type, which is applied in the direction of pigment paste, dyeing physical treatment, dyeing low molecular organic compound treatment, etc. It can solve the problem of insufficient whiteness and high flash silver brightness, damage to aluminum flakes, and harm to human health, etc. problems, to improve stability and storage time, increase whiteness and sparkle, and easy to float

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of floating aluminum silver paste, the method has the following steps:

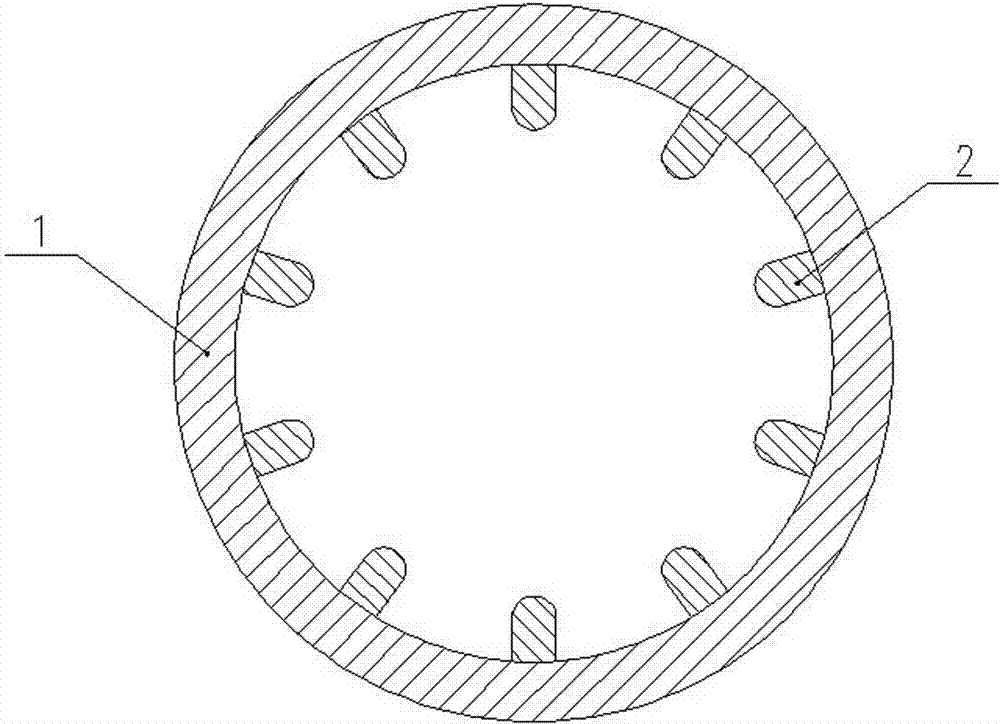

[0033] (1) Selection of ball mill: use horizontal ball mill 1, such as figure 1 As shown, the number of lifting ribs 2 in the horizontal ball mill 1 is nine or ten equally divided angles, the cross section of the lifting ribs 2 is finger-shaped, and the height of the lifting ribs 2 is 10 cm;

[0034] (2) Selection and ratio of solvent oil: D70 solvent oil is used, and the ratio of D70 solvent oil to aluminum powder is 1.5:1;

[0035] (3) Mixing: Add aluminum powder and D70 solvent oil with a selected ratio and a certain amount of ball milling additives into the ball mill and mix them. The ball milling additives are a certain proportion of surfactants, coupling agents, grinding aids, and micron spherical aluminum particles. , the surfactant is one or a mixture of oleic acid and erucic acid, the coupling agent is one or a mixture of titanate and γ-ampropyltrihexyloxysilane, and ...

Embodiment 1

[0044] Example 1: steel ball diameter 0.8mm, small steel ball weight 2000Kg, aluminum powder 80Kg, D70 solvent oil 120Kg, ball milling time 155 minutes, frequency 45 Hz, temperature 42°C.

Embodiment 2

[0045] Example 2: steel ball diameter 0.8mm, small steel ball weight 2000Kg, aluminum powder 80Kg, D70 solvent oil 120Kg, ball milling time 160 minutes, frequency 42 Hz, temperature 40°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com