Patents

Literature

47 results about "Marine coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Marine coatings are a type of protective coating used mostly in the marine environment to protect ships, vessels, tankers, and other materials from saline water or fresh water. A marine coating has specific functional properties, therefore it can provide superior protection to the surfaces to which it is applied.

Marine antifouling coating compositions

InactiveUS7335248B2Toxic reductionMinimize bio-foulingBiocideSulfur/selenium/tellurium active ingredientsMarine coatingsOrganism

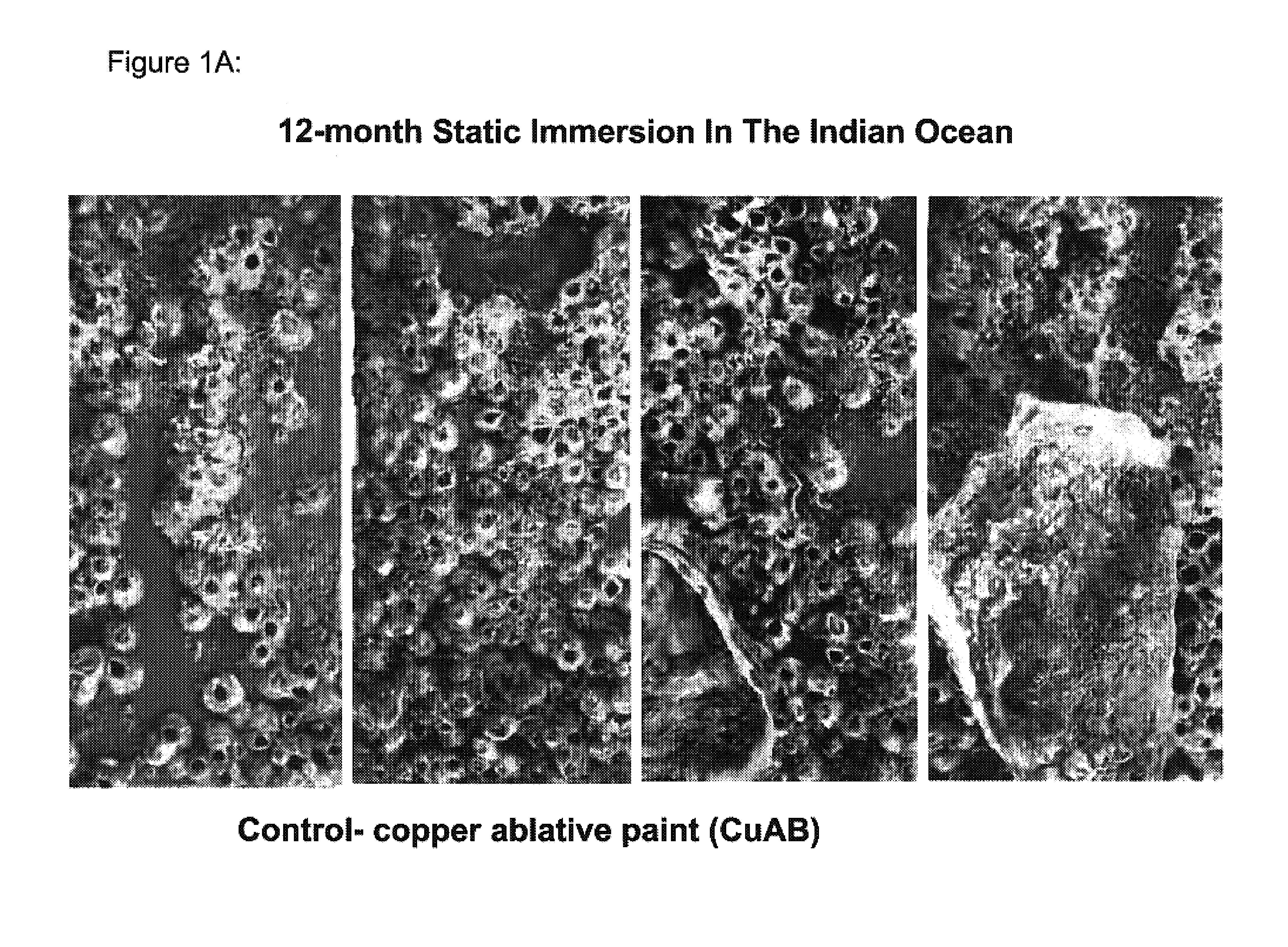

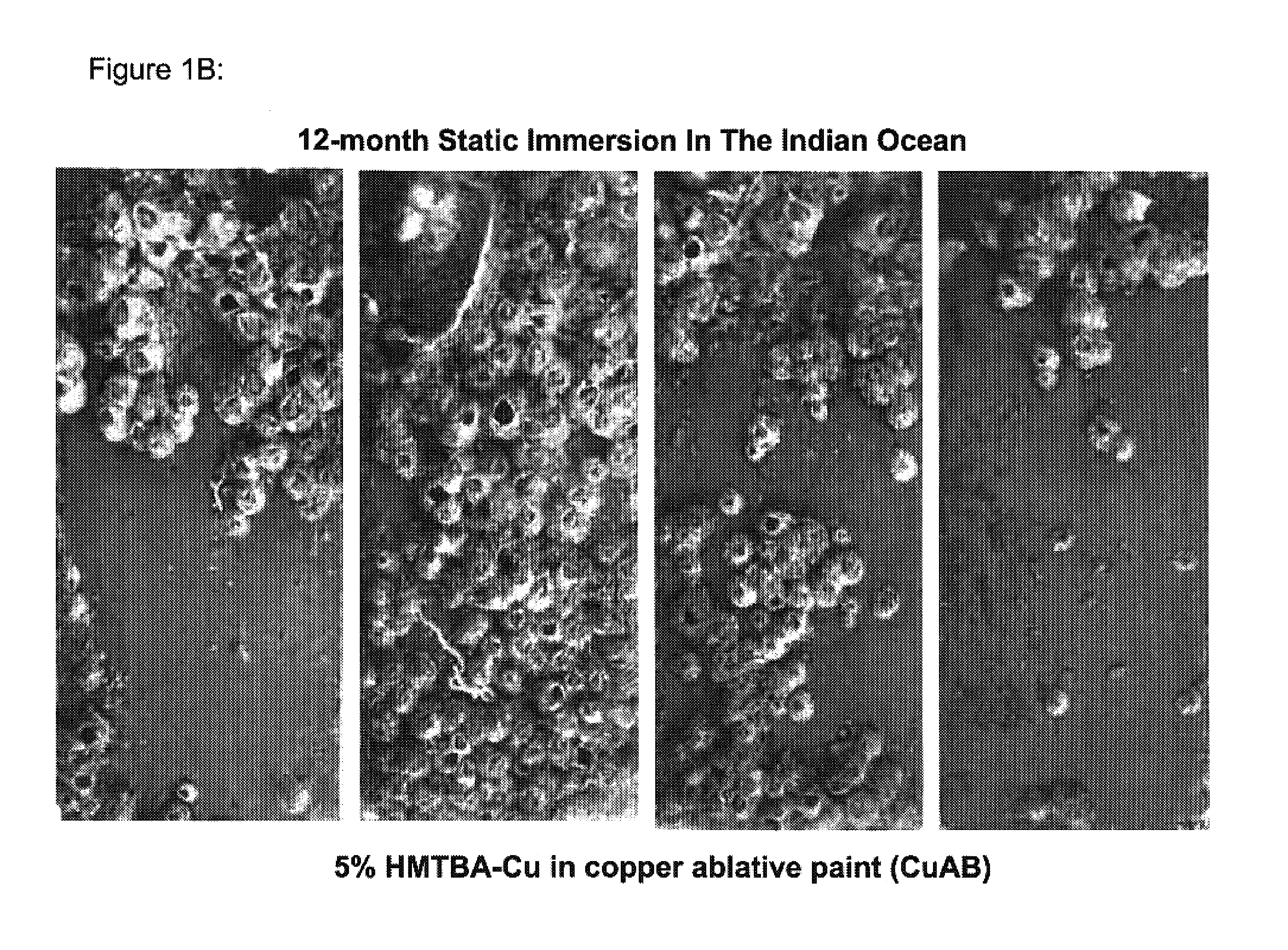

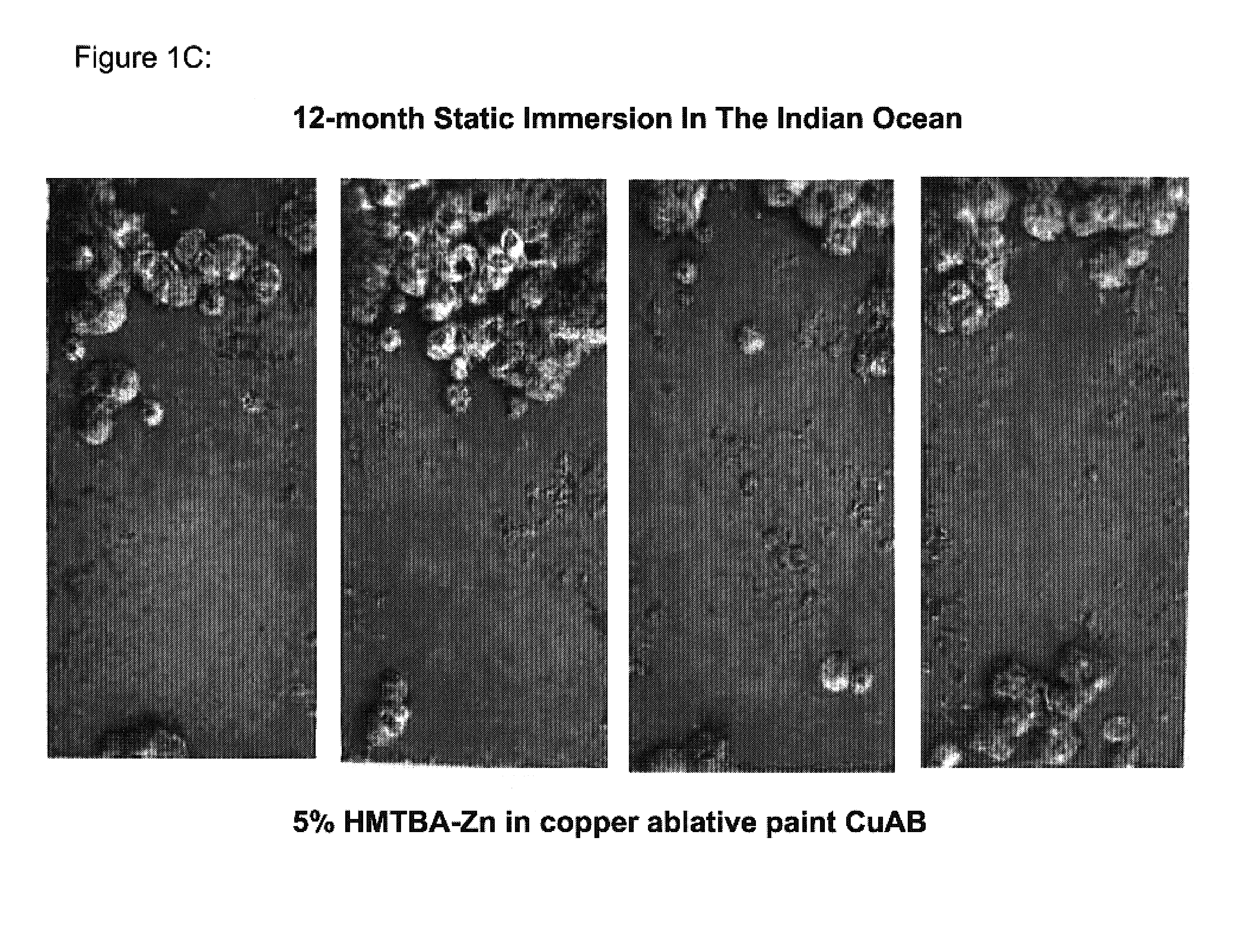

Disclosed are marine coating compositions that are useful to inhibit the fouling of a marine structure by a broad spectrum of organisms. Generally, the marine coating composition comprises an antifouling agent and an organic vehicle.

Owner:NOVUS INTERNATIONAL INC

Marine coatings

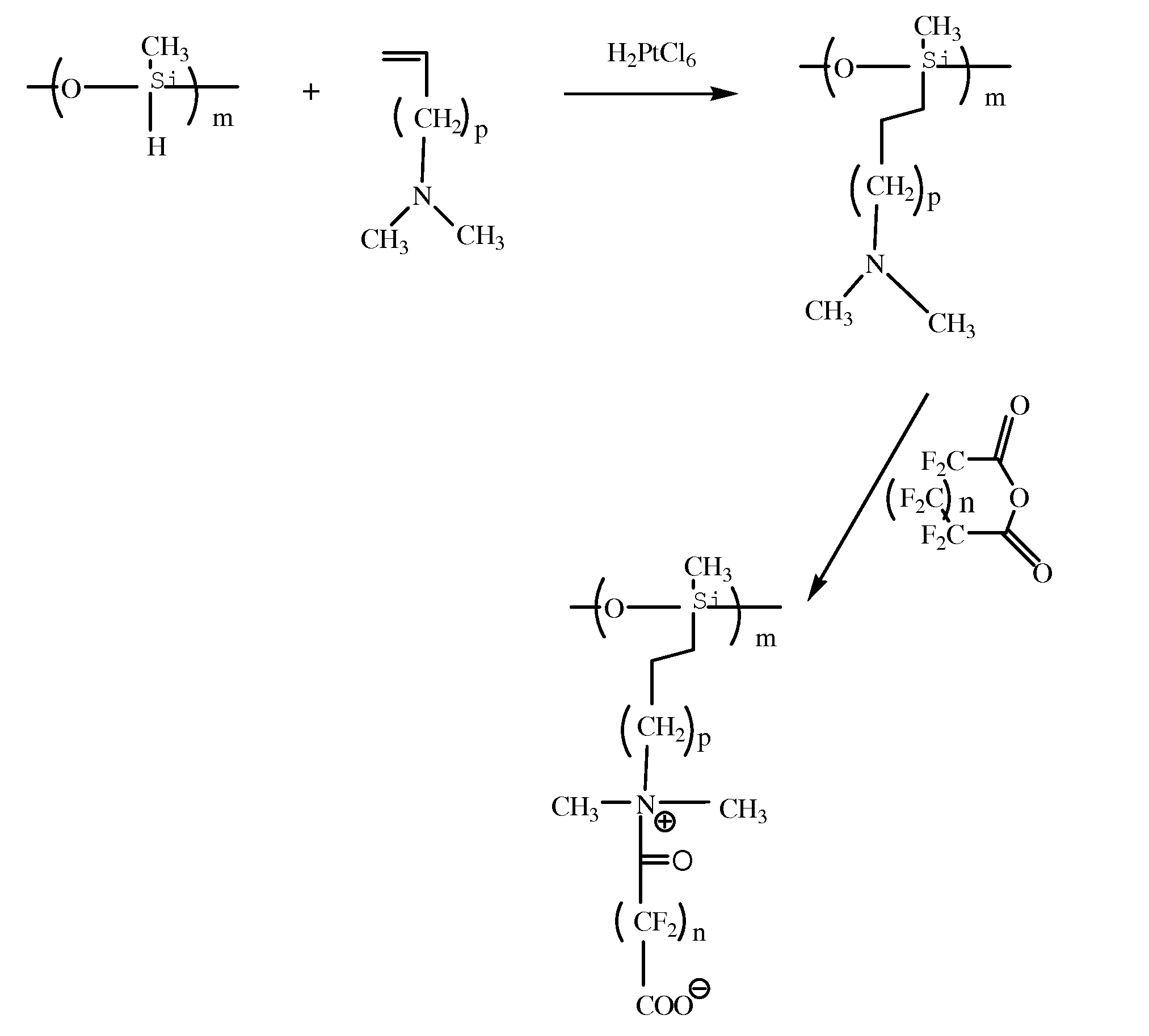

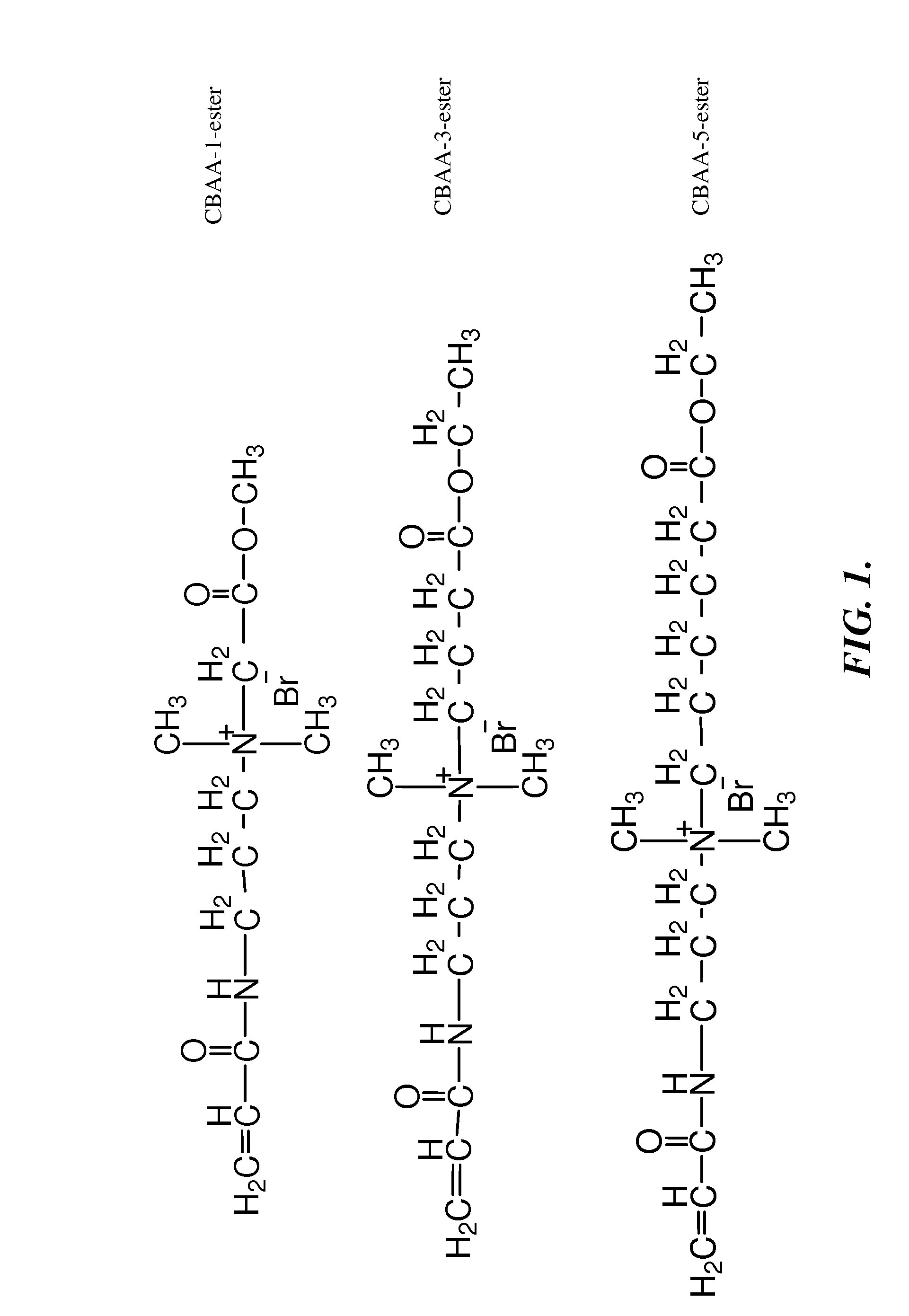

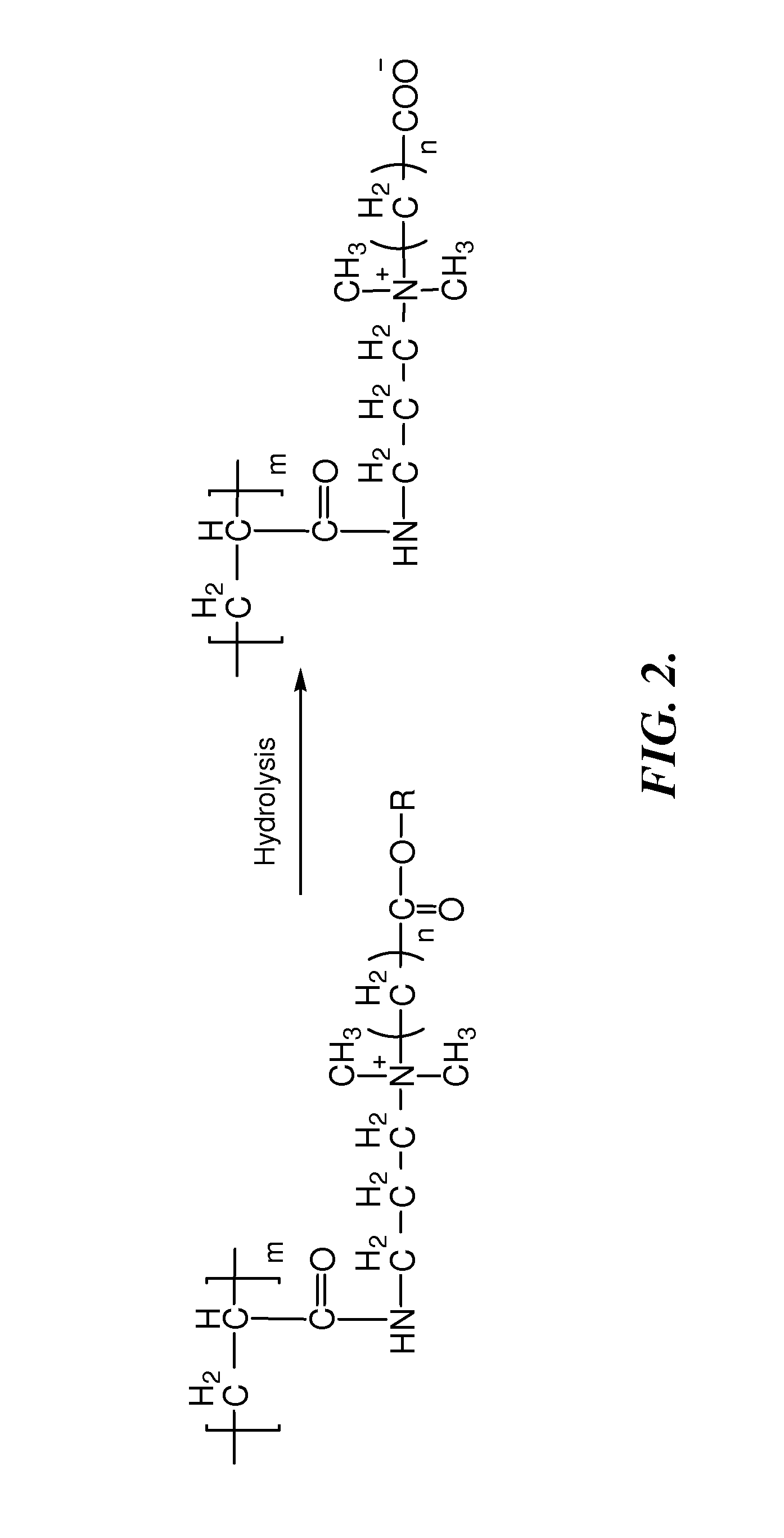

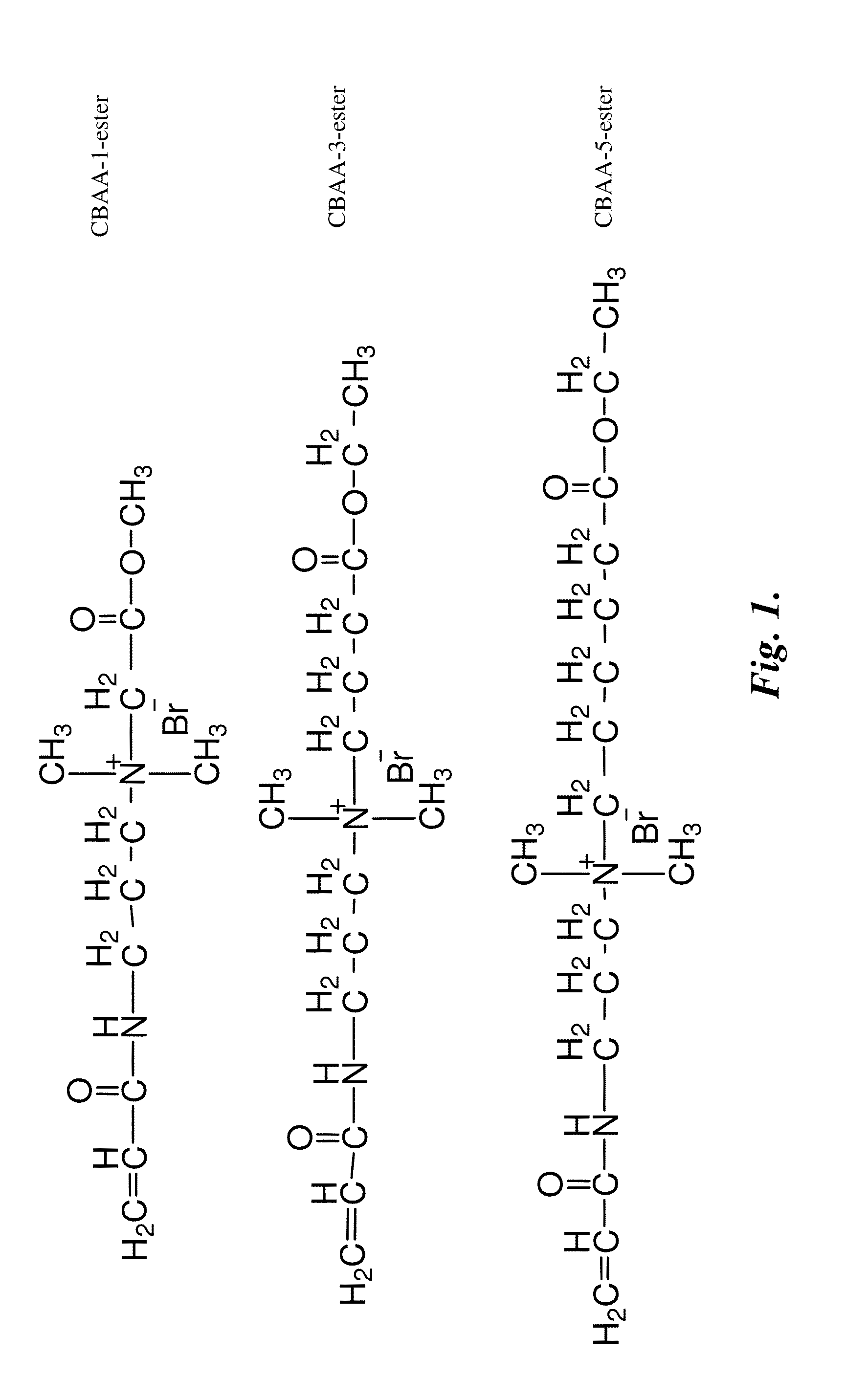

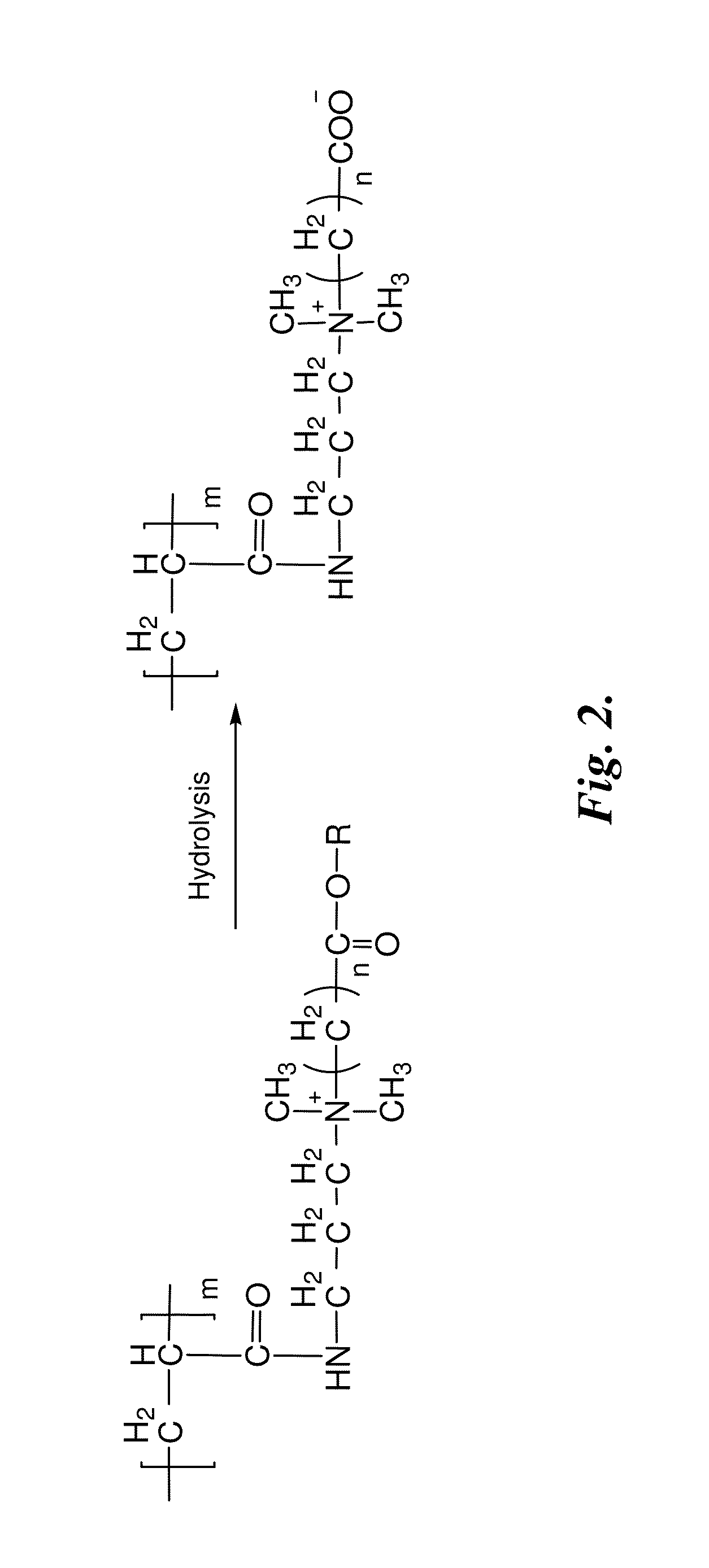

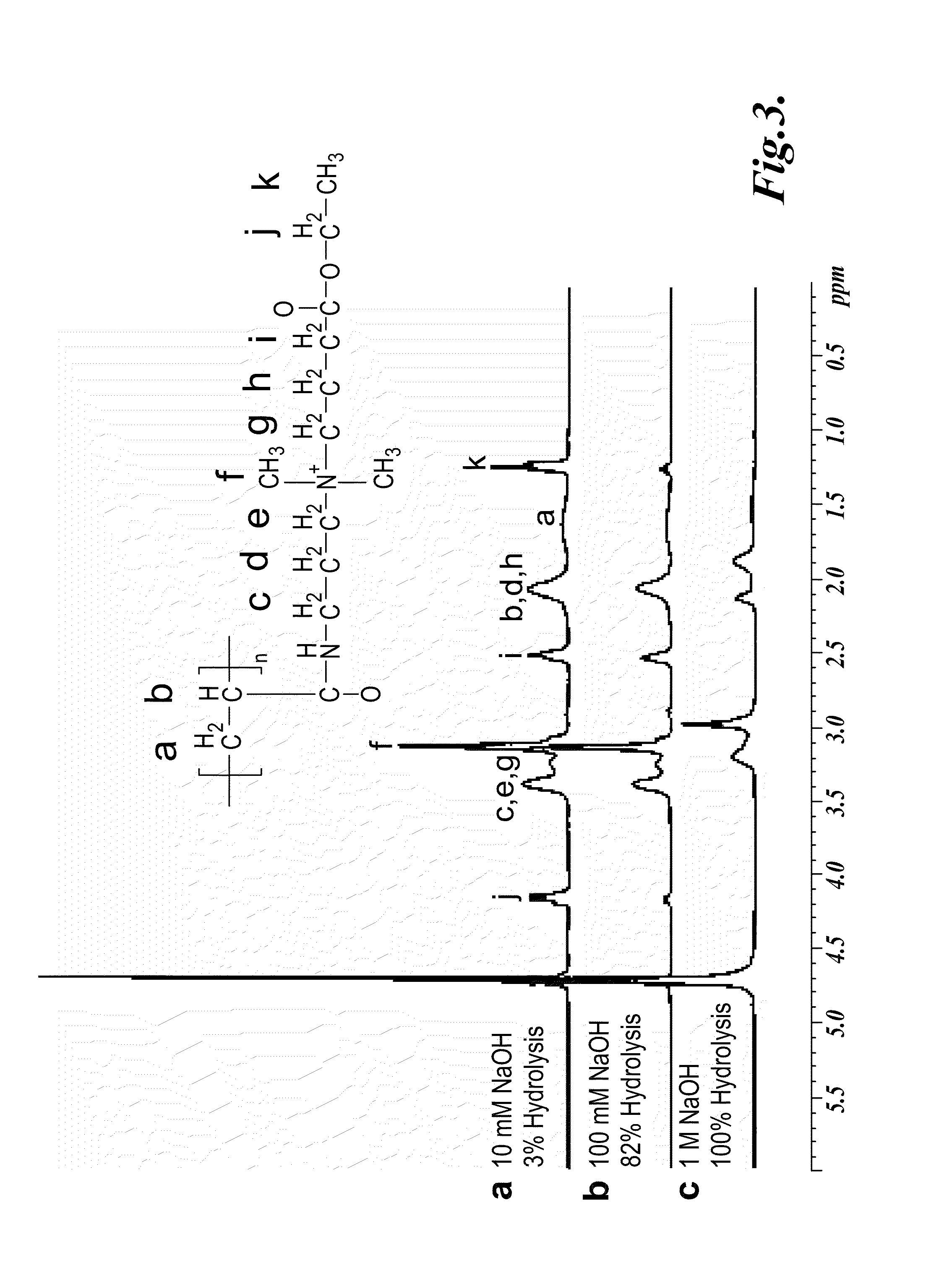

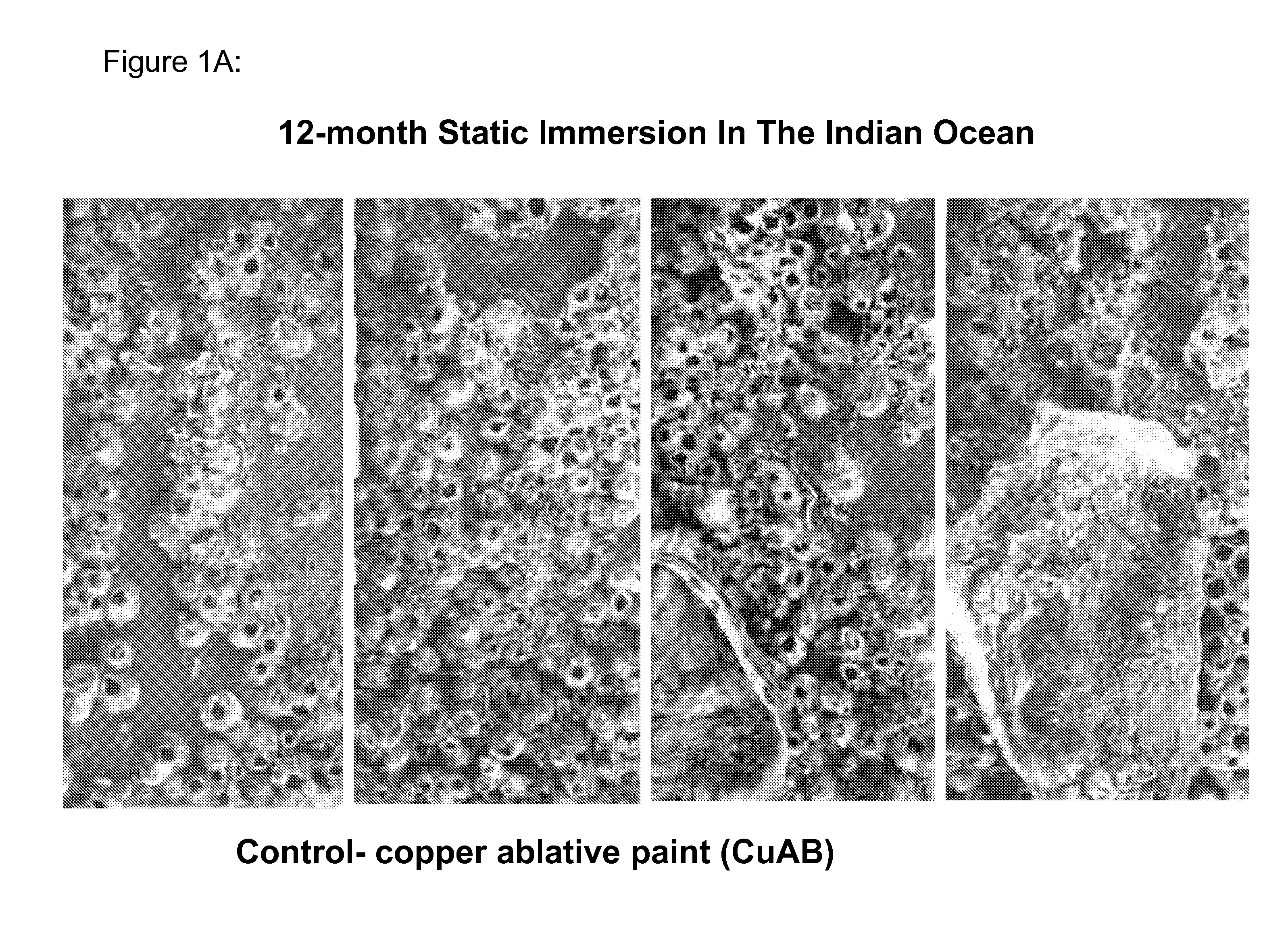

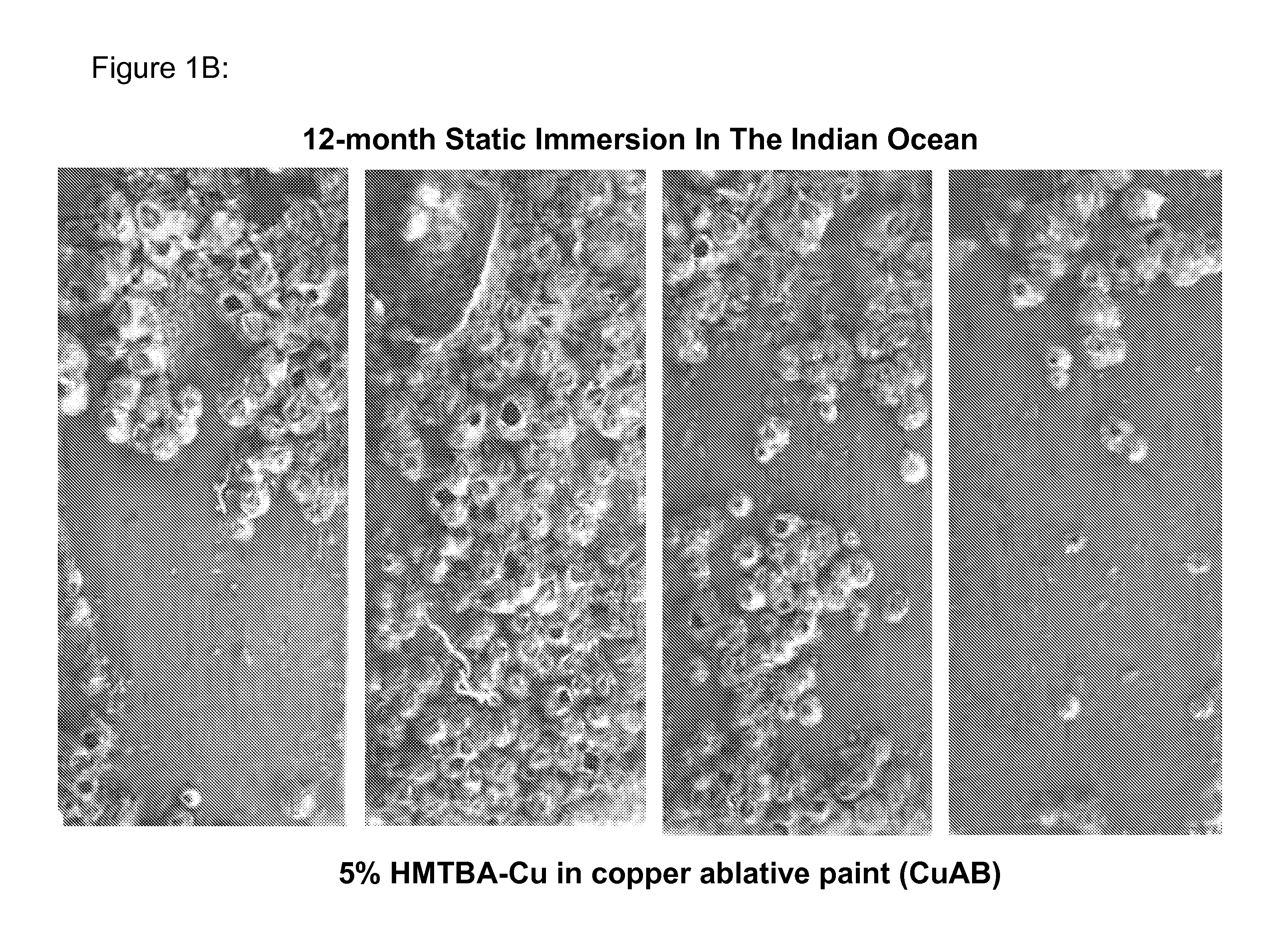

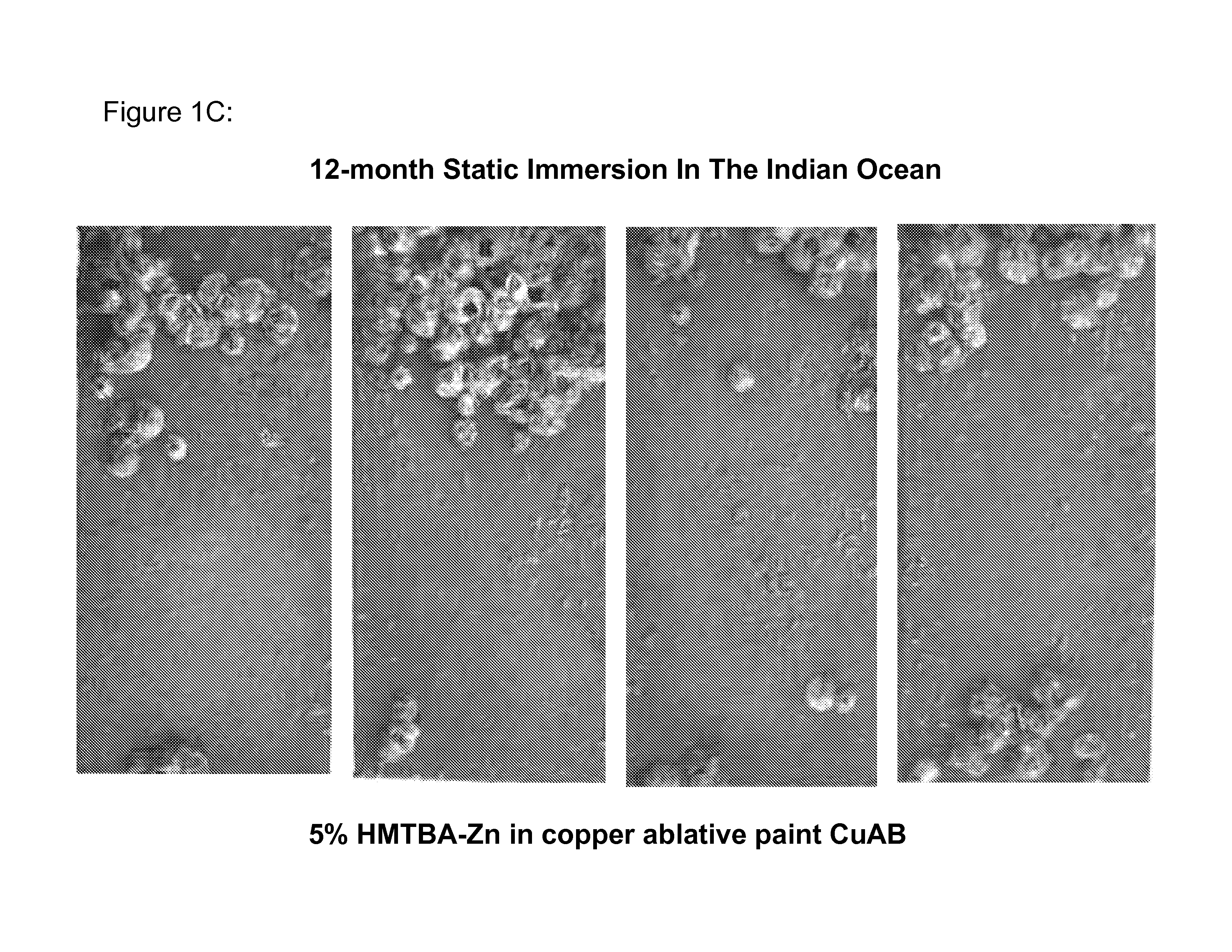

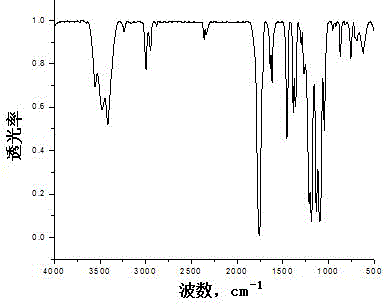

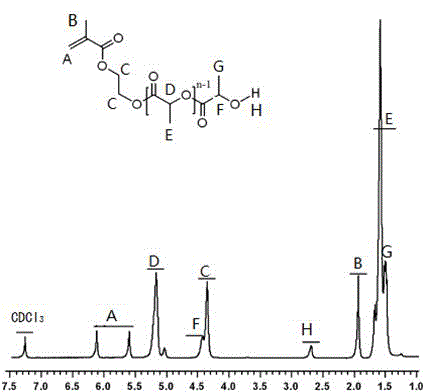

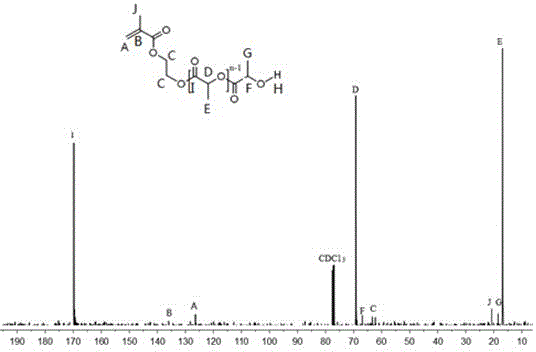

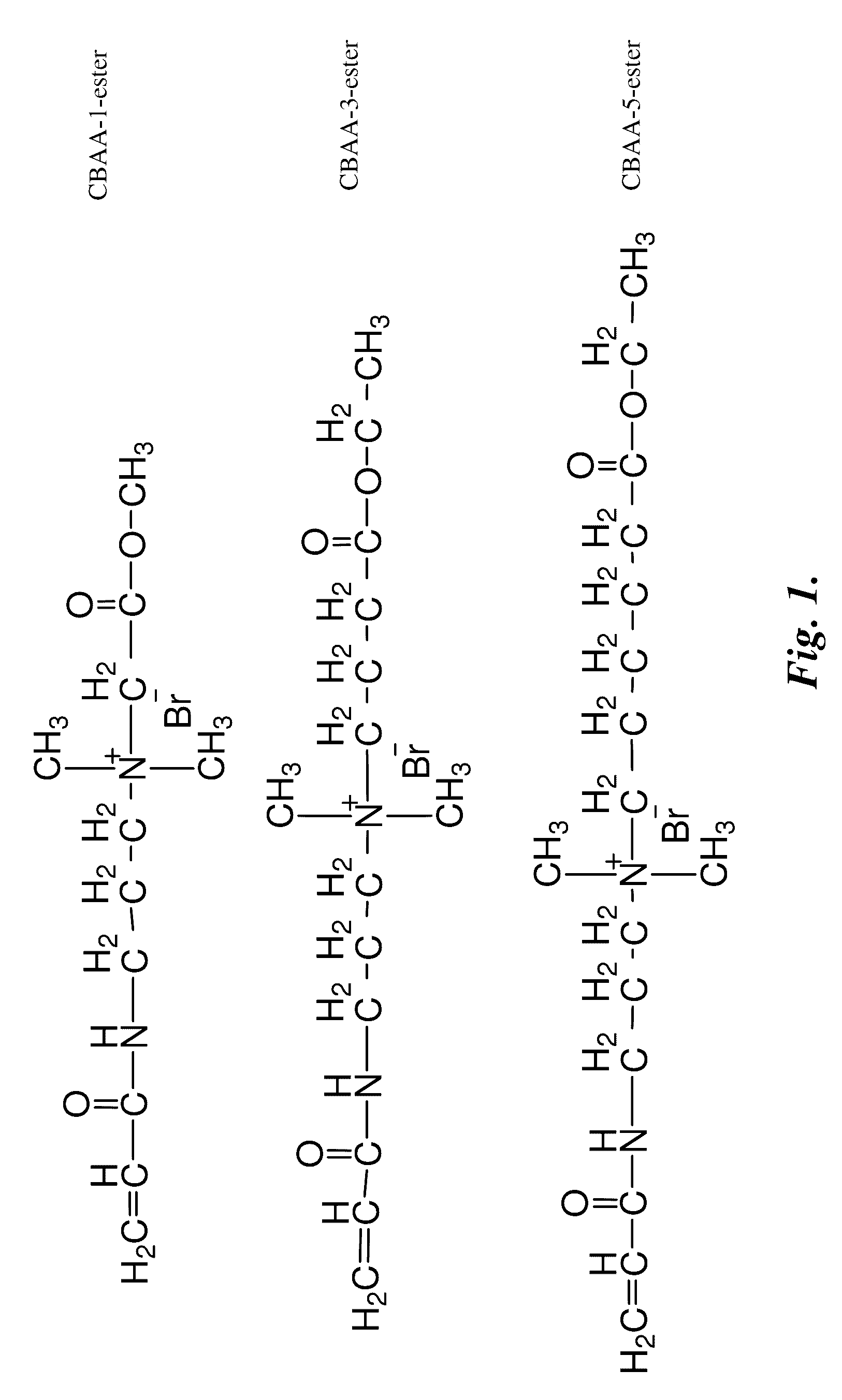

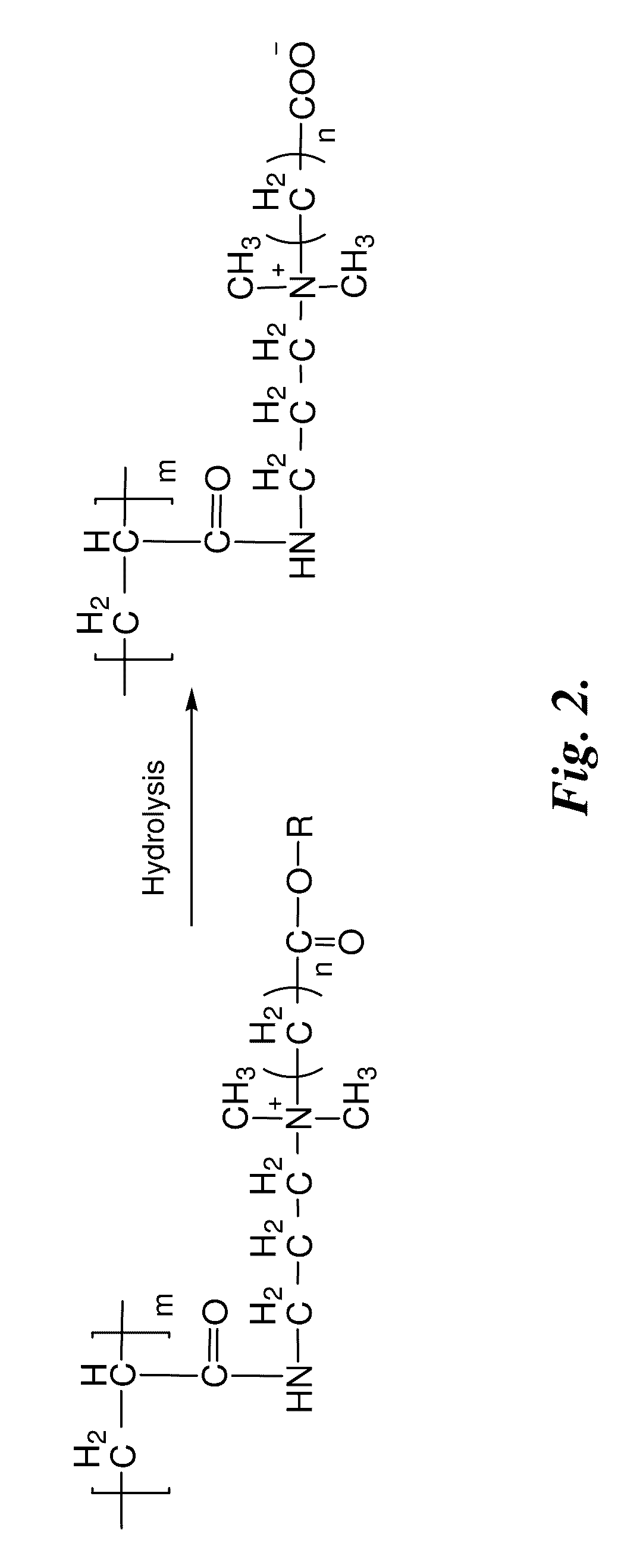

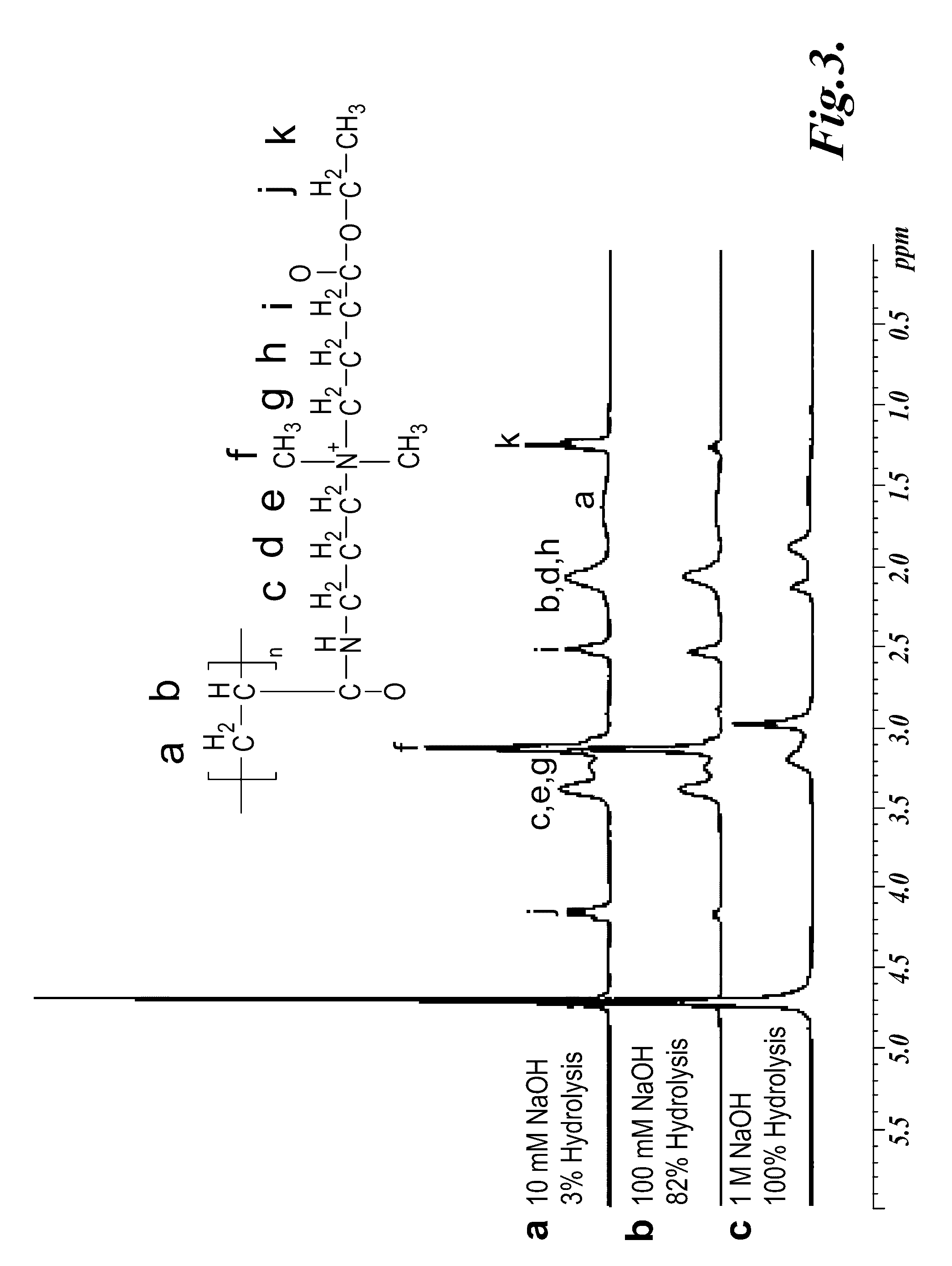

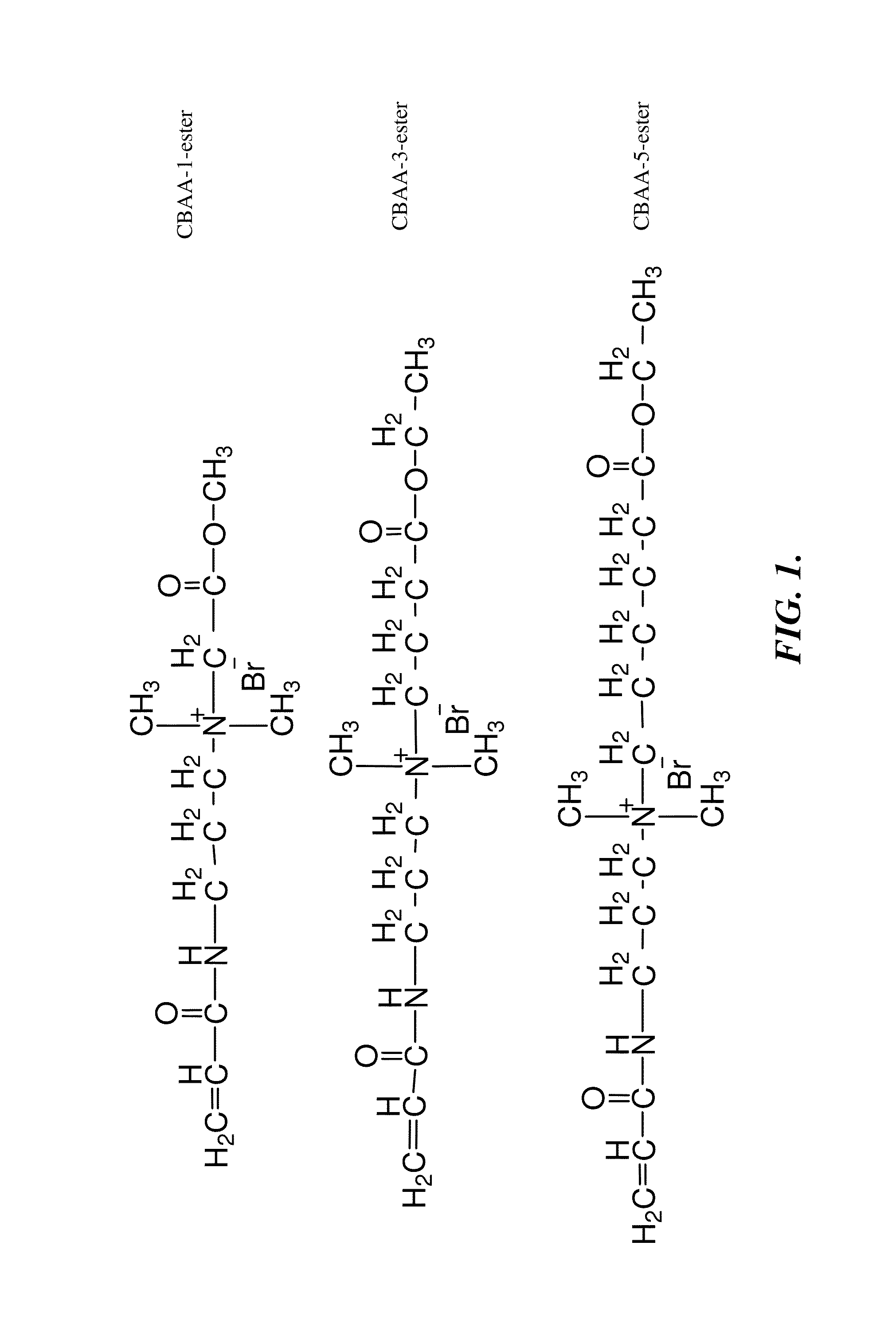

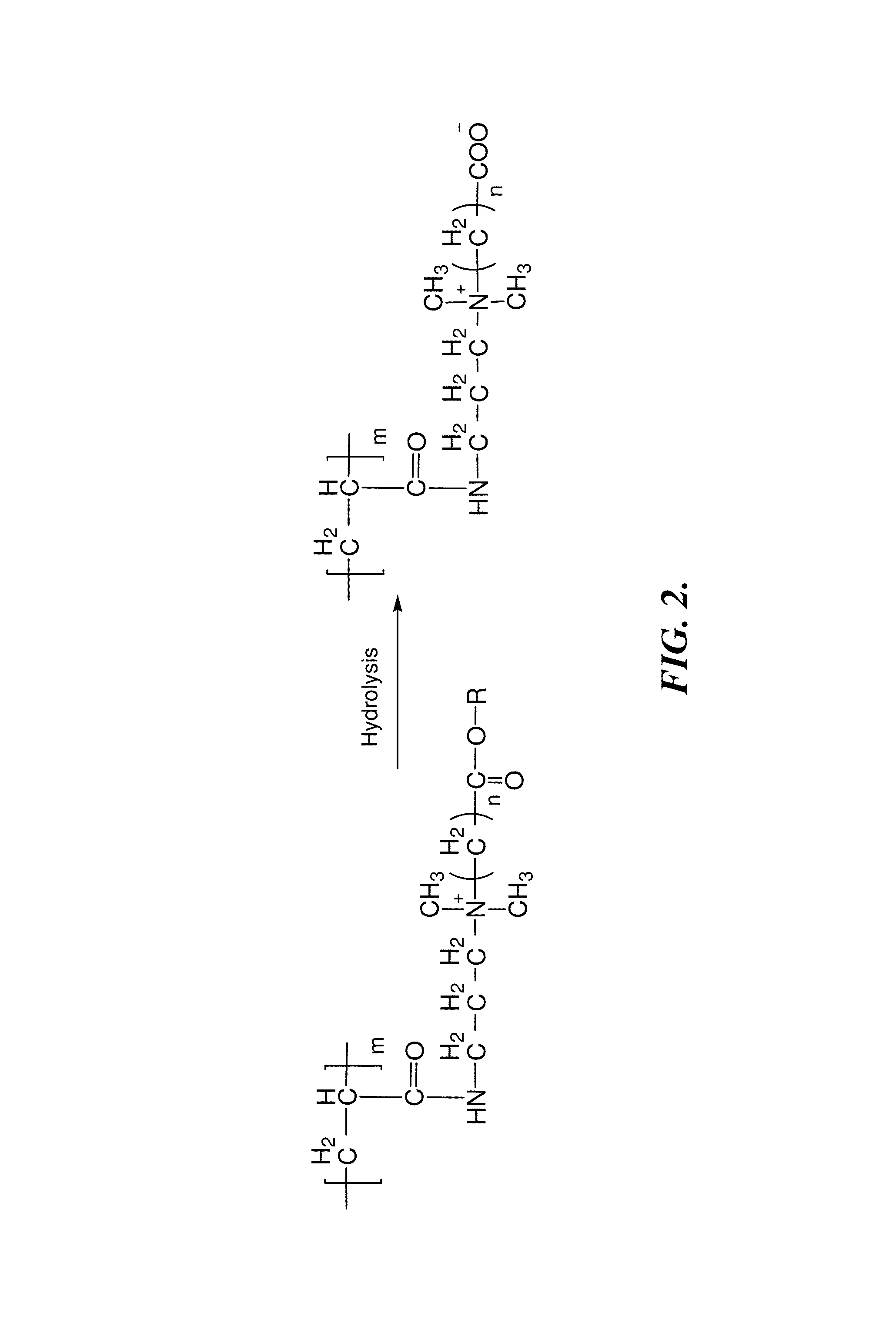

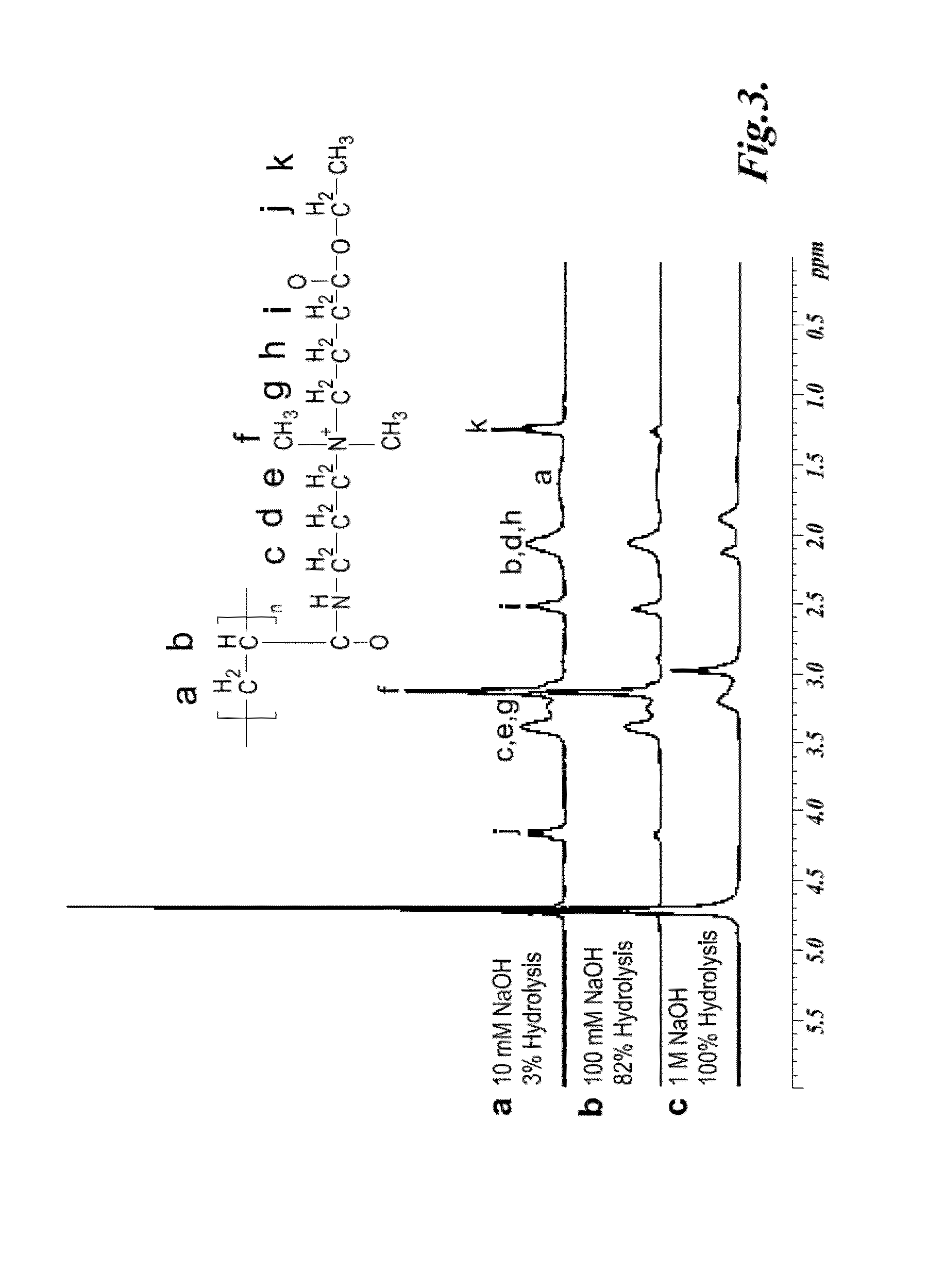

Marine coatings including cationic polymers hydrolyzable to nonfouling zwitterionic polymers, coated marine surfaces, and methods for making and using the marine coatings.

Owner:UNIV OF WASHINGTON

Marine coatings

Marine coatings including cationic polymers hydrolyzable to nonfouling zwitterionic polymers, coated marine surfaces, and methods for making and using the marine coatings.

Owner:UNIV OF WASHINGTON

Marine antifouling coating compositions

InactiveUS20070213426A1Minimize bio-foulingToxic reductionBiocideSulfur/selenium/tellurium active ingredientsBiological bodyMarine coatings

Disclosed are marine coating compositions that are useful to inhibit the fouling of a marine structure by a broad spectrum of organisms. Generally, the marine coating composition comprises an antifouling agent and an organic vehicle.

Owner:NOVUS INTERNATIONAL INC

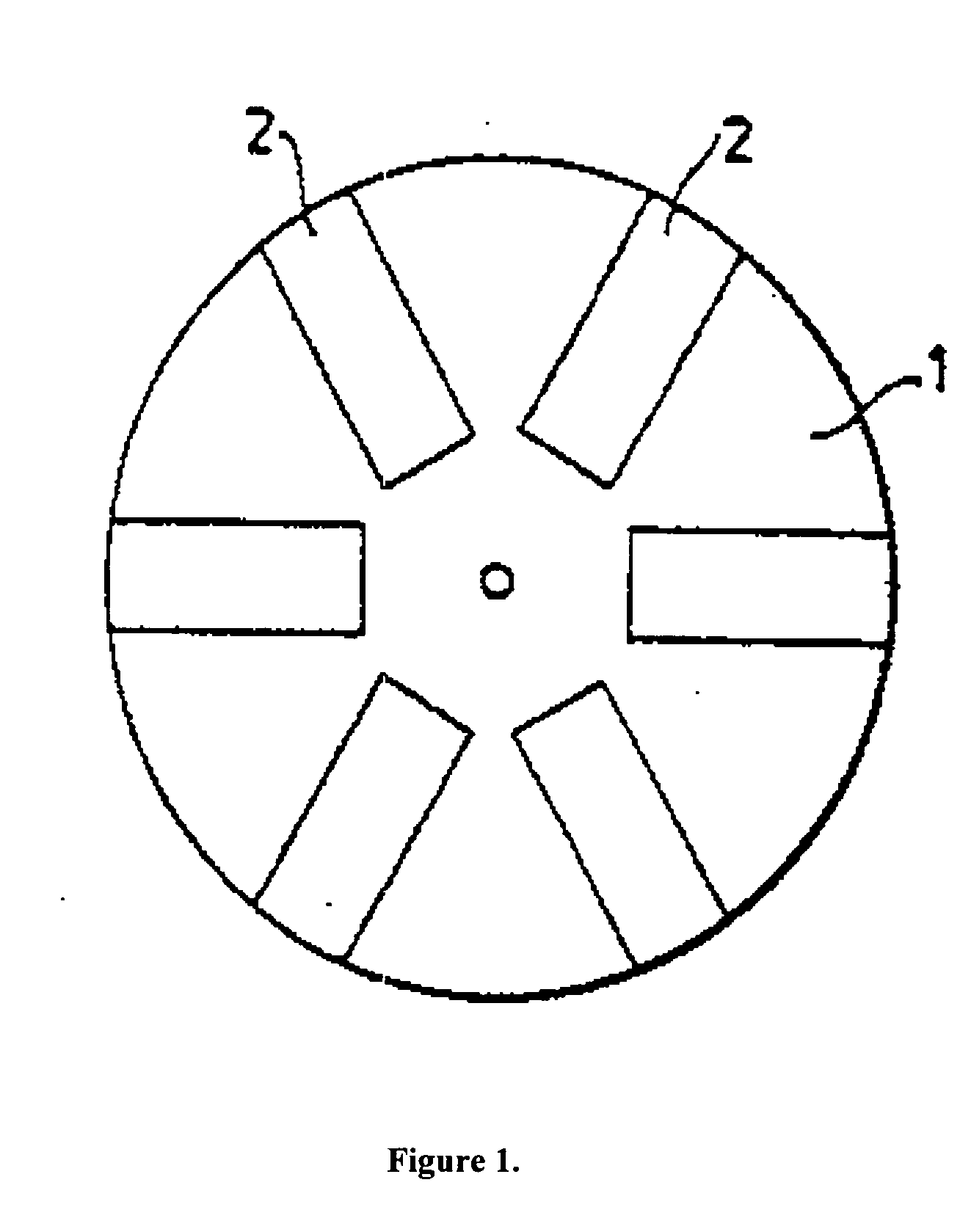

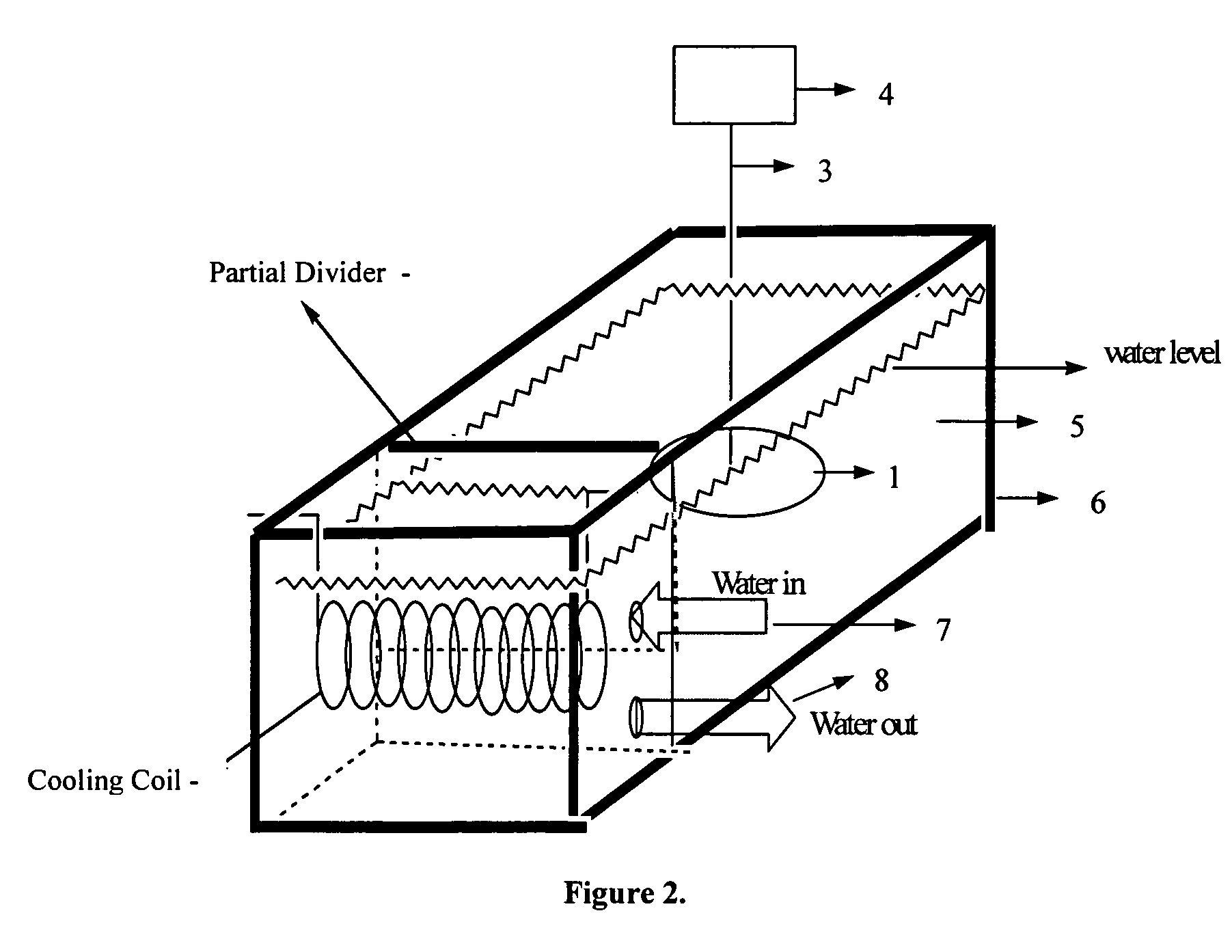

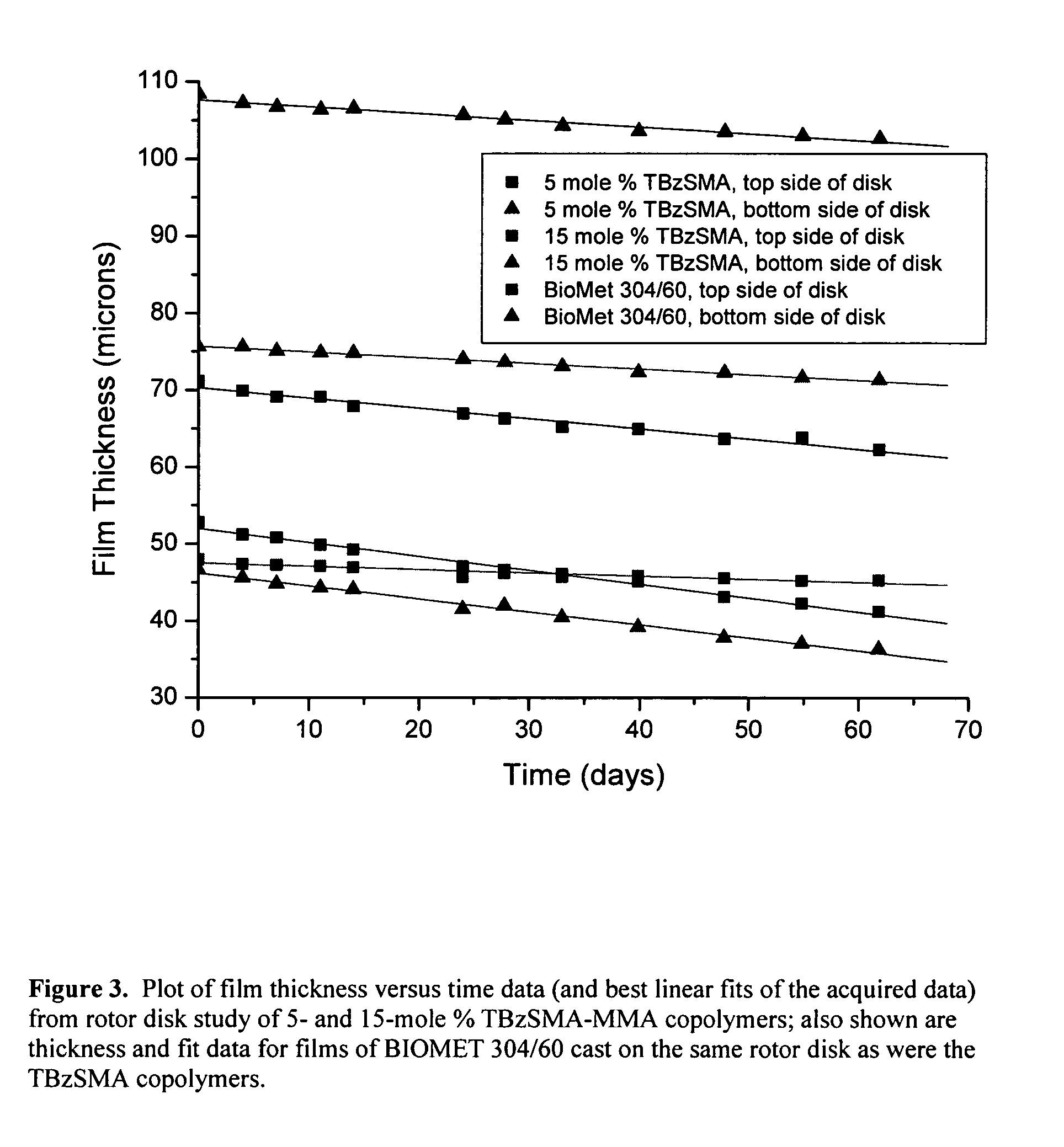

Benzylsilyl(meth)acryloyl-containing polymers for marine coating compositions

InactiveUS20060189708A1Control erosionAntifouling/underwater paintsPaints with biocidesMeth-Erosion rate

This invention relates to polymers for self-polishing marine antifouling coatings. More particularly, the invention relates to polymer binders, which provide an erosion rate in seawater that is suitable for use in marine antifouling coatings. These polymer binders contain pendant benzylsilylacrylate groups. Additionally it was found that marine antifouling coatings could be formed with lower silyl acrylate levels using the monomers of the invention, and still achieve a suitable erosion rate in seawater.

Owner:ARKEMA INC

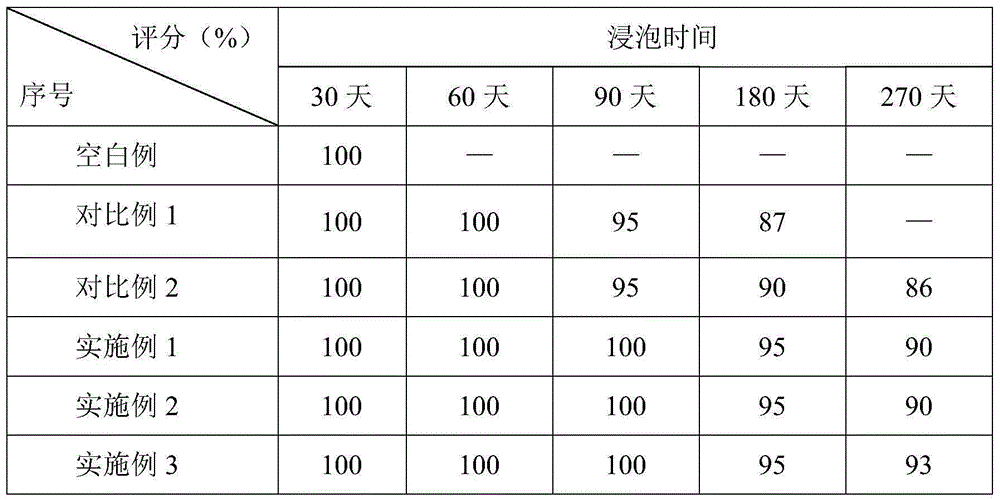

Antibacterial antifouling agent and antibacterial antifouling coating

InactiveCN105017830AEfficient use ofImprove protectionAntifouling/underwater paintsLuminescent paintsMass ratioOxide composite

The invention provides an antibacterial antifouling agent and antibacterial antifouling coating. The antibacterial antifouling agent is zinc oxide composite powder where shell powder load is doped with magnesium oxide and comprises shell powder, the magnesium oxide and zinc oxide. The mass ratio of the shell powder to the zinc oxide is (1-2) to 1. The molar ratio of the magnesium oxide to the zinc oxide is (0.01-0.5) to 1. Due to the adoption of the technical scheme, the waste shell powder is effectively utilized, and the application field of the waste shell powder in the aspect of marine coating is widened. The surface of concrete is coated with the coating prepared through the technical scheme, corrosion of seawater and corrosive ions and the like in the seawater can be prevented, the concrete can have an effective biological adhesion preventing function when soaked in the seawater for a long time, and the safety and the durability of a marine concrete structure is improved. The antibacterial antifouling coating has the antibacterial antifouling function and meanwhile has the light-emitting performance and plays a marine engineering role.

Owner:GUANGXI UNIV +1

Marine steel structure surface antifouling and anticorrosion preparation and preparation method thereof

InactiveCN108084837AIncrease the degree of cross-linkingImprove water resistanceAntifouling/underwater paintsPaints with biocidesEpoxyComposite film

The invention discloses a marine steel structure surface antifouling and anticorrosion preparation and a preparation method thereof. The emulsion is prepared from the following raw materials in partsby mass: 1100 to 1500 parts of a polyurethane monomer, 1000 parts of polyether glycol, 200 to 400 parts of an alcohol chain extender, 100 to 250 parts of a hydrophilic chain extender, 200 to 400 partsof epoxy resin polyol, 100 to 150 parts of triethylamine, 400 to 1000 parts of an acrylic ester monomer, 1000 to 1500 parts of graphene oxide-protamine composite emulsion and 5 to 20 parts of an initiator. The solvent-free type composite film-forming resin emulsion has antifouling and anticorrosion functions, is applied to production of an environment-friendly marine coating, and can protect thesurface of the marine steel structure and prevent bioattachment and marine corrosion.

Owner:ZHEJIANG UNIV OF TECH

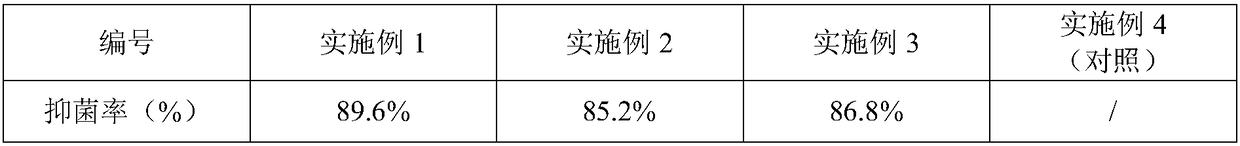

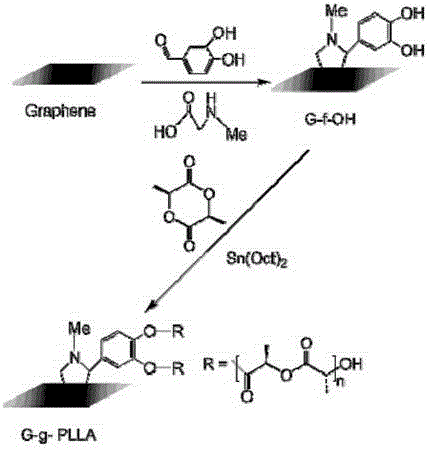

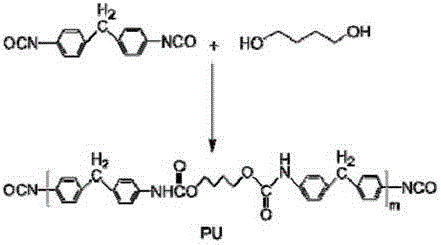

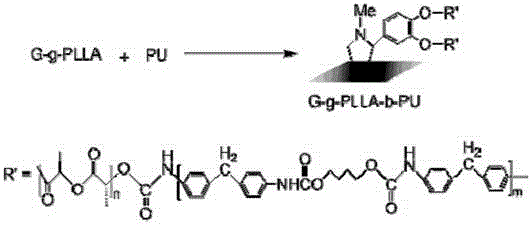

Method for preparing biodegradable ocean antifouling polyurethane hybrid materials and product thereof

ActiveCN105111407AFall off in timeAchieve antifouling effectAntifouling/underwater paintsPaints with biocidesPolymer scienceChemical reaction

The invention discloses a method for preparing biodegradable ocean antifouling polyurethane hybrid materials and a product thereof. The method for preparing the biodegradable ocean antifouling polyurethane hybrid materials and the product thereof adopt stannous octoate as a catalyst, adopts double hydroxyl functional grapheme which is prepared by adopting reduction grapheme to react with 2, 2-hydroxy benzaldehyde and N-glycine as an initiator, and the initiator triggers L-lactide monomers to prepare graphene grafted poly lactic acids through ring opening polymerization. 1, 4-butanediol and 4, 4-diphenyl methane diisocyanate prepare polyurethane prepolymers containing Isocyanate functional groups on the tail ends through condensation polymerization. The biodegradable ocean antifouling polyurethane hybrid materials are prepared by utilizing a chemical reaction between graphene grafted hydroxyl-terminated poly lactic acids and polyurethane prepolymers. The method for preparing biodegradable ocean antifouling polyurethane hybrid materials and the product thereof improve strength of target materials by leading into grapheme, and the grapheme plays the role of antibacterial function during the degradation process, and control crystallinity and hydrophobic property of grafted poly lactide by adjusting the contents of the grapheme and the L-lactide monomers, thereby effectively adjusting and controlling degradation of polyurethane. hybrid materials which are prepared through the method for preparing biodegradable ocean antifouling polyurethane hybrid materials has excellent mechanical properties and can adjust degradation rate, degradation products are non-toxic and do not pollute the environment, and can be applied in antifouling marine coatings and drug controlled release carriers in a biomedical medical engineering.

Owner:HUNAN UNIV OF SCI & TECH

Biodegradable antifouling marine coating and preparation method thereof

ActiveCN104592851AHas self-polishing propertiesLower surface energyAntifouling/underwater paintsPaints with biocidesCopolymerSeawater

The invention relates to a biodegradable antifouling marine coating and a preparation method thereof. The synthetic antifouling marine coating is prepared from the following raw materials in percentage by weight: 65%-85% of copolymer, 10%-30% of a solvent, 1%-2% of nano SiO2, 1%-2% of nano TiO2, 1%-1.5% of KLE-333, 1%-2% of KF-64 and 0.5%-1% of KSL-52. The synthetic biodegradable antifouling marine coating can be hydrolyzed under the action of seawater and the like; the surface layer automatically falls off; the coating has self-polishing property; and the surface energy of a base material is reduced, so that the base material has dual characteristics of self-polishing property and low surface energy. The nano TiO2 is added to the coating as an antifouling agent; growth of planktons in sea and adhesion of the coating can be inhibited under the photo-catalysis action; and the problems that an existing single antifouling marine coating is poor in use effect and large in dosage, and generates secondary pollution to a marine environment are solved.

Owner:NORTHWEST UNIV(CN)

Marine coatings

Owner:UNIV OF WASHINGTON

Graphene-fluorine modified waterborne polyurethane resin and preparation method thereof

ActiveCN106832138AHigh hardnessGood flexibilityAntifouling/underwater paintsPaints with biocidesChemical reactionWind power generation

The invention relates to graphene-fluorine modified waterborne polyurethane resin which is prepared through chemical reaction of polyisocyanate, polyhydric alcohol, a polyamine chain extender, oligomer polyhydric alcohol, dimethylolpropionic acid, graphene, hydroxy acrylic acid, fluoroalkene monomer, acrylic acid monomer, a neutralizing agent and deionized water. The invention also provides a preparation method of graphene-fluorine modified waterborne polyurethane resin. The prepared graphene-fluorine modified waterborne polyurethane resin has good properties of adhesion, stain resistance, high hardness, corrosion resistance, durability, hydrophobicity, static resistance, self cleaning and the like and can be applied to single-component waterborne coating, dual-component waterborne coating and normal-temperature curing coating and is widely applied to waterborne wood coating, waterborne industrial coating, waterborne antifouling coating, waterborne anticorrosion coating, waterborne antistatic coating and waterborne special engineering coating such as wind power generation, nuclear power and marine coating.

Owner:UNION FOSHAN CHEM +1

Single-component acrylate coating with corrosion-resisting and wear-resisting properties

InactiveCN106957579AIncrease crosslink densityIncrease the crosslink density, greatly improve the water resistance of the coatingAntifouling/underwater paintsPaints with biocidesDrying timeCorrosion

The invention discloses a single-component acrylate coating with corrosion-resisting and wear-resisting properties and belongs to the field of coating preparation. The single-component acrylate coating with corrosion-resisting and wear-resisting properties is prepared from the following components in parts by weight: 200-400 parts of a special acrylate emulsion, 1-10 parts of propylene glycol, 20-40 parts of titanium dioxide, 10-20 parts of precipitated barium sulphate, 20-50 parts of a coalescing agent, 5-10 parts of a dispersant, 1-5 parts of a defoamer, 0.1-1 part of a wetting agent, 0.1-1 part of a bactericide, 0.5-2 parts of a multifunctional assistant, 0.1-1 part of a thickener, 0.1-1 part of a flatting agent and 0.1-1 part of an acrylic thickener. The coating disclosed by the invention is good in water resistance, corrosion resistance and wear resistance, short in drying time and good in ventilating property, the film is not bubbled and does not fall off, and the coating can be used in an environment of 20 DEG C below to 95 DEG C and can be applied to industrial anti-corrosive fields such as terrace coatings, metal anti-corrosive coatings, ship coatings and the like.

Owner:北京华腾东光科技发展有限公司

Anti-fouling and anti-corrosion agent for marine steel structure surface and preparation method thereof

ActiveUS10167395B1Increase the degree of cross-linkingGood coating effectAntifouling/underwater paintsPaints with biocidesEpoxyComposite film

The present invention provides an anti-fouling and anti-corrosion agent for the marine steel structure surface and preparation method thereof. The emulsion is made of raw materials at the following mass ratios: 1100 to 1500 parts of a polyurethane monomer, 1000 parts of polyether glycol, 200 to 400 parts of an alcohol chain extender, 100 to 250 parts of a hydrophilic chain extender, 200 to 400 parts of epoxy resin polyols, 100 to 150 parts of triethylamine, 400 to 1000 parts of an acrylate monomer, 1000 to 1500 parts of a graphene oxide-protamine composite emulsion, and 5 to 20 parts of an initiator. The solvent-free and composite film-forming resin emulsion of the present invention has both anti-fouling and anti-corrosion functions, which applies to a production of a green and environmental marine coating and protects the marine steel structure surface to prevent from organism attachment and sea water corrosion.

Owner:ZHEJIANG UNIV OF TECH

High-hardness water-resistant polyurethane marine coating

InactiveCN104946109AImprove propertiesGood compatibilityPolyurea/polyurethane coatingsDiacetone alcoholWater resistant

The invention discloses a high-hardness water-resistant polyurethane marine coating. Raw materials of the marine coating comprise the following ingredients, by weight, 50-60 parts of a modified waterborne polyurethane emulsion, 15-20 parts of teflon, 3-9 parts of hydroxyl-terminated polybutadiene liquid rubber, 1-5 parts of 4,4'-methyl diphenylene diisocyanate, 4-10 parts of kaolin, 3-9 parts of silicon nitride, 5-15 parts of diglycol, 5-10 parts of propylene glycol, 10-15 parts of diacetone alcohol, 3-10 parts of 3-aminopropyltriethoxysilane, 4-8 parts of ethylene glycol monobutyl ether, 2-10 parts of 2,2,4-trimethyl-1,3-pentanediol isobutyrate, 1-10 parts of 2-butyl-2-ethyl-1,3-propylene glycol, 10-20 parts of deionized water and 2-8 parts of an auxiliary agent. The high-hardness water-resistant polyurethane marine coating brought forward in the invention has advantages of high hardness, good scratch resistance and excellent water resistance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Marine coatings

Marine coatings including cationic polymers hydrolyzable to nonfouling zwitterionic polymers, coated marine surfaces, and methods for making and using the marine coatings.

Owner:UNIV OF WASHINGTON

Marine coating capable of effectively preventing marine organism adhesion and preparation method thereof

InactiveCN111100529AInhibition of attachmentReduce viscosityAntifouling/underwater paintsPaints with biocidesXylyleneEthylic acid

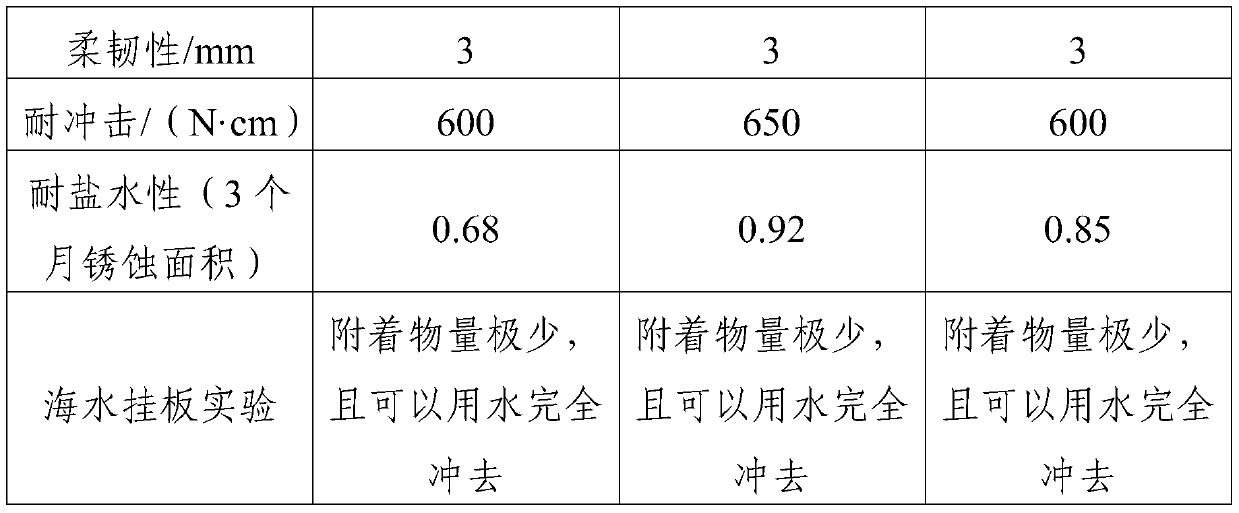

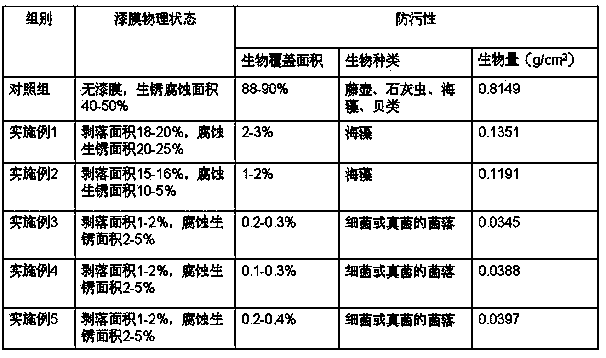

The invention provides a marine coating capable of effectively preventing marine organism adhesion and a preparation method thereof, and relates to the field of marine coatings. The coating comprisesa component A and a component B. The component A comprises the following components in parts by weight: 30-50 parts of dimer acid modified epoxy resin, 10-20 parts of fluorosilicone resin, 5-12 partsof hydroxyl carbon nano tubes, 4-8 parts of polydimethylsiloxane, 15-20 parts of tourmaline, 5-10 parts of functionalized graphene, 2-5 parts of bentonite, 1-2 parts of tributyl phosphate, 1-1.5 partsof capsaicin, 0.5-3 parts of a composite bactericidal component, 3-7 parts of liquid polysulfide rubber, 5-10 parts of hyperbranched polyether, 0.1-0.5 parts of methyldiethanolamine, 0.1-0.5 parts ofdioctyl phthalate, 1-3 parts of hydrogen-terminated silicone oil, 5-10 parts of butyl acetate and 20-40 parts of xylene. The component B is a polyamide curing agent. The marine coating has excellentproperties and high mechanical strength and can effectively protect a ship body from seawater corrosion, and seawater hanging plate experimental verification shows that the coating can effectively prevent marine organism adhesion.

Owner:安徽禹锋数据科技有限公司

Environment-friendly waterproof corrosion-resistant marine coating

InactiveCN104927553AImprove mechanical propertiesImprove waterproof performanceAnti-corrosive paintsPolyester coatingsLead ChromatePhosphate

The invention discloses an environment-friendly waterproof corrosion-resistant marine coating. The environment-friendly waterproof corrosion-resistant marine coating consists of the following materials in parts by weight: 30 to 40 parts of polyvinyl acetal-modified phenolic resin, 10 to 15 parts of poly(ethyl acrylate) emulsion, 20 to 30 parts of organic silicon-modified polyester resin, 10 to 15 parts of isophthalic unsaturated polyester resin, 3 to 13 parts of lead chromate, 3 to 12 parts of hydroxypropyl methylcellulose, 2 to 6 parts of sodium carboxymethylcellulose, 1 to 5 parts of hydroquinone, 5 to 15 parts of aluminium nanopowder, 10 to 15 parts of modified mica, 10 to 15 parts of aluminium hydroxide, 15 to 20 parts of nano calcium oxide, 5 to 10 parts of zinc oxide, 2 to 4 parts of chromium phosphate, 1 to 3 parts of barium phosphate, 5 to 10 parts of calcium phosphate, 1 to 3 parts of iron oxide red and 2 to 5 parts of phthalocyanine blue. The waterproofness of the environment-friendly waterproof corrosion-resistant marine coating is good, the corrosion resistance of the environment-friendly waterproof corrosion-resistant marine coating is excellent, and moreover, the environment-friendly waterproof corrosion-resistant marine coating does not pollute the environment.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Multifunctional marine coating

ActiveCN103666242AExtends the path of penetration to the substrateImprove anti-corrosion performanceAntifouling/underwater paintsPaints with biocidesLacquerMarine coatings

The invention discloses a multifunctional marine coating. The multifunctional marine coating comprises the following raw materials in parts by weight: 15-30 parts of polyamide resin, 5-15 parts of flaky aggregate, 3-10 parts of biological antifouling agent, 2-10 parts of antirust pigments, 1-5 parts of flash-rust inhibitor, 20-35 parts of nanoscale filler and 5-15 parts of additive. The multifunctional marine coating is distributed on the surface of a material in a flaky manner, and multiple layers of flakes are arranged in a horizontal overlapping manner, so that the path of a corrosive medium penetrating into a base material is prolonged, and the anticorrosion property of the coating is improved; as the multifunctional marine coating contains the natural biological antifouling agent, the multifunctional marine coating has very strong avoidance and blunting effects on marine organisms, is capable of stopping the adhesion of the marine organisms but has no toxic effect on the marine organisms; the antirust pigment is capable of preventing equipment from rusting and facilitates the improvement of dry adhesive force of the coating; the antirust pigment is matched with the flash-rust inhibitor to obtain a very good flash-rust inhibition effect.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

Antifouling and anticorrosive marine coating

ActiveCN112521783AAchieve the effect of attachmentGood antibacterial effectAntifouling/underwater paintsPaints with biocidesCelluloseCyclopentene

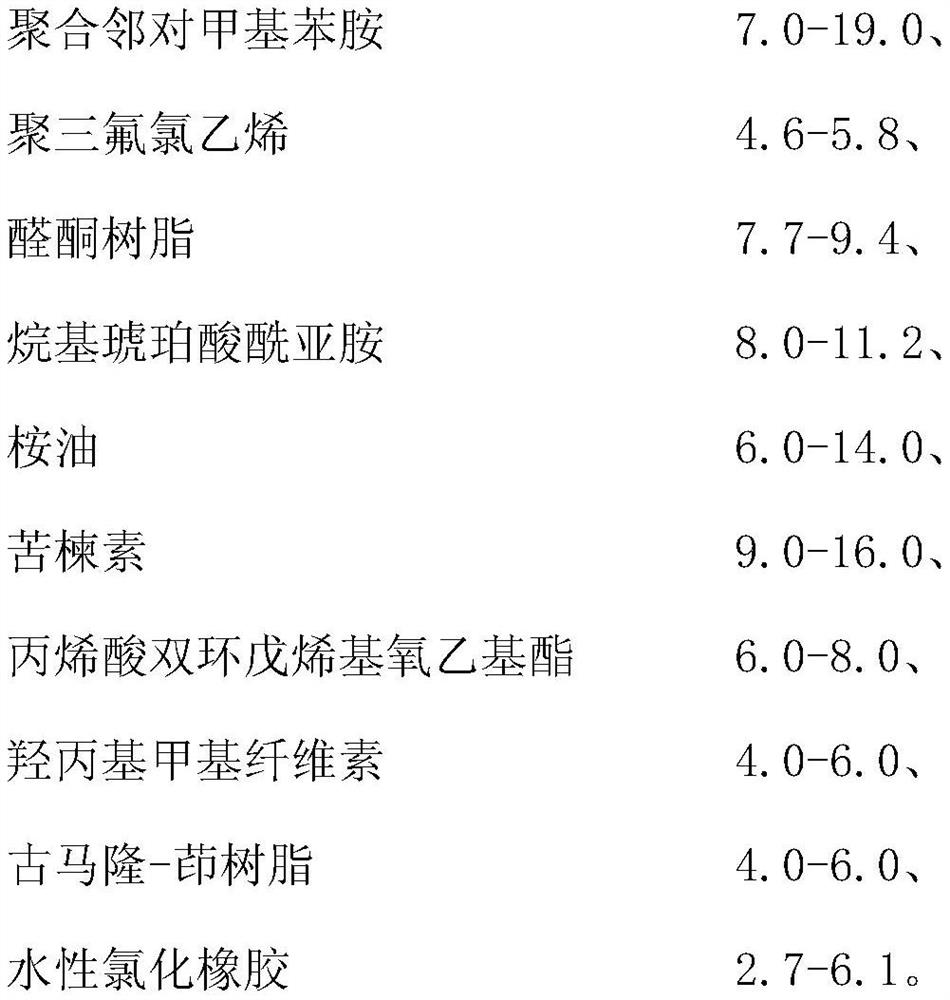

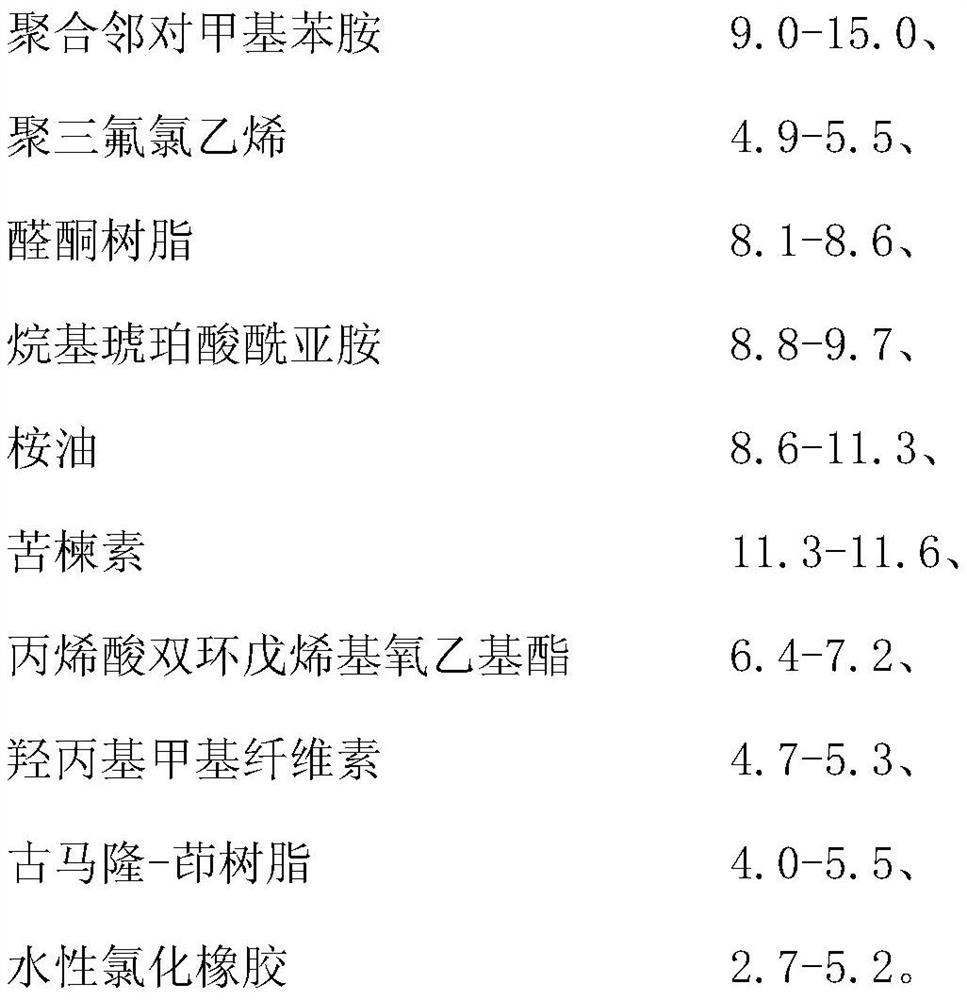

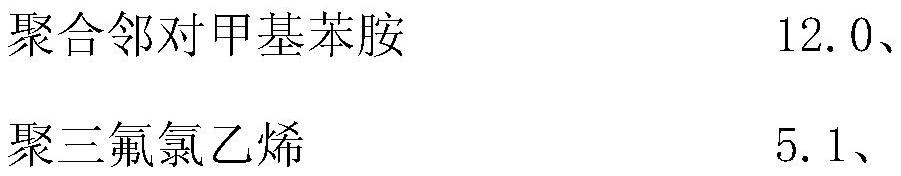

The invention discloses an antifouling and anticorrosive marine coating which is prepared from polymerized o-toluidine, polytrifluorochloroethylene, aldehyde ketone resin, alkyl succinimide, eucalyptus oil, toosendanin, dicyclopentenyl oxyethyl acrylate, hydroxypropyl methyl cellulose, coumarone indene resin and water-based chlorinated rubber, and the mixture is prepared according to the mass ratio of 7-19: 4.6-5.8: 7.7-9.4: 8-11.2: 6-14: 9-16: 6-8: 4-6: 4-6: 2.7-6.1. The marine coating is excellent in performance, the effective component obtaining mode is simple, convenient and rapid, a shipbody can be effectively protected against seawater erosion influences, and marine neoplasm attachment is effectively prevented.

Owner:北部湾海洋新材料研究院

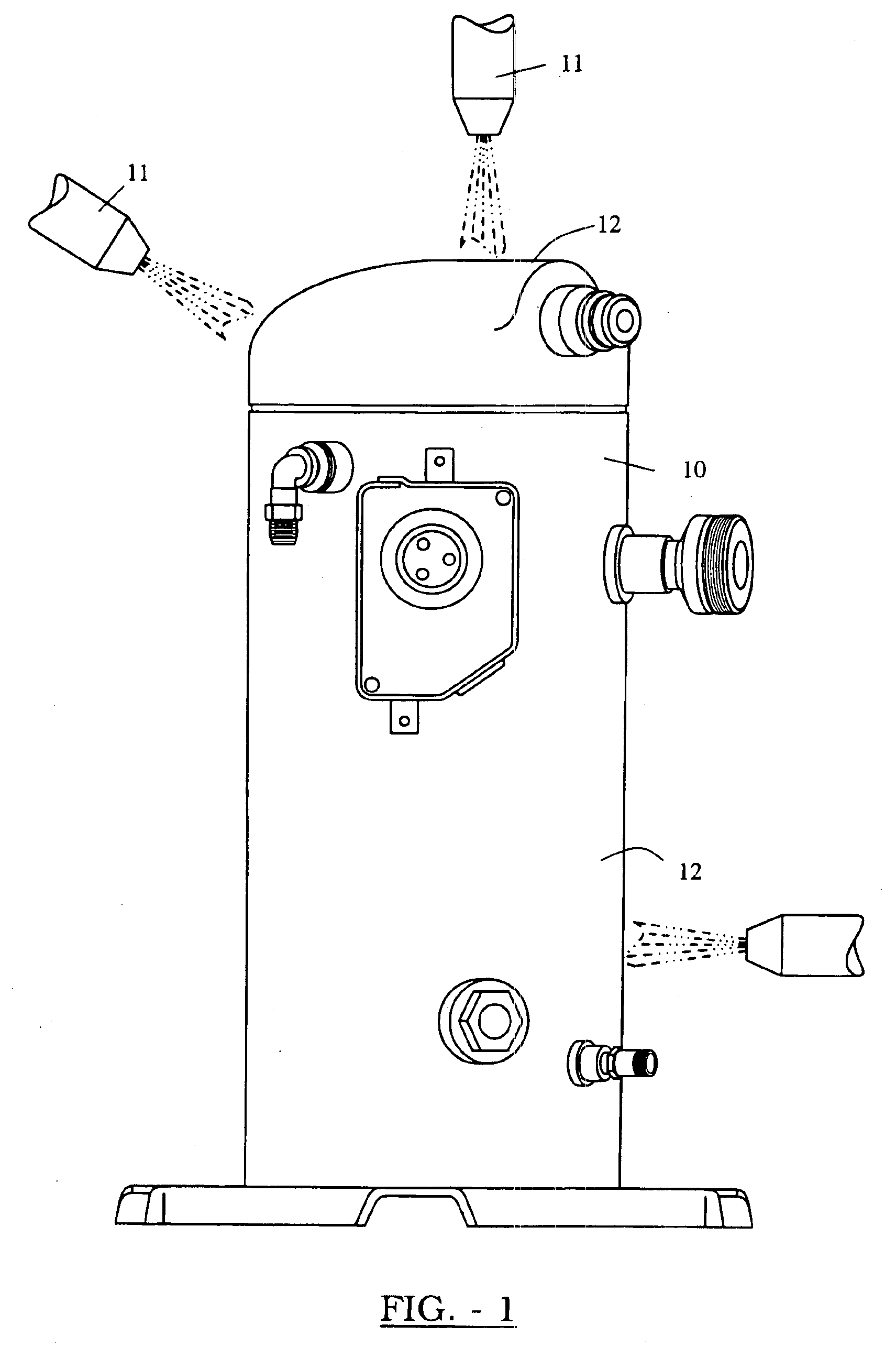

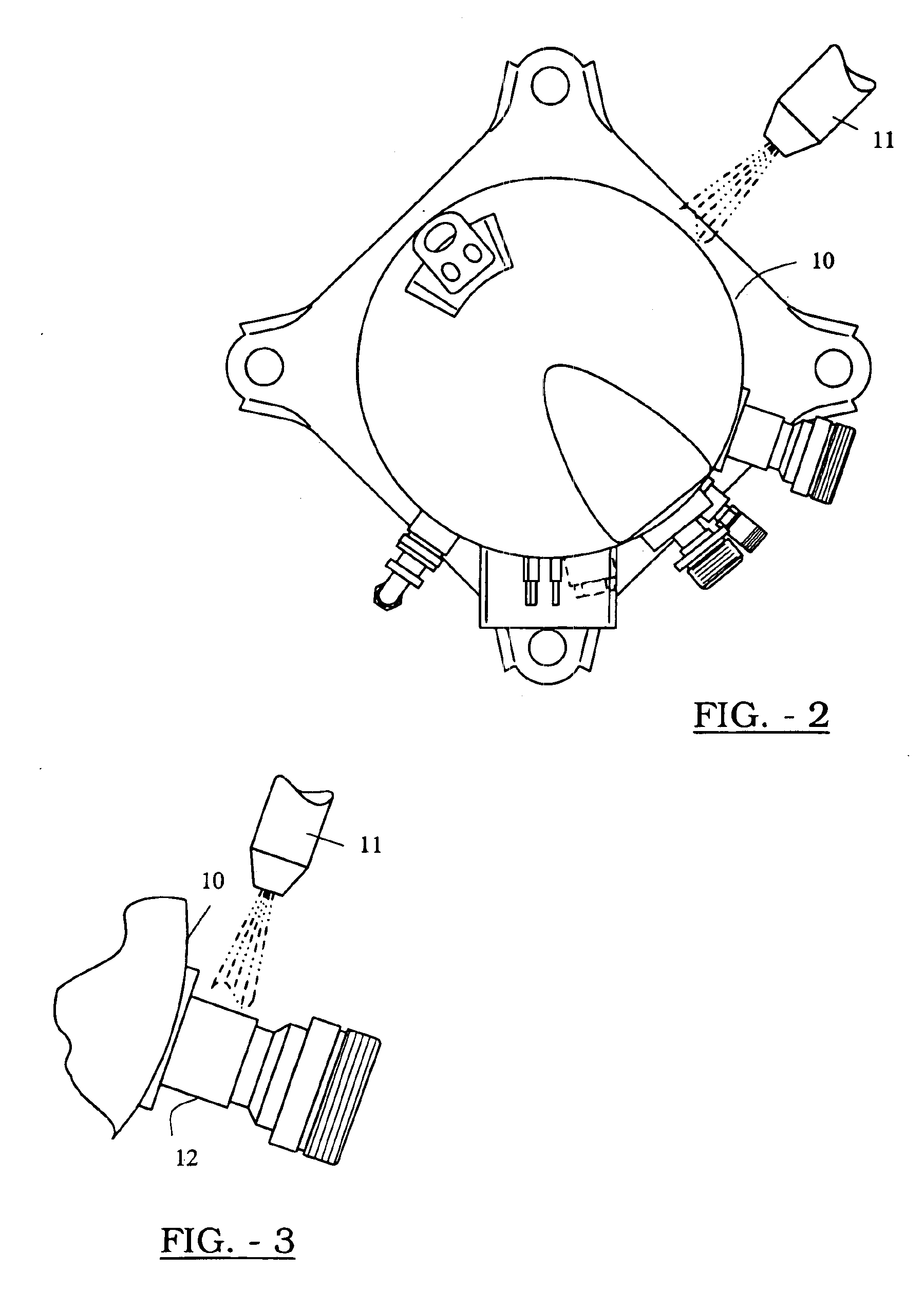

Marine coating

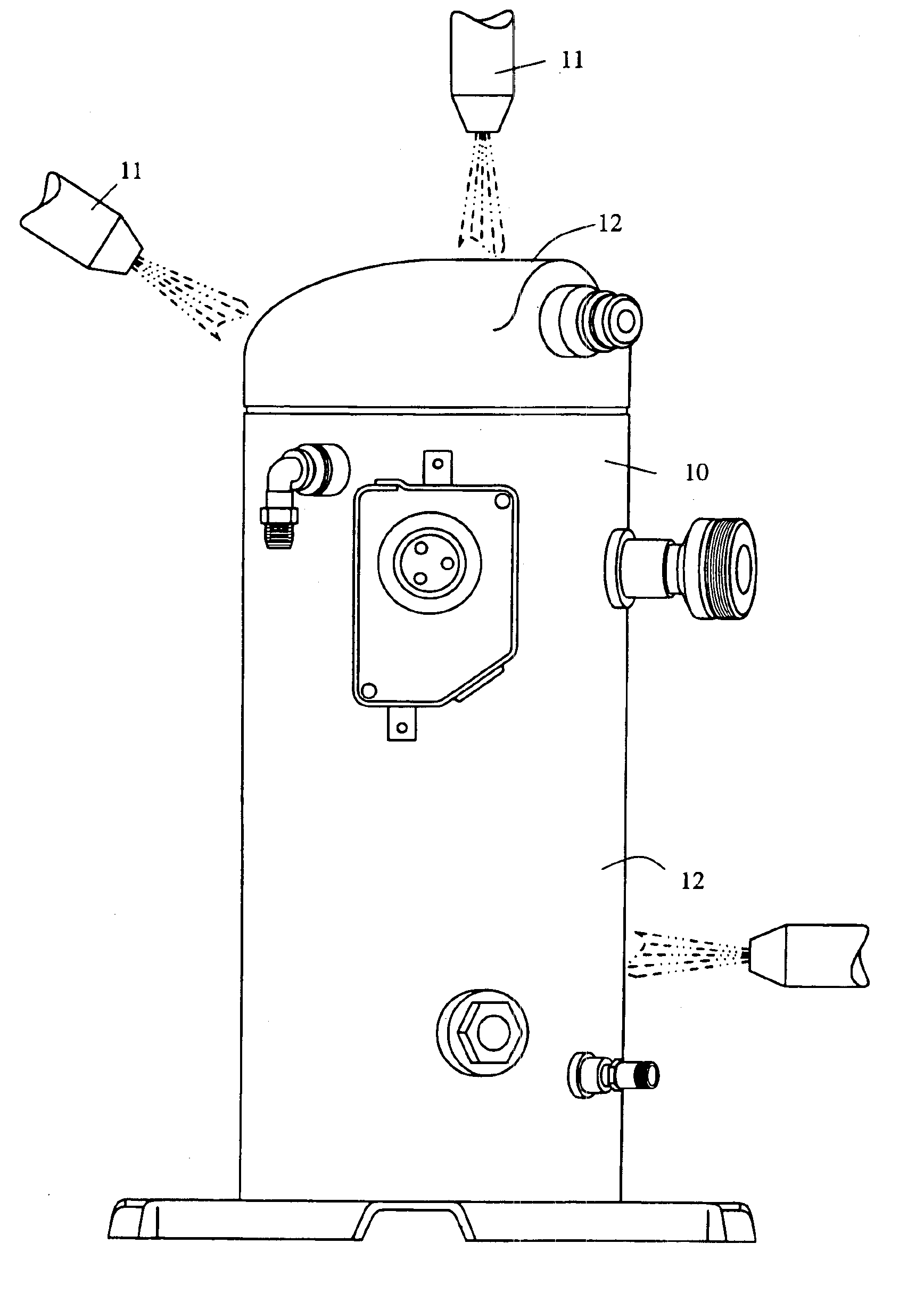

InactiveUS6866941B2Improve corrosion resistanceHot-dipping/immersion processesMolten spray coatingMarine coatingsSolvent

A compressor having a corrosive resistant coating is disclosed. The coating has a first spray coated metallic layer. A sealant layer is disposed over the sprayed metallic coating which has an organic component, a solvent component, and an inorganic phase.

Owner:EMERSON CLIMATE TECH INC

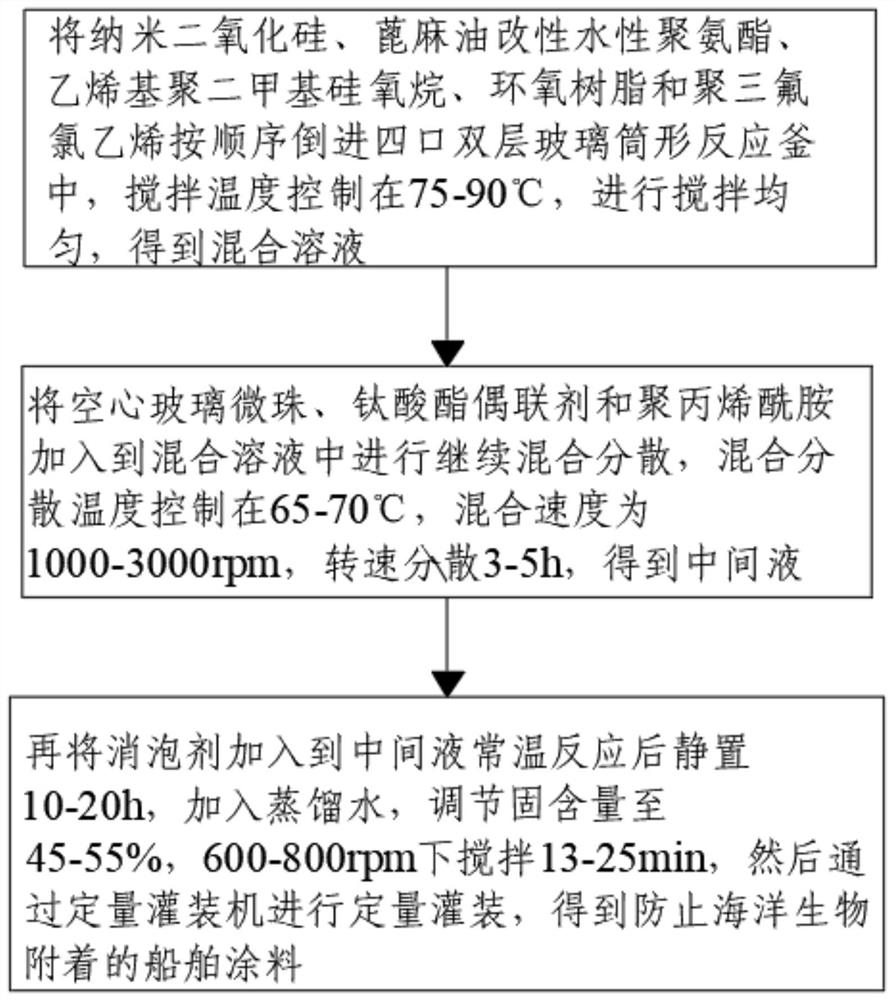

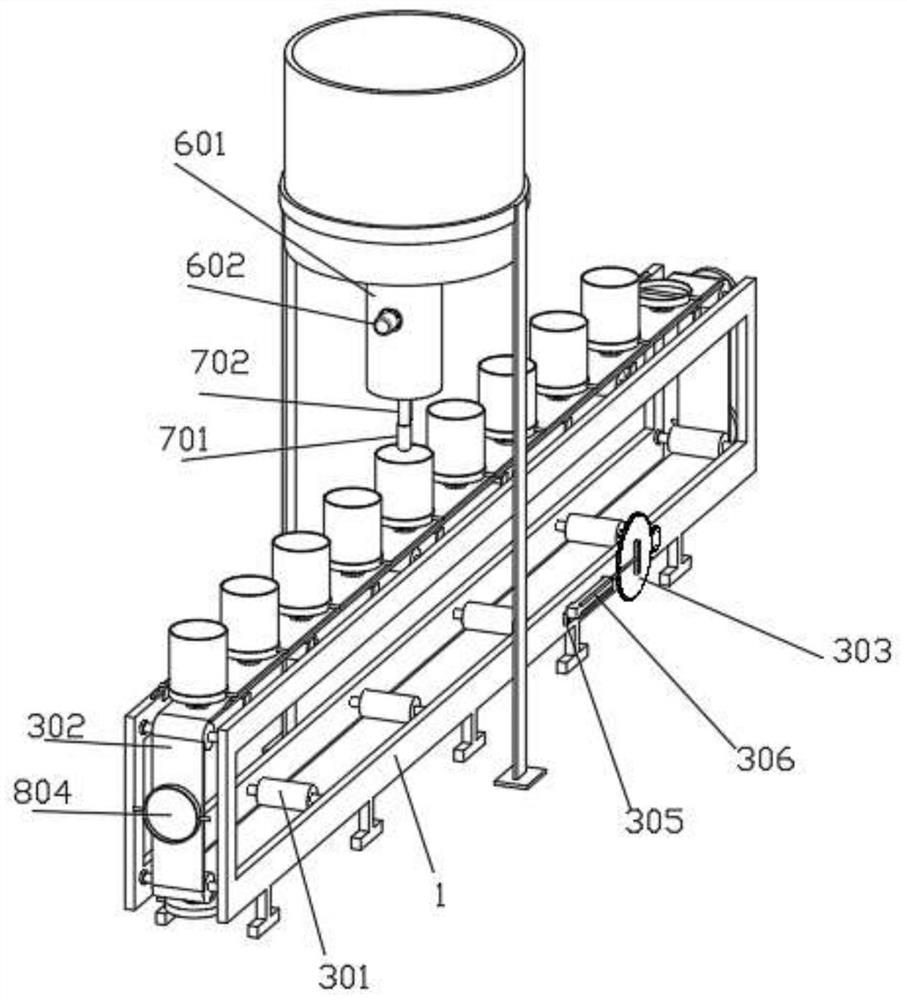

Marine coating for preventing adhesion of marine organisms and processing technology

InactiveCN113355009AEasy dischargeEasy quantitative fillingAntifouling/underwater paintsBarrels/casks fillingEpoxyDimethyl siloxane

The invention discloses a marine coating for preventing adhesion of marine organisms and a processing technology, and relates to the technical field of coatings. The marine coating for preventing adhesion of the marine organisms is prepared from the following raw materials in parts by weight: 9 to 12 parts of nano silicon dioxide, 4.5 to 7.5 parts of castor oil modified waterborne polyurethane, 2.3 to 4.5 parts of vinyl polydimethylsiloxane, 10 to 12 parts of hollow glass beads, 13 to 18 parts of epoxy resin, 8.3 to 11.8 parts of polytrifluorochloroethylene, 1.5 to 1.8 parts of titanate coupling agent, 4.5 to 5.8 parts of polyacrylamide and 12 to 24 parts of defoaming agent. The marine coating for preventing adhesion of the marine organisms has good hydrophobicity, lipophobicity, antifouling property and corrosion resistance, can effectively prevent adhesion of marine organisms, is suitable for the use environment of the surface of a ship, ensures actual use of the coating, and is convenient for quantitative filling during filling.

Owner:广州市修米德科技有限公司

Water-based inorganic zinc silicate shop primer and preparation method thereof

InactiveCN113563748AImprove substrate wettabilityGood flexibilityAlkali metal silicate coatingsPriming paintsSilicic acidMaterials science

The invention belongs to the field of marine coating, and particularly relates to a water-based inorganic zinc silicate workshop primer and a preparation method thereof. Potassium silicate with the modulus being 3.7 is adopted as a raw material, silica sol and a silane coupling agent are added to prepare high-modulus potassium silicate with the modulus being 6, then styrene-butadiene emulsion or styrene-acrylic emulsion is added to modify the high-modulus potassium silicate, and finally zinc powder, ferrophosphorus powder and feldspar powder are added to prepare the water-based inorganic zinc silicate shop primer. Various properties of the emulsion are researched by testing viscosity, solid content, modulus and storage stability of the emulsion, and appearance, initial water resistance, adhesive force, weather-proof protection period and the like of a coating film. The addition of the silica sol and the silane coupling agent improves the dryness, the early water resistance, the crosslinking curing degree and the adhesive force, and the addition of the styrene-butadiene emulsion or the styrene-acrylic emulsion greatly improves the substrate wettability, the flexibility and the adhesive force of a coating film.

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

Waterproof antibacterial marine coating

InactiveCN104945969AImprove adhesionReduce adhesionAntifouling/underwater paintsPaints with biocidesFuranGluconic acid

The invention discloses a waterproof antibacterial marine coating. Raw materials of the marine coating comprise the following ingredients, by weight, 45-60 parts of a fluorine-silicon modified acrylic emulsion, 30-45 parts of a vinyl acetate emulsion, 4-10 parts of polypropylene fiber, 5-15 parts of silicon nitride, 1-5 parts of graphite oxide, 20-35 parts of liquid petroleum resin, 1-3 parts of ethylene dimethacrylate, 2-5 parts of 3-methacryloxy propyl trimethoxy silane, 0.5-2 parts of tri-n-butyl phosphate, 3-8 parts of oxidized starch, 5-10 parts of polyvinyl alcohol, 1-3 parts of glycol, 1-4 parts of dipropylene glycol mono butyl ether, 0.3-1 part of hydroxy propyl distarch phosphate, 0.3-1.5 parts of sodium gluconate, 0.3-1.5 parts of 2-furan-dimethyl silanol, 5-10 parts of an auxiliary agent and 20-35 parts of water. The waterproof antibacterial marine coating brought forward in the invention has advantages of high hardness, excellent waterproofness and antibacterial property, good comprehensive performance and long service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

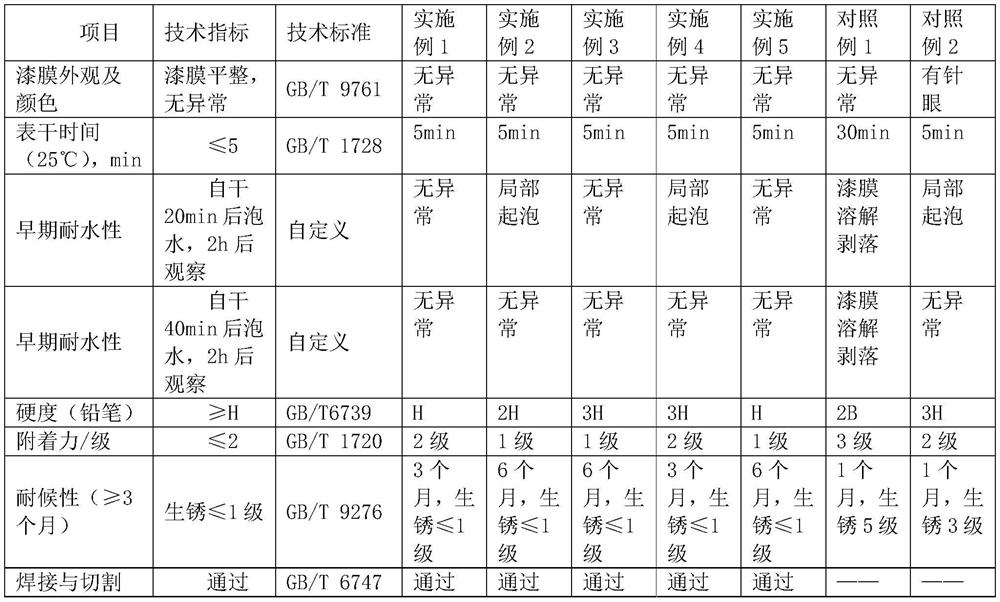

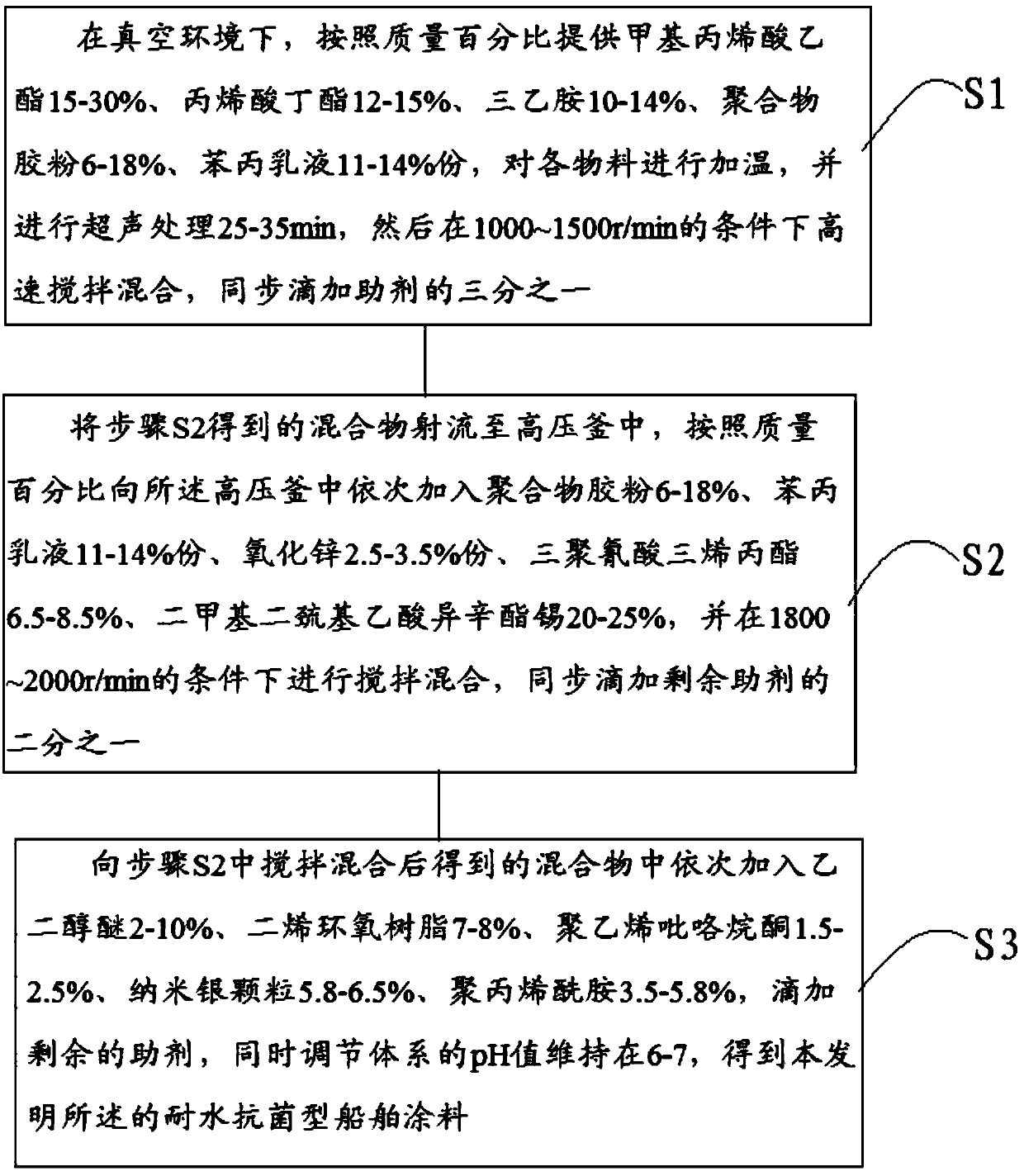

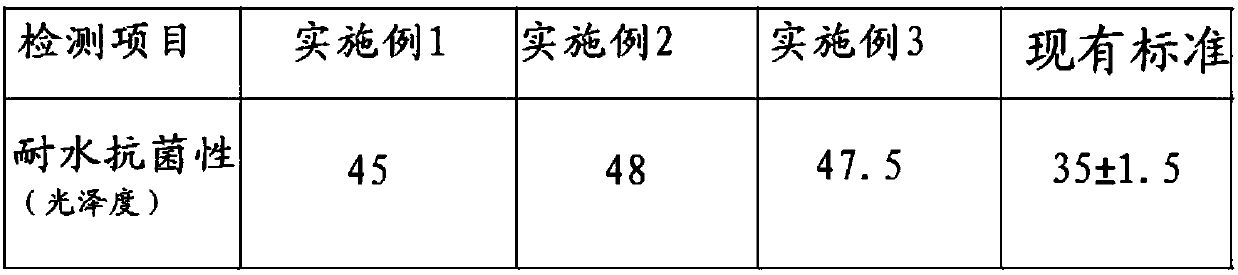

Water-resistant antibacterial marine coating and preparation method thereof

InactiveCN107674469AImprove water resistanceImprove antibacterial propertiesAntifouling/underwater paintsPaints with biocidesIsooctyl acrylateMethacrylate

The invention provides a water-resistant antibacterial marine coating and a preparation method thereof. The marine coating includes, by mass percentage, 15-30% of ethyl methacrylate, 12-15% of butyl acrylate, 10-14% of triethylamine, 6-18% of polymer powder, 11-14% of styrene-acrylic emulsion, 2.5-3.5% of zinc oxide, 6.5-8.5% of triallyl cyanurate, 20-25% of dimethyltin bis(isooctylmercaptoacetate), 2-10% of glycol ether, 7-8% of diene epoxy resin, 1.5-2.5% of polyvinylpyrrolidone, 5.8-6.5% of nanosilver particles, 3.5-5.8% of polyacrylamide and 12-24% of additives. According to the water-resistant antibacterial marine coating, by optimizing the content of components in the coating and the contents of the components, water resistance and antibacterial properties of the coating formed afterthe coating are improved, and a surface layer of a ship using the coating is not abraded and damaged easily and has a long service life.

Owner:JIANGSU MARINE VICTORY COATING

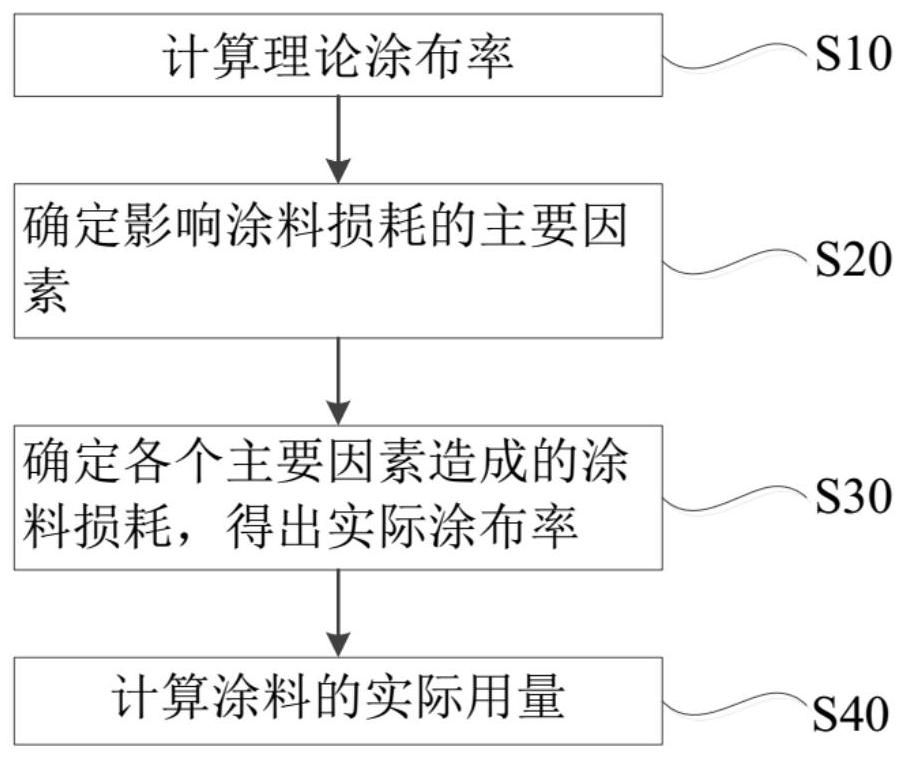

Marine coating dosage calculation method

PendingCN113499960AAccurate dosageCost controlLiquid surface applicatorsCoatingsPhysical chemistryMarine coatings

The invention discloses a marine coating dosage calculation method, and relates to the technical field of ship coating. The marine coating dosage calculation method comprises the following steps that S10, a theoretical coating rate is calculated; S20, main factors influencing coating loss are determined; S30, the coating loss caused by each main factor is determined to obtain an actual coating rate; and S40, the actual dosage of coating is calculated. By means of the marine coating calculation method, the more accurate coating dosage can be obtained, and the coating cost can be more accurately controlled.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

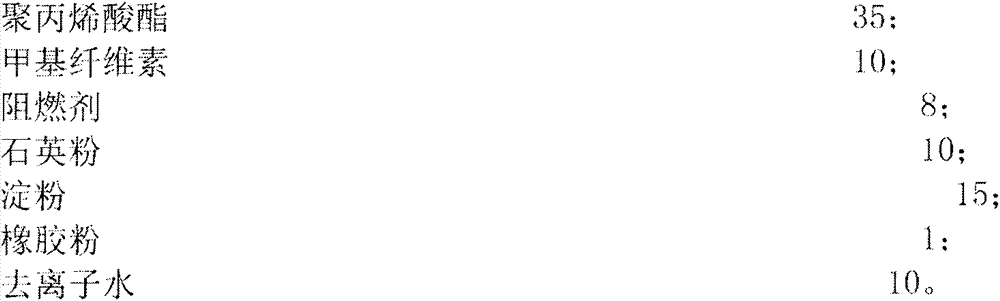

Corrosion-resistant heatproof coating

InactiveCN107446448AWide range of usesFireproof paintsAnti-corrosive paintsMarine coatingsFire retardant

Owner:广西贵港市长雄干燥科技有限公司

Marine high-performance anticorrosion coating and preparation method thereof

InactiveCN109439109AAvoid corrosionImprove thermal stabilityAntifouling/underwater paintsPaints with biocidesAcrylic resinGlycerol

The invention provides a marine high-performance anticorrosion coating and a preparation method thereof. The marine high-performance anticorrosion coating is made with, by weight, 60-70 parts of waterborne acrylic resin, 9-14 parts of nano calcium carbonate, 10-30 parts of nano alumina powder, 5-10 parts of sodium dodecyl benzene sulfonate, 3-8 parts of nicotine, 2-4 parts of an anti-settling agent, 2-6 parts of tributyl acetate, 25-40 parts of a filling material, 20-30 parts of an anti-fouling agent, 2-5 parts of an adhesion promoter, 5-15 parts of zein, 90-110 parts of ethanol solution, 2-5parts of glycerol, and 25-50 parts of deionized water. The marine high-performance anticorrosion coating is environmentally friendly, good in thermal stability, corrosion resistance, adhesion and barrier property, and effective in extending the service time of marine coating film, thereby preventing ships from being corroded by sea water.

Owner:安徽康瑞高科新材料技术工程有限公司

Preparation method of marine coating emulsion

InactiveCN101962501AEliminate Construction HazardsNo pollution in the processAntifouling/underwater paintsPaints with biocidesEmulsionMarine coatings

The invention relates to a preparation method of a marine coating emulsion, which comprise the following steps of: (1) respectively dissolving a 1631 surfactant and an OP (Polyoxyethylene Pctylphenol Ether) emulsifier with 50-55 DEG C of hot water according to the ratio of 3:7, and cooling; (2) pouring neoprene latex in an agitating tank, and agitating for 5-10 min while gradually adding the 1631 surfactant and the water solution according to the ratio of 5:5; (3) pouring the OP emulsification solution and the water solution into a chlorine partial emulsion according to the ratio of 3:7, and stirring for 3-5 min; and (4) pouring the chlorine partial emulsion into the neoprene mixture emulsion according to the ratio of 4:6, and stirring for 10 min while gradually pouring a defoamer. Because the hot water is used as an additive and no solvent is used, the preparation method has the advantages of environmental protection and no environmental pollution, and the construction harm of the traditional coating is eliminated.

Owner:NANTONG REPAIR AIR CHEM BIOENG

Water-based salt-fog-resistant marine coating and preparation formula thereof

PendingCN113088149AHigh resistance to salt sprayImprove practicalityAnti-corrosive paintsEpoxy resin coatingsEmulsionAcrylic resin

The invention discloses a water-based salt-fog-resistant ship coating and a preparation formula of the water-based salt-fog-resistant ship coating. The coating is prepared from the following raw material components in parts by mass: 25 to 35 parts of deionized water, 20 to 25 parts of acrylic resin, 10 to 15 parts of vinyl acetate, 2 to 4 parts of waterborne epoxy emulsion, 1 to 2 parts of a waterborne epoxy curing agent, 1 to 2 parts of an ultraviolet absorbent, 1 to 3 parts of a defoaming agent, 5 to 10 parts of a filling agent, 3 to 7 parts of a neutralizing agent, 1 to 6 parts of a thickening agent, 1 to 3 parts of coalescing agent, 2 to 6 parts of a waterborne antirust agent and 3 to 9 parts of a salt spray resistant additive. Instruments and equipment required for preparing the water-based salt-fog-resistant ship coating comprise a stirring tank, a stirrer and a filter. The water-based salt-fog-resistant ship coating has the advantages that the salt-fog resistance is enhanced, the ship surface which is frequently contacted with seawater is prevented from being corroded by chlorides, the influence of the chlorides on the service life of the ship is reduced, the economic loss of a user caused by the damage of the ship surface is avoided, and the water-based salt-fog-resistant ship coating is green and environment-friendly and conforms to the green industrial development concept.

Owner:上海涂固安高科技有限公司

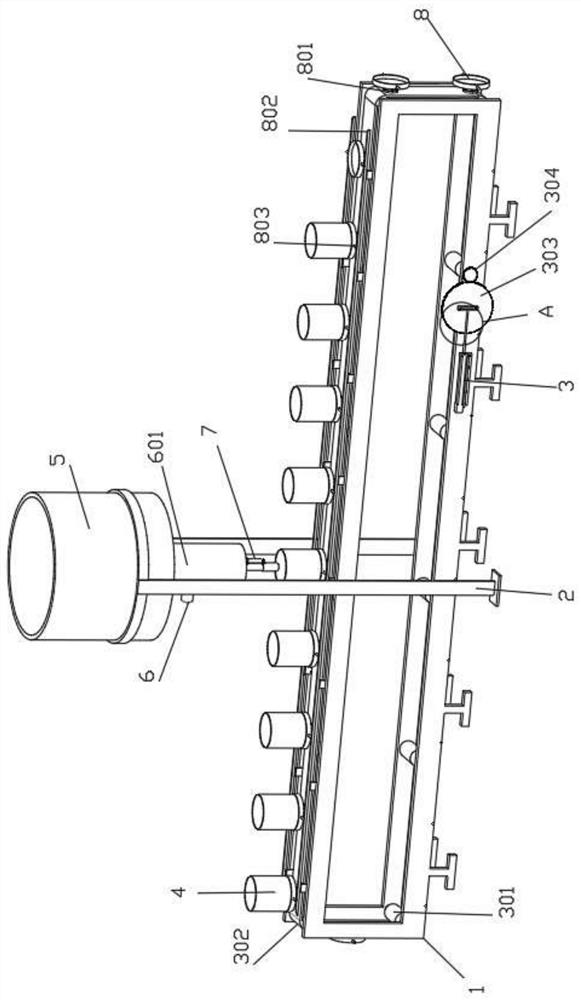

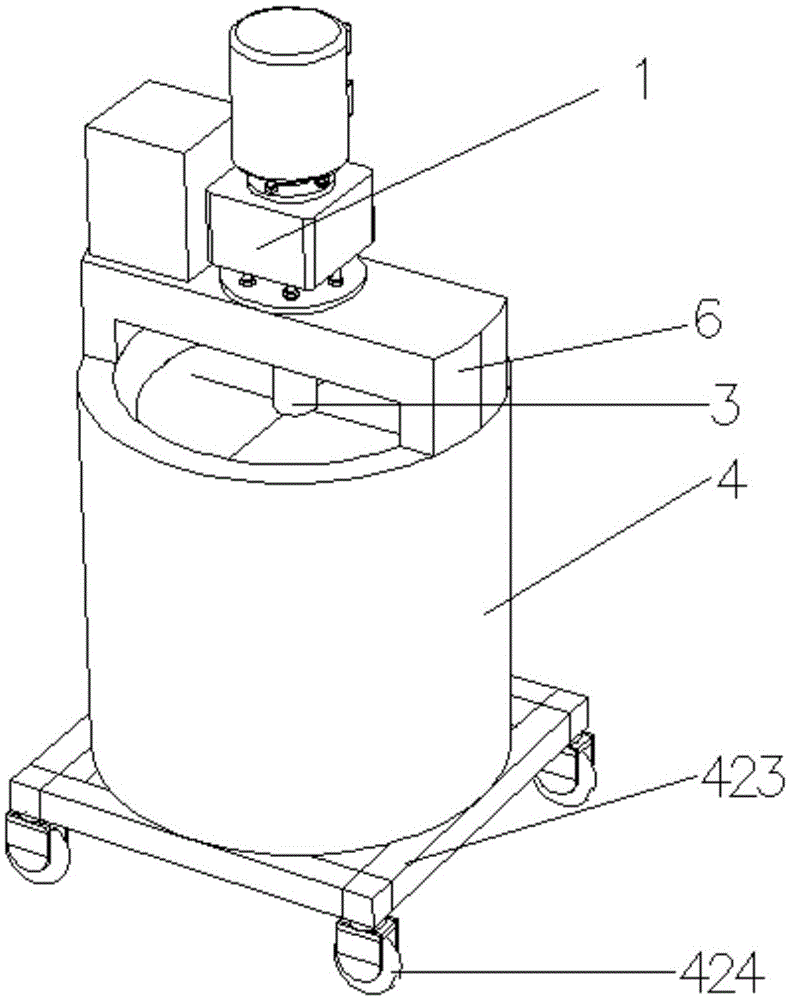

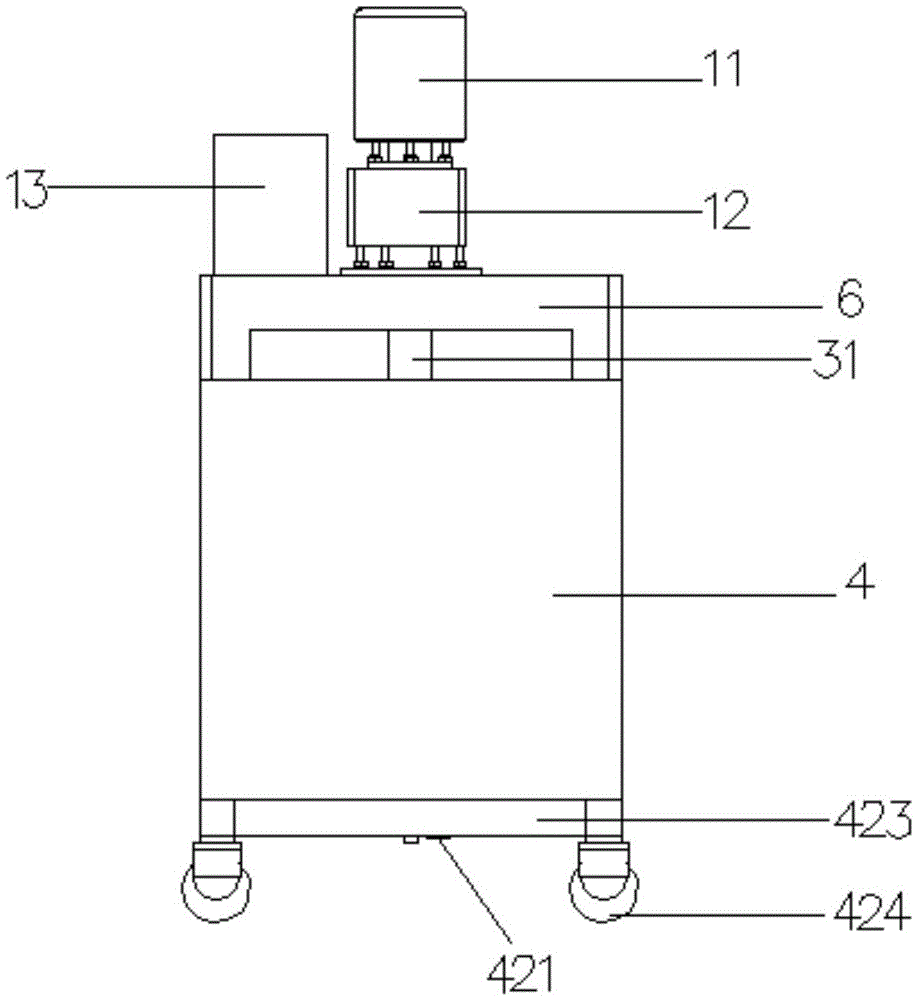

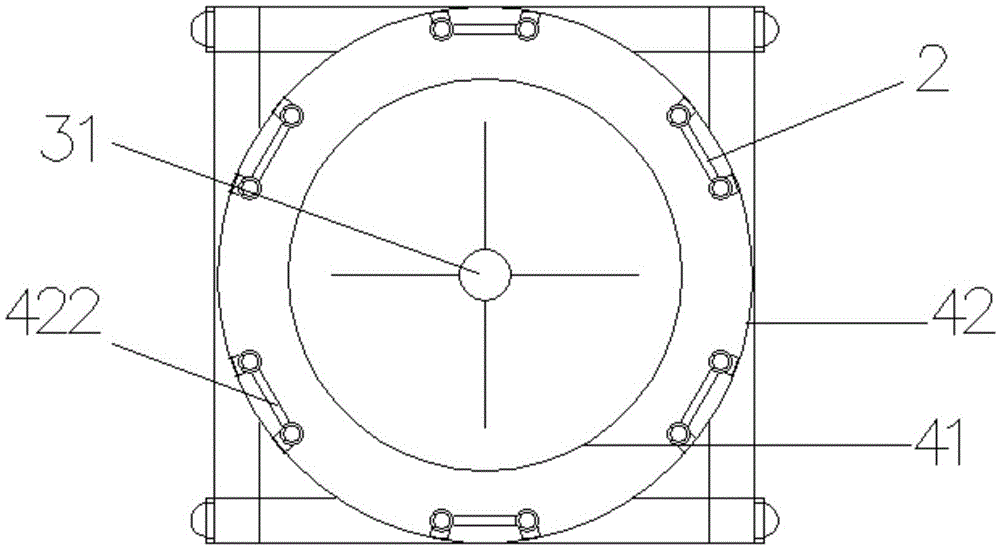

Machine for testing abrasion property of marine coating

InactiveCN106680189AImprove stabilityEasy to operateWeather/light/corrosion resistanceMarine coatingsEngineering

The invention relates to equipment for testing property of coating, in particular to testing equipment suitable for testing abrasion property of marine coating, and specifically relates to a machine for testing the abrasion property of the marine coating. The machine comprises a power system, a sample plate fixing mechanism, a drive mechanism and a stirring mechanism, wherein the power system is connected with the drive mechanism, and is arranged on the stirring mechanism through a bracket; the power system is used for driving, through the drive mechanism, the sample plate fixing mechanism hung on the stirring mechanism to test. The machine has the advantages that the operation is simple and convenient, the structure is simple, the stability in running of equipment is good, the maintenance of the equipment is convenient, and the defects of the prior art are overcome.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com