Stone Refinement Rolling Device

A stone and accommodating space technology, which is applied in the field of stone fine rolling equipment, can solve the problems of high working noise and low crushing efficiency, and achieve the effect of strengthening strength, reducing crushing difficulty, and avoiding upward movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

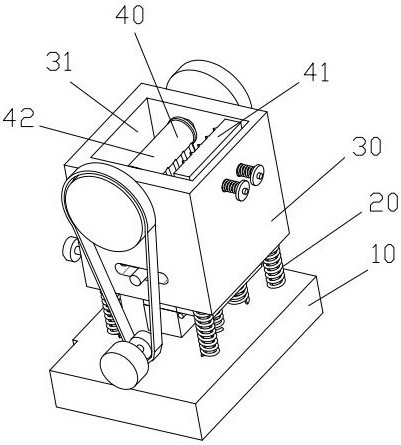

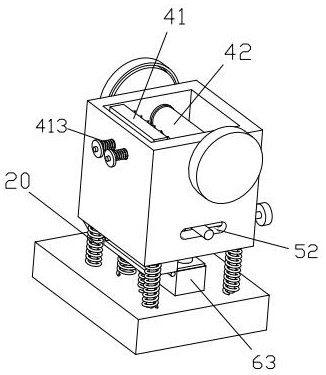

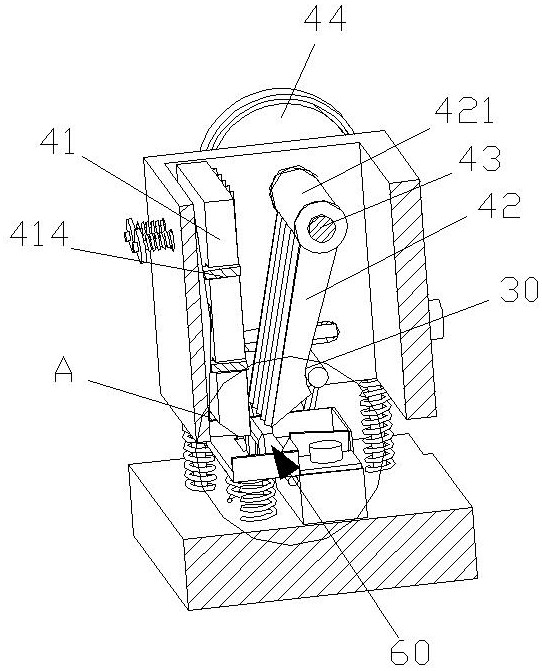

[0036] Attached below Figure 1-10 The present invention is further described with embodiment:

[0037] Stone refinement rolling device, including:

[0038] The support base 10 is used as the support base of the device, and the upper end is provided with a support plane;

[0039] The buffer assembly 20 is arranged on the upper part of the support base 10, and includes a guide column 21 perpendicular to the support plane and a first elastic member 22 sleeved on the guide column 21, and there are at least four guide columns 21;

[0040] The outer casing 30 has a sliding hole at the bottom corresponding to the position of the guide column 21, and is slidably connected with the guide column 21, and is elastically supported by the first elastic member 22; the upper end of the outer casing 30 is open, and the middle part is provided with an accommodating space 31 The outer casing 30 is supported by the first elastic member 22 and guided by the guide column 21, which not only has g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com