Marine coating capable of effectively preventing marine organism adhesion and preparation method thereof

A technology for marine organisms and ships, applied in the field of marine coatings and their preparation, can solve the problems of reducing the ship's load, increasing the resistance of the hull, reducing the speed of the ship, etc., and achieves improved anti-corrosion performance, strong chain segment movement ability, and small steric resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

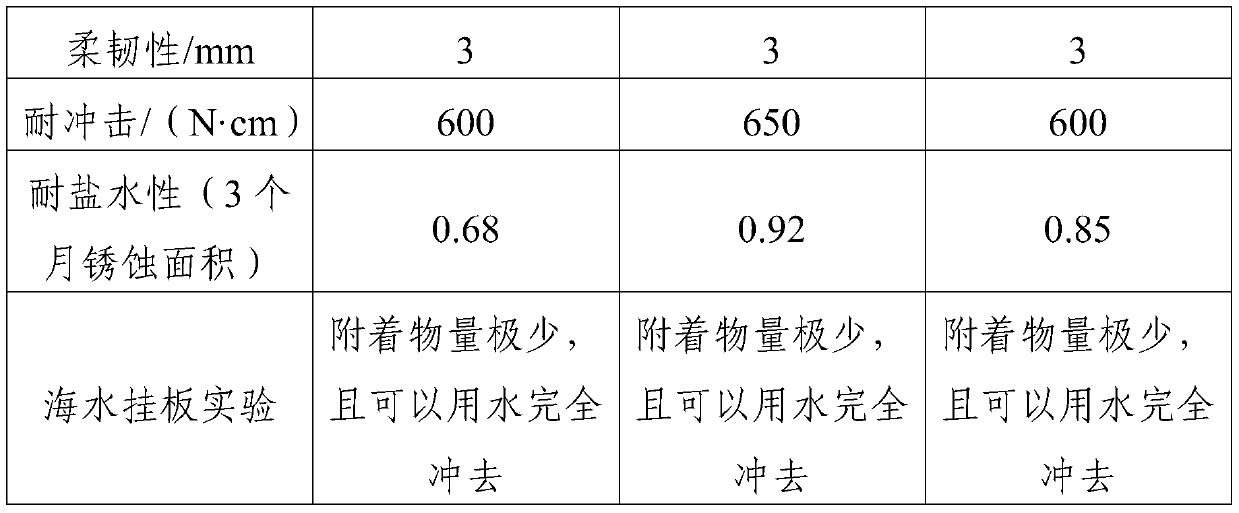

Embodiment 1

[0033] A marine coating that can effectively prevent marine organisms from adhering, comprising A component and B component with a weight ratio of 10:1, and the A component includes the following components in parts by weight:

[0034] 38 parts of dimer acid modified epoxy resin, 15 parts of fluorosilicone resin, 10 parts of hydroxyl carbon nanotubes, 5 parts of polydimethylsiloxane, 16 parts of tourmaline, 10 parts of functionalized graphene, 3 parts of bentonite, 1 part of tributyl phosphate, 1.2 parts of capsaicin, dodecyl dimethylphenoxyethyl ammonium bromide, dodecyl dimethyl benzyl ammonium chloride, dioctadecyl dimethyl chloride Ammonium and dimethyl benzyl ammonium chloride compound 2 parts of compound bactericidal ingredients, 6 parts of liquid polysulfide rubber, 10 parts of hyperbranched polyether, 0.2 parts of methyldiethanolamine, 0.1 parts of dioctyl phthalate 3 parts, 3 parts of terminal hydrogen-containing silicone oil, 8 parts of butyl acetate, 3 parts of xyle...

Embodiment 2

[0042] A marine coating that can effectively prevent marine organisms from adhering, comprising A component and B component with a weight ratio of 12:1, and the A component includes the following components in parts by weight:

[0043] 40 parts of dimer acid modified epoxy resin, 12 parts of fluorosilicone resin, 12 parts of hydroxyl carbon nanotubes, 4 parts of polydimethylsiloxane, 15 parts of tourmaline, 10 parts of functionalized graphene, 2 parts of bentonite, 1 part of tributyl phosphate, 1 part of capsaicin, dodecyl dimethylphenoxyethyl ammonium bromide, dodecyl dimethyl benzyl ammonium chloride, dioctadecyl dimethyl chloride Ammonium and dimethyl benzyl ammonium chloride compound compound bactericidal component 1 part, liquid polysulfide rubber 6 parts, hyperbranched polyether 5 parts, methyldiethanolamine 0.5 part, dioctyl phthalate 0.1 part 1 part, 1 part of terminal hydrogen-containing silicone oil, 5 parts of butyl acetate, 40 parts of xylene;

[0044] The prepara...

Embodiment 3

[0051] A marine coating that can effectively prevent marine organisms from adhering, comprising A component and B component with a weight ratio of 10:1, and the A component includes the following components in parts by weight:

[0052] 30 parts of dimer acid modified epoxy resin, 10 parts of fluorosilicone resin, 5 parts of hydroxyl carbon nanotubes, 5 parts of polydimethylsiloxane, 20 parts of tourmaline, 10 parts of functionalized graphene, 5 parts of bentonite, 1 part of tributyl phosphate, 1 part of capsaicin, dodecyl dimethylphenoxyethyl ammonium bromide, dodecyl dimethyl benzyl ammonium chloride, dioctadecyl dimethyl chloride Ammonium and dimethyl benzyl ammonium chloride compound compound bactericidal component 1.5 parts, liquid polysulfide rubber 6 parts, hyperbranched polyether 10 parts, methyldiethanolamine 0.1 part, dioctyl phthalate 0.1 part 2 parts, 2 parts of terminal hydrogen-containing silicone oil, 10 parts of butyl acetate, 20 parts of xylene;

[0053] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com