Patents

Literature

50results about How to "Reduce the difficulty of breaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

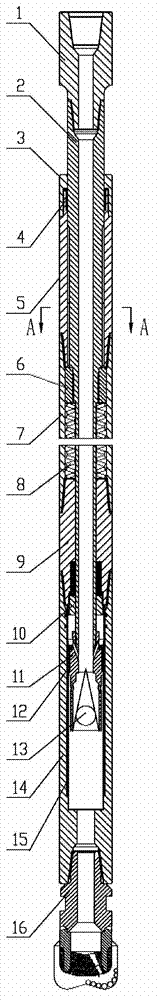

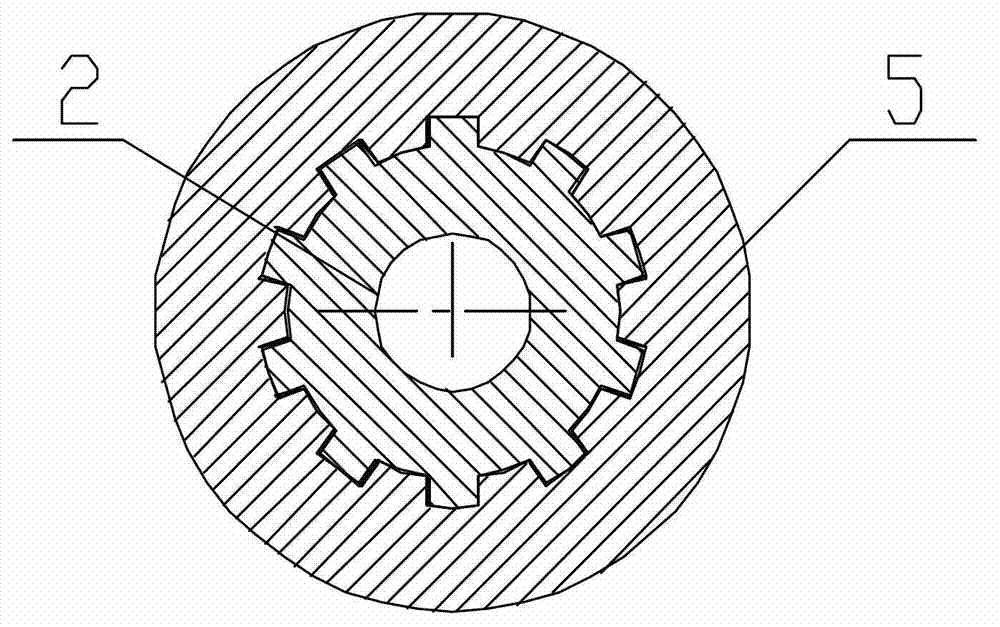

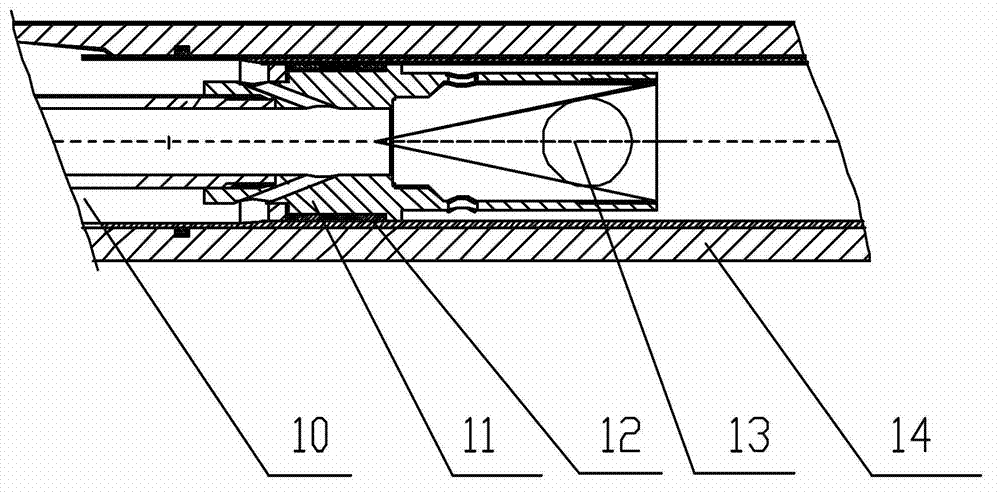

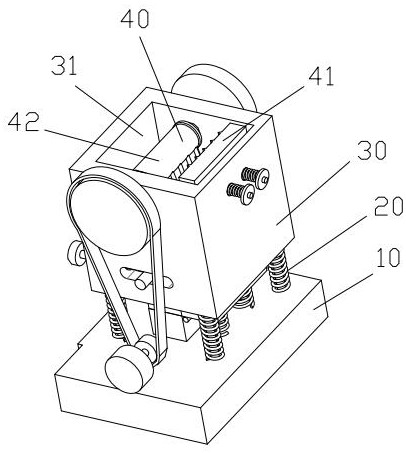

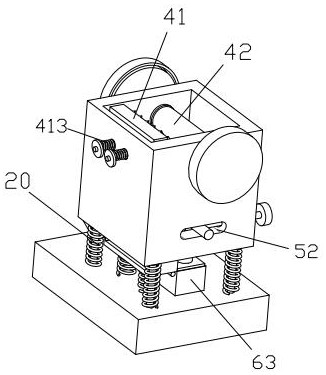

Vibration absorption type downhole hydraulic pulse generation device and well drilling method thereof

ActiveCN103114809AAchieve transferReduce the difficulty of breakingLiquid/gas jet drillingFlushingEnergy transferJet flow

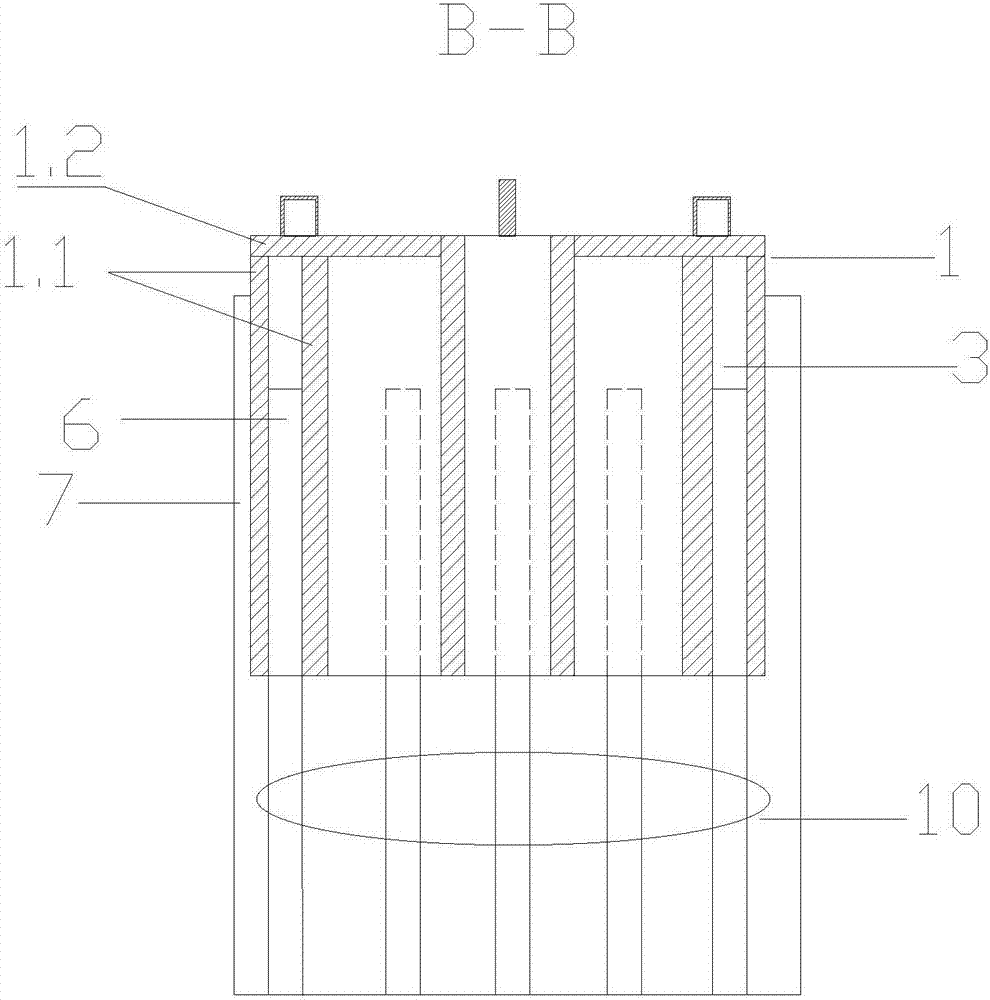

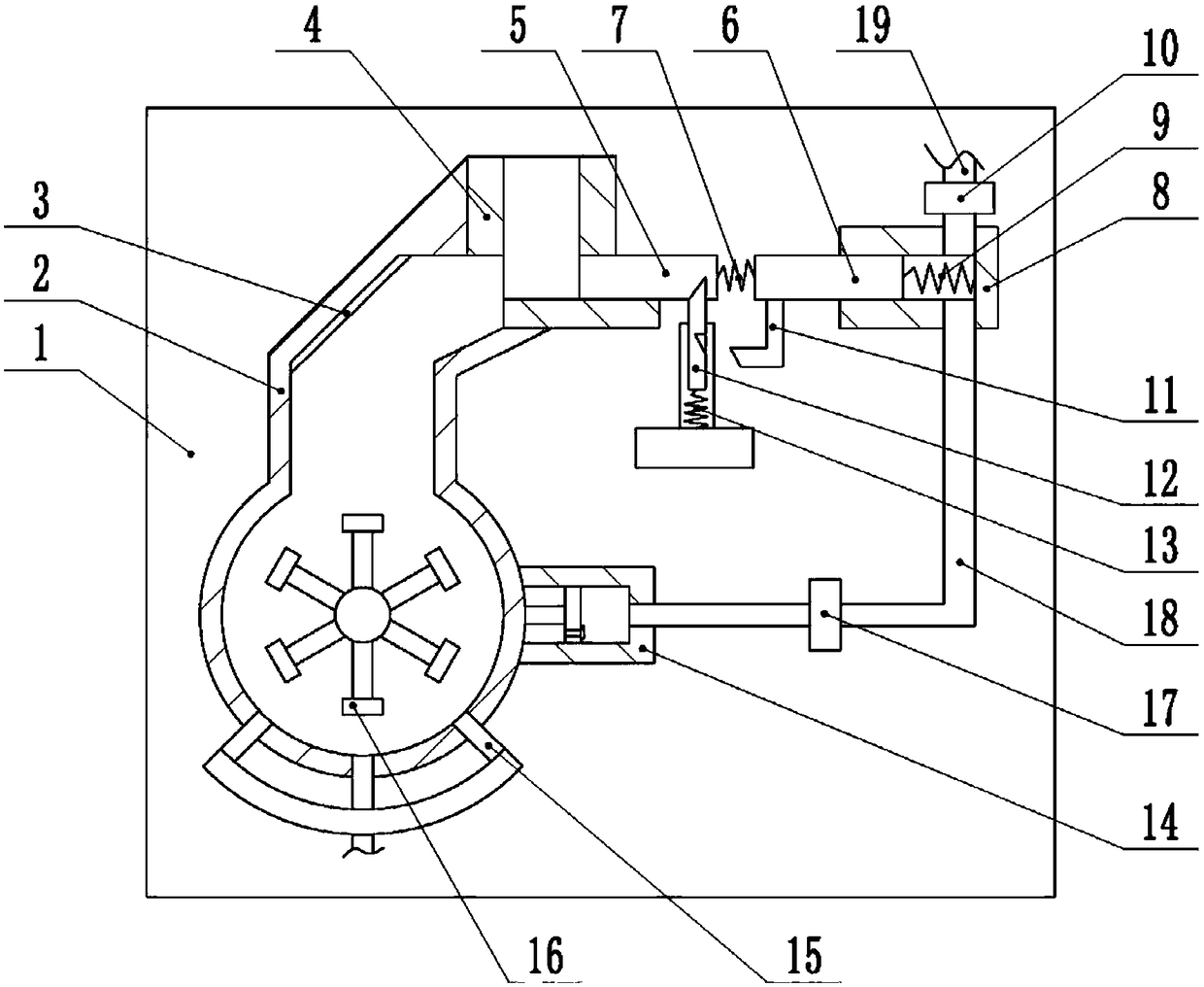

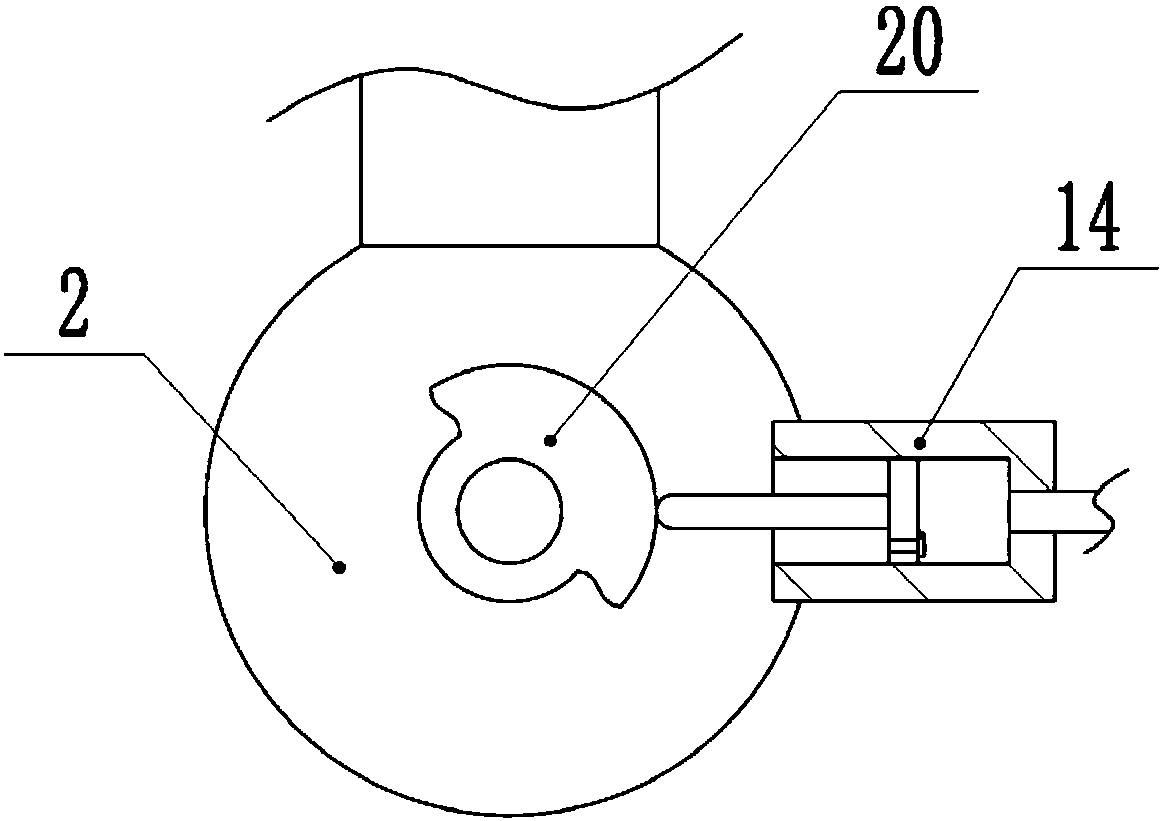

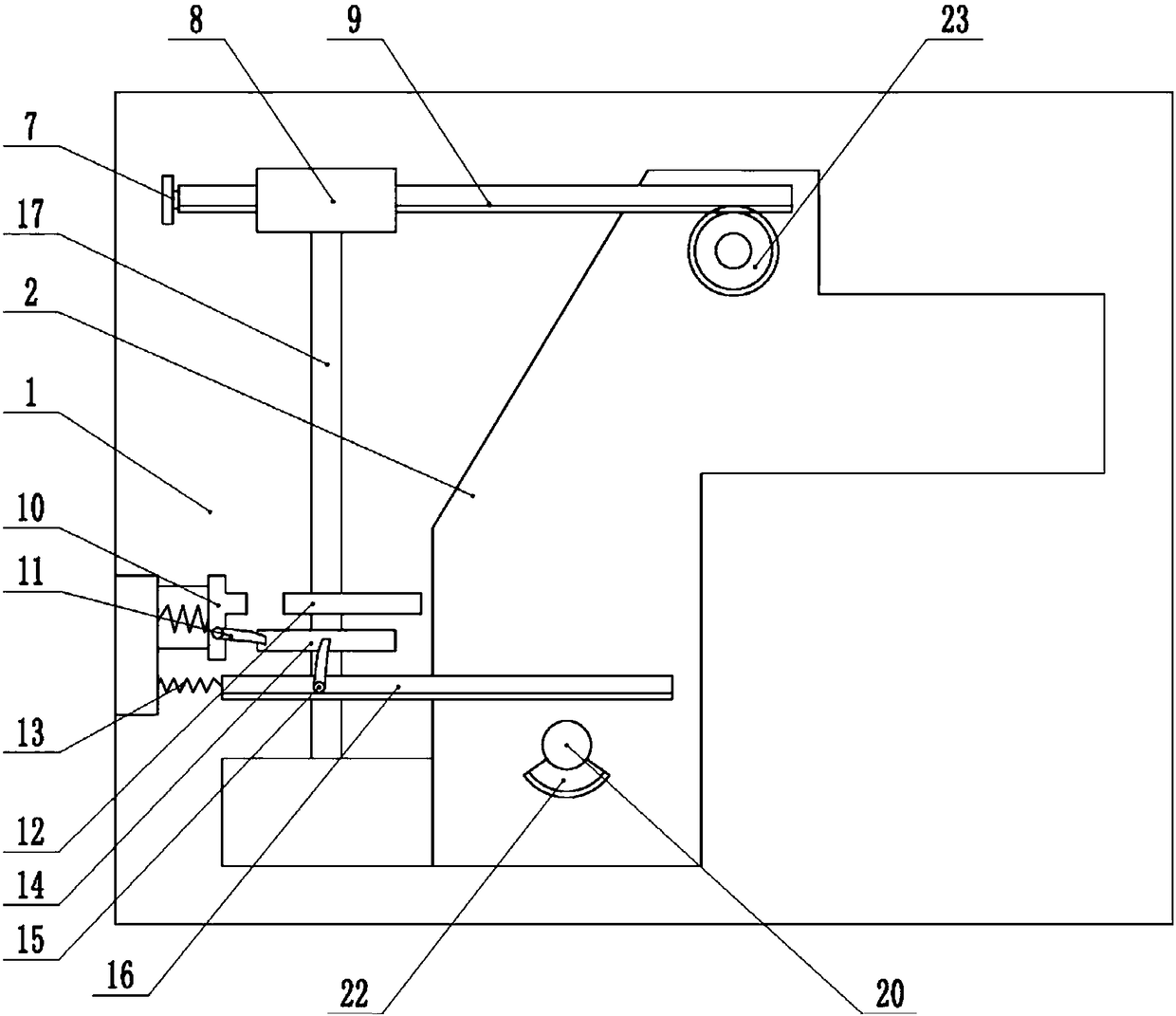

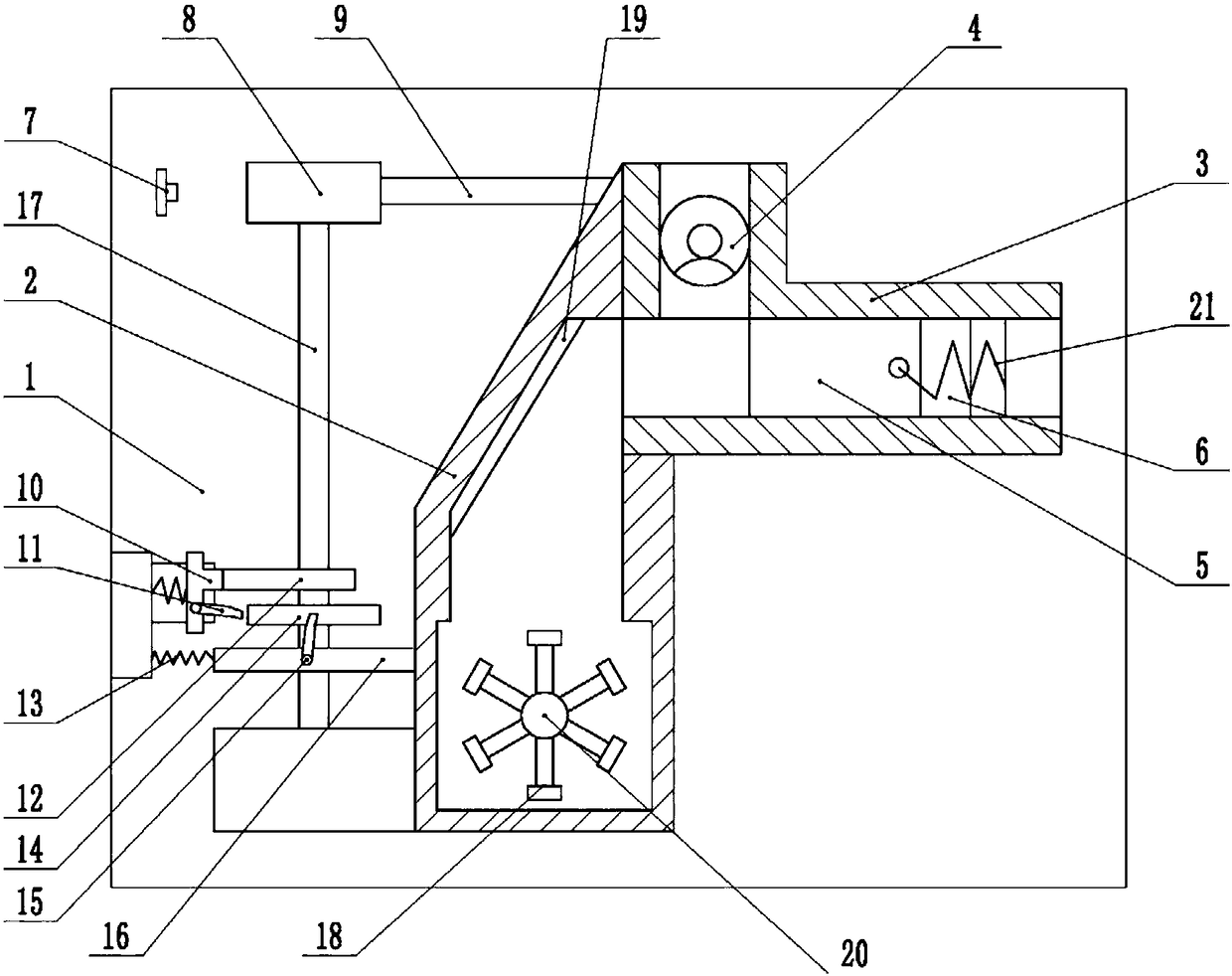

The invention belongs to the field of well drilling of oil and natural gas and relates to a vibration absorption type downhole hydraulic pulse generation device and a well drilling method thereof. The device comprises a drill column linkage body and a drill column transfer body. The device is capable of effectively carrying out periodic compression pressurizing on all downhole drilling fluid, achieving vibration energy transfer of a drill column and generation of pulse jets, and achieving pulse jet modulation of downhole jet flows. Besides, pulse amplitude is high, the principle and the structure are simple, and production, maintenance and application are easy. According to the well drilling method, the pulse generation device is utilized to transfer energy generated by vibration of the drill column, energy generated by vibration of the drill column is effectively utilized, generation of pulse jets is achieved, and drilling speed is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

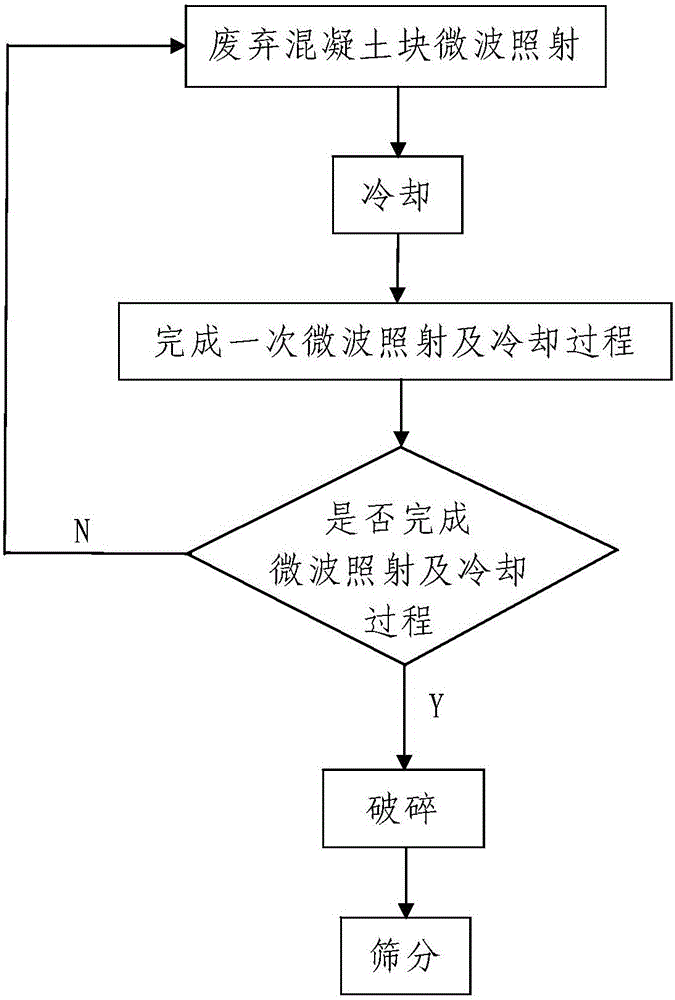

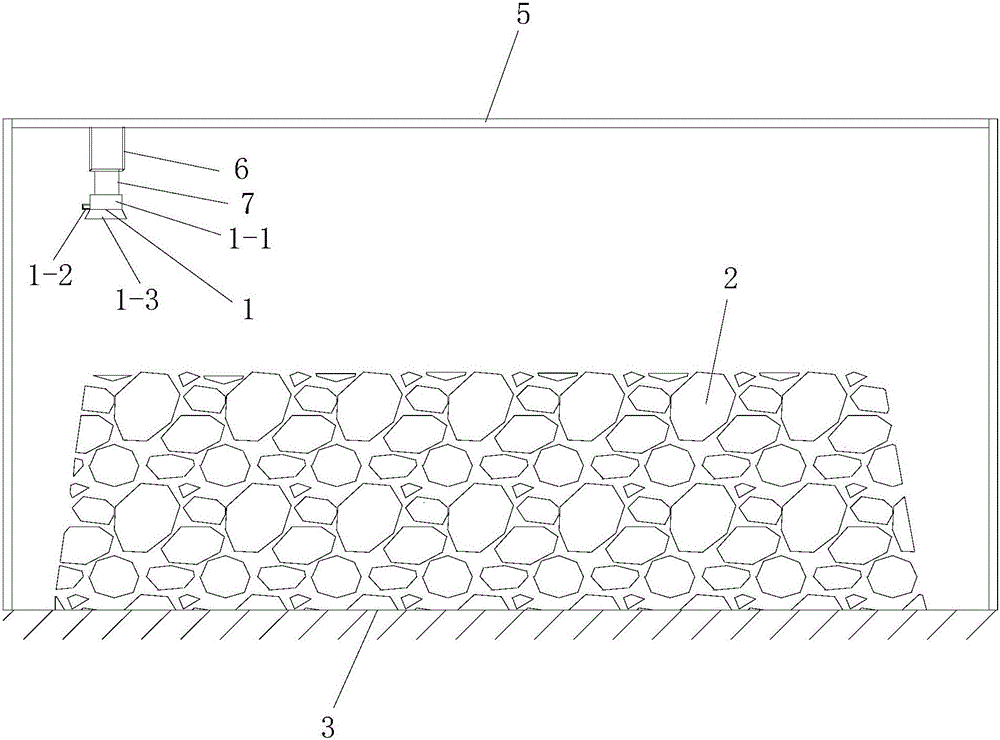

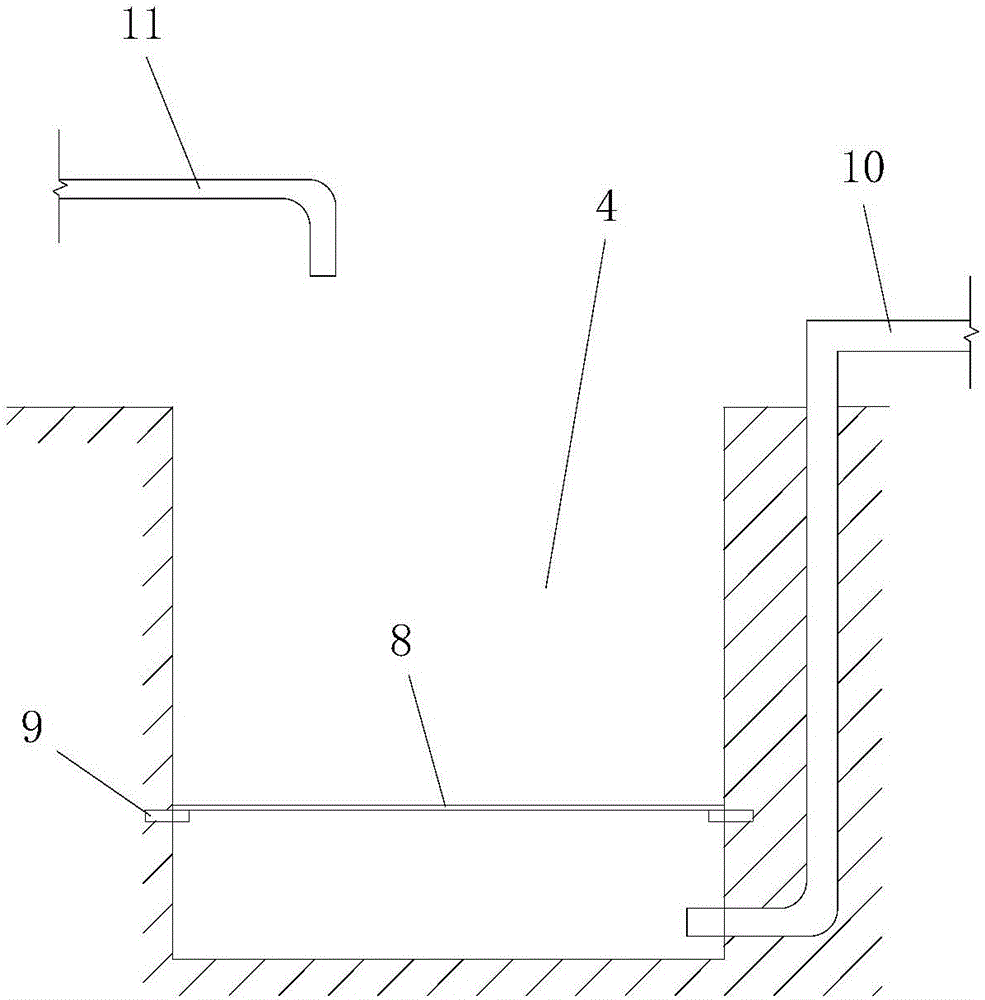

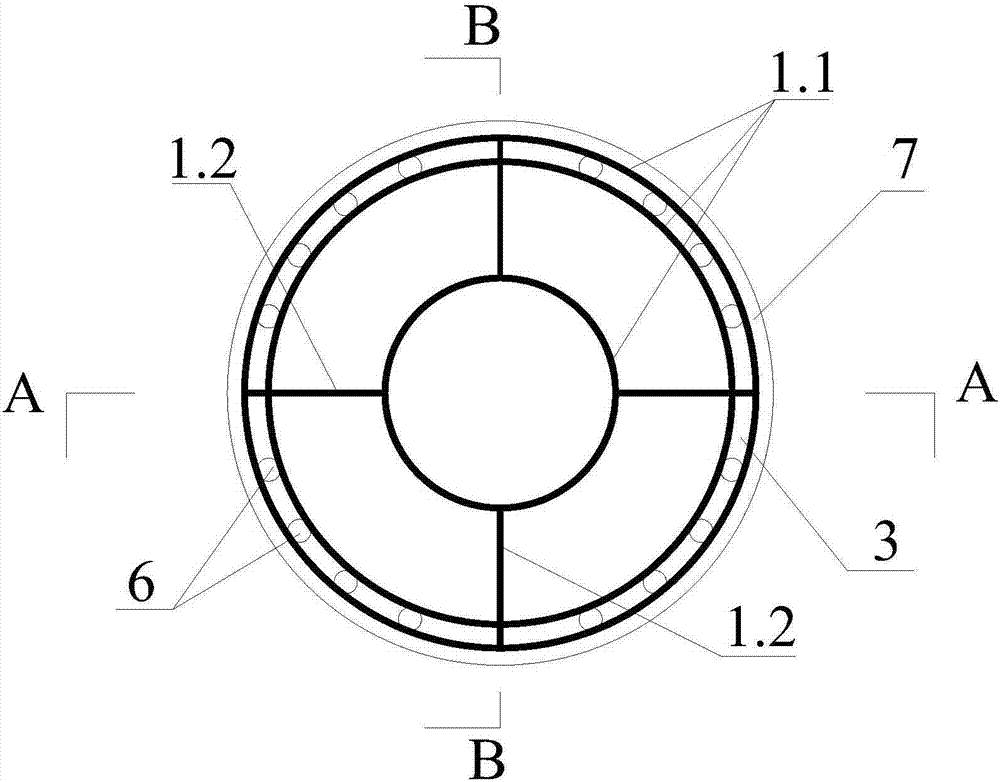

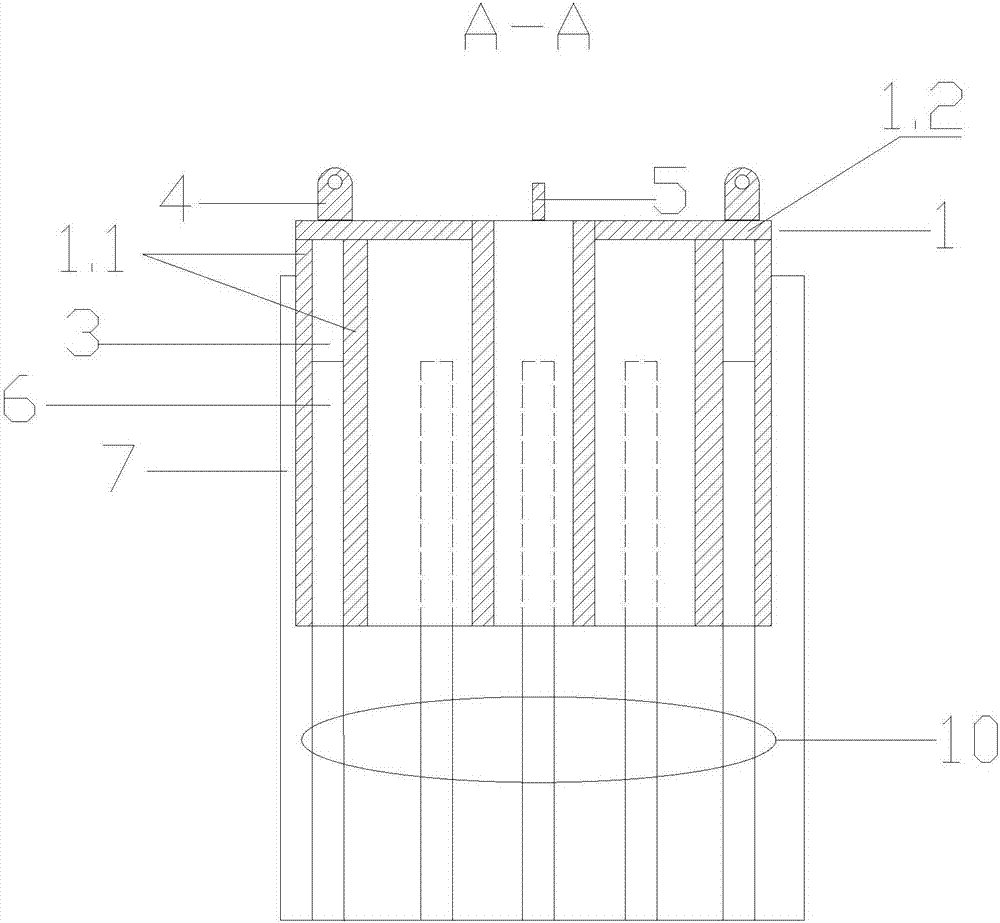

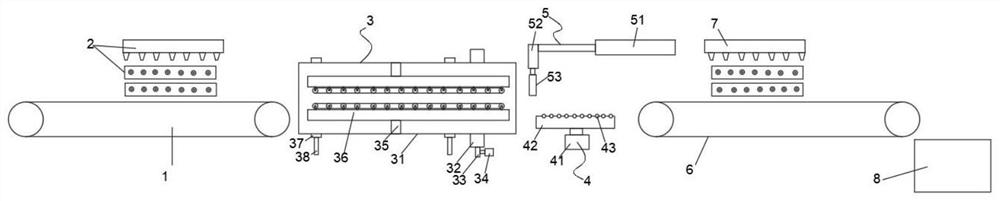

Microwave-assisted recycled concrete coarse aggregate picking method

InactiveCN105776930AThe method steps are simpleLow input costSolid waste managementMicrowave emissionMicrowave irradiation

The invention discloses a microwave-assisted recycled concrete coarse aggregate picking method. The method comprises the following steps of: firstly, carrying out microwave irradiation and cooling, namely 101, carrying out microwave irradiation for the first time and cooling, namely 1011 carrying out microwave irradiation on waste concrete blocks and 1012 cooling, wherein the step 1011 comprises the steps of transporting and piling the waste concrete blocks in a microwave irradiation region and then carrying out microwave irradiation on the waste concrete blocks by adopting a microwave transmitting device, and the step 1012 comprises the steps of transporting and soaking the waste concrete blocks subjected to microwave irradiation in a cooling water tank for cooling; 102, carrying out microwave irradiation for the next time and cooling; and 103, repeating the step 102 for once or twice; secondly, breaking; and thirdly, screening. The method disclosed by the invention is simple in steps, reasonable in design, easy to realize and good in use effect, and the problems of an existing recycled concrete aggregate picking method that the picking efficiency is low, mass production of recycled concrete aggregate is not applicable and the quality of the picked recycled concrete aggregate is difficult to guarantee can be effectively solved.

Owner:XIAN UNIV OF SCI & TECH

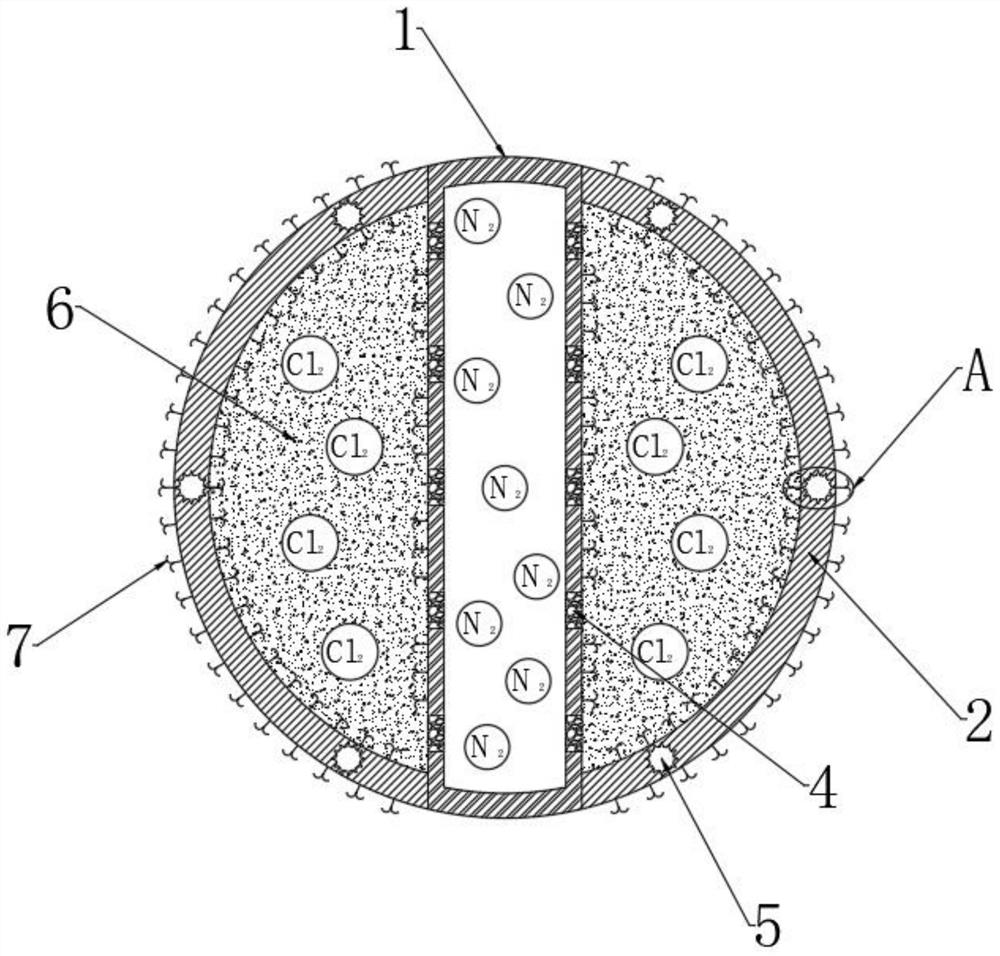

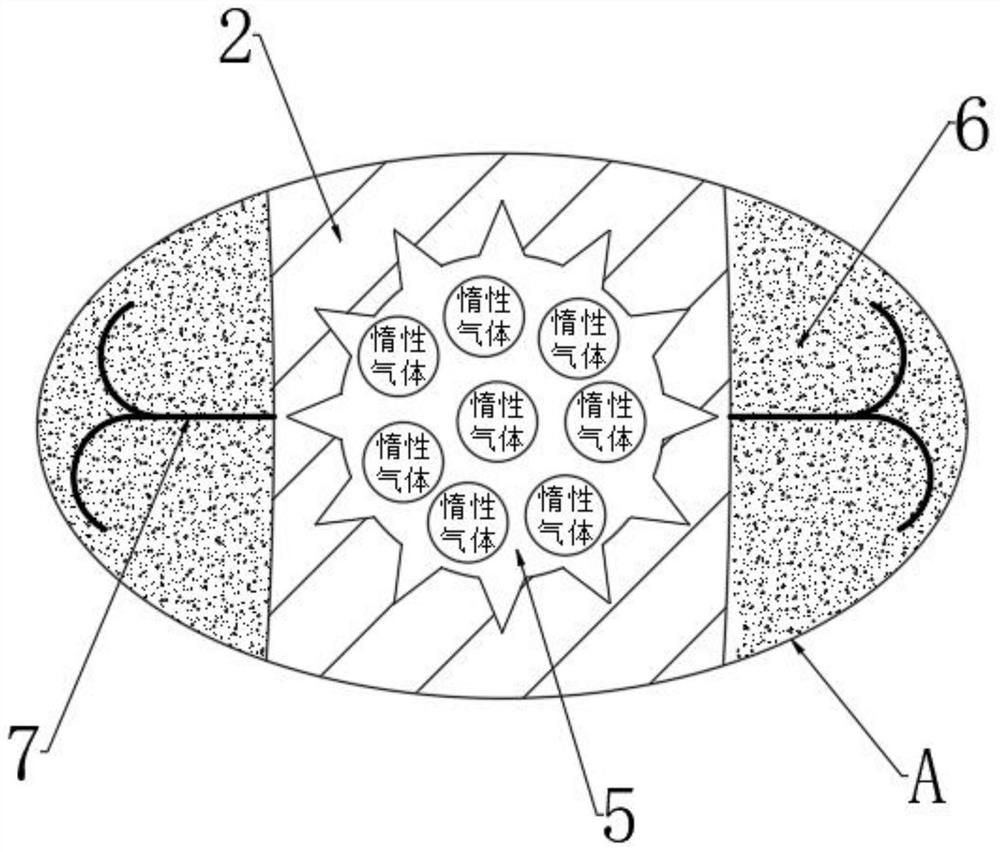

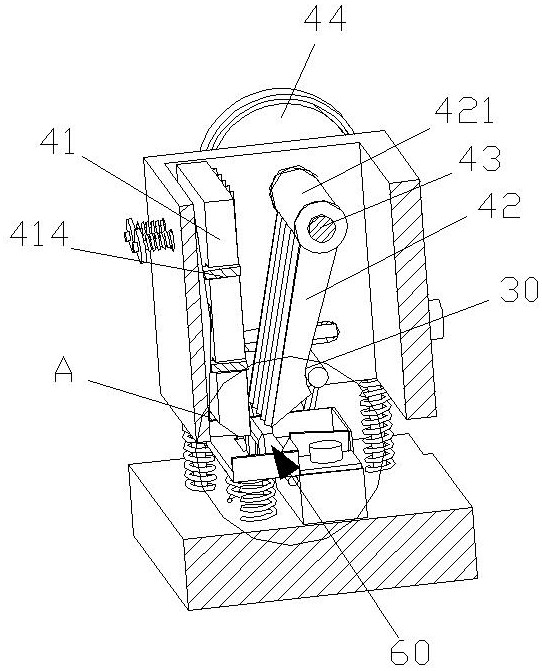

Explosion device of filling pile head and construction method thereof

PendingCN106996107AReduce the difficulty of breakingImprove the efficiency of demolition workBulkheads/pilesRebar

The invention discloses an explosion device of a filling pile head. The explosion device comprises a plurality of coaxial annular protective cylinders, wherein the tops of the annular protective cylinders are fixedly connected into an integral device body by virtue of a connecting device, a main reinforcement positioning interlayer is arranged in a gap between the outmost annular protective cylinder and the adjacent annular protective cylinder of the device body, and a lifting ear plate and a rebar through bracket which enables support rebar of a reinforcement cage to pass through and is used for positioning the support rebar of the reinforcement cage are fixed to the top of the device body. According to the explosion device, the bonding strength between the main reinforcement and concrete of the pile head is reduced, the risk of easy damage to the main reinforcement is eliminated, additionally, the pile head are changed into small blocks, the pile head can be exploded block by block, the performance requirement on lifting equipment is reduced, the construction efficiency and application range of the explosion construction of an original pile head are improved, the construction dust is reduced, and the construction cost is reduced.

Owner:CCCC SECOND HARBOR ENG

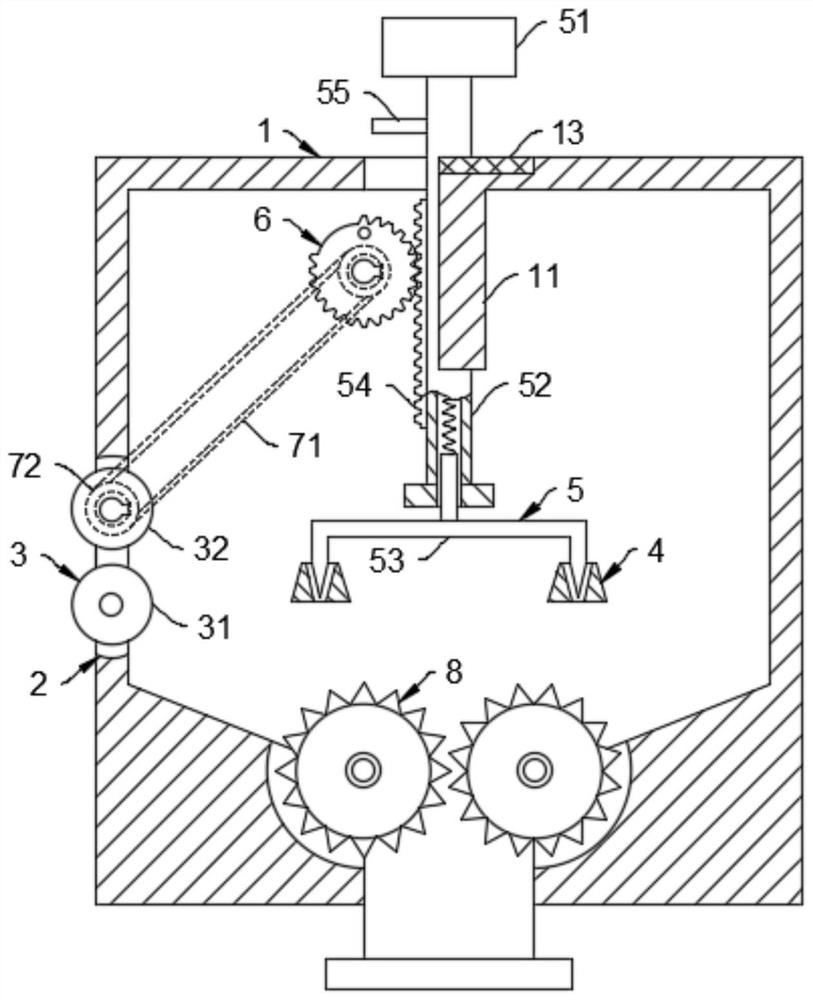

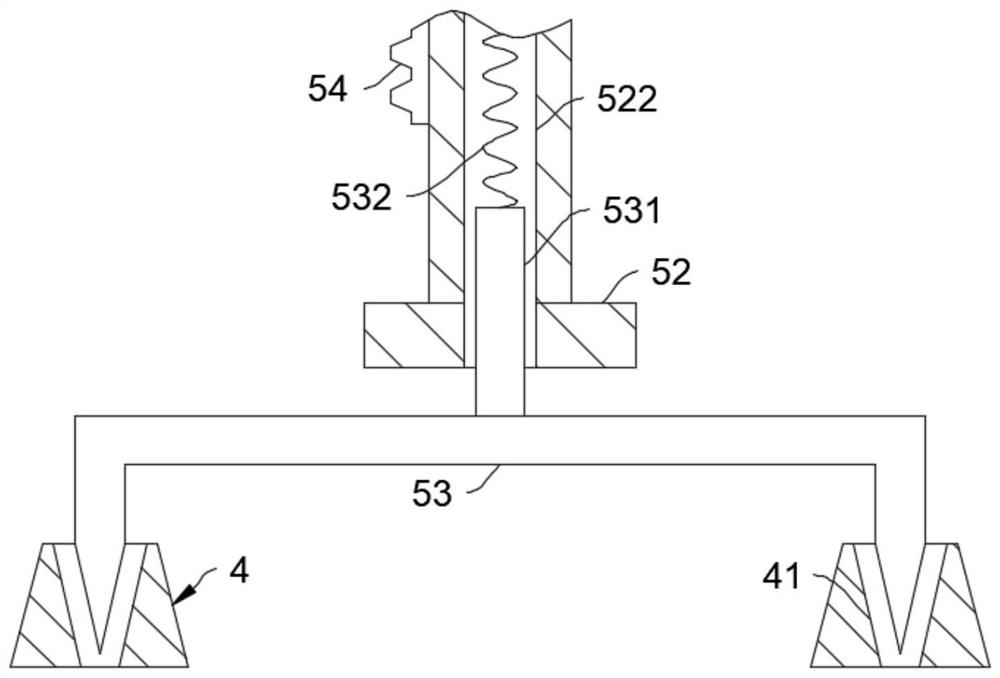

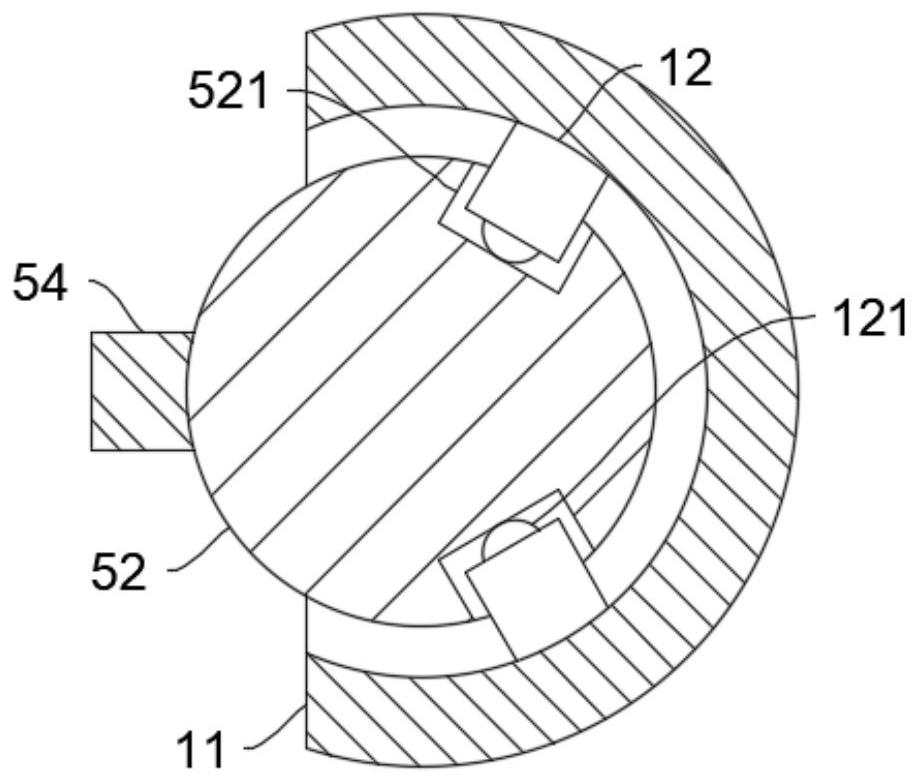

Crusher for waste plastics

InactiveCN108214999AReduce the difficulty of breakingReduce crushing timePlastic recyclingGrain treatmentsPulp and paper industryCrusher

The invention relates to a crusher for waste plastics. The crusher comprises a rack and a crushing barrel, wherein the crushing barrel is fixed on the rack and is communicated with a feeding channel;the crushing barrel is internally and rotatably connected with a crushing mechanism; the feeding channel is connected with a pushing plate in a sliding way; a first piston cylinder is fixed on the rack; a first piston is connected in the first piston cylinder in a sliding way; a first wedge groove is formed in the pushing plate; a first wedge rod, inserted into the first wedge groove, is fixed onthe rack; a third spring is connected between the first wedge rod and the rack; a second wedge groove is formed in the first wedge rod; a second wedge rod, inserted into the second wedge groove, is fixed on the first piston; the first piston cylinder is communicated with an air inlet pipe; the rack is provided with an air inflating mechanism, and the air inflating mechanism is communicated with the air inlet pipe; the piston cylinder is also communicated with an air outlet pipe; an inclined plate, opposite to the pushing plate is fixed in the crushing barrel. Compared with the prior art, the crusher can be used for preliminarily crushing the waste plastics by means of the pushing plate and the inclined plate which are cooperatively used, so that the production efficiency is improved.

Owner:宁波得晴电器科技有限公司

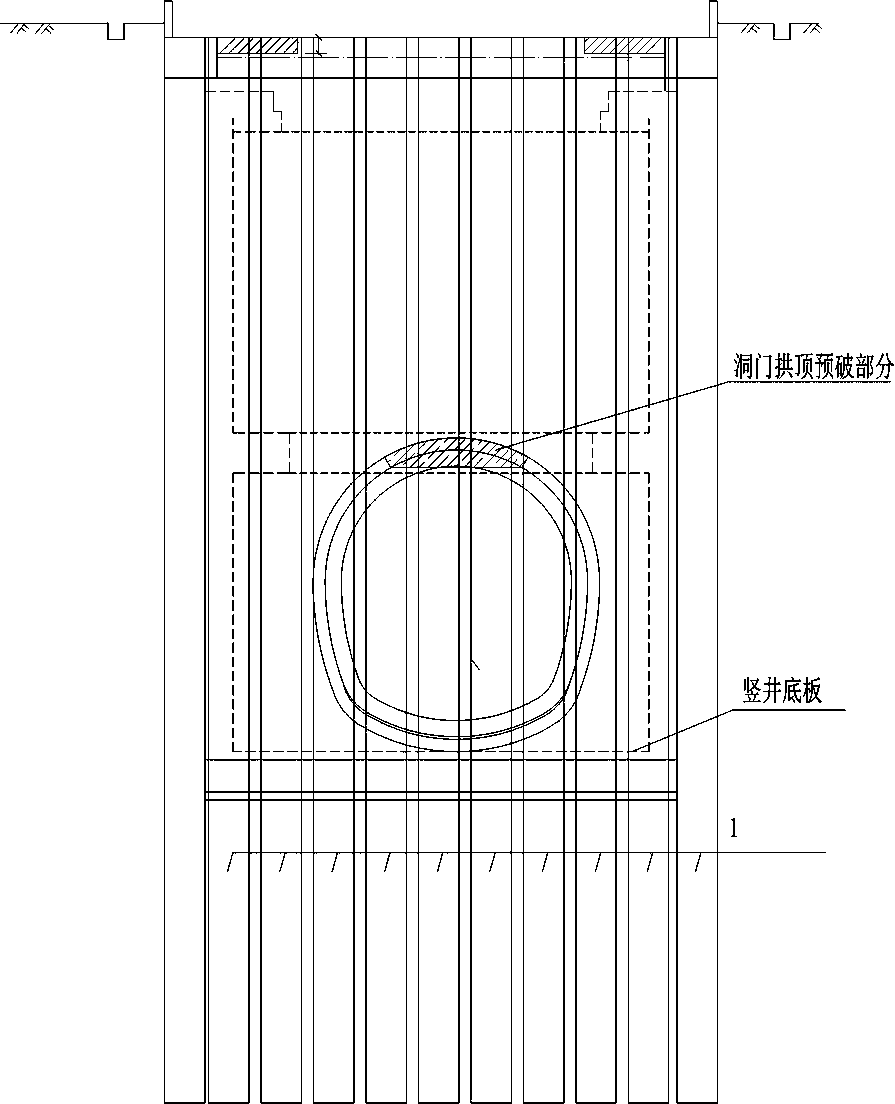

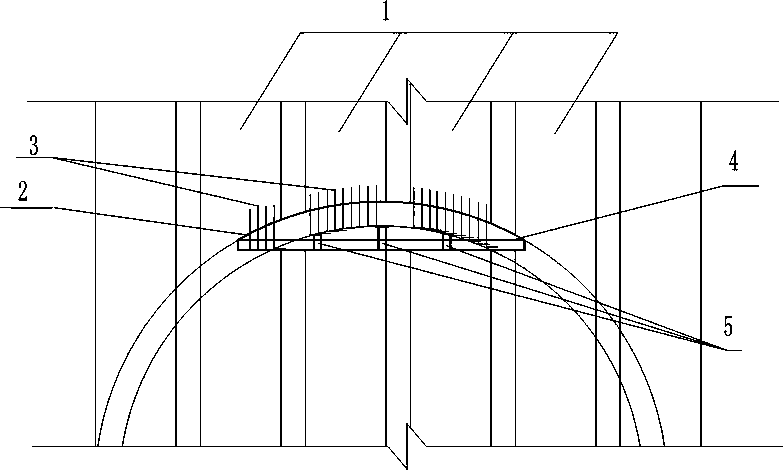

Construction method for subway tunnel to enter subsurface excavation interval tunnel door from shaft

ActiveCN110145328AEnsure safetyAvoid breakingUnderground chambersTunnel liningStructural engineeringEngineering

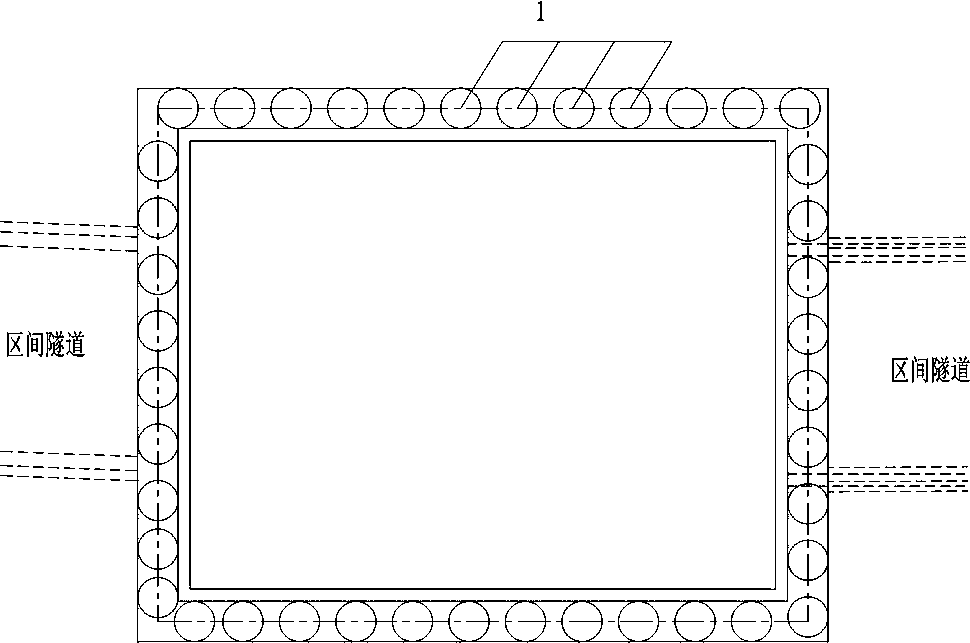

Provided is a construction method for a subway tunnel to enter a subsurface excavation interval tunnel door from a shaft. According to the construction method, a pre-hanging structure for the arch portion of the tunnel door is designed in the stage of excavation from the shaft to the top elevation position of the tunnel door; when the shaft is excavated to the arch portion of the tunnel door, parts of enclosure piles are broken ahead under effective construction monitoring, and construction of the arch portion of the tunnel door is carried out; the construction of the part which may require reverse breaking of the arch portion of the horsehead of the interval subsurface excavation tunnel is carried out in advance, the conventional construction methods which may involve the high-place operation of a bracket at the bottom of the shaft and the safety hazard caused by manually upwardly breaking enclosing piles can be effectively avoided, the operation difficulty and construction risks of similar engineering processes are lowered, the processing requirements of the bad formation during the operation are avoided, and meanwhile the construction period can be shortened to a certain extent.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

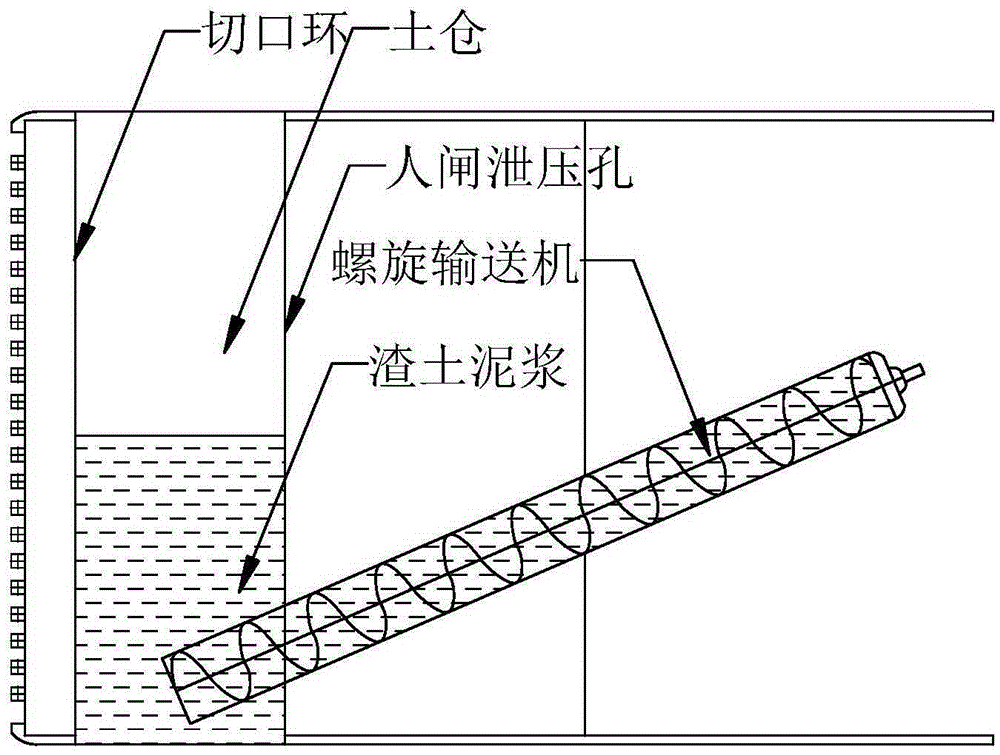

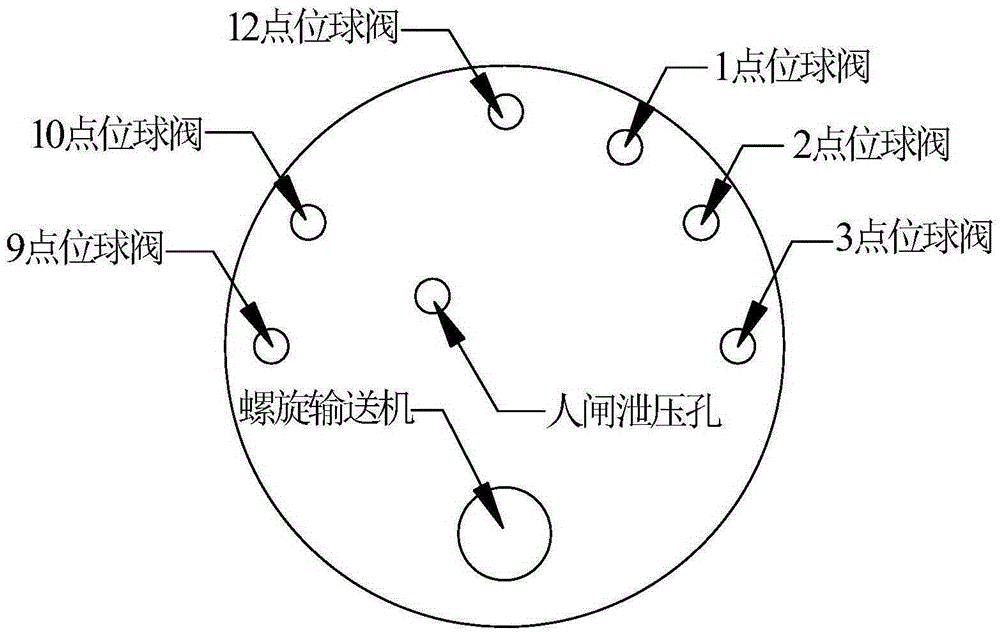

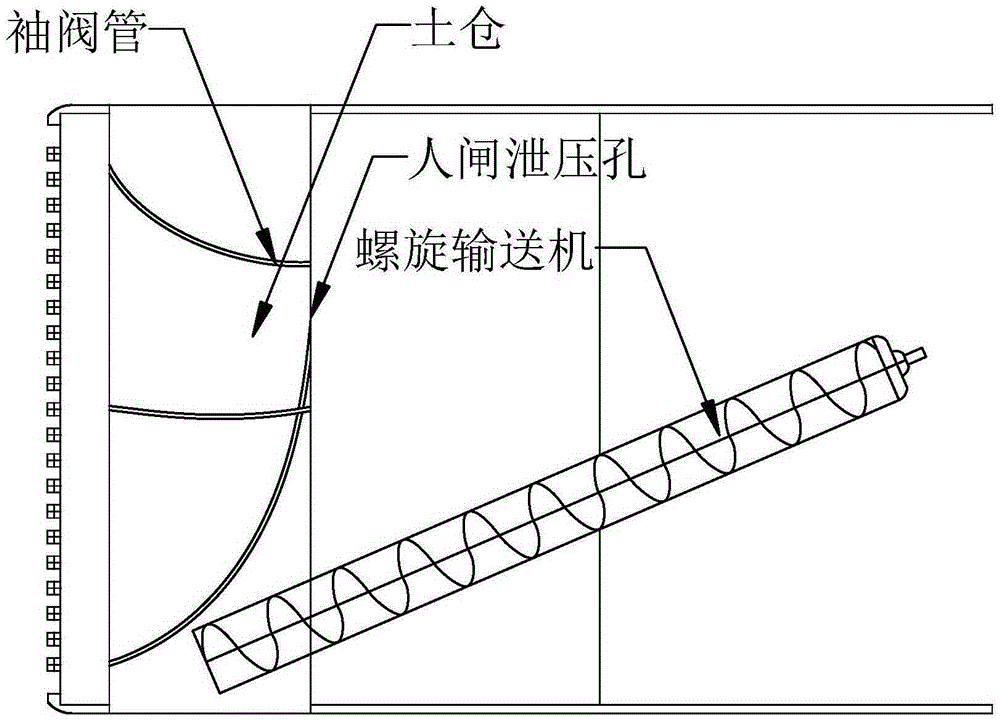

Reinforced warehouse-filling cutter-replacement construction method in shield tunneling machine warehouse

InactiveCN105257306AReduce the difficulty of breakingAvoid advanced grouting construction workTunnelsStructural engineeringSlurry

The invention provides a reinforced warehouse-filling cutter-replacement construction method in a shield tunneling machine warehouse. The method comprises the following steps: the first step: grouting a soil warehouse with bentonite slurry; the second step: replacing muck and slurry in the soil warehouse with air; the third step: filling gaps under pressure; the fourth step: connecting sleeve valve tubes; the fifth step: grouting cement mortar to backfill the soil warehouse; the sixth step: injecting an accelerator into cement mortar at the front part of the soil warehouse, and injecting a retarder into cement mortar at the rear part of the soil warehouse; the seventh step: cleaning up the soil warehouse for cutter replacement; the eighth step: recovering tunneling. With the adoption of the method provided by the invention, the difficult pre-grouting construction operation is avoided, the situation that equipment is damaged due to hardening of cement mortar in a screw conveyer is prevented, a grouting construction operation mode is defined, the difficulty of breaking and removing hardened bodies in the soil warehouse is reduced, the workload for cleaning up the warehouse is reduced effectively, the construction time is short, the efficiency is high and the safety is high.

Owner:SHANGHAI JIAO TONG UNIV

Method for using granite waste to prepare raw materials for producing ceramic

InactiveCN107721386AEnhanced magnetic forceLower iron levelsCeramic materials productionClaywaresMagnetic separatorSlurry

The invention discloses a method for using granite waste to prepare raw materials for producing ceramic, and belongs to the technical field of recycling of the granite waste. The method comprises thesteps of pulverizing the granite waste in a graded mode and then adding water to grind the granite waste into stone slurry with specific grain composition; conducting preliminary magnetic separation on the stone slurry in a magnetic separator at 15,000 G-16,000 G; then diluting the stone slurry till the solid content is 20 wt%-30 wt%, and then conducting further magnetic separation on the stone slurry in a magnetic separator at 50,000 G-60,000 G; dewatering and drying the stone slurry which is subjected to further magnetic separation. By firstly pulverizing the granite waste and grinding the granite waste into the grain composition with specific size, the specific strong magnetic field of the magnetic separator is fully utilized as much as possible, the magnetic force on iron is increased,95% or above of iron is removed, and then by conducting dilution and using the specific strong magnetic field of the magnetic separator again to remove residual iron, the iron content in final products is lowered.

Owner:广西烽顺新材料有限公司

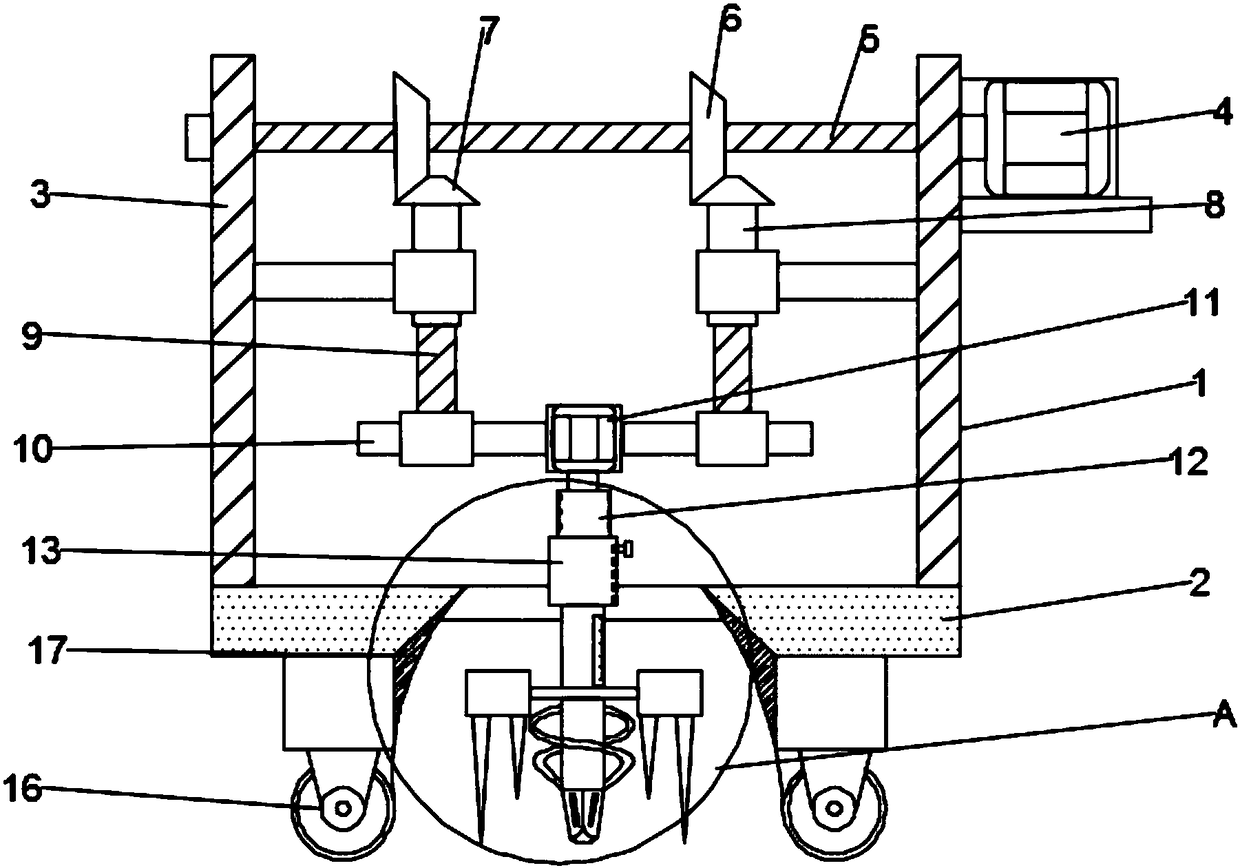

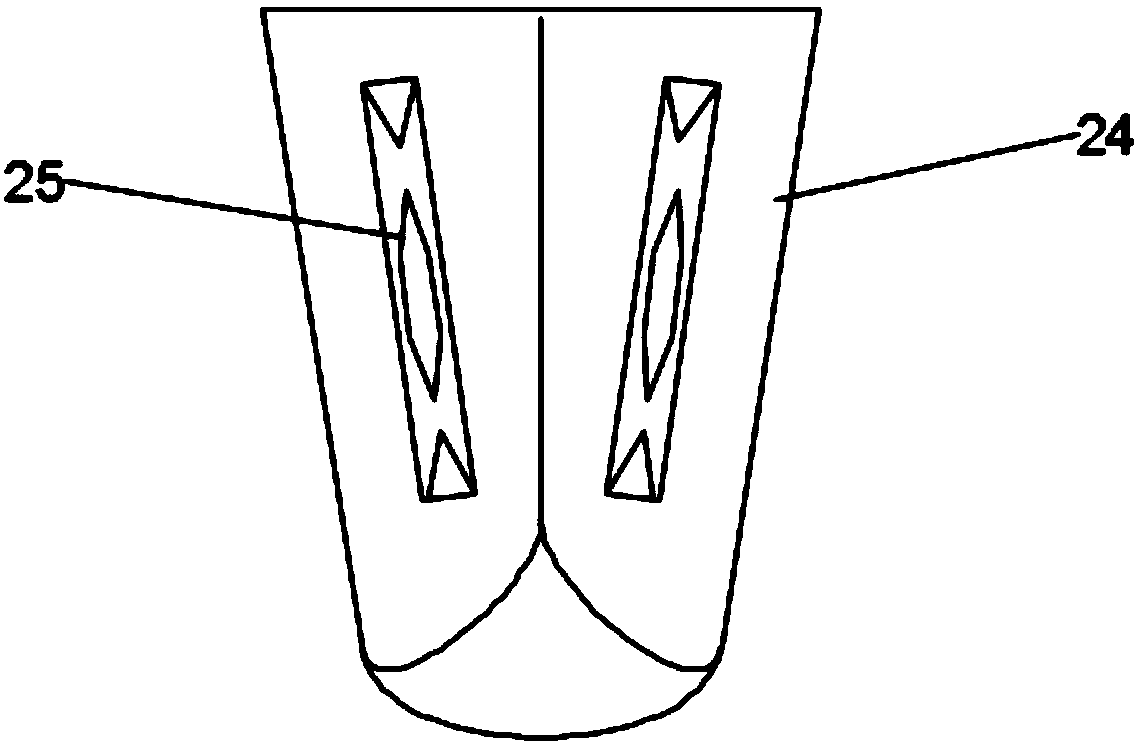

Concrete pile head crushing device

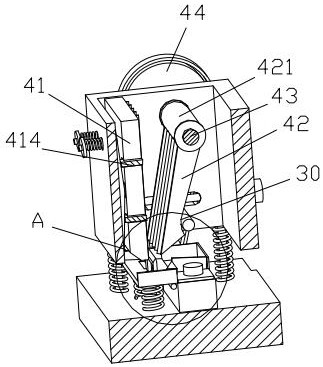

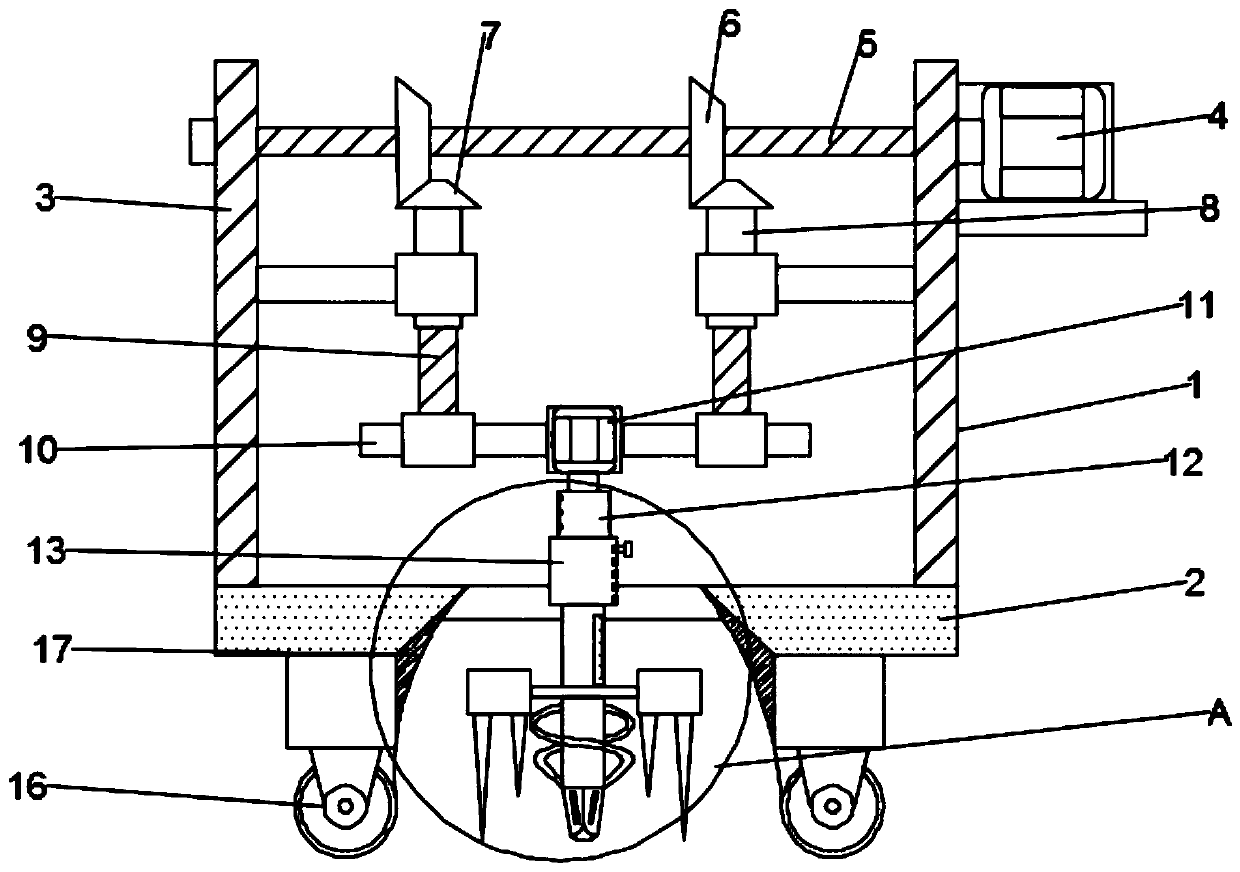

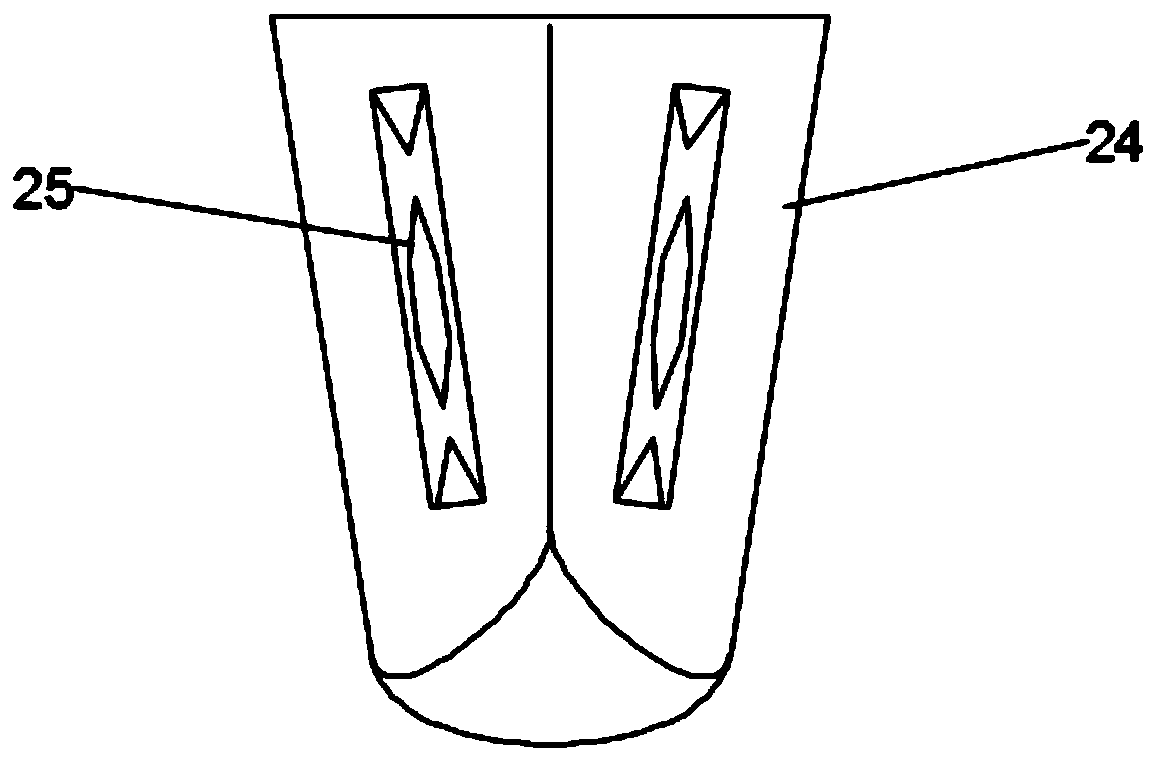

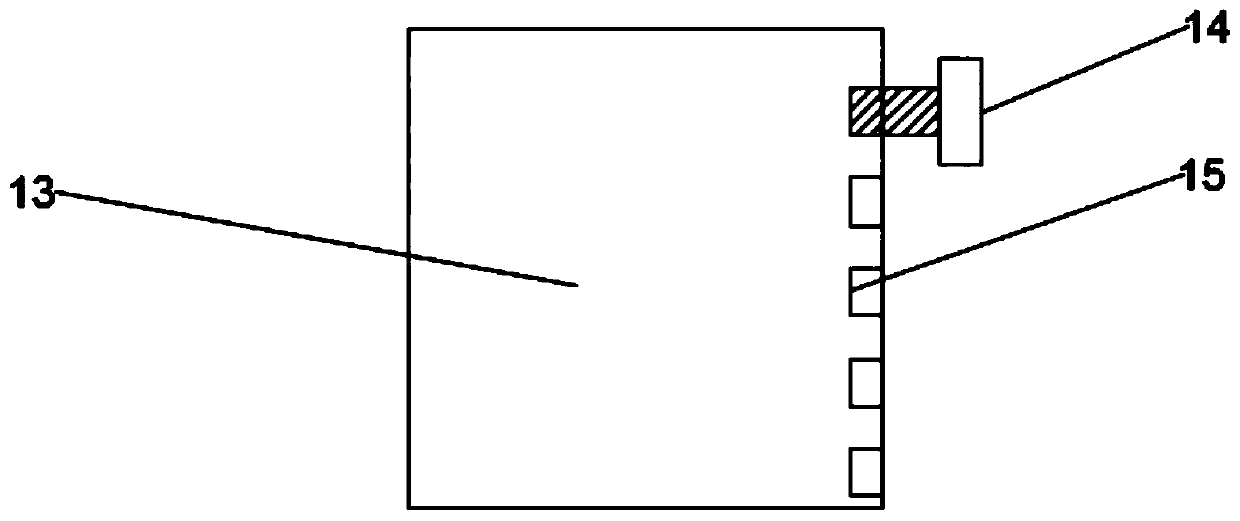

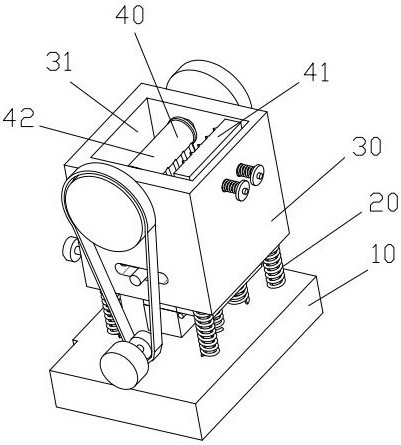

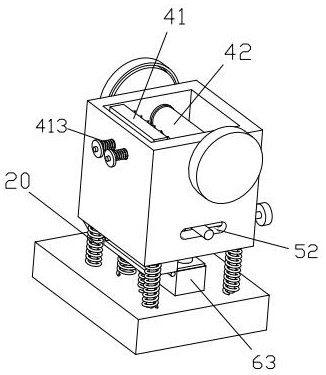

InactiveCN108532598AAchieve looseningAvoid accumulationBulkheads/pilesThreaded pipeElectric machinery

The invention discloses a concrete pile head crushing device. The device comprises a machine body, a movable base and supporting arms, wherein the movable base is arranged at the bottom of the machinebody, rolling wheels are installed at four corners of the bottom of the movable base, and the supporting arms are welded on the two sides of the upper surface of the movable base; a rotating shaft ishorizontally arranged at the upper part of the machine body, and the machine body is characterized in that the left end of the rotating shaft is rotationally connected with the supporting arms on theleft side, and the right end of the rotating shaft penetrates through the supporting arms on the right side and extends to the right side of the machine body; and a first servo motor is arranged on the right upper portion of the machine body, the right end of the rotating shaft is welded with an output shaft of the first servo motor, the rotating shaft is provided with two first bevel gears withthe same size, an inner threaded pipe is vertically arranged below the rotating shaft, and the lower end of the inner threaded pipe is connected with a screw rod in a rotating mode. According to the device, the design is reasonable, the pile head which can be crushed is quickly realized, time and labor are saved, the construction difficulty is lowered, the life safety of constructors is guaranteed, and the device is suitable for popularization.

Owner:张显

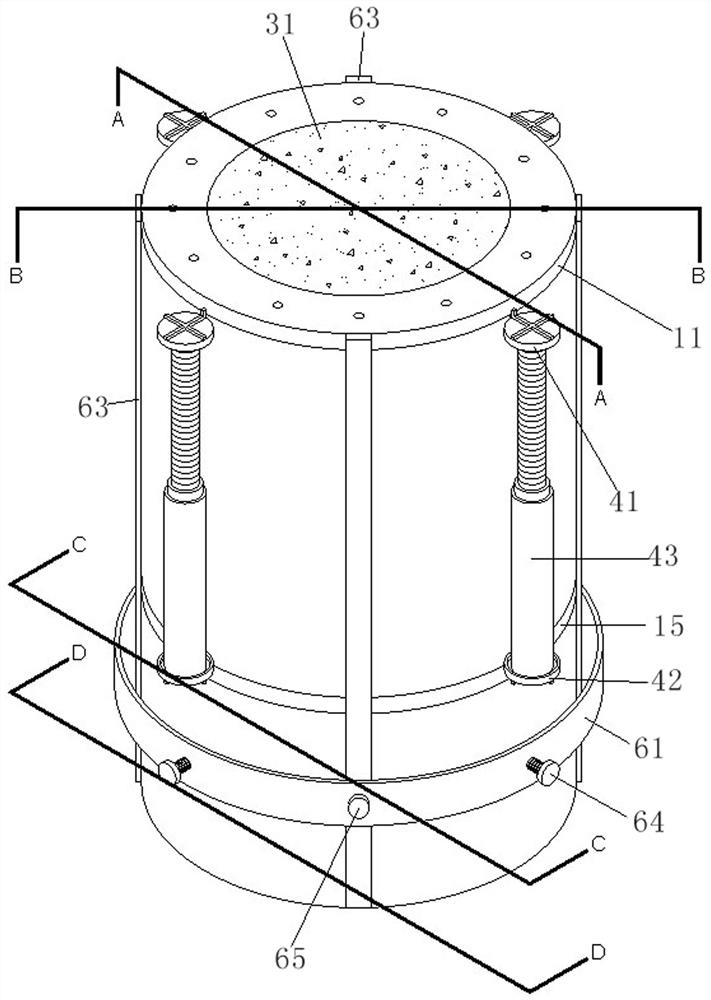

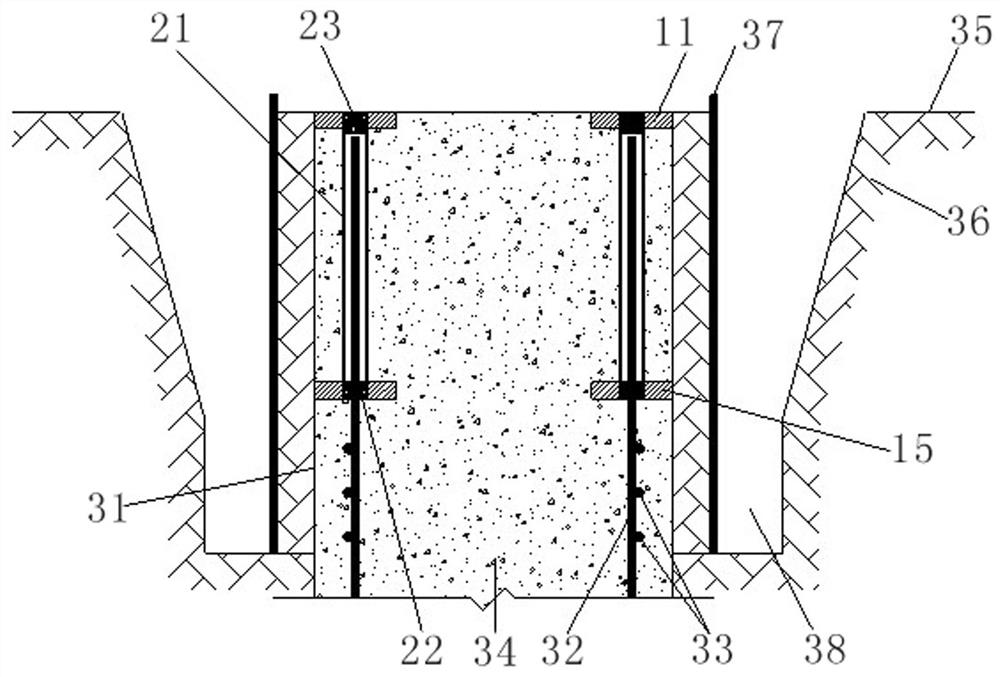

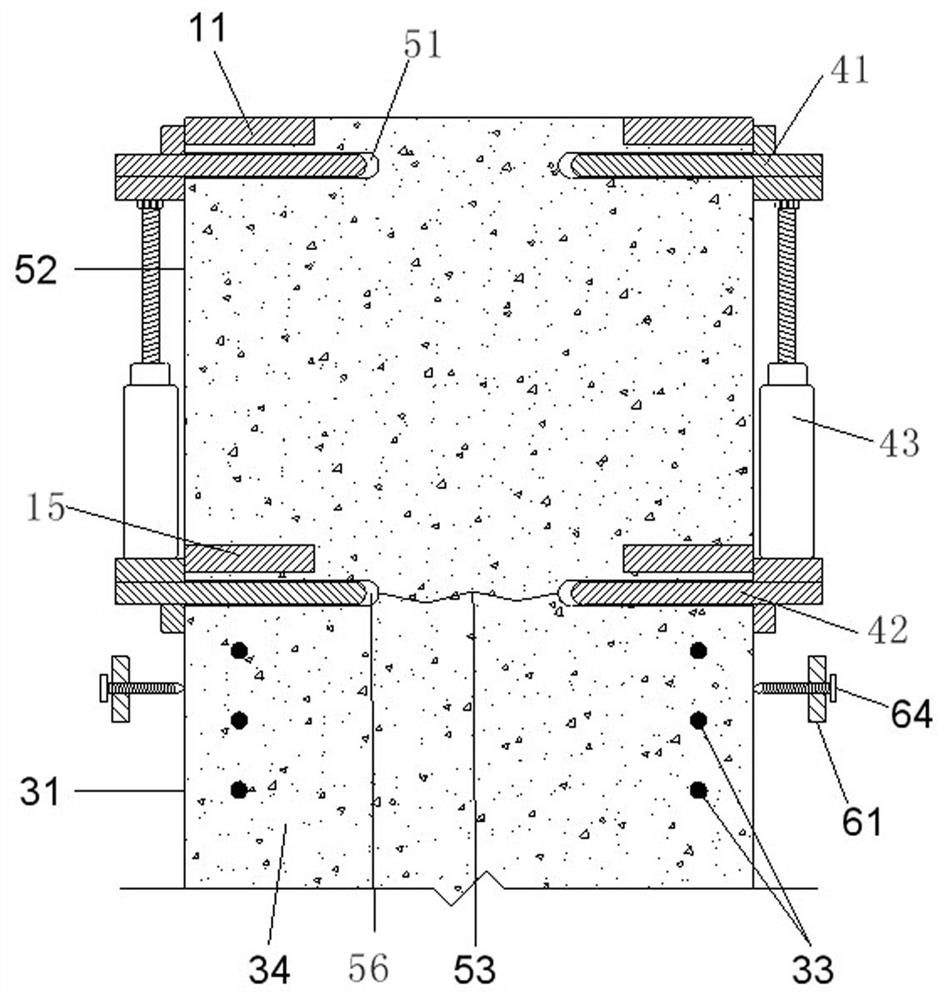

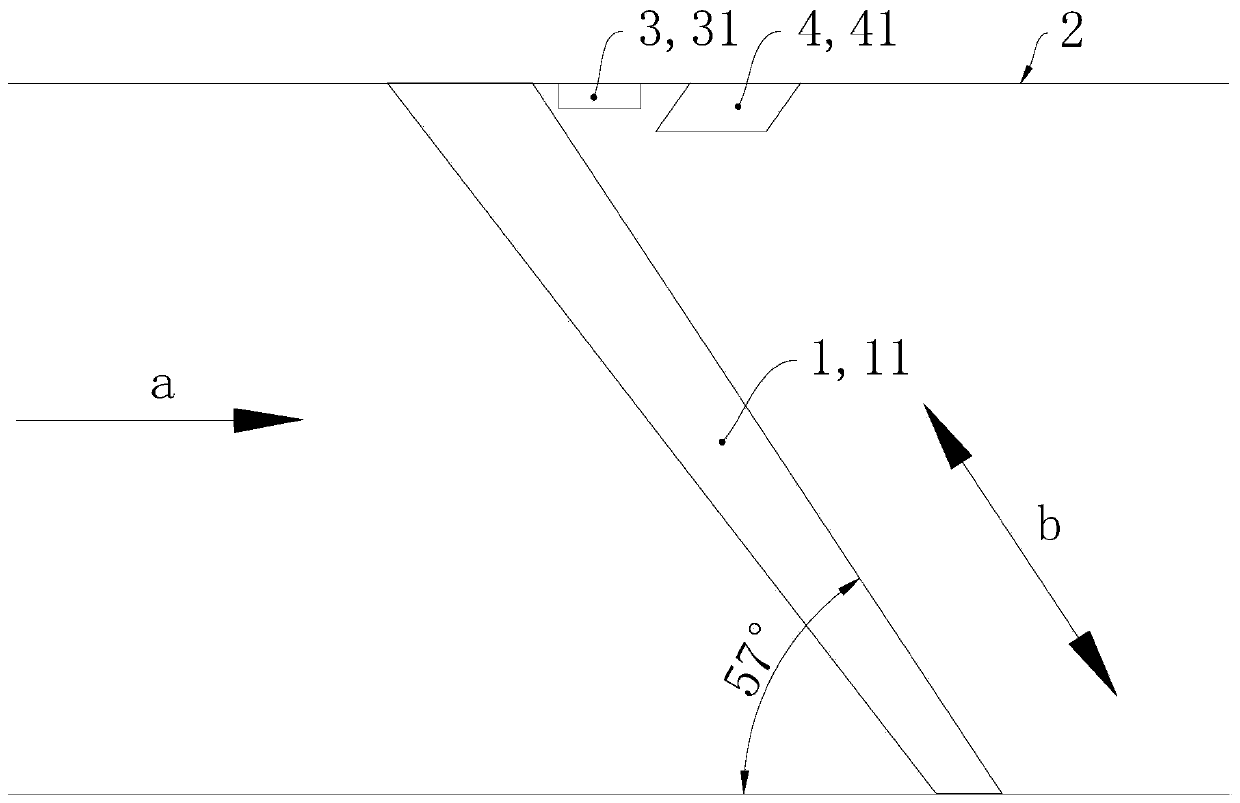

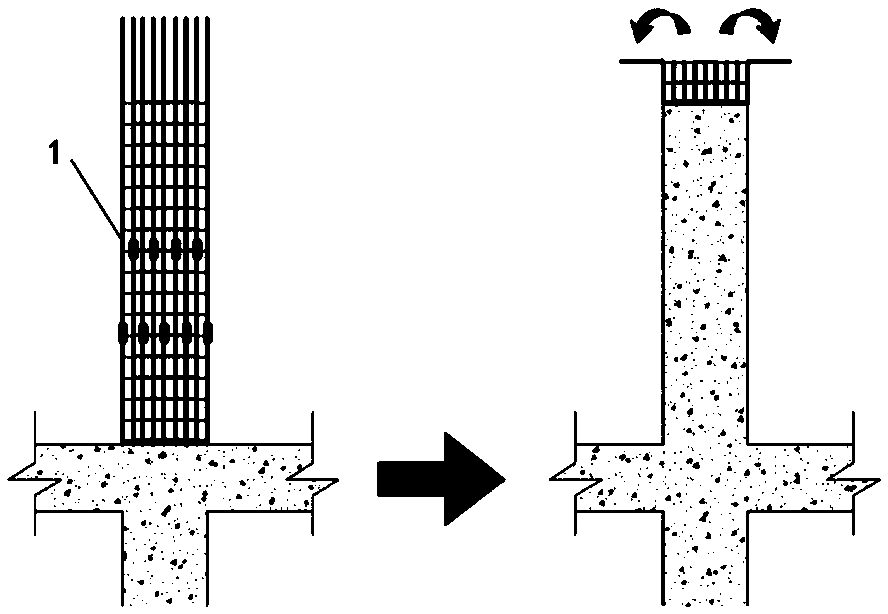

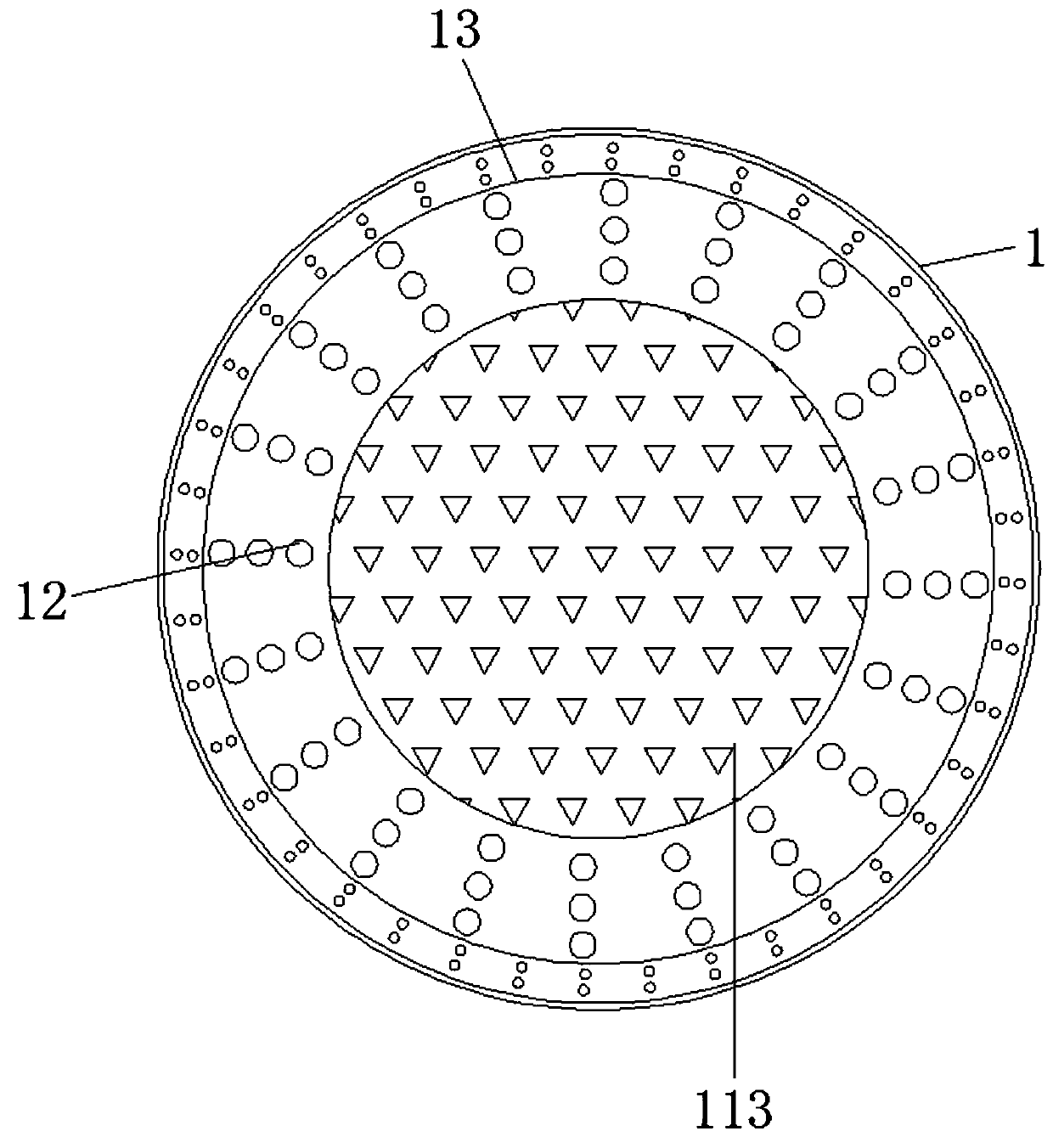

Large-diameter cast-in-situ bored pile head overall breaking system and construction method

The invention belongs to the technical field of cast-in-situ pile construction. A large-diameter cast-in-situ bored pile head overall breaking system comprises a pile head separation support, isolation sleeves, a first counter-force frame, a second counter-force frame and a driving part, wherein the first counter-force frame and the second counter-force frame are correspondingly arranged up and down; the multiple isolation sleeves are arranged on the pile head separation support, longitudinal main ribs on the upper portion of a steel reinforcement cage of a cast-in-situ pile are arranged in the isolation sleeves in a matched and penetrating manner, and the pile head separation support and the isolation sleeves are poured on the top of the cast-in-situ pile; and a plurality of first counter-force holes are circumferentially distributed in a pile head of the cast-in-situ pile, a plurality of second counter-force holes are circumferentially distributed in the position, on the lower portion of the pile head separation support, of the cast-in-situ pile, and the first counter-force frame and the second counter-force frame are correspondingly arranged in the first counter-force holes and the second counter-force holes correspondingly. The invention further discloses a large-diameter cast-in-situ bored pile construction method. The large-diameter cast-in-situ bored pile head overall breaking system is reasonable in overall design, the problem existing in breaking of the pile head of the large-diameter cast-in-situ bored pile in the prior art can be solved, the breaking efficiency is improved, and the structural damage to a pile body is reduced.

Owner:HENAN HIGHWAY ENG GROUP +1

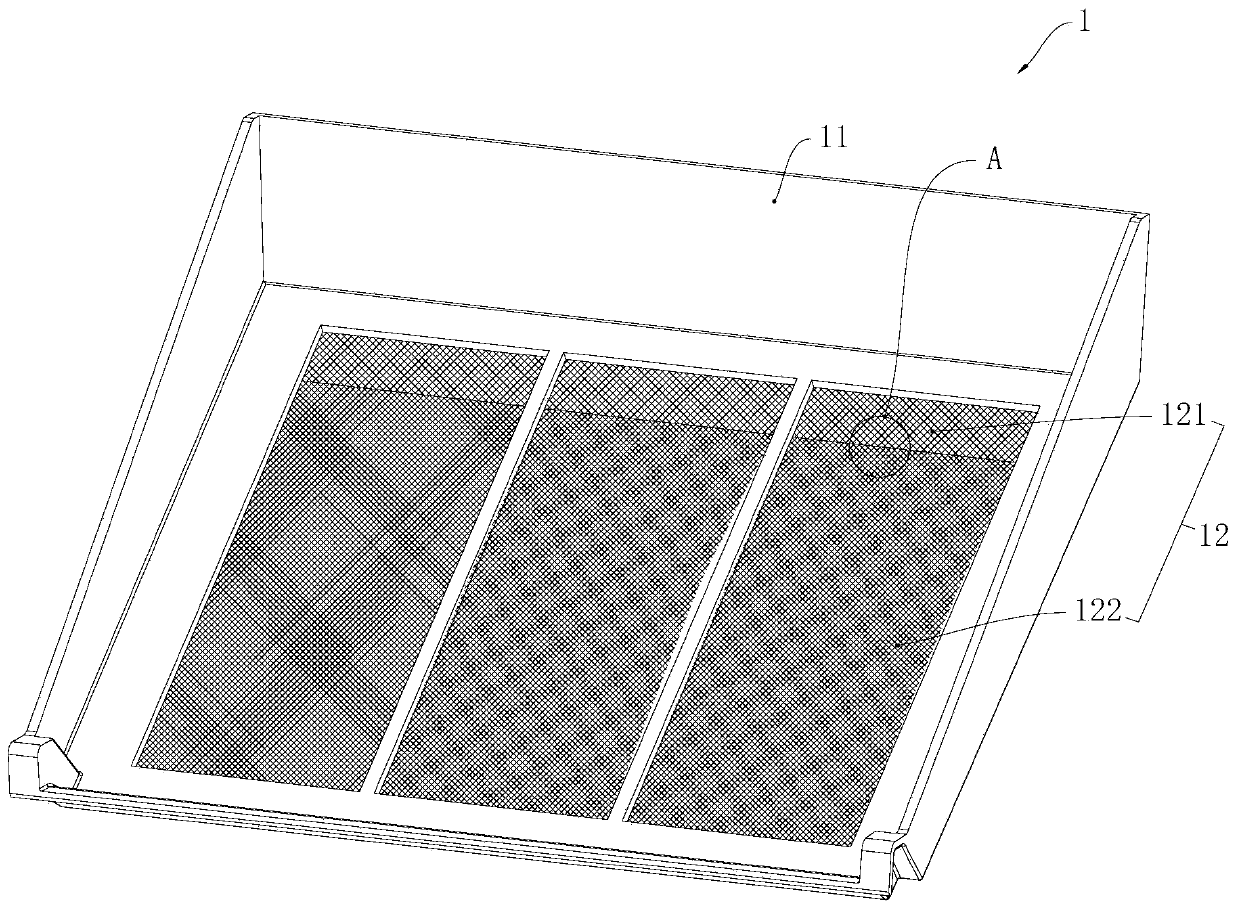

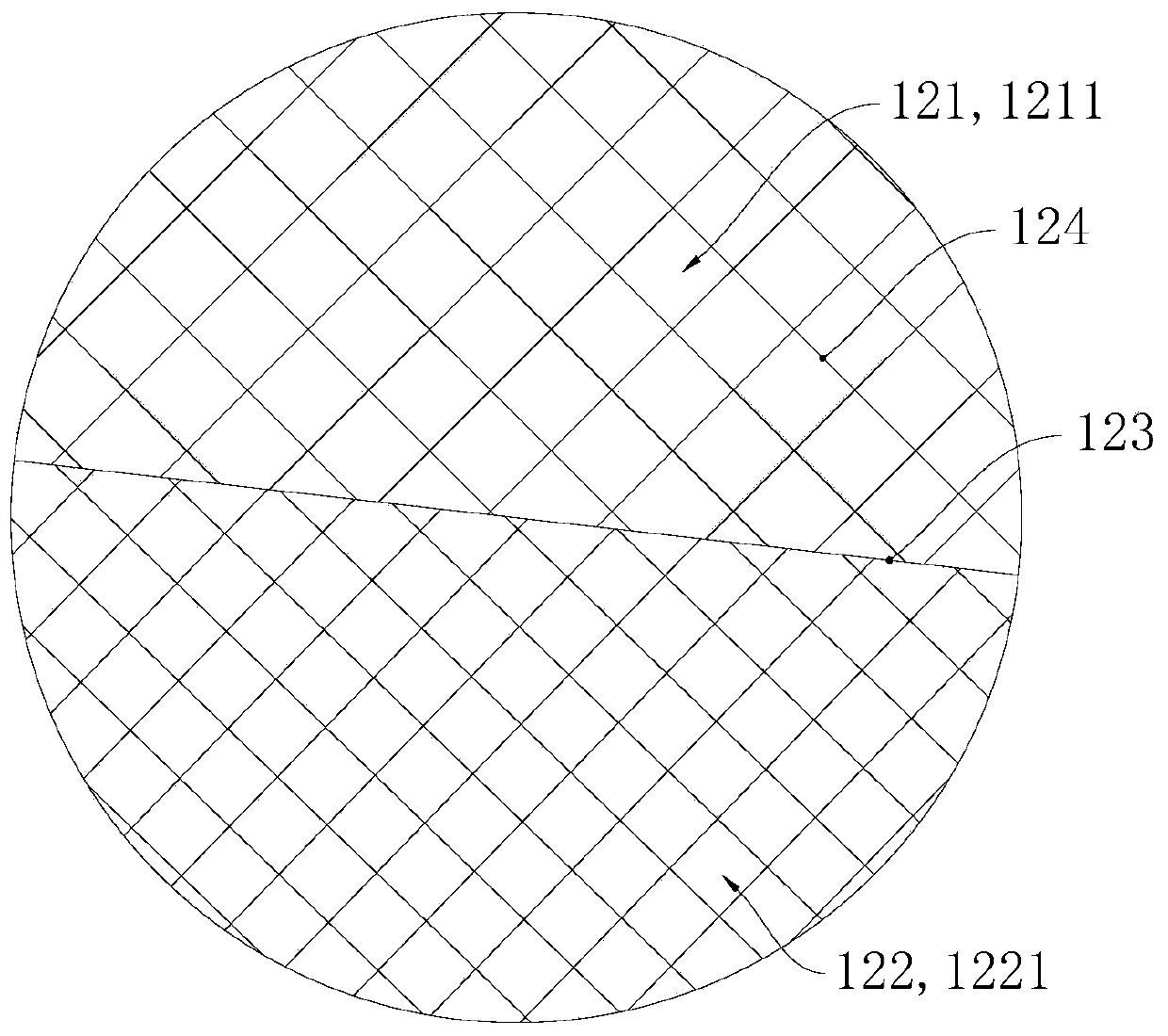

Clothes drying system, clothes dryer and clothes washing and drying integrated machine

PendingCN111235844AAvoid affecting normalityReduce the difficulty of breakingWashing machine with receptaclesTextiles and paperProcess engineeringMechanical engineering

The invention relates to the field of clothes drying equipment. A clothes drying system comprises a filter screen, a spraying device and an air channel; the filter screen is installed in the air channel; the filter screen comprises a base frame and a screen surface arranged in the base frame; the spraying hole of the spraying device is towards the screen surface; the screen surface has a first area and a second area; multiple first meshes are distributed in the first area; multiple second meshes are distributed in the second area; and the cross section area of a single first mesh is larger than that of a single second mesh. The invention further provides a clothes dryer and a clothes washing and drying integrated machine by adopting the clothes drying system. The rupture difficulty of a water film in the first area is easily reduced; rupture of the water film in the first area drives rupture of the water film in the second area; therefore, the rupture difficulty of the water film on the whole screen surface is easily reduced; therefore, when the clothes drying system runs, the water film on the screen surface can be ruptured smoothly; air easily circulates in the air channel; and influence on the normal performance of the clothes drying system is easily avoided.

Owner:GREE ELECTRIC APPLIANCES INC

Printed paper product recycling method

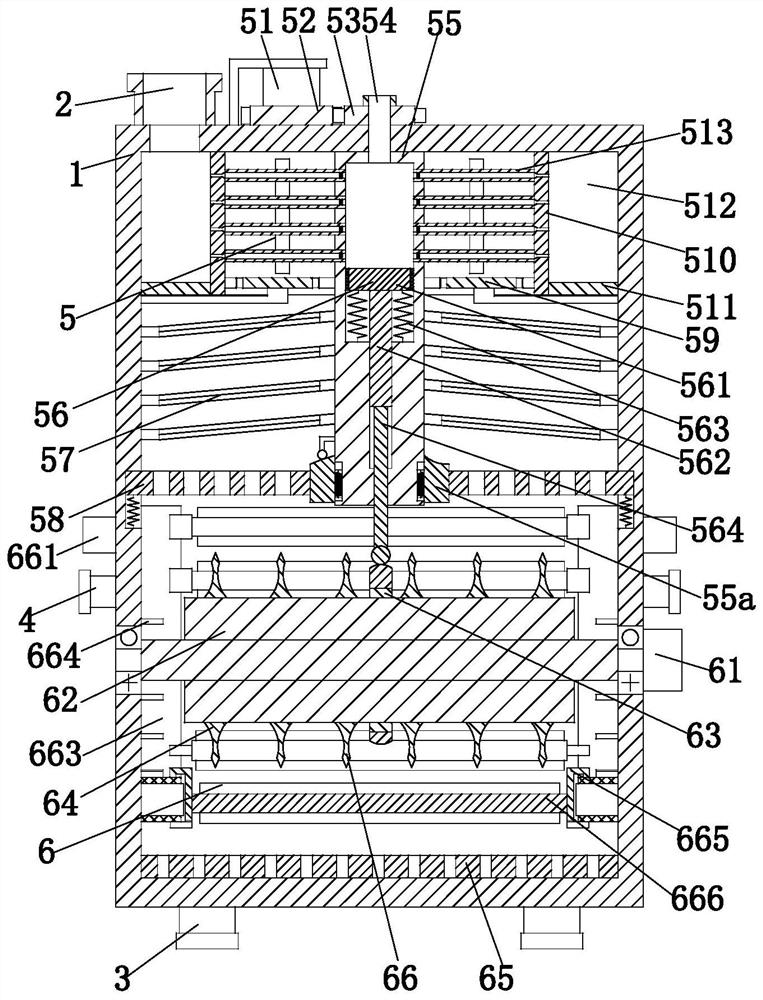

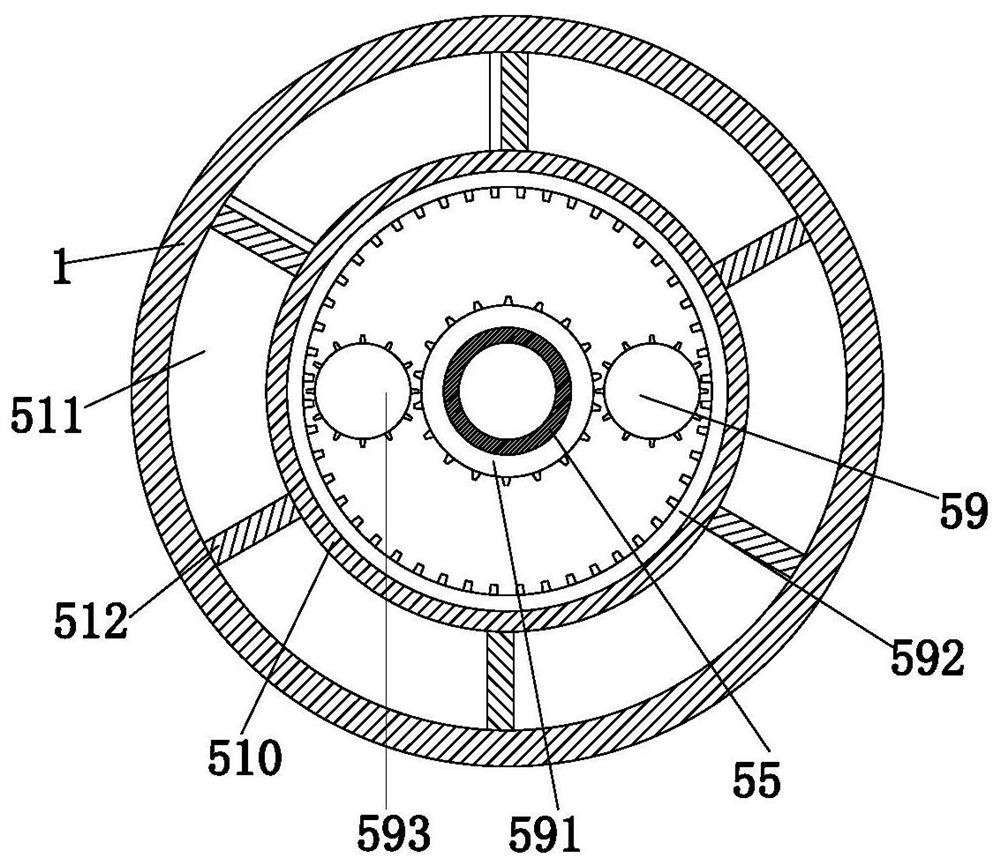

InactiveCN112030587AReduce the difficulty of breakingFully contactedPaper recyclingSecondary cellulose fibresCompression moldingGear wheel

The invention relates to a printed paper product recycling method, which uses pulping equipment. The pulping equipment comprises a shell, a feeding pipe, a discharging pipe, a water inlet pipe, a crushing device and a pulping device. The specific method for recycling printed paper products by adopting the pulping equipment comprises the steps of classifying and recycling, crushing and pulping, deinking and bleaching, compression molding and paperboard cutting. The crushing device comprises a driving motor, a driving gear, a driven gear ring, a connecting pipe, a driving rotating shaft, a spraying mechanism, a crushing cutter, a first sieve plate, a transmission mechanism, a baffle ring, a supporting plate, a partition plate and a water spraying pipe. Through the cooperation of the crushingdevice and the pulping device, the function of making waste paper printed matter into paper pulp is achieved, paper products can be wetted in advance before crushing so as to reduce the crushing difficulty, the homogenizing mechanism can continuously stir the pulp in the pulping process, and the paper pulp at all positions can make full contact with crushing blades.

Owner:株洲市红三角包装印刷有限责任公司

Industrial waste residue crushing method

PendingCN112456839AAutomatic frictionConvenient crushing operationProcess engineeringToxic industrial waste

The invention discloses an industrial waste residue crushing method, which comprises the following operation steps: mixing various industrial waste residues with one another, and putting the mixture into a stirrer for preliminary stirring; heating and cooling circulation: carrying out primary crushing on the mixture obtained by primary stirring by adopting a hammer type crushing device, heating the mixture subjected to primary crushing to 700 DEG C or above, cooling the mixture to 300 DEG C or below at a cooling speed of 100 DEG C / min or above, heating the mixture to 700 DEG C or above at a heating speed of 20 DEG C / min or above, cooling the mixture to be below 300 DEG C at a cooling speed of 100 DEG C / min or above, and circulating for more than two times; and carrying out secondary crushing on the mixture by adopting a hammer type crushing device, cooling and sieving to obtain industrial waste residue powder. The industrial waste residue crushing method can effectively improve the crushing efficiency of industrial waste residues, reduce the crushing difficulty and improve the crushing fineness.

Owner:罗定市宏泰建材有限公司

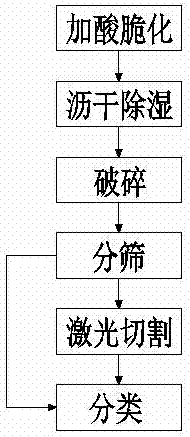

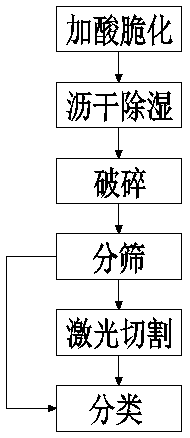

Crushing method for nitrided ferrovanadium

The invention discloses a crushing method for nitrided ferrovanadium. The crushing method for the nitrided ferrovanadium comprises the following steps: a, adding an acid into an acidification pond to perform acidifying and embrittling on the nitrided ferrovanadium to be crushed; b, draining an acid liquid, and drying the acid liquid on the surface of a nitrided ferrovanadium raw material; c, crushing by using a crushing roller; d, screening the crushed nitrided ferrovanadium raw material according to particle sizes; e, performing laser cutting on the nitrided ferrovanadium with the particle sizes of above 100 mm to make the average particle size of the nitrided ferrovanadium less than 100 mm; and f, holding the nitrided ferrovanadium in a classified manner by taking every 10 mm as a classifying grade according to the particle sizes. According to the crushing method for the nitrided ferrovanadium, the overall toughness of the nitrided ferrovanadium is reduced after the nitrided ferrovanadium is acidified, and then the nitrided ferrovanadium is crushed into specified particle sizes; the crushing difficulty of the nitrided ferrovanadium is reduced; the loss of equipment is reduced; the crushing cost of the nitrided ferrovanadium is reduced; and the crushing work production efficiency of the nitrided ferrovanadium is improved.

Owner:HUNAN ZHONGXIN NEW MATERIALS TECH

Recycling method of waste plastic barrels

InactiveCN110509454AReduce the difficulty of breakingReduce dosagePlastic recyclingMechanical material recoveryHigh concentrationRecovery method

The invention discloses a recycling method of waste plastic barrels. The method comprises the steps of pouring residual liquid of the plastic barrels, crushing at low temperature, cleaning, friction separation, dehydration and drying. According to the resource recycling method of the waste plastic barrels, the waste liquid with high concentration in the plastic barrels can be removed in a centralized way by introducing vacuum liquid removal and air breaking according to the characteristics of dangerous waste plastic packaging barrels, so that the introduction of excessive residual liquid in the subsequent process is avoided. The plastic barrels become brittle at a low temperature, the crushing difficulty is greatly reduced, the crushing time is shortened, and the crushing efficiency is improved, so that the defects of large water consumption and large time consumption of the water-carrying crushing process in the prior art are overcome, the waste liquid in the waste plastic barrels isrecycled, and the consumption of the waste water is reduced by about 60 percent compared with the process in the prior art.

Owner:南通天地和环保科技有限公司

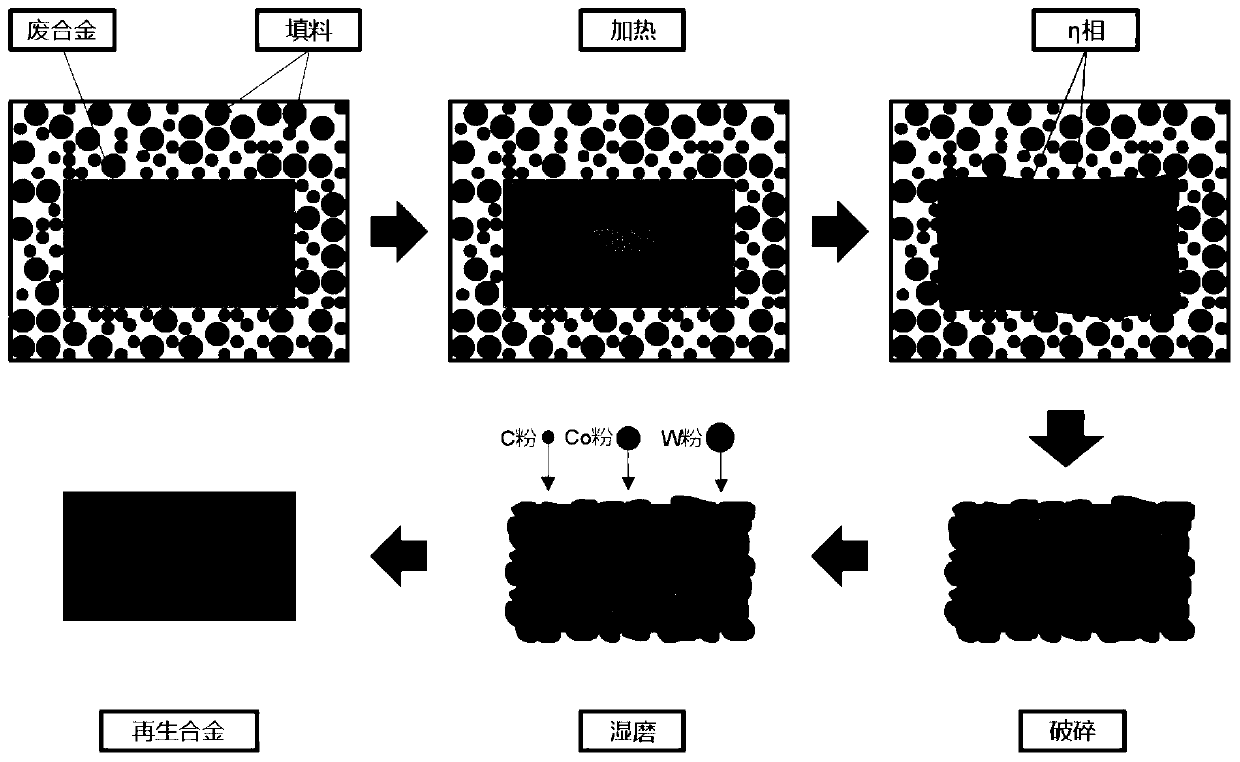

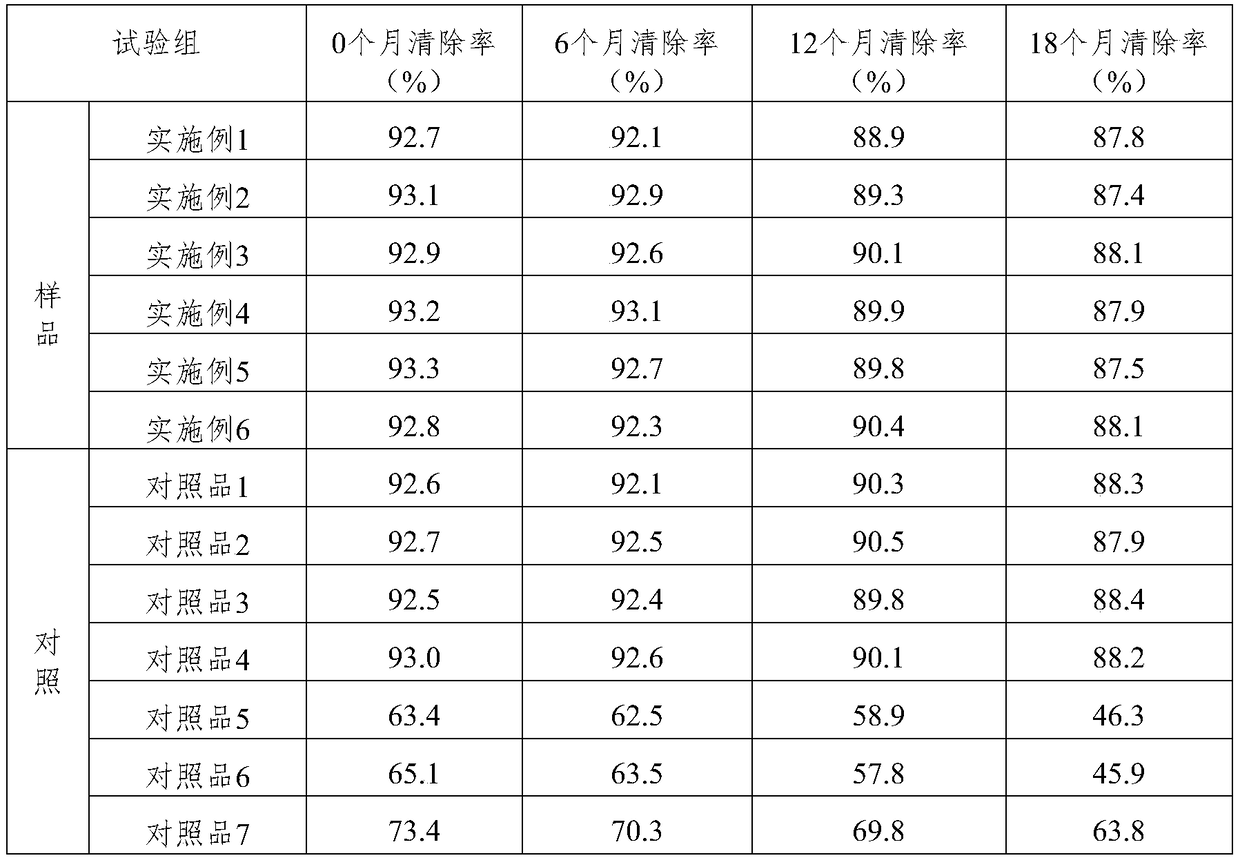

Regeneration method of waste high-cobalt coarse-grain hard alloy

ActiveCN111575567AReduce energy consumptionReduce the difficulty of breakingCemented carbideDecarburization

The invention discloses a regeneration method of a waste high-cobalt coarse-grain hard alloy. The regeneration method comprises the following steps that (1) the waste high-cobalt coarse-grain hard alloy is buried into a decarburization filler, and the calcination treatment is carried out in a decarburization atmosphere; the decarburization filler is one or two of aluminum oxide and magnesium oxide; (2) the waste hard alloy subjected to the calcination treatment in the step 1 is crushed and sieved, and waste hard alloy powder is obtained; and (3) Co powder and C powder are added into the wastehard alloy powder obtained in the step (2) according to the structure and components of a regenerated alloy, the Co powder, the and C powder and the waste hard alloy powder are uniformly mixed, the granulation, pressing and sintering are carried out to obtain the regenerated hard alloy. According to the regeneration method of the waste high-cobalt coarse-grain hard alloy, the high-cobalt hard alloy is embedded into the aluminum oxide and / or magnesium oxide particles and sintered in the decarburization protective atmosphere, a brittle eta-phase structure is easily formed, and an eta-phase wastealloy structure is loose and easy to crush, so that the crushing energy consumption and the crushing difficulty of the high-cobalt hard alloy are reduced.

Owner:JIANGXI UNIV OF SCI & TECH +2

Cosmetic composition and preparation method thereof

ActiveCN109010220AKeep active ingredientsAvoid forced breaking processCosmetic preparationsToilet preparationsBULK ACTIVE INGREDIENTActive ingredient

The invention relates to the technical field of biological medicine, in particular to a cosmetic composition and a preparation method thereof. Two kinds of raw materials of herba dendrodii officinalisdendrobium officinale and rhizoma bletillae are reasonably proportioned, so that active ingredients in the two kinds of raw materials achieve mutual effectsinteract; the effects of protecting the skin, caring the skin and preserving the moisture can be achieved.

Owner:贵州真阳纳米医药科技有限公司

Stone refining and rolling device

The invention relates to a stone refining and rolling device. The stone refining and rolling device comprises a supporting base, a temporary store assembly and an outer shell; the supporting base serves as a supporting foundation body of the device, and a supporting plane is arranged at the upper end of the supporting base; the temporary store assembly is arranged at the upper part of the supporting base and comprises at least four guide columns perpendicular to the supporting plane and first elastic parts arranged on the guide columns in a sleeving mode; and the bottom of the outer shell is provided with a sliding hole corresponding to the position of a guide shaft, and the outer shell is slidably connected with the guide shaft and elastically supported through the first elastic part. Stones are extruded through a second crushing plate, the stones extrude the lower end of a first crushing plate, the upper end of the first crushing plate swings in the direction close to the second crushing plate, at the moment, the second crushing plate is in the rising trend to rub the stones upwards, and the first crushing plate has the trend of stirring the stones downwards, therefore, the stones can be prevented from moving upwards, the strength of rubbing the stones by the second crushing plate is enhanced, and various factors are combined, so that the stones are crushed more easily.

Owner:重庆市庆岩建材有限公司

A concrete pile head crushing device

InactiveCN108532598BAchieve looseningAvoid accumulationBulkheads/pilesThreaded pipeArchitectural engineering

Owner:张显

Preparation method of foamed polyester slurry

ActiveCN105061802AReduce the difficulty of breakingLarge specific surface areaPolyesterPolymer science

The invention discloses a preparation method of foamed polyester slurry, and belongs to the technical field of water soluble polyester slurry. The invention aims to solve the problems that in the prior art, the cutter is damaged easily, and the slurry dissolution wastes too much energy and time. The preparation method is characterized by comprising the following steps: mixing recycled polyester, glycol, water soluble monomers, and a catalyst according to a certain ratio, then throwing the mixture into a pre-melting kettle to carry out pre-melting; then introducing the mixture to a final polymerization kettle, gradually increasing the vacuum degree in the kettle until the pressure in the kettle reaches an absolute pressure of 133 Pa or less; keeping on raising the temperature in the kettle, wherein the reactions are finished when the kettle temperature reaches 275 + / - 2 DEG C, and the stirring power is 10 KW or so; introducing high-purity nitrogen gas into the kettle to break the vacuum state until the pressure in the kettle reaches 0.1-0.2 MPa, keeping on stirring for 5 to 10 minutes, discharging polymer to a hopper; naturally cooling the polymer, and breaking the foamed blocks into powder by a powerful pulverizer. The provided preparation method has the advantages of the breaking difficulty is reduced, the dissolution speed is accelerated, and the energy and material consumption is reduced, and is mainly used to produce foamed polyester slurry.

Owner:湖北山特莱新材料有限公司

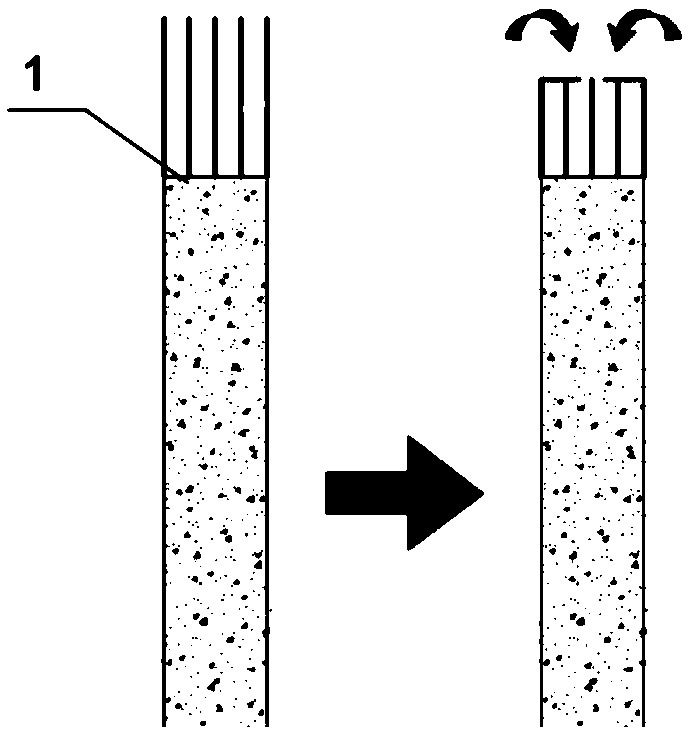

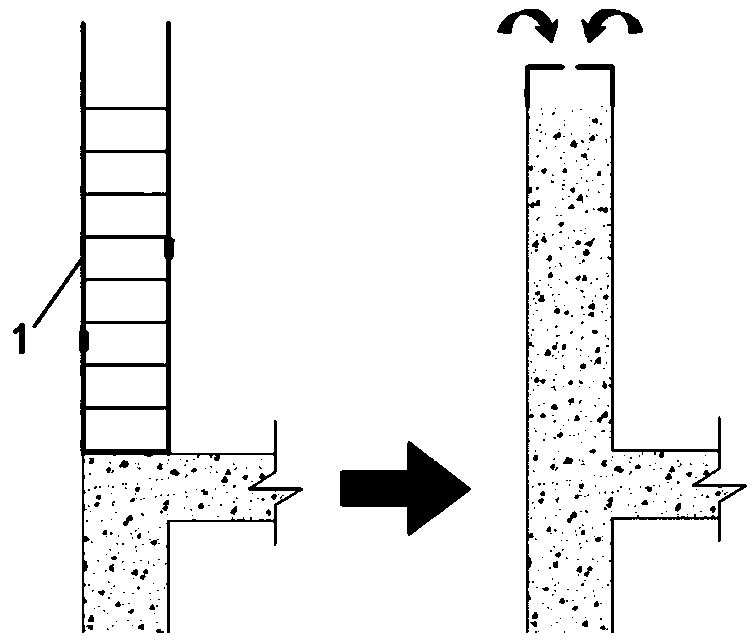

Method for constructing after bent anchoring of reinforcing steel bars in subway engineering

InactiveCN108517878AImprove construction efficiencyReduce the difficulty of breakingExcavationsBulkheads/pilesRebarUltimate tensile strength

The invention relates to the technical field of construction of subway reinforcing steel bars, in particular to a method for constructing after bent anchoring of reinforcing steel bars in subway engineering. The method comprises the following steps: adding the length of bent anchoring of the reinforcing steel bars in the linear length of a reinforcing cage to prepare straight reinforcing steel bars; and bending after binding forming and concrete pouring are carried out. In construction of a subway retaining structure, the construction efficiency is improved, the difficulty on breakage of piletop / wall top super-filling concrete is relieved, damage to pile top / wall top reinforcing steel bars in a breakage process is relieved, and the engineering quality is improved. In construction of a subway main body structure, the construction efficiency is improved, strength reliability of mechanical connection is improved further, loose connection of straight-reverse-thread sleeves is avoided effectively, for columns such as frame columns, the binding difficulty on stirrups is also reduced, and the method brings great benefits for engineering quality.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

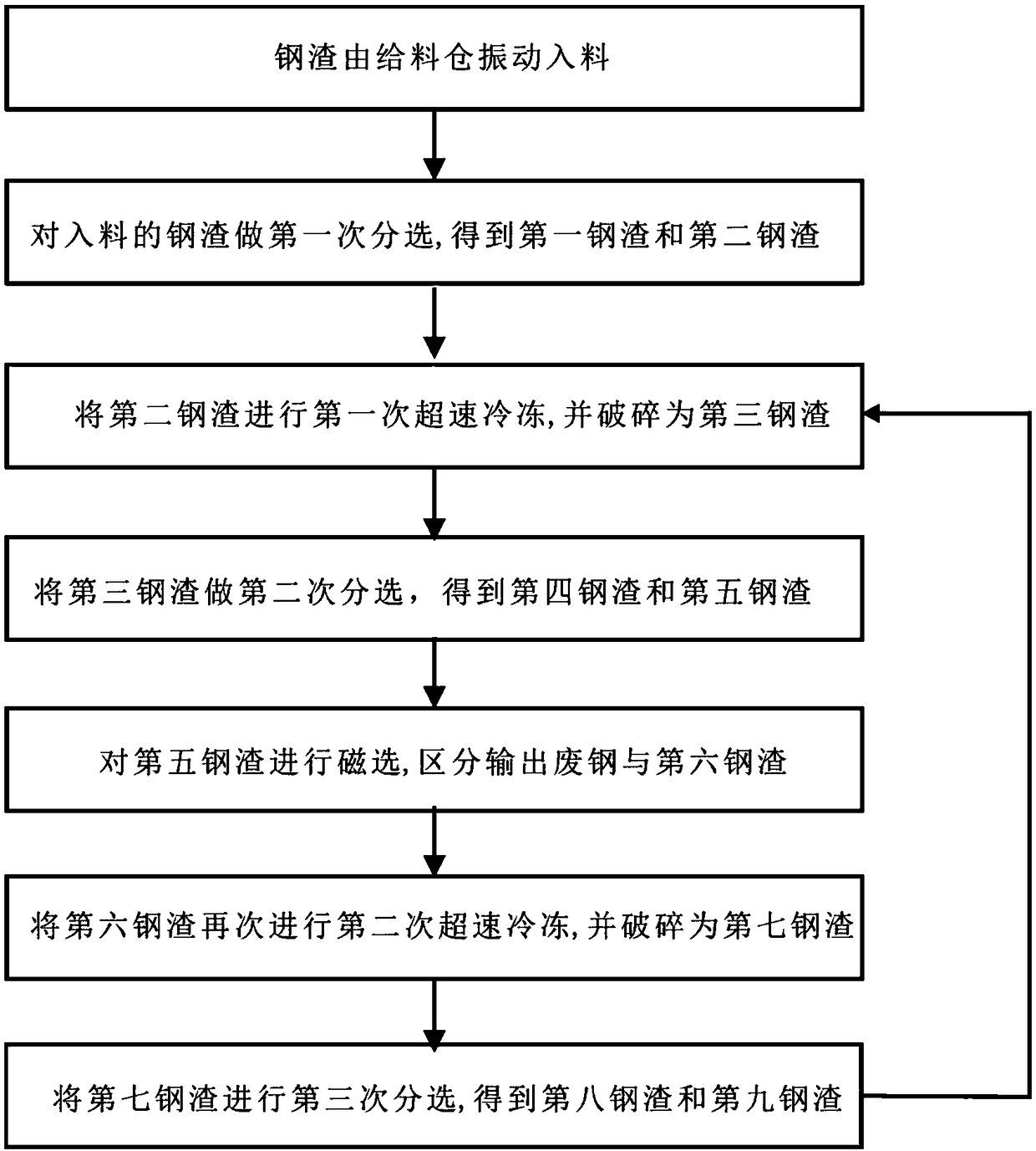

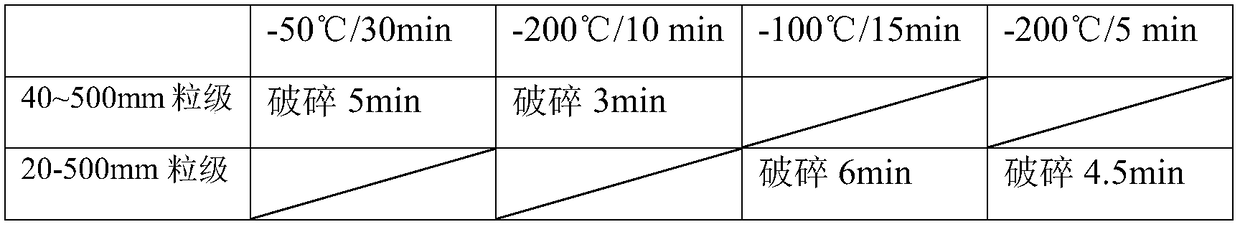

Frozen-breaking method for steel slag

The invention relates to a frozen-breaking method for steel slag. The frozen-breaking method for the steel slag comprises the following steps that first-time sorting is conducted on fed steel slag, and first steel slag and second steel slag are obtained; first-time ultra-rapid freezing is conducted on the second steel slag, the second steel slag is further broken into third steel slag, second-timesorting is conducted on the third steel slag, and fourth steel slag and fifth steel slag are obtained; magnetic separation is conducted on the fifth steel slag, and steel scrap and sixth steel slag are output in a distinguished mode; second-time ultra-rapid freezing is conducted on the sixth steel slag again, the sixth steel slag is broken into seventh steel slag, third-time sorting is conductedon the seventh steel slag, and the steps are cyclically conducted. According to the frozen-breaking method for the steel slag, the hardness and the brittleness of the steel slag are improved along with falling of the temperature according to the low-temperature cold brittleness of the steel slag, the steel slag is broken through a freezing mode, the steel slag becomes brittle when the environmenttemperature falls to a certain degree, the mechanical properties are changed, the breaking difficulty is greatly reduced, the breaking time is shortened, and the breaking efficiency is improved.

Owner:淮北卓颂建筑工程有限公司

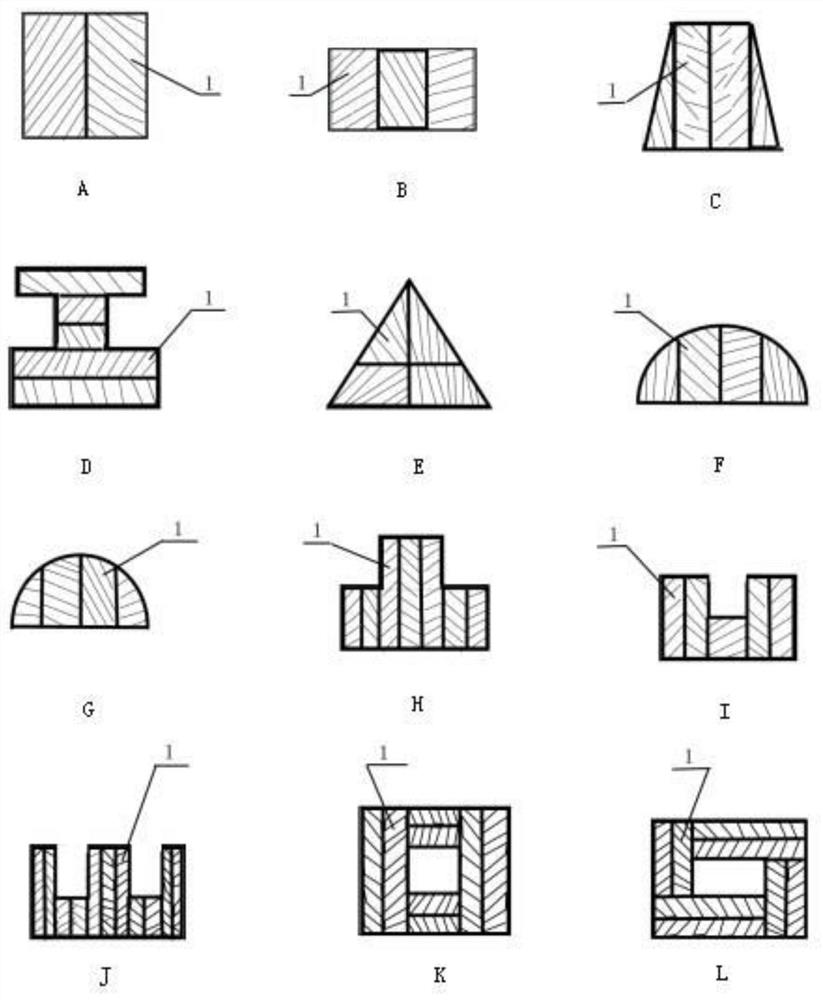

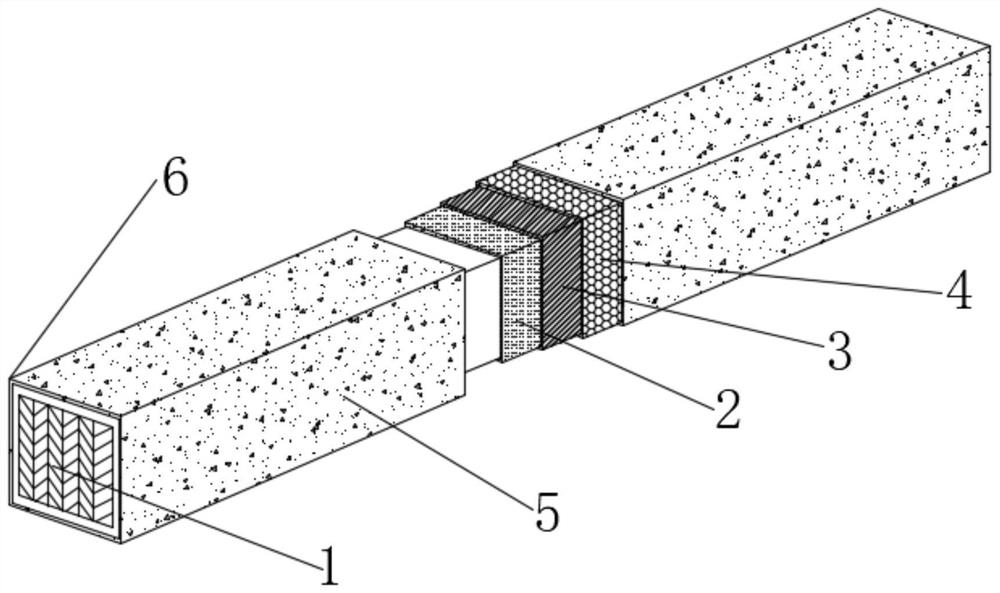

Composite wood rod profile capable of being repeatedly used in multiple fields and easy to regenerate

PendingCN113338612AReasonable designAchieve reuseWood veneer joiningForms/shuttering/falseworksAgricultural engineeringPulp and paper industry

The invention discloses a composite wood rod profile capable of being repeatedly used in multiple fields and easy to regenerate, and relates to a sawed strip material, a binding wire, a waterproof layer and a net wire in the composite wood rod profile. Beneficial effects are as follows: a large amount of waste wood generated in the modern building industry and the like is used as a raw material to prepare wood rod profile products which originally need to use new wood, including keel rod pieces for buildings, such that dependence of the products on high-quality imported log resources is thoroughly blocked; crushing and separation difficulty during regeneration is reduced by taking measures of tightly limiting the content of high-price materials such as steel, aluminum and plastic in the composite wood rod profile; and a synergetic industrial chain relation is established between use or regeneration and developed steel-wood keel or plastic-wood keel.

Owner:中铁建设集团华东工程有限公司

Medical adhesive applicator

PendingCN110721397AReduce the difficulty of breakingIncrease pressurePharmaceutical containersMedical packagingAdhesiveLocal pressure

The invention discloses a medical adhesive applicator, and relates to a device for applying medical adhesives packaged by glass ampoule tubes. The medical adhesive applicator disclosed by the invention comprises an applying head, an ampoule plug, a filter core, an ampoule tube, an applying ampoule and an extruder. The filter core is adhered with the interior of the ampoule plug; one end of the ampoule plug is connected with the unenclosed end of the applying ampoule inside of which the ampoule tube is mounted while the other end of the ampoule plug is provided with a sharp end catheter, and the sharp end catheter is inserted into a hollow part of the inner part of the applying head; and the enclosed end of the applying ampoule is inserted into an enclosed circular tube part of the bottom of the extruder; and two protruding points are arranged on the inner wall of the extruder. According to the device disclosed by the invention, the ampoule tube arranged in the applying bottle contactswith the protruding points formed in the inner wall of the extruder through extruding the applying bottle, local pressure intensity is increased by utilizing a lever principle, so that a better crushing effect of the ampoule tube can be achieved, and higher utilization ratio of glue liquid and higher glue discharging velocity can be achieved; and moreover, a user also can crush the glass ampoule tube more easily, and thus, the convenient and quick using effect is achieved. The medical adhesive applicator disclosed by the invention has the advantages of being simple in structure and higher in practicability.

Owner:江西博恩锐尔生物科技有限公司

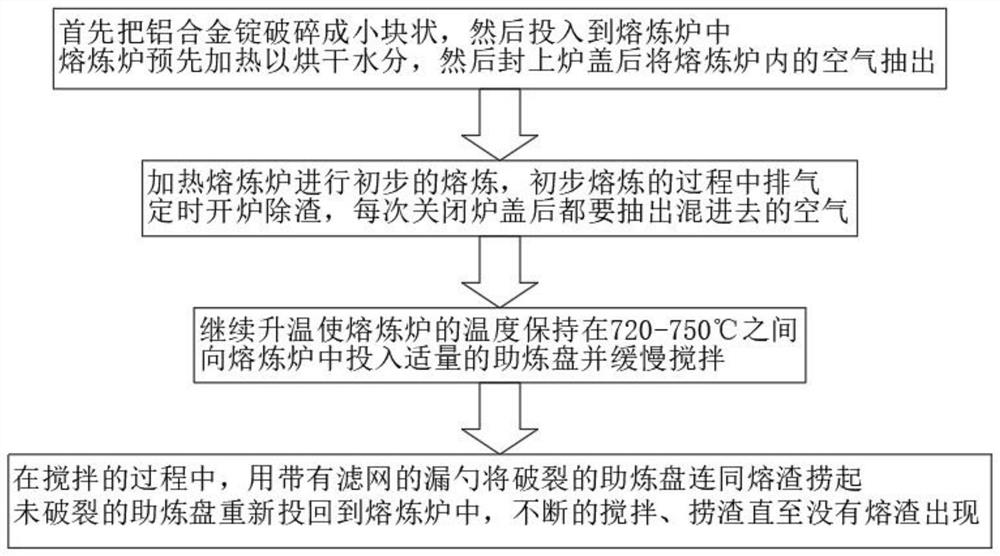

Automobile part die-casting aluminum alloy smelting process

InactiveCN112921197AHigh removal rateImprove purification effectProcess efficiency improvementAluminium chlorideMotor vehicle part

The invention discloses an automobile part die-casting aluminum alloy smelting process, and belongs to the field of aluminum alloy smelting. The automobile part die-casting aluminum alloy smelting process comprises the following steps that S1, firstly, an aluminum alloy ingot is crushed into small blocks, then the small blocks are put into a smelting furnace, the smelting furnace is preheated to dry moisture, and then a furnace cover is closed and air in the smelting furnace is pumped out. According to the scheme, high temperature of smelting is utilized to enable gas to be heated and expanded so as to enable a smelting assisting disc to be broken, both zinc chloride and chlorine can be subjected to chemical reaction in the furnace to generate gaseous aluminum chloride, impurities, gas and the like are adsorbed together to float upwards in the floating process, and the purification effect is effectively improved; aluminum alloy and manganese chloride react to generate the aluminum chloride, the purification effect is deepened, nitrogen is released through consumption of the manganese chloride, the nitrogen forms bubbles to take away aluminum oxide and hydrogen, the deslagging and degassing effects are further improved, and in the upward floating process of the broken smelting assisting disc, a catcher can take away suspended aluminum oxide to a liquid level so as to improve the deslagging rate.

Owner:王修强

Efficient crusher

InactiveCN114082764AReduce the difficulty of breakingReduce energy consumptionConstruction waste recoverySolid waste disposalStructural engineeringWater jet cutter

The invention discloses an efficient crusher which comprises a first conveying device, first water jet cutters are installed on the top and the two sides of the first conveying device, a turnover device is installed at the conveying tail end of the first conveying device, a torsion device is installed at the conveying tail end of the turnover device, and a pushing device is installed in cooperation with the torsion device. A second conveying device is installed at the conveying tail end of the torsion device, second water jet cutters are installed on the top and the two sides of the second conveying device, and a crusher body is installed at the tail end of the second conveying device. According to the invention, six surfaces of concrete construction waste can be pre-cut, so that most particles obtained by crushing the concrete construction waste are particles with required sizes, and gaps formed by pre-cutting form stress concentration points, so that the crushing difficulty is reduced, and the energy consumption is reduced.

Owner:怀化明达建材有限公司

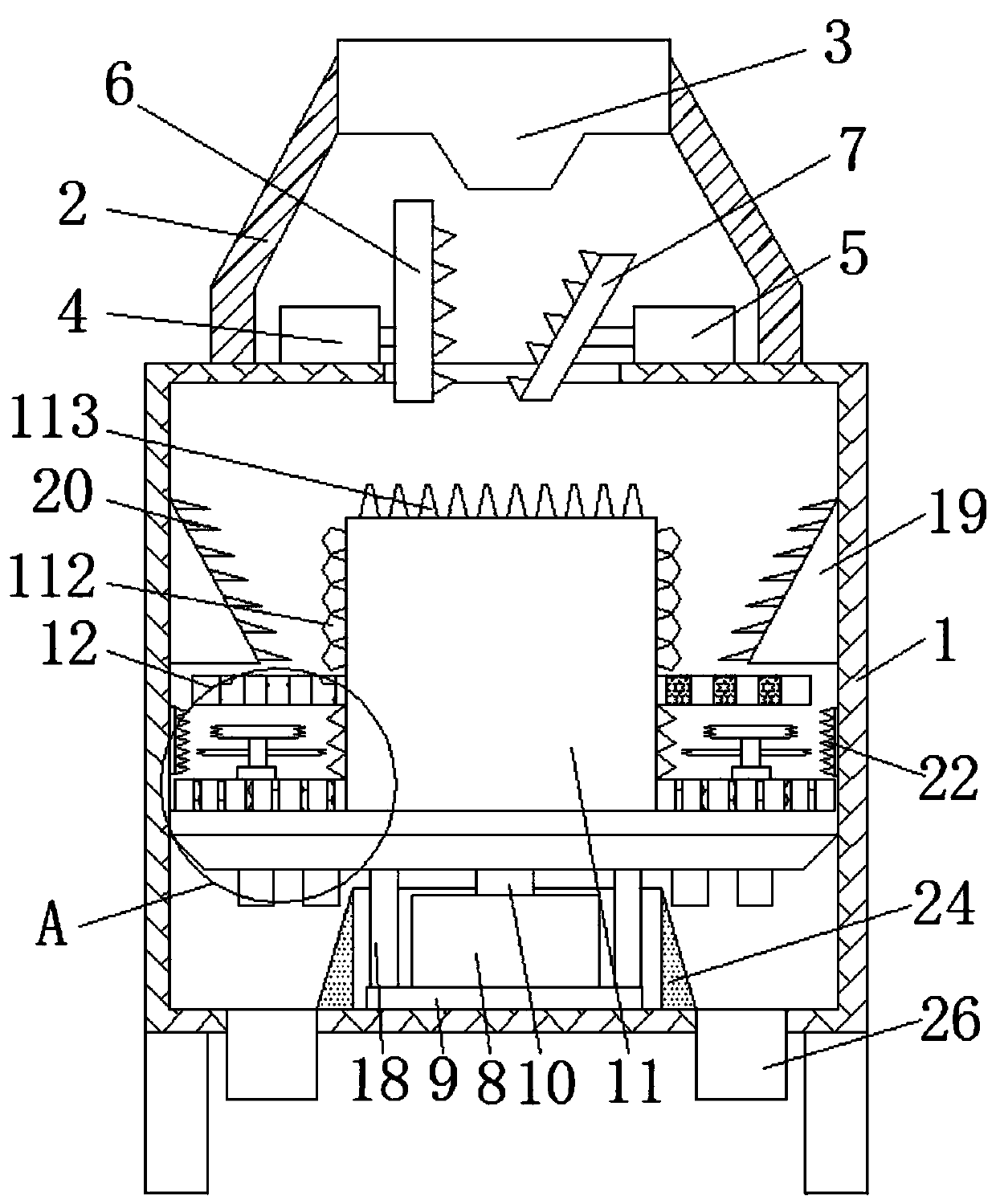

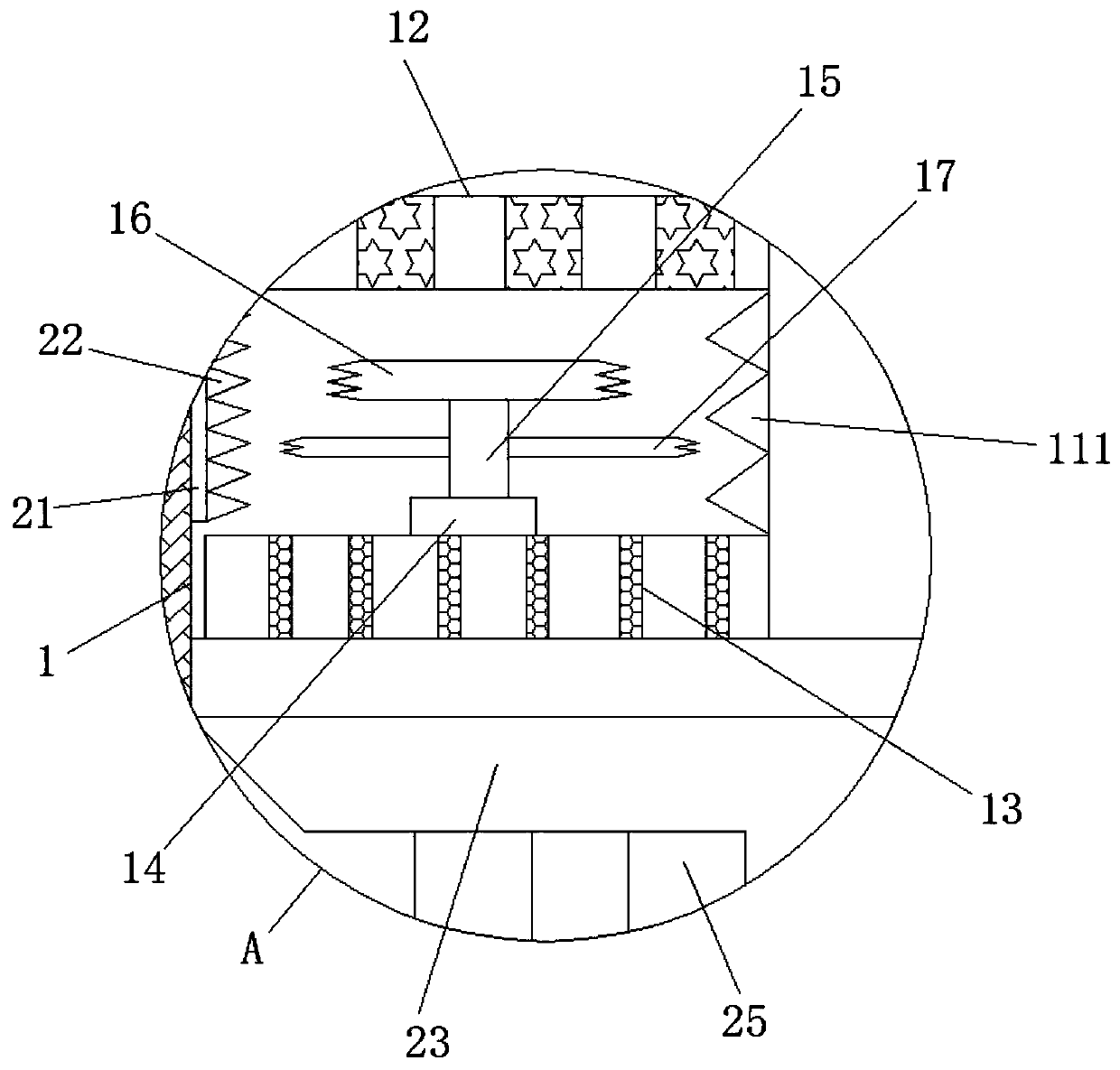

An efficient and controllable ore particle size crusher

ActiveCN109046529BReduce the difficulty of breakingReduce impact lossGrain treatmentsHydraulic pumpElectric machinery

The invention discloses a high-efficiency crusher capable of controlling ore particle size. The high-efficiency crusher capable of controlling ore particle size comprises a crusher box, an outer coveris fixedly arranged at the top of the crusher box, moreover, the top of the outer cover is fixedly provided with a feeding groove, the top of the crusher box is fixedly provided with a first hydraulic pump and a second hydraulic pump, the output end of the first hydraulic pump is fixedly provided with a first crushing plate, the output end of the second hydraulic pump is fixedly provided with a second crushing plate, a first motor and an annular guide rail are fixedly arranged in the middle of the inner bottom wall of the crusher box, the output end of the first motor is fixedly provided witha first rotating shaft, the end, far away from the first motor, of the first rotating shaft is fixedly provided with a crushing column body. Simple crushing is achieved firstly, ore is crushed through crushing teeth with different specifications on the outer surface of the crushing column body, a separation plate plays a role in screening, the crushing process is efficiently completed, and it isfurther ensured that the ore particle size meets the follow-up process requirements.

Owner:中煤第三建设(集团)有限责任公司三十工程处 +1

A kind of crushing method of ferrovanadium nitride

The invention discloses a crushing method for nitrided ferrovanadium. The crushing method for the nitrided ferrovanadium comprises the following steps: a, adding an acid into an acidification pond to perform acidifying and embrittling on the nitrided ferrovanadium to be crushed; b, draining an acid liquid, and drying the acid liquid on the surface of a nitrided ferrovanadium raw material; c, crushing by using a crushing roller; d, screening the crushed nitrided ferrovanadium raw material according to particle sizes; e, performing laser cutting on the nitrided ferrovanadium with the particle sizes of above 100 mm to make the average particle size of the nitrided ferrovanadium less than 100 mm; and f, holding the nitrided ferrovanadium in a classified manner by taking every 10 mm as a classifying grade according to the particle sizes. According to the crushing method for the nitrided ferrovanadium, the overall toughness of the nitrided ferrovanadium is reduced after the nitrided ferrovanadium is acidified, and then the nitrided ferrovanadium is crushed into specified particle sizes; the crushing difficulty of the nitrided ferrovanadium is reduced; the loss of equipment is reduced; the crushing cost of the nitrided ferrovanadium is reduced; and the crushing work production efficiency of the nitrided ferrovanadium is improved.

Owner:HUNAN ZHONGXIN NEW MATERIALS TECH

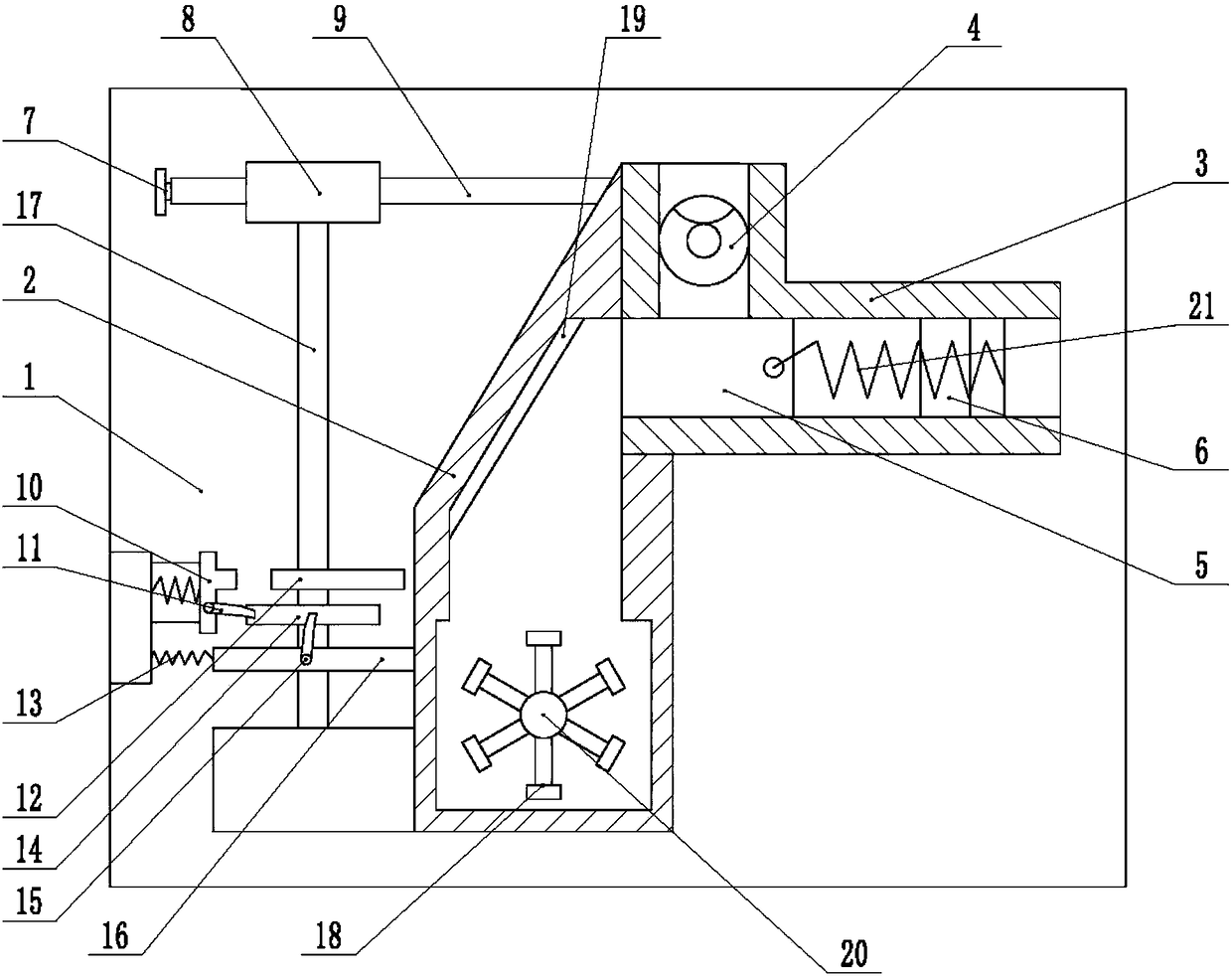

Cutting equipment special for reed papermaking

InactiveCN113099863AImprove cutting efficiencyImprove processing qualityCuttersPapermakingProcessing cost

The invention belongs to the technical field of papermaking equipment, and particularly relates to cutting equipment special for reed papermaking, which comprises a box body, wherein a feeding port is formed in the box body, one end, close to the feeding port, of the box body is rotatably connected with a guide roller, cutting tables are symmetrically arranged at the horizontal position, close to the guide roller, of the box body, the cutting tables are movably connected with a cutting device to realize pre-cutting work of reed, the cutting device is in sliding connection with the box body, one end of the cutting device is in meshed connection with a driving part used for reed cutting driving work, the driving part is in transmission connection with the guide roller through a belt wheel mechanism, and crushing teeth are arranged at the other end of the cutting device in a matched mode. According to the cutting equipment with the automatic rolling, slitting and crushing process for papermaking reed, the defects that in the manual cutting process, the labor intensity is large, the working efficiency is low, and the processing cost is large are overcome, the cutting efficiency and the processing quality in the reed papermaking process are effectively improved, and the cutting equipment is suitable for being popularized.

Owner:范保学

Pulverization system for plastic product

InactiveCN108215000AReduce the difficulty of breakingReduce crushing timePlastic recyclingMechanical material recoveryEngineeringBevel gear

The invention relates to a pulverization system for a plastic product. The pulverization system comprises a frame and a crushing barrel, wherein the crushing barrel is fixedly arranged on the frame; the crushing barrel is communicated with a material inlet passage; a rotating shaft is rotationally connected into the crushing barrel; the rotating shaft is fixedly provided with crushing hammers; thematerial inlet passage is connected with a magnetic material push plate in a sliding manner; the material inlet passage is fixedly provided with an electromagnet; the rotating shaft is coaxially connected with a bevel gear; the bevel gear is meshed with a first rack; the first rack is connected with a first pawl in a pivoting manner; the frame is rotationally connected with a main rotating shaft;the main rotating shaft is fixedly provided with a ratchet; the ratchet is coaxially connected with a first gear; the first gear is meshed with a second rack; a turn table is rotationally connected into the material inlet passage; the turn table is provided with a groove; the turn table is coaxially connected with a second gear; the second gear is meshed with the second rack; the frame is also provided with a limiting mechanism. In comparison with the prior art, according to the scheme, waste plastic quickly crashes the wall of the crushing barrel; the waste plastic is preliminarily crushed;the crushing difficulty of the waste plastic is decreased, and the production efficiency is improved.

Owner:宁波得晴电器科技有限公司

Stone Refinement Rolling Device

Owner:重庆市庆岩建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com