Method for preparing biodegradable ocean antifouling polyurethane hybrid materials and product thereof

A hybrid material and marine antifouling technology, applied in polyurea/polyurethane coatings, antifouling/underwater coatings, medical preparations with non-active ingredients, etc., can solve high crystallization, limitations, poor substrate adhesion, etc. problems, to achieve excellent mechanical properties, excellent adjustable degradation rate, and enhanced mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

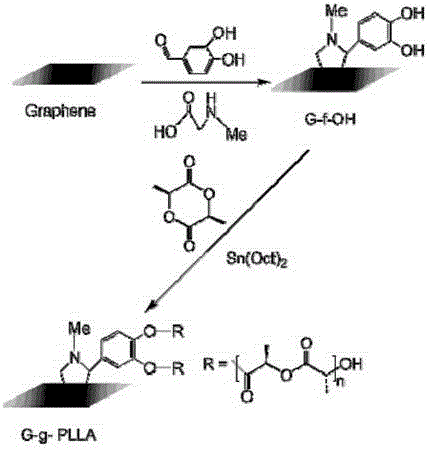

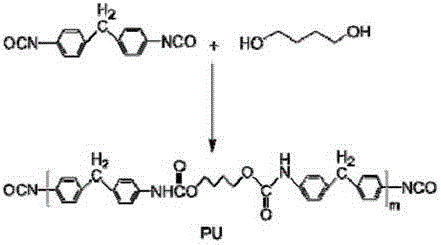

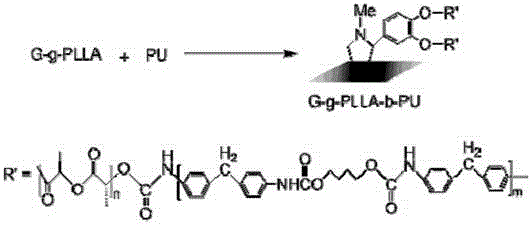

[0031] A preparation method of a degradable marine antifouling polyurethane hybrid material is carried out according to the following steps:

[0032] (1) Add 1.0g of dried flake graphite to the mixture of 1.2g of potassium nitrate and 46mL of concentrated sulfuric acid, mix evenly by ultrasonic, stir in an ice-water bath and slowly add 6.0g of potassium permanganate, then the temperature of the system rises to 40 ℃, high-speed stirring for 6h; then slowly add distilled water, and the system is heated to 70°C for 0.5h; then add 80mL distilled water and 6mL hydrogen peroxide) to the system to continue the reaction for 5min to obtain a bright yellow graphene oxide mother liquor, which is centrifuged and washed with distilled water pH= 7. Obtain pure graphene oxide, add 0.5g sodium dodecylbenzenesulfonate therein, and mix it uniformly by ultrasonic to obtain graphene oxide gel;

[0033] (2) Take 3.0g of graphene oxide gel and prepare a graphene oxide water suspension with a mass con...

Embodiment 2

[0040] In step (4), the two hydroxyl functionalized graphene is 0.083g, stannous octoate is 1.0mL, and anhydrous toluene is 60mL;

[0041] Others are the same as in Example 1.

Embodiment 3

[0043] In step (4), the two hydroxyl functionalized graphene is 0.174g, stannous octoate is 1.5mL, and anhydrous toluene is 70mL;

[0044] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com